U-shaped belt corrugated energy dissipation part damper

A technology of dampers and waveforms, which is applied to building components, earthquake resistance, building types, etc., can solve the problems of small earthquakes that cannot produce plastic energy consumption, insufficient out-of-plane stability, and single energy consumption mechanism, achieving good economic benefits and reducing Seismic response and stable energy dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

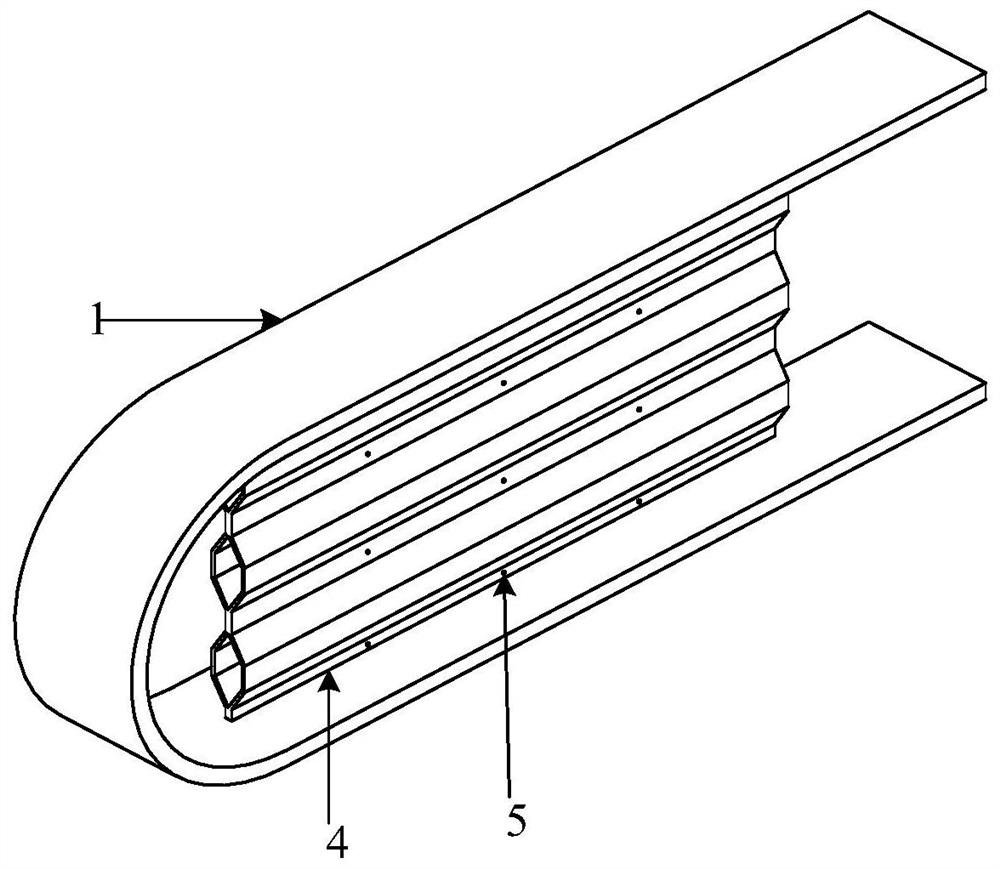

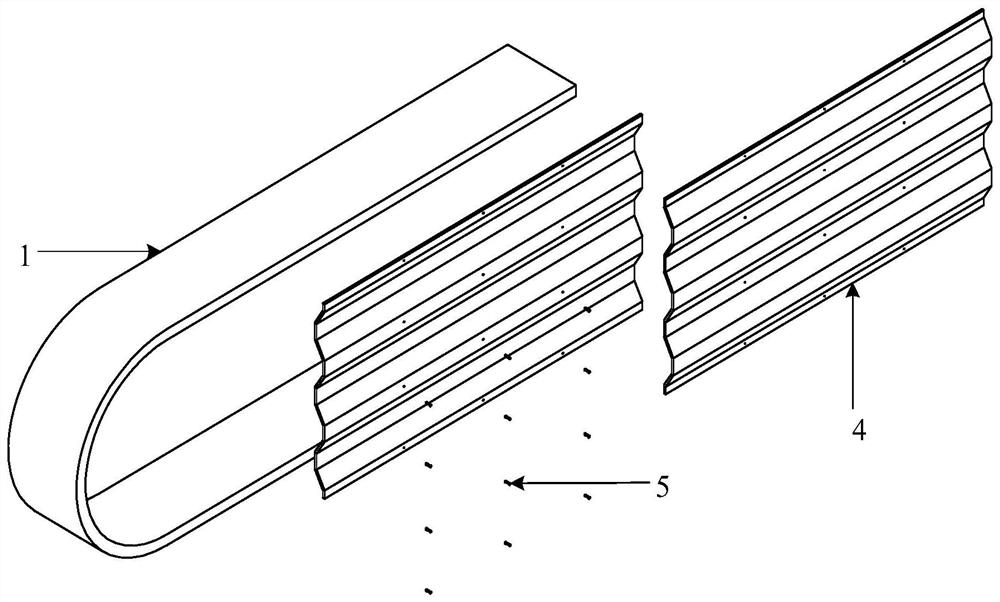

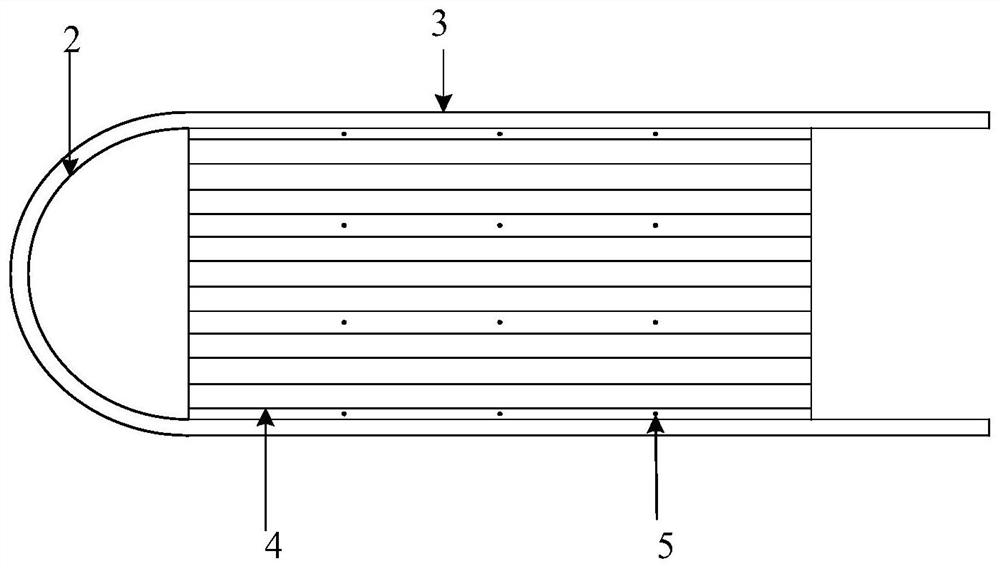

[0027] Attached below Figure 1-7 , detailing the implementation of this patent.

[0028] Such as Figure 1-7 As shown, a U-shaped damper with wave-shaped energy dissipation parts includes the following components:

[0029] 1——U-shaped energy-consuming parts;

[0030] 2 - arc segment;

[0031] 3——straight section;

[0032] 4——Double-layer waveform energy-consuming parts;

[0033] 5——Self-tapping screw;

[0034] Such as Figure 1-7 As shown, a U-shaped damper with wave-shaped energy-dissipating parts is characterized in that: the metal damper is composed of U-shaped energy-consuming parts (1) and double-layer wave-shaped energy-consuming parts (4); each U-shaped energy-dissipating part The part (1) is composed of an arc segment (2) and two straight segments (3); the double-layer wave energy dissipation part is composed of two symmetrically arranged wave energy dissipation parts, and is connected by self-tapping screws (5). Its connection; the double-layer corrugated ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com