Simple fixed tool fracture for unconventional lens coating

A tooling fixture, an unconventional technology, applied in the optical field, can solve the problems of prolonging the coating time, increasing the cost, increasing the delivery cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

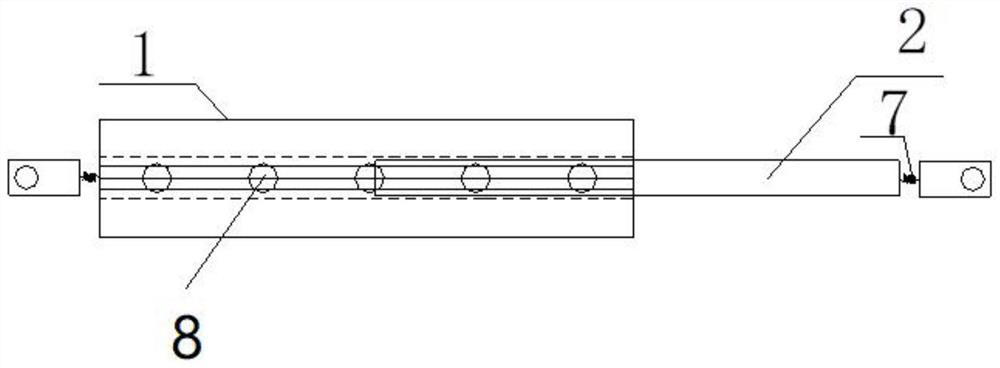

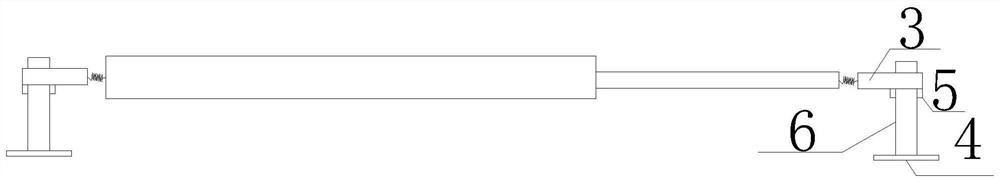

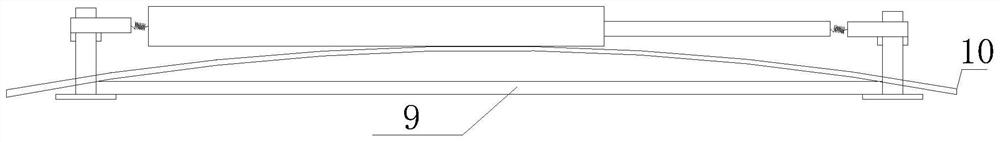

[0022] A simple and fixed unconventional lens coating tooling fixture, comprising a sleeve 1, the sleeve 1 includes a through groove, a puller 2 that can slide along the through groove is arranged in the through groove, and the two ends of the puller 2 are A connecting piece 3 is connected through the elastic piece, and a pressing piece 4 is fixed on the connecting piece 3 .

[0023] In this embodiment, the elastic member is a spring, and at the same time, the connecting member 3 and the pressing member 4 are fixedly connected together by bolts and nuts.

[0024] In this embodiment, the drawing member 2 is a steel bar, and at the same time, the sleeve 1 is provided with a plurality of threaded through holes, and the position of the drawing member 2 in the through groove is fixed by threads.

[0025] In this embodiment, the length of the drawing member 2 is greater than or equal to the length of the through slot.

[0026] In this embodiment, the connecting member 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com