A CO2 laser cutting power control method and system

A power control and laser cutting technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as insufficient and inability to meet the process requirements of cutting workpiece ablation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

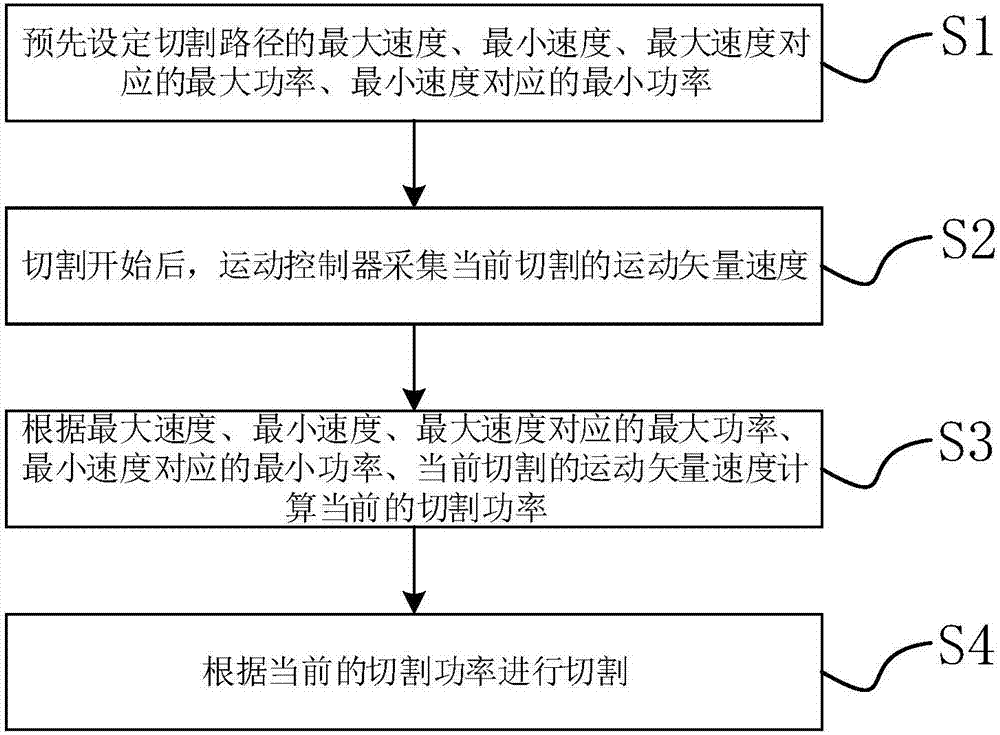

[0033] figure 1 It is a CO2 laser cutting power control method flow chart of the present invention, comprising the following steps,

[0034] S1. Preset the maximum speed, minimum speed, maximum power corresponding to the maximum speed, and minimum power corresponding to the minimum speed of the cutting path in advance;

[0035] S2. After the cutting starts, the motion controller collects the motion vector speed of the current cutting;

[0036] S3. Calculate the current cutting power according to the maximum speed, the minimum speed, the maximum power corresponding to the maximum speed, the minimum power corresponding to the minimum speed, and the current cutting motion vector speed;

[0037] S4. Cutting is performed according to the current cutting power.

[0038] Generally, in a cutting process, the cutting program is pre-designed according to the drawings. Since the speed of the cutting path may be constantly changing during the cutting process, however, the cutting speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com