Lifting single bodies for vertical landing gear with fixed wings

A vertical take-off and landing, lift unit technology, applied in vertical take-off and landing aircraft, transportation and packaging, aircraft and other directions, can solve the problems of insufficient concentration of high-speed airflow, long blowing distance, and reduced lift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

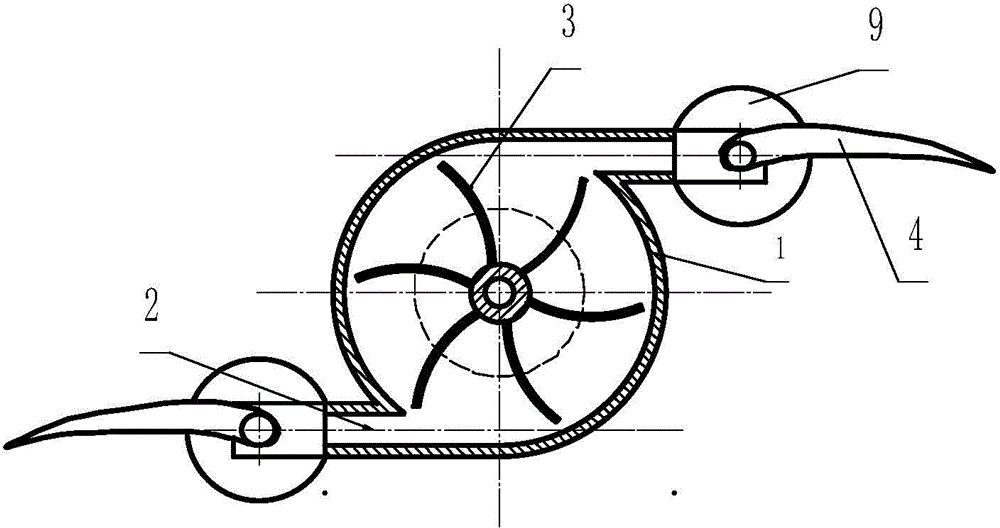

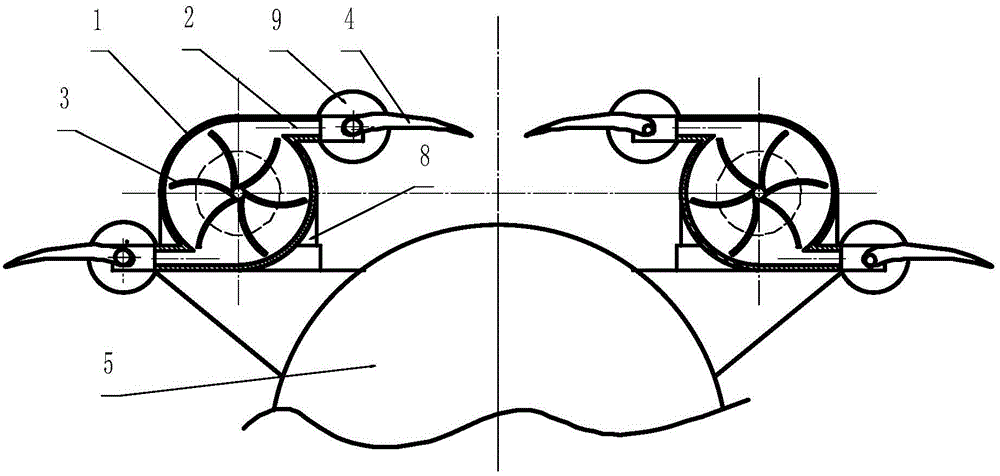

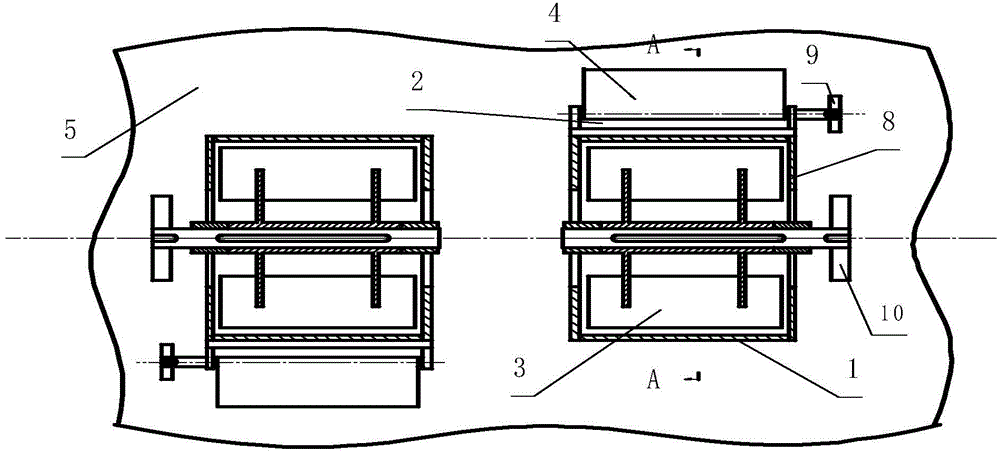

[0021] Such as figure 1 As shown, a lift unit of a vertical landing gear with a fixed wing includes a cylindrical body 1, an air outlet 2, a rotor 3, a wing 4, a carrier 5, a wing shaft 6, an end plate 8, a wing drive wheel 9 and rotor drive wheel 10; among them, the cylindrical barrel 1 used as the casing of the centrifugal fan is fixed with end plates 8 with circular air inlet holes at both ends; the rotor 3 with backward curved blades is fixed by means of solid The bearing seat and the rotor driving wheel 10 installed on the axis of the end plate 8 rotate in the cylindrical shell 1; the highest position and the lowest position in the cylindrical shell 1 are each equipped with a rectangular shell as the air outlet of the centrifugal fan 2. The long side of the rectangular section is along the generatrix direction of the cylindrical cylinder 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com