The transmission device of flapping and torsion combined motion of bionic flapping wing for micro air vehicle

A micro-aircraft and transmission technology, applied in aircraft, transportation and packaging, motor vehicles, etc., can solve problems such as difficulty in hovering or vertical take-off and landing, complex structure, low aerodynamic efficiency, etc., to achieve improved lift and simple operation Convenience and drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

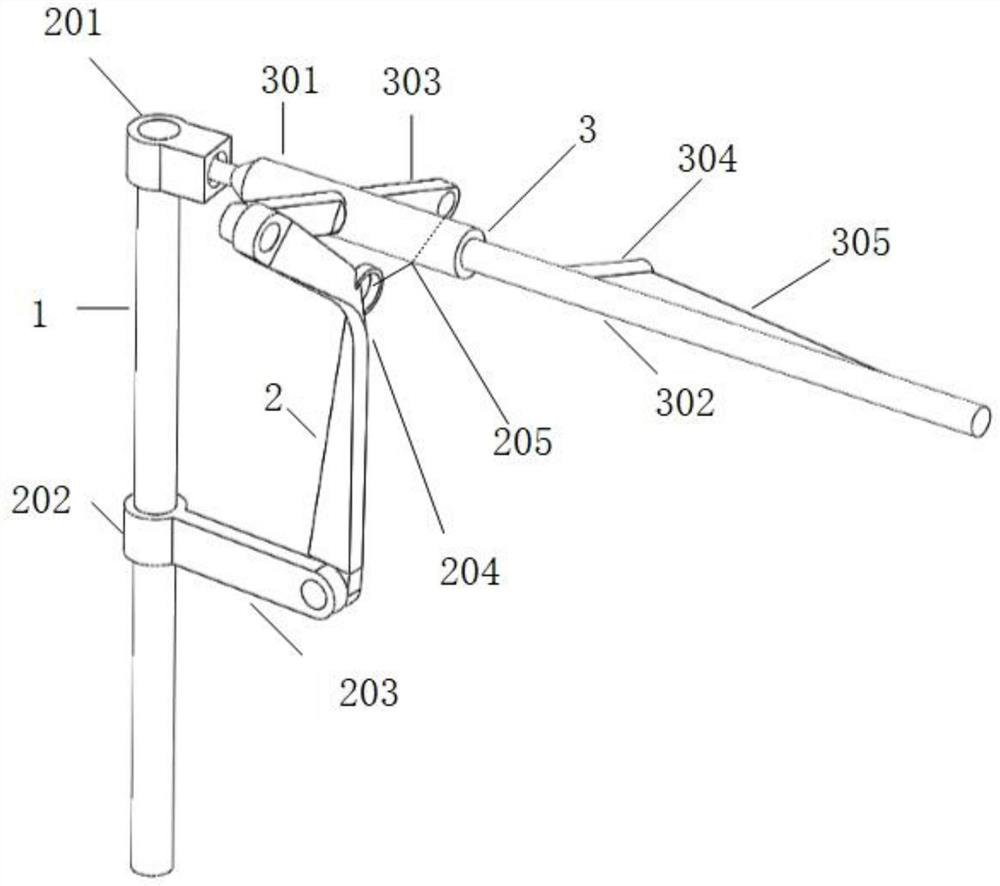

[0032] Such as figure 1 As shown, the bionic flapping wing flapping and twisting combined motion transmission device disclosed in this embodiment includes a support rod 1 , a transmission mechanism 2 , and a flapping wing main structure 3 .

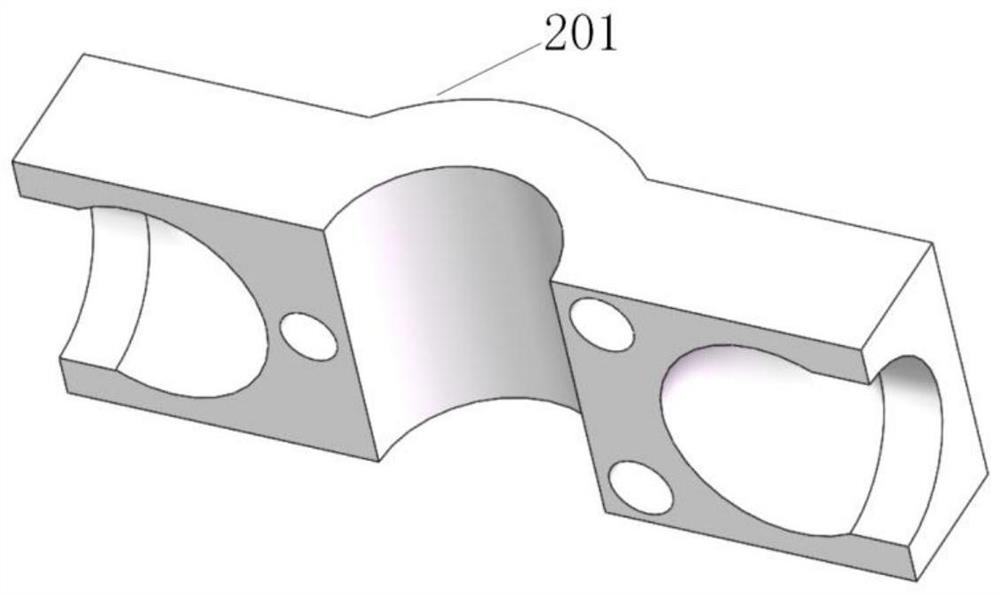

[0033] Such as figure 1 As shown, the transmission mechanism includes an upper sleeve 201, a lower sleeve 202, a drive rod 203, a Γ-shaped connecting rod 204, and a limit rope 205; Beam 302, flapping wing main rib 303, flapping wing sub-beam 304, wing membrane 305.

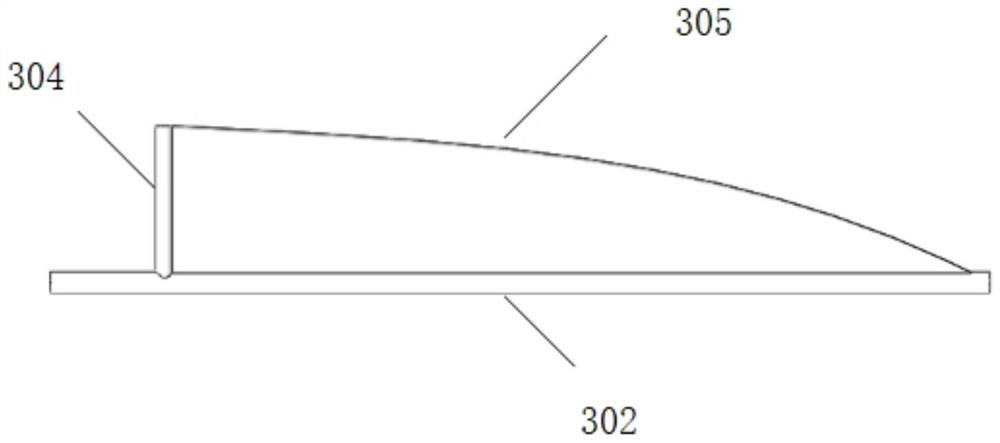

[0034] Such as figure 2 As shown, the wing includes a flapping wing outer spar 302 , a flapping wing sub-spar 304 , and a wing membrane 305 , wherein the flapping wing membrane 305 is bonded to the flapping wing outer spar 302 and the flapping wing sub-spar 304 .

[0035] The support rod 1 is arranged vertically, and the upper casing 201 is fixed on the top of the support rod 1, and can be used for a flapping rotorcraft through a bearing.

[0036] The lower bushing 202 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com