Planting device for planting fluorescent microfilaments on surface of airfoil profile

An airfoil and fluorescent technology, which is applied in the field of wind tunnel testing, can solve the problems of cumbersome operation and infirmity, and achieve the effect of simplifying the complicated and cumbersome, stabilizing the wire, and simplifying the cumbersome installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

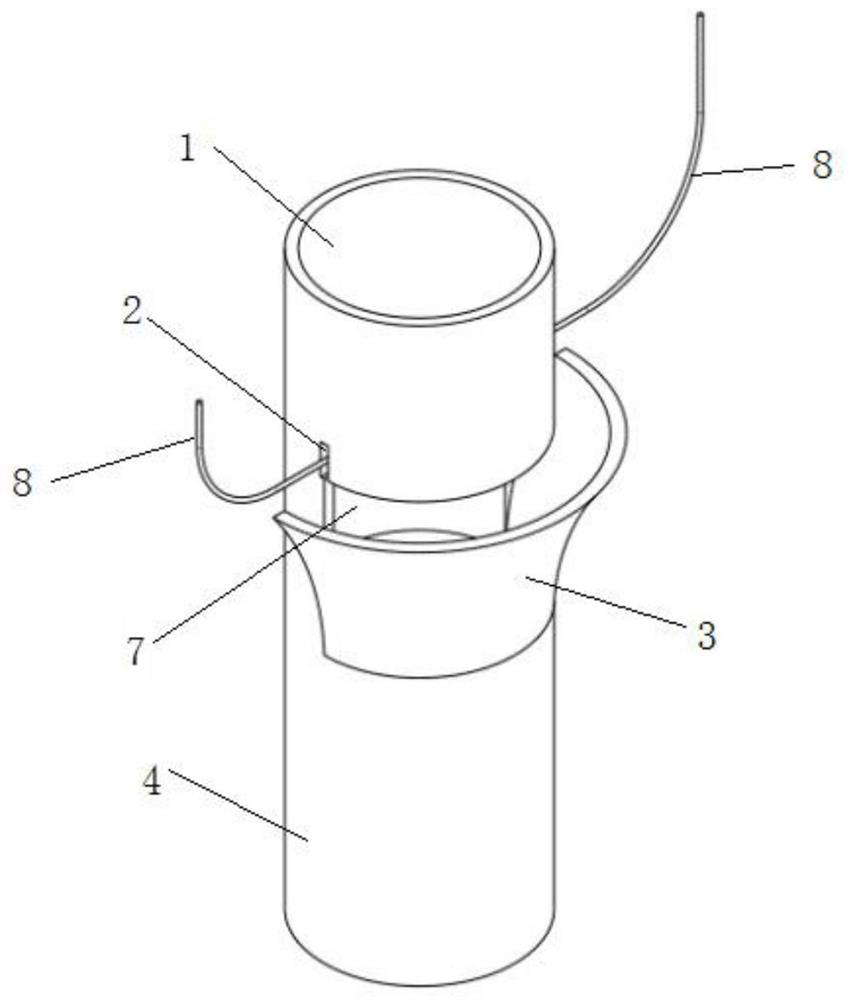

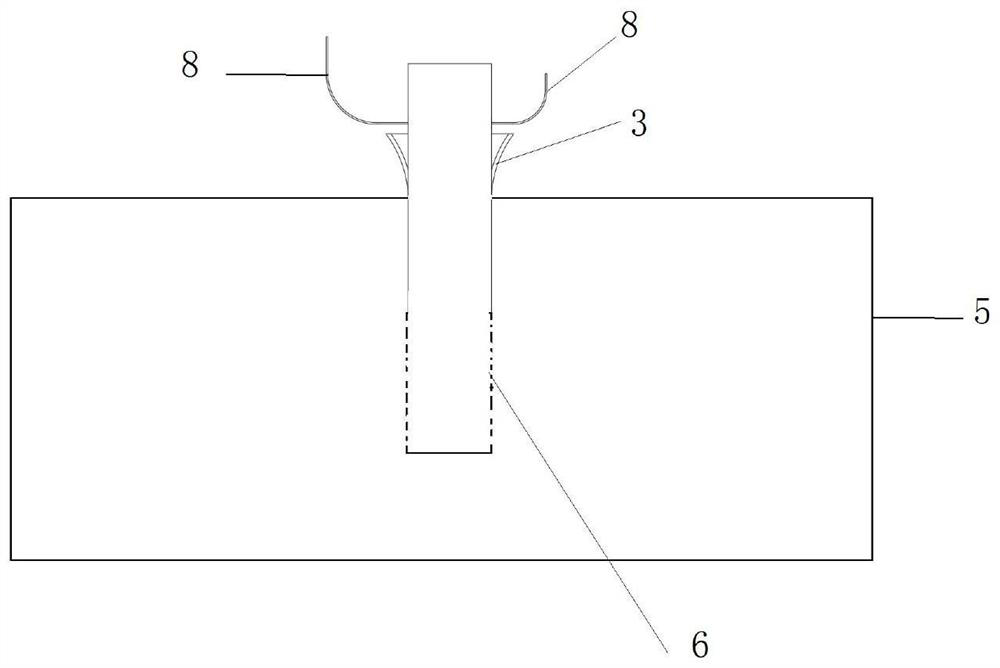

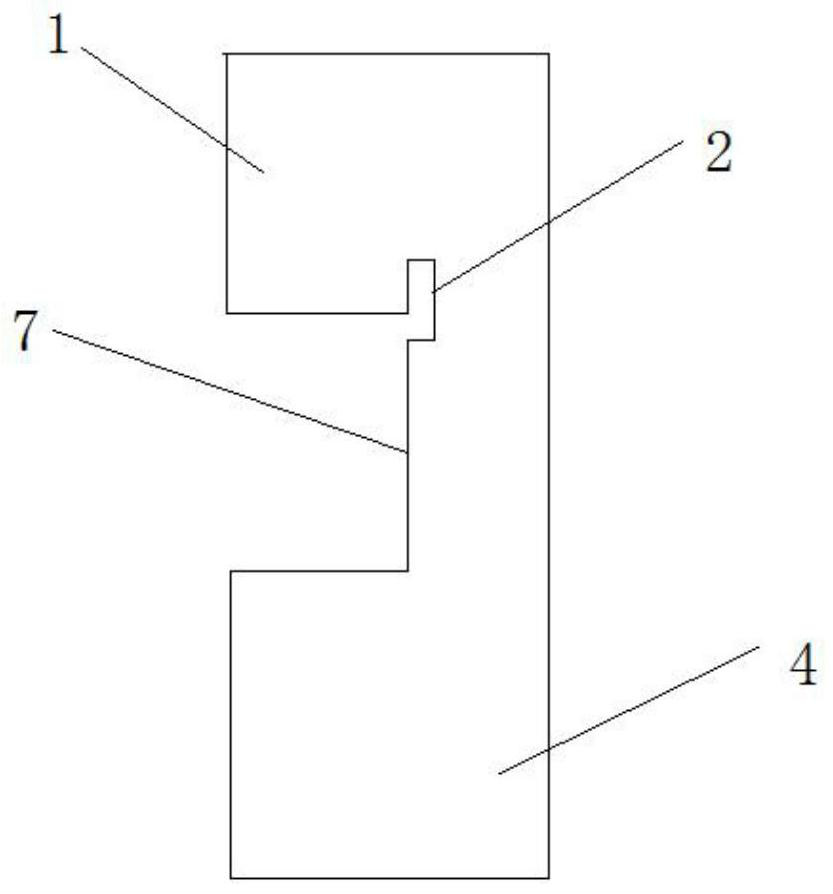

[0022] Such as figure 1 As shown, the present invention provides a planting device for planting fluorescent microfilaments on the airfoil surface. In some embodiments, it includes: a copper tube, two wire clamping slots 2 and an opening 7 . Wherein, the copper tube is divided into upper and lower parts, the upper part is a hollow cylinder 1, and the lower part is a solid cylinder 4, and the inside of the hollow cylinder 1 is used for injecting the adhesive for fixing the wire and the copper tube. The outer wall of the hollow cylinder 1 is provided with two wire-holding grooves 2, the direction of the two wire-holding grooves 2 is the same as the axial direction of the hollow cylinder 1, the two wire-holding grooves 2 are arranged at intervals, and the size of the wire-holding grooves 2 is different. The limit is usually selected according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com