Split type multi-bundle conductor spacing fixing device

A wire spacing and fixing device technology, which is applied to devices maintaining parallel conductor spacing, overhead lines/cable equipment, etc., can solve problems such as the influence of maintenance work, the instability of wires, and the impact on operation safety, and achieve stable and reliable support and standardization of repairs. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

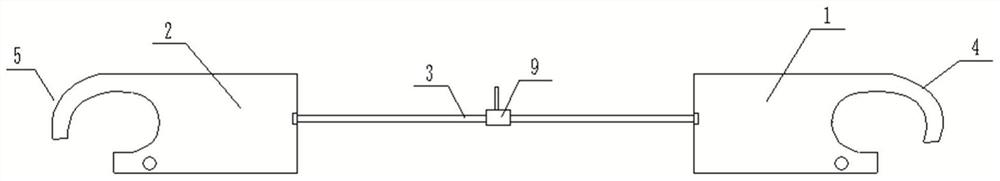

Embodiment 1

[0039] Such as Figure 1-2 As shown, a split-type multi-split wire spacing fixing device includes: a screw rod 3, the first end of the screw rod 3 is a left-handed thread, the second end of the screw rod 3 is a right-handed thread, and the screw rod 3 is provided with a driving rod 9, The driving rod 9 is vertically arranged with the screw mandrel 3; the first connecting plate 1, the first side of the first connecting plate 1 is provided with a left-handed threaded hole, and the first end of the screw mandrel 3 is threadedly connected with the threaded hole of the first connecting plate 1; Connecting plate 2, the first side of the second connecting plate 2 is provided with a right-handed threaded hole, the second end of the screw mandrel 3 is threadedly connected with the threaded hole of the second connecting plate 2; the wire hook, the wire hook includes the first wire hook 4 and the second wire hook Two wire hooks 5; the first wire hook 4 is fixedly connected with the secon...

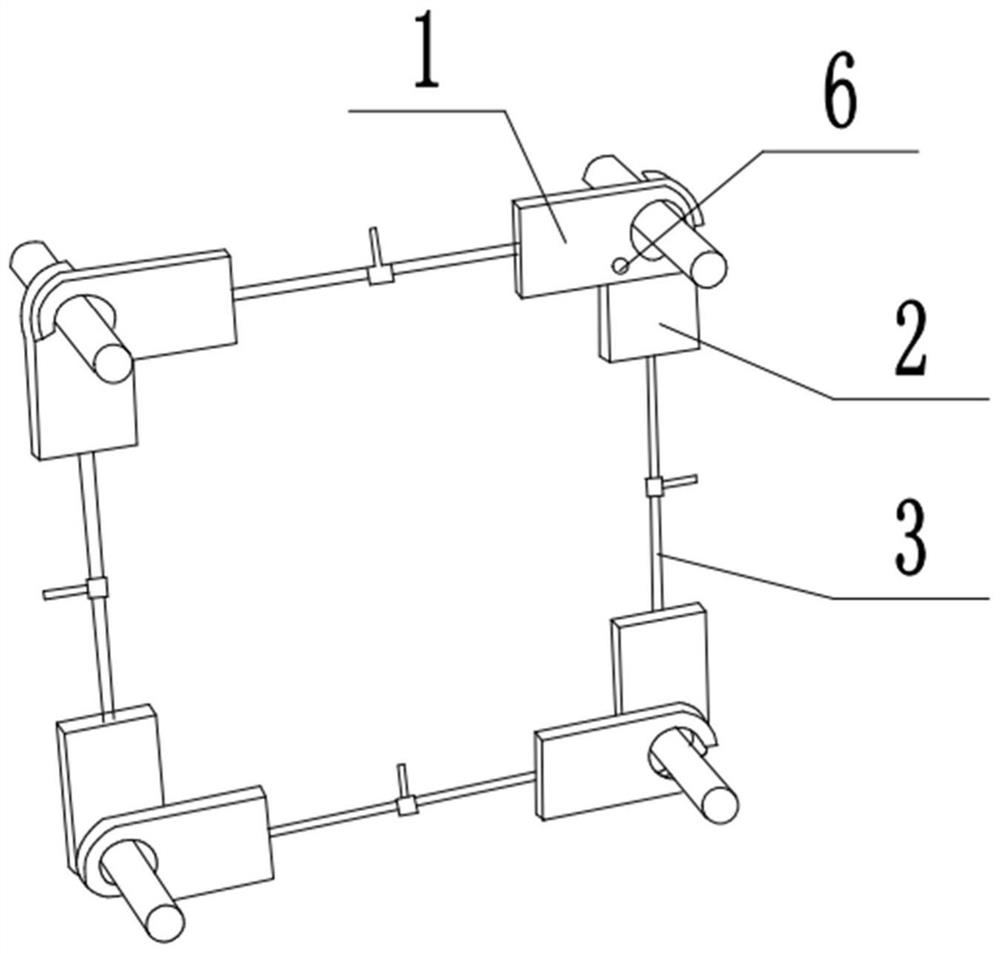

Embodiment 2

[0066] Such as figure 1 and image 3 As shown, a split-type multi-split wire spacing fixing device includes: a screw rod 3, the first end of the screw rod 3 is a left-handed thread, the second end of the screw rod 3 is a right-handed thread, and the screw rod 3 is provided with a driving rod 9, The driving rod 9 is vertically arranged with the screw mandrel 3; the first connecting plate 1, the first side of the first connecting plate 1 is provided with a left-handed threaded hole, and the first end of the screw mandrel 3 is threadedly connected with the threaded hole of the first connecting plate 1; Connecting plate 2, the first side of the second connecting plate 2 is provided with a right-handed threaded hole, the second end of the screw mandrel 3 is threadedly connected with the threaded hole of the second connecting plate 2; the wire hook, the wire hook includes the first wire hook 4 and the second wire hook Two wire hooks 5; the first wire hook 4 is fixedly connected wit...

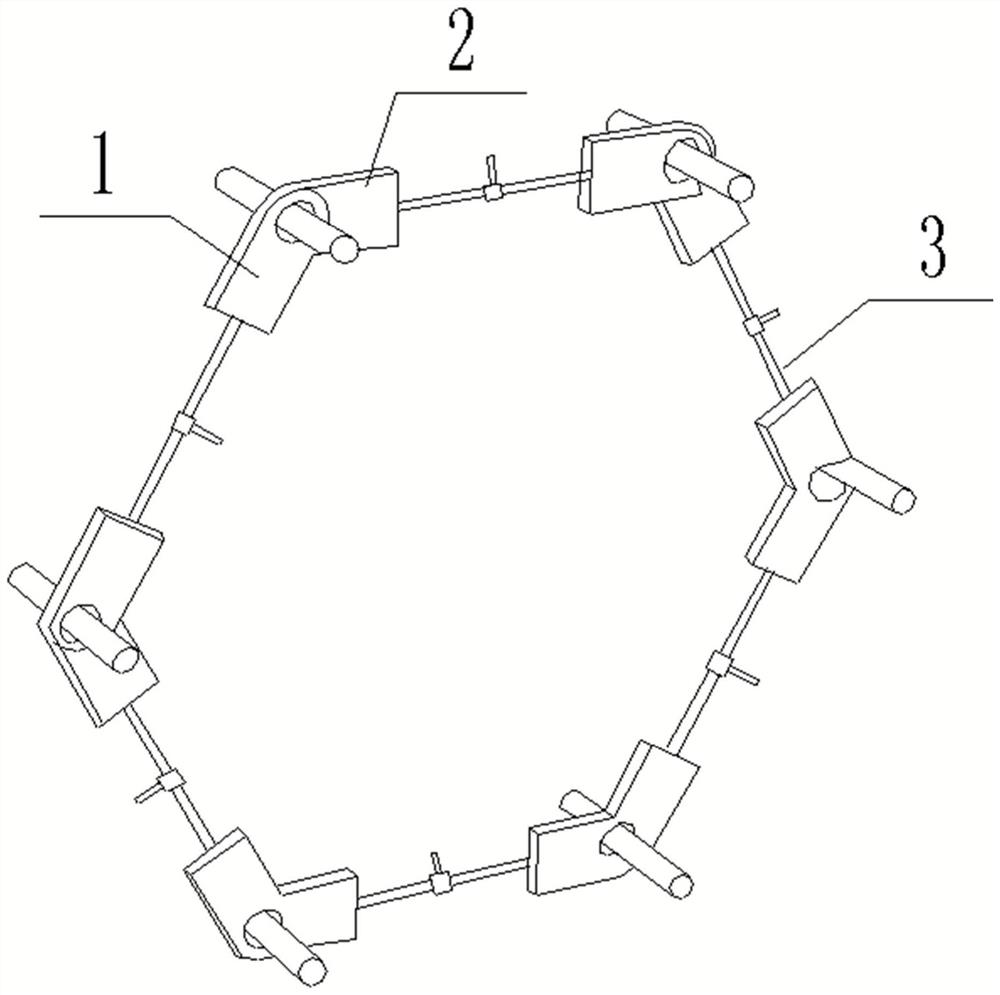

Embodiment 3

[0098]This embodiment provides a split-type multi-split wire spacing fixing device, including: a screw rod 3, the first end of the screw rod 3 is a left-handed thread, the second end of the screw rod 3 is a right-handed thread, and the screw rod 3 is provided with a lever 9. The driving rod 9 is vertically arranged with the screw rod 3; the first connecting plate 1, the first side of the first connecting plate 1 is provided with a left-handed threaded hole, and the first end of the screw rod 3 is threadedly connected with the threaded hole of the first connecting plate 1; The second connection plate 2, the first side of the second connection plate 2 is provided with a right-hand threaded hole, the second end of the screw mandrel 3 is threadedly connected with the threaded hole of the second connection plate 2; the wire hook, the wire hook includes the first wire hook 4 And the second wire hook 5; the first wire hook 4 is fixedly connected to the second side of the first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com