Cutting machining device for building insulation board and cutting machining method

A technology for building insulation and cutting processing, which is used in measuring devices, optical devices, metal processing equipment, etc., can solve the problems of cutting errors with cutters and the inability to form uniform specifications of building insulation boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

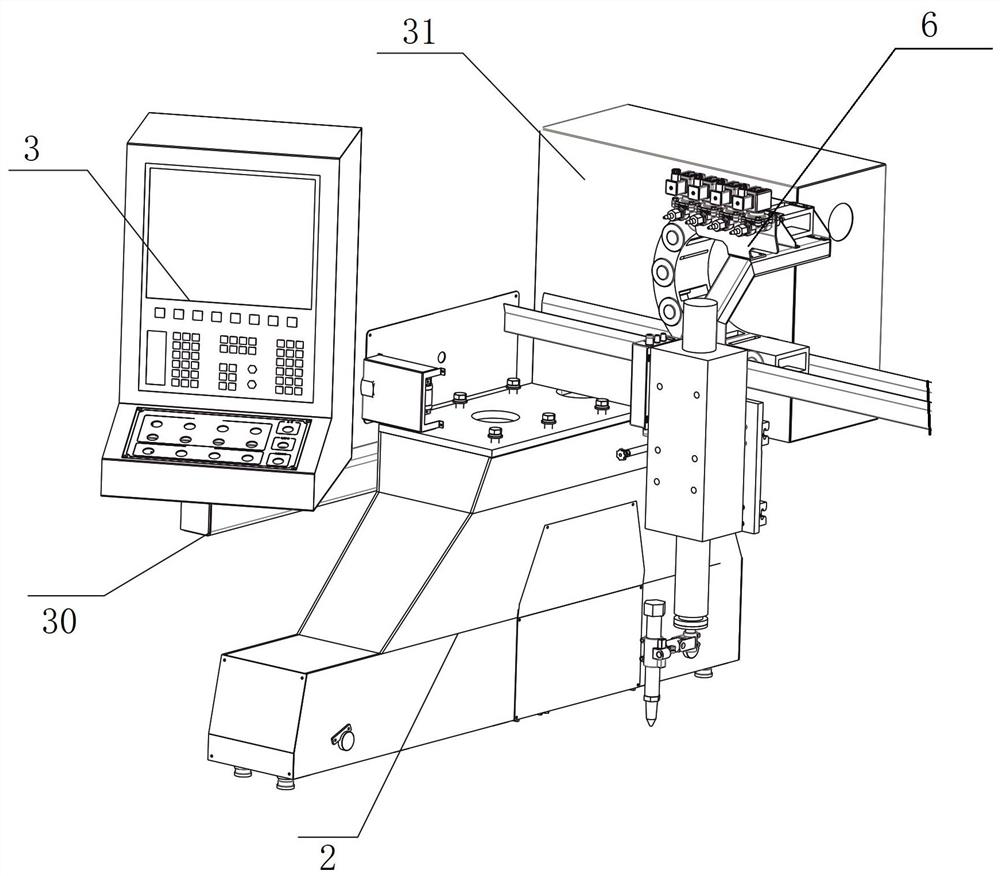

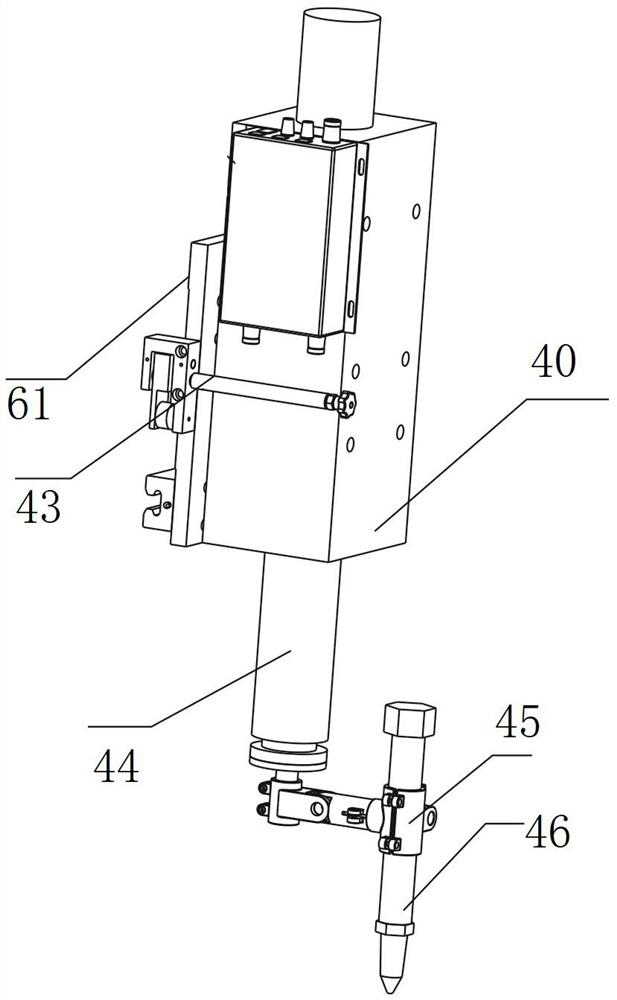

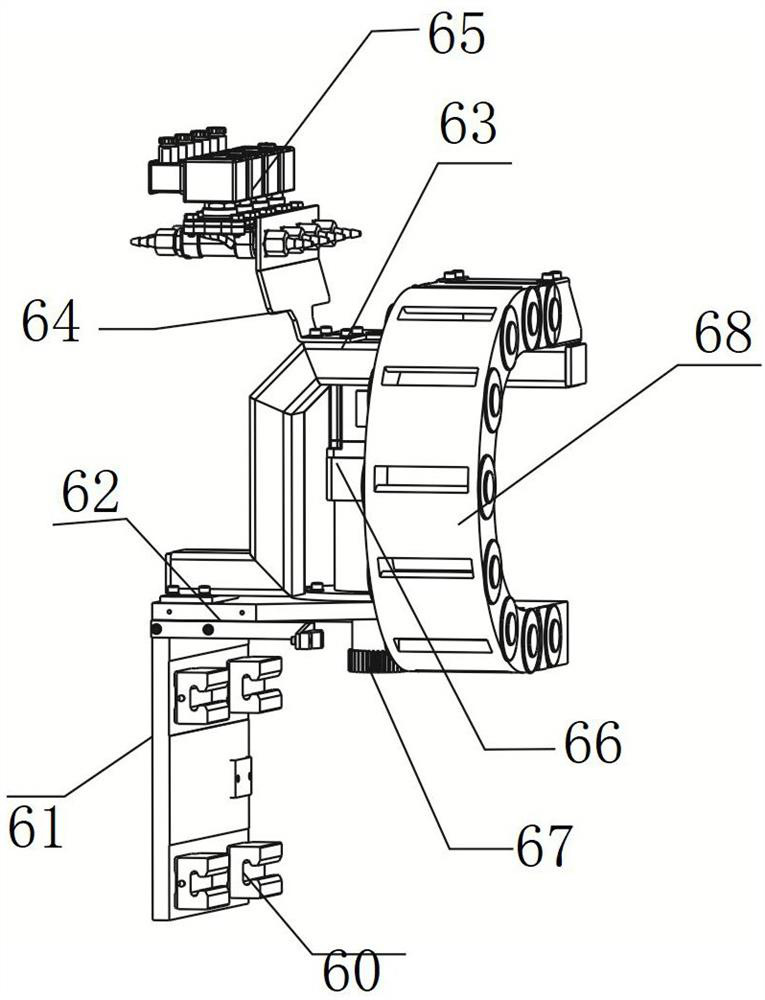

[0037] For specific implementation, refer to Figure 1 to Figure 6 .

[0038] The invention provides a cutting and processing device for a building insulation board, comprising

[0039] A set of base frame assemblies 1, a moving assembly 2 is arranged above each base frame assembly 1,

[0040] A beam frame 5 is arranged on the upper ends of the two moving assemblies 2,

[0041] The beam frame 5 is provided with a first mobile bracket assembly and a second mobile bracket assembly,

[0042] A laser cutting assembly 4 is arranged on the first moving bracket assembly,

[0043] A three-dimensional scanner 7 is arranged on the second mobile bracket assembly,

[0044] A seat plate 30 is also provided at the front end of the upper part of one of the mobile components 2, a control device 3 is arranged on the support plate, and a power supply device 31 is provided at the rear end of the upper part of the mobile component 2,

[0045] The control device 3 and the power supply device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com