Patents

Literature

37results about How to "Meet coating needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of NiCrAlYSi powder spraying material

InactiveCN103045909AGood qualityRealize engineering applicationMolten spray coatingChemical compositionCrucible

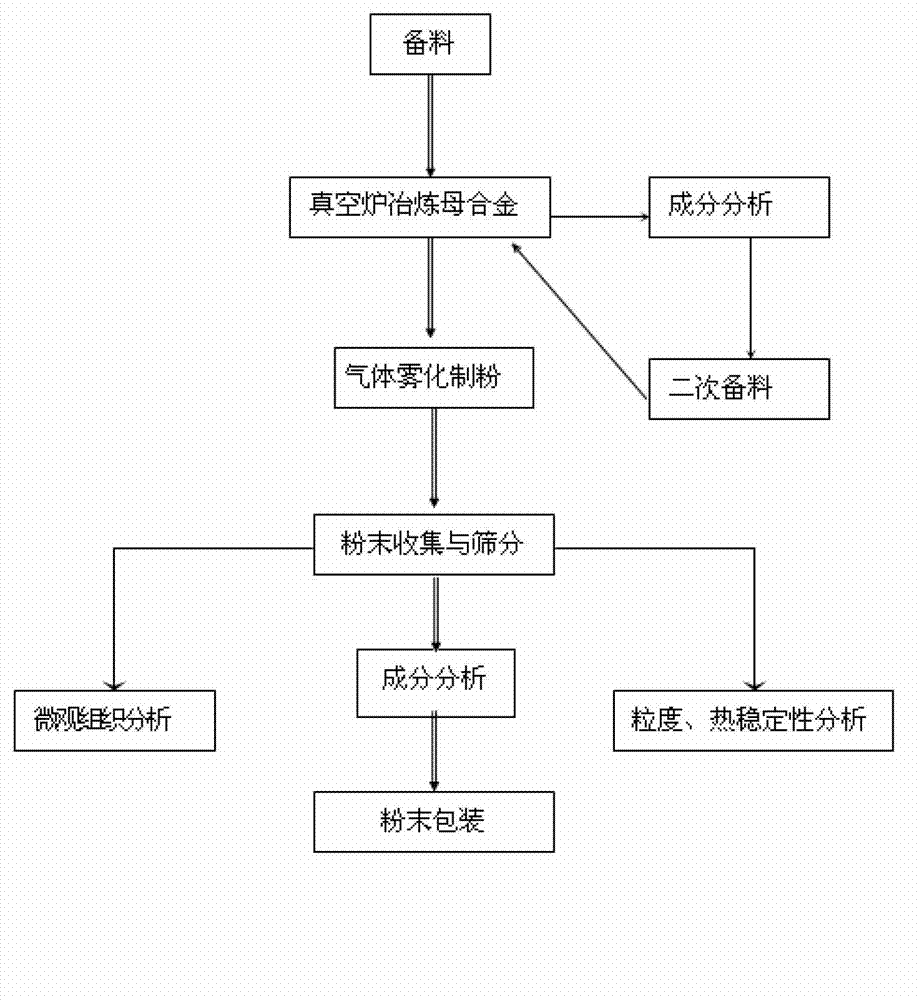

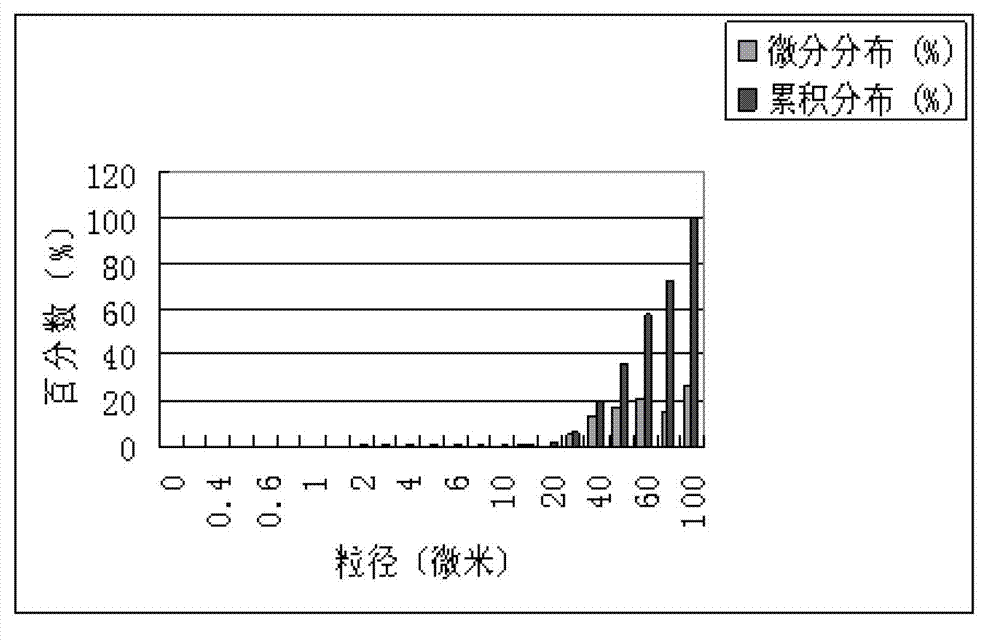

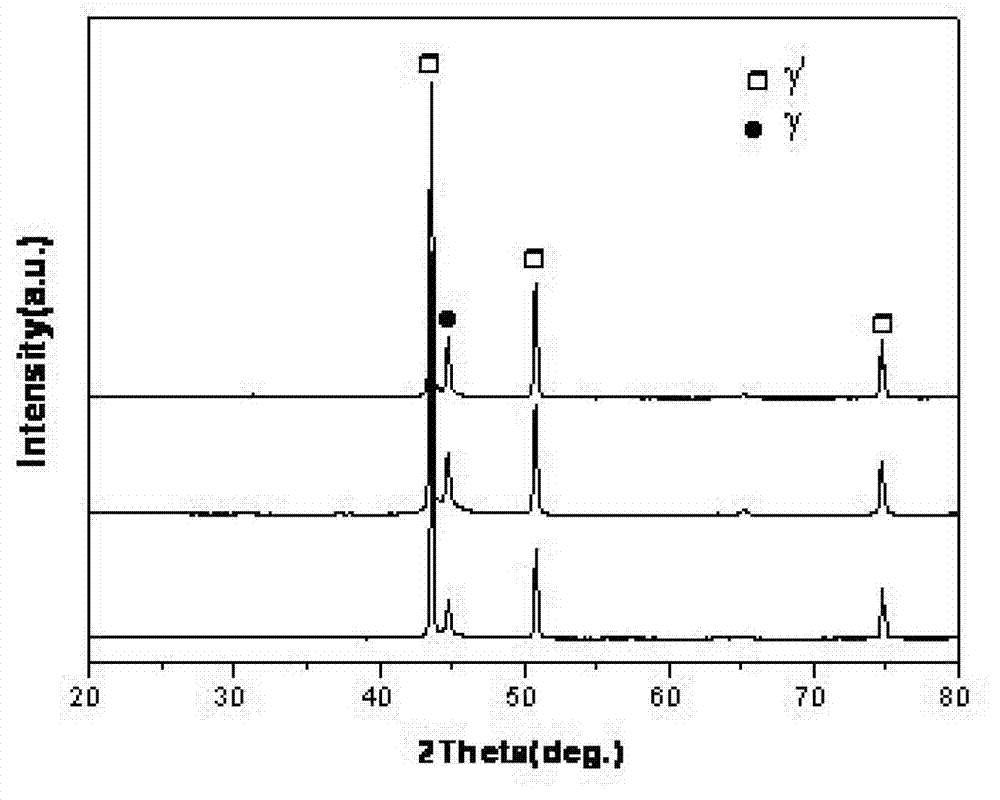

The invention aims at provides a preparation method of an NiCrAlYSi powder spraying material. The method adopts a technology of 'mother alloy pre-preparation and ultrasonic gas atomization' and a purpose of uniform control for chemical components of powder is achieved. The method comprises the specific steps that (1), a mother alloy is pre-prepared by a vacuum induction heating method; raw materials are placed into a magnesia crucible, with forvacuum degree higher than 2Pa, refining temperature of 1390-1430 DEG C, refining period of 15-20min, and casting temperature of 1420-1460 DEG C; the raw materials are cooled and cast to an alloy bar with a diameter of 70-100mm; (2) component analysis is conducted on the obtained mother alloy; if components of the obtained alloy exceed a proportion of the chemical components of the NiCrAlYSi powder, secondary stock preparation is conducted according to the proportion; (3), gas atomization pulverization is conducted, with atomization temperature of 1500-1530 DEG C, atomization pressure of 8-10MPa, gas flow of 10-15m<3> / min, alloy liquid flow of 2-4kg / min, and an atomization medium of pure argon.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

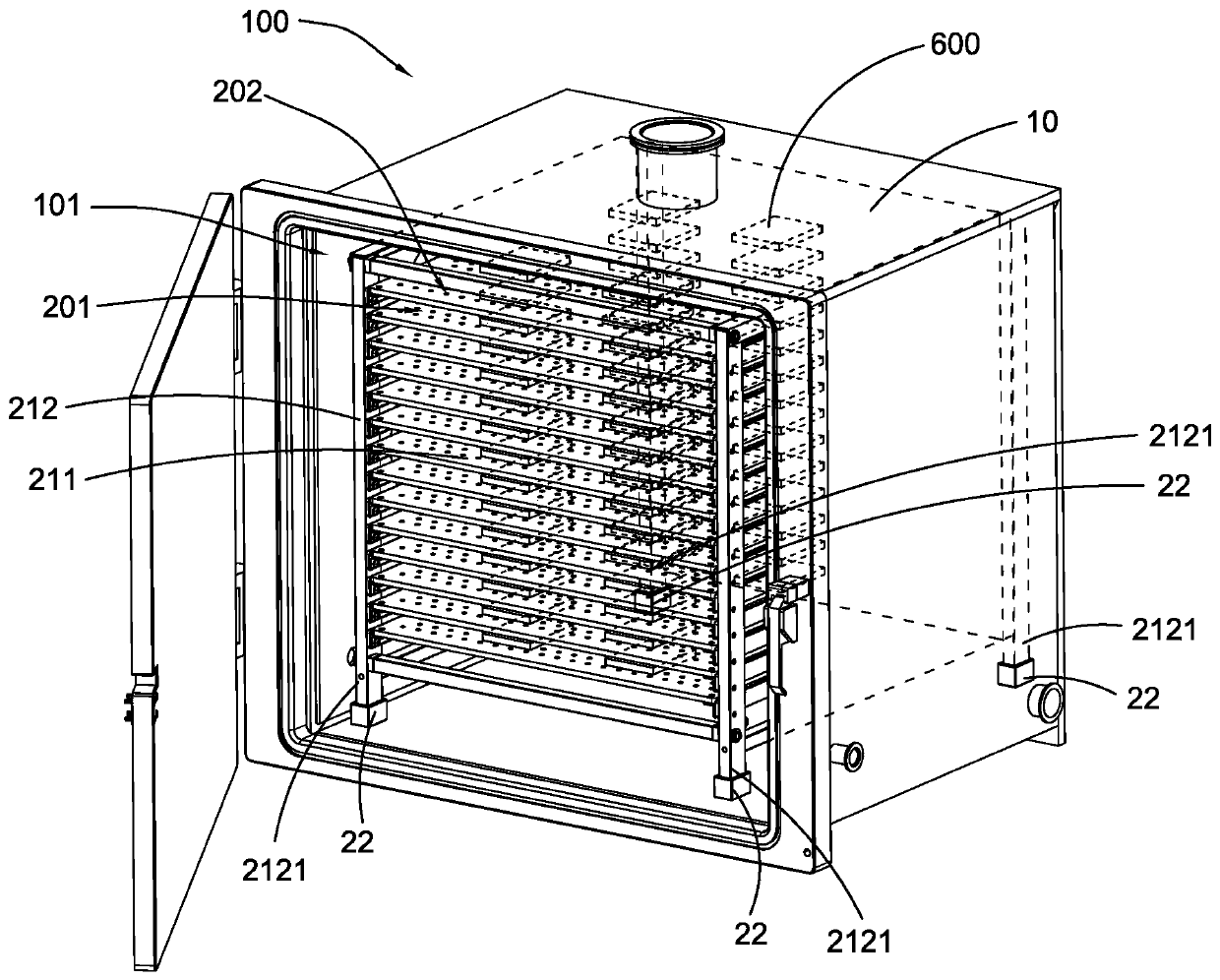

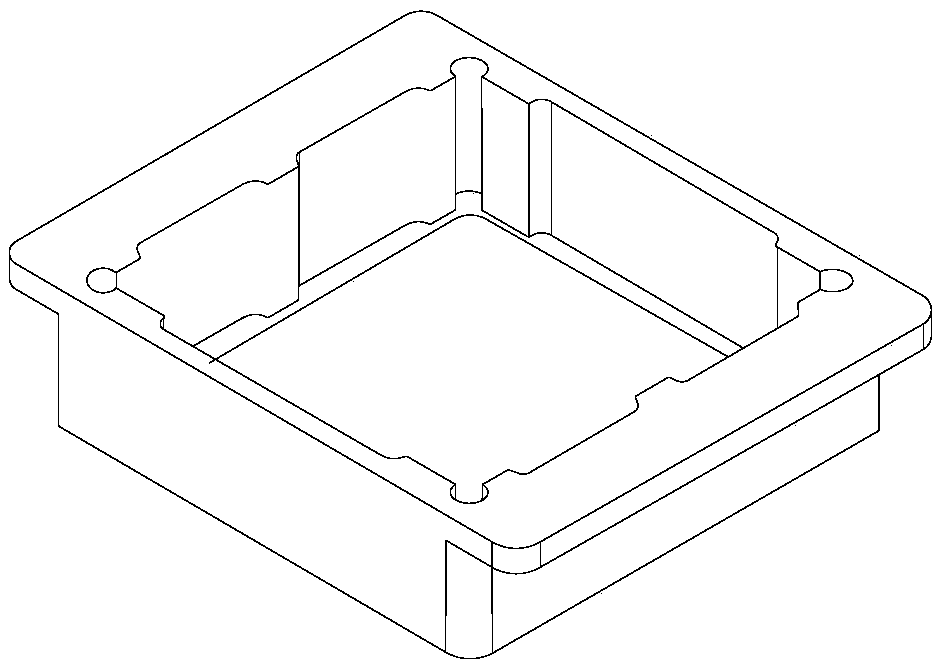

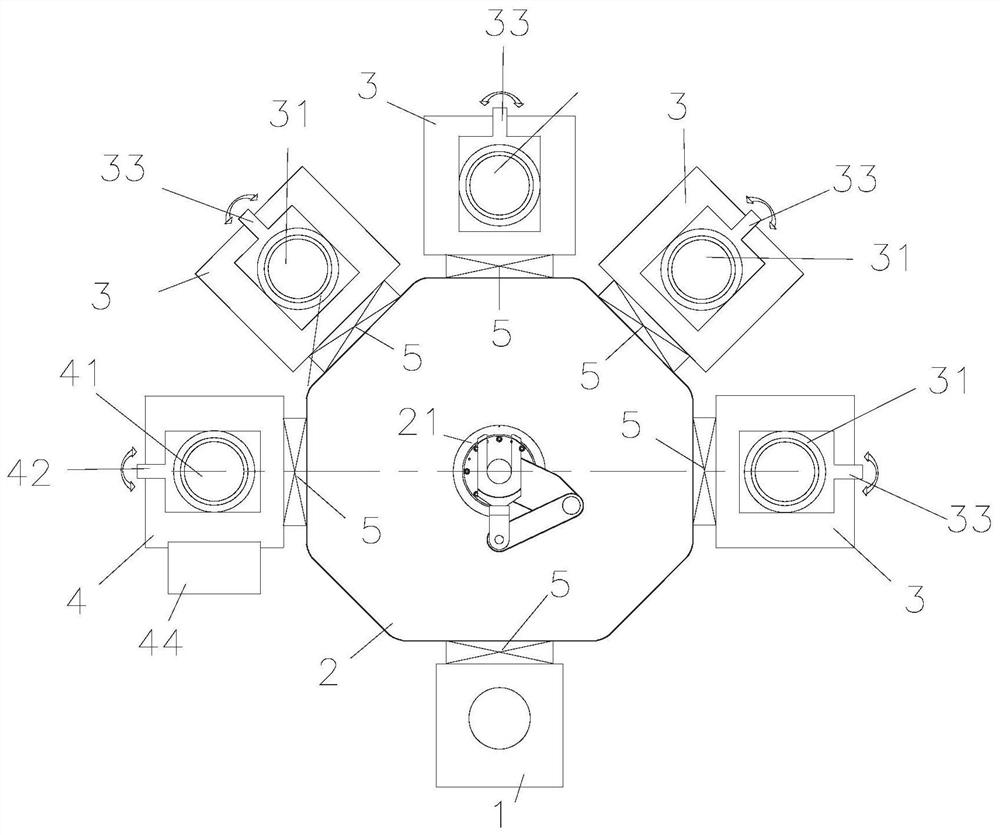

Coating equipment and electrode device and application thereof

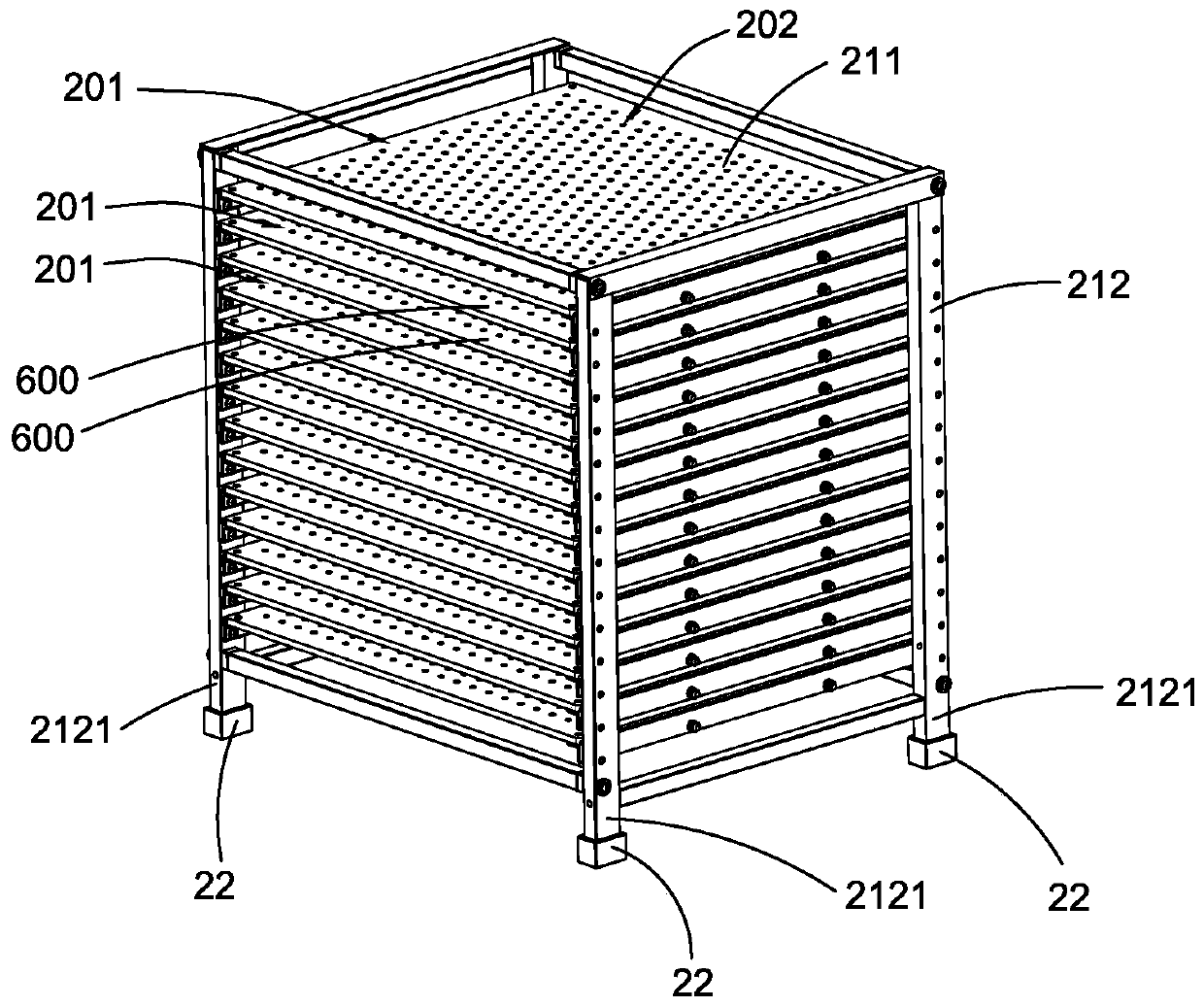

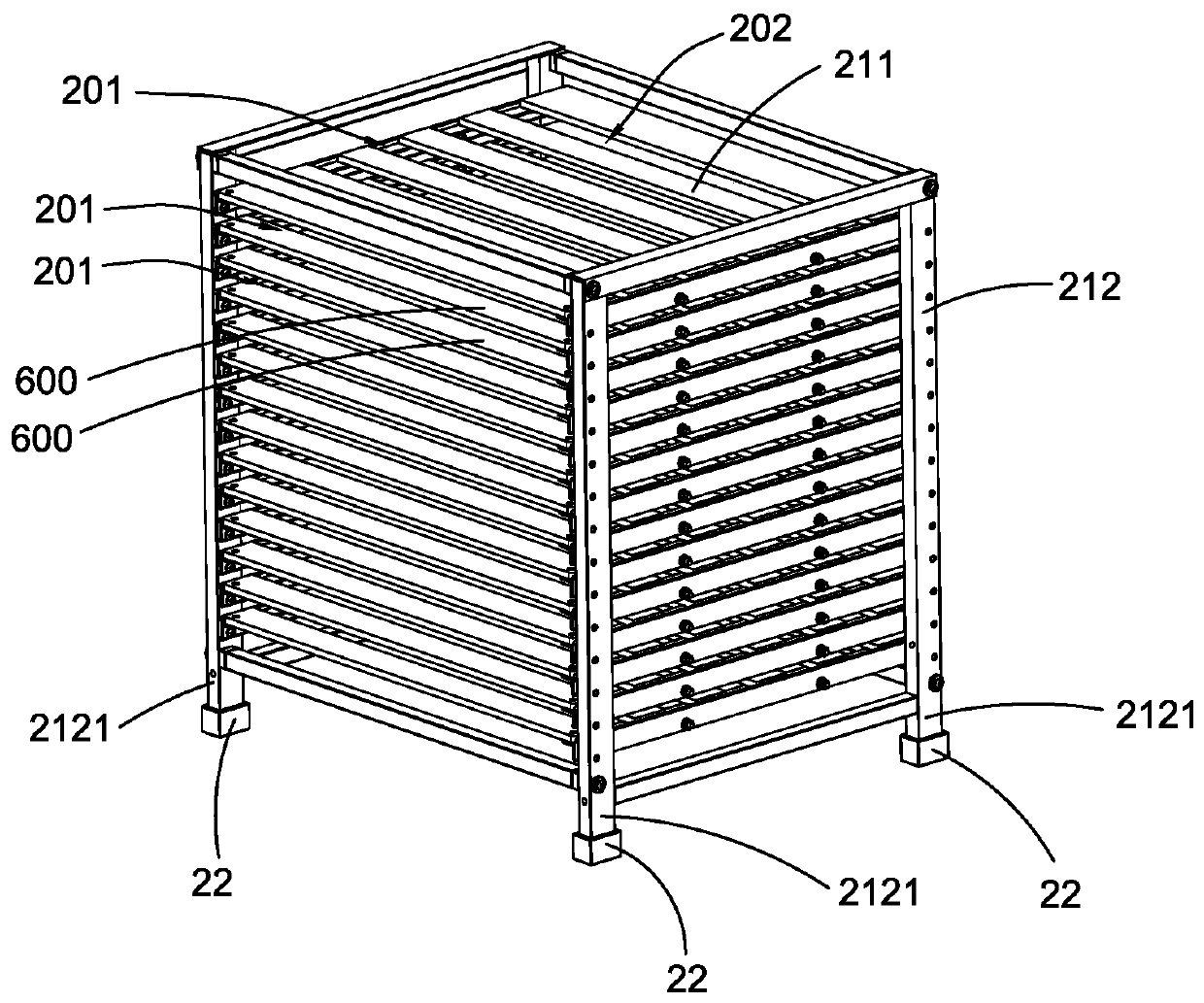

ActiveCN110904430AMeet the needs of mass productionImprove space utilizationChemical vapor deposition coatingThin membraneEngineering

The invention provides a coating equipment and electrode device and application thereof. The coating equipment is used for preparing a film on a substrate surface. The coating equipment includes a cavity, as least a bracket and a power supply unit. The cavity is provided with a chamber. The chamber is suitable to be inlet with a gas raw material used for preparing the film. The bracket is arrangedin the chamber. The bracket is used for supporting the substrate. The cavity body acts as a positive pole. The bracket acts as a cathode. A gas in the chamber is deposited directionally in a direction towards the substrate on the bracket under the voltage, and eventually forms the film on the substrate surface, in order to maximize the number of the substrate arranged on the bracket and meet allthe coating requirements of the substrate.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

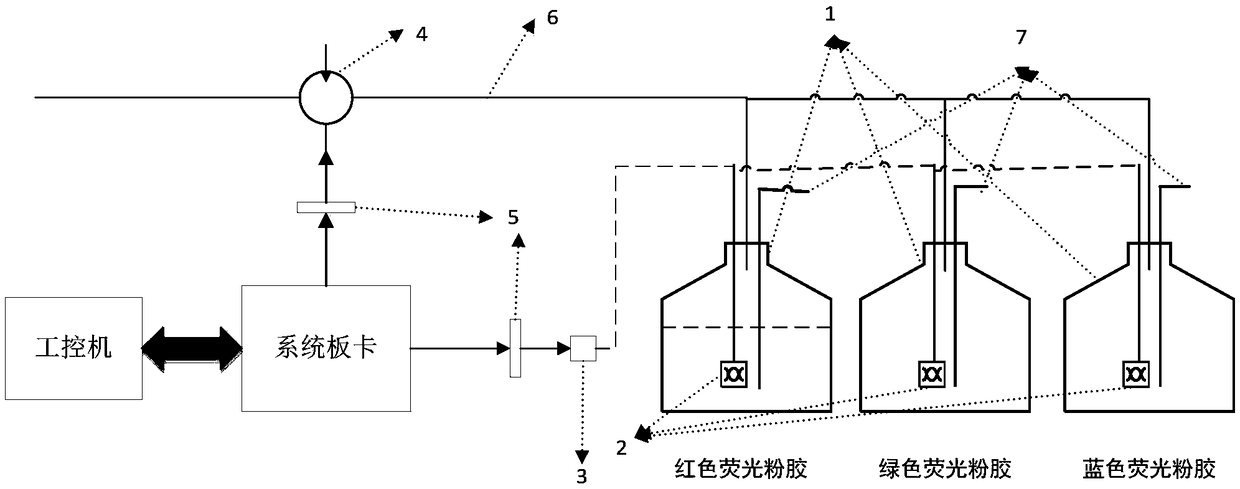

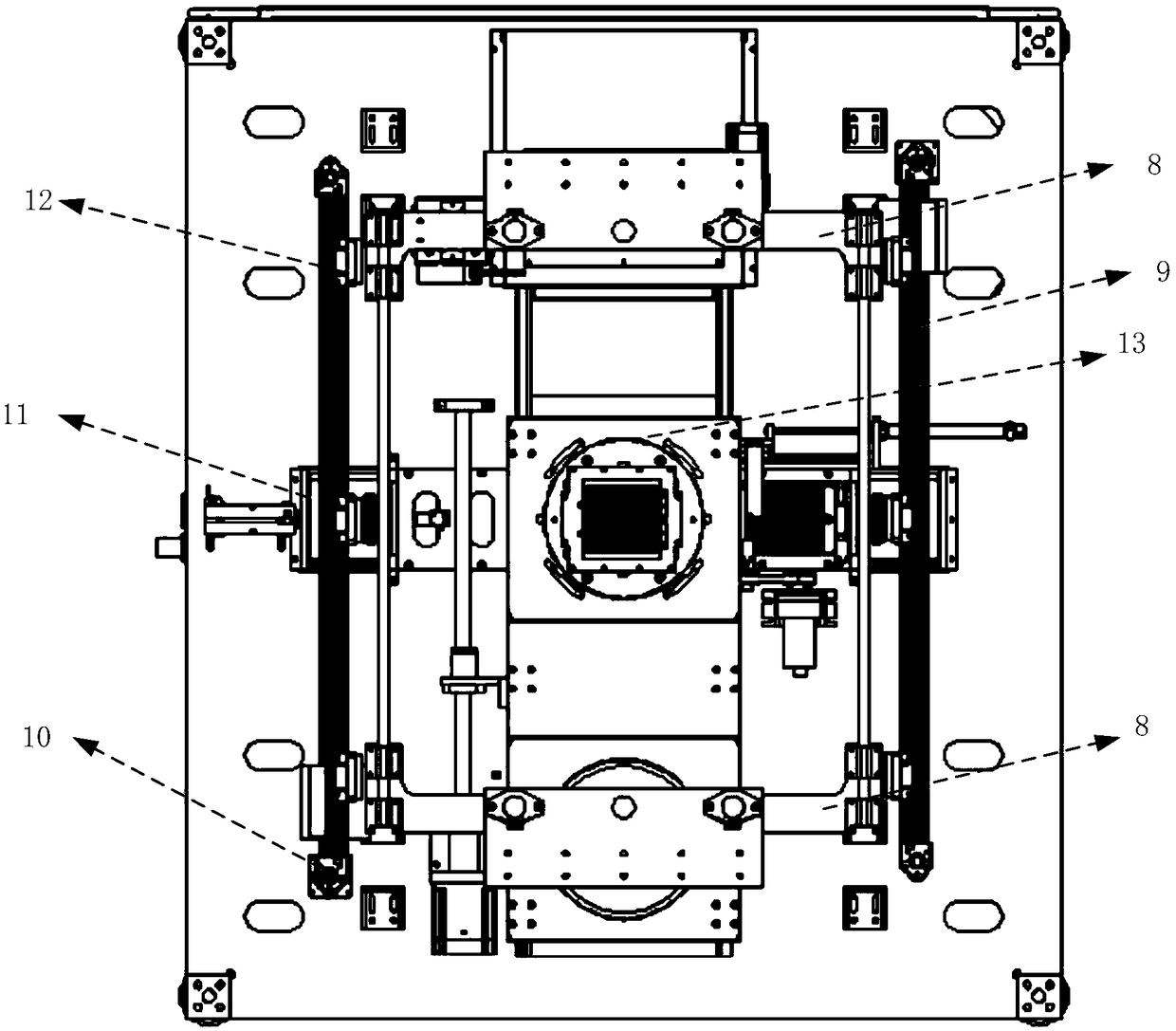

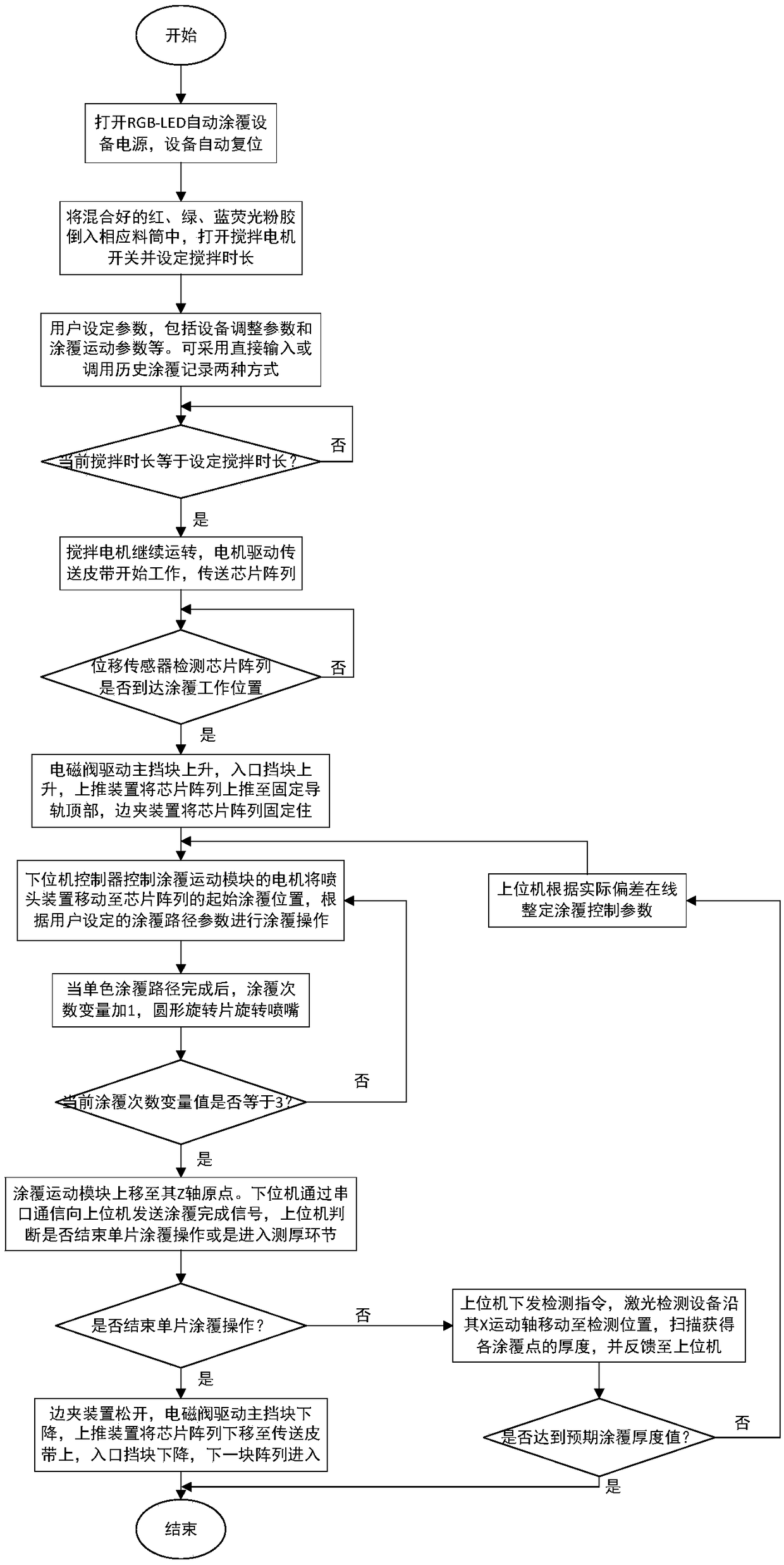

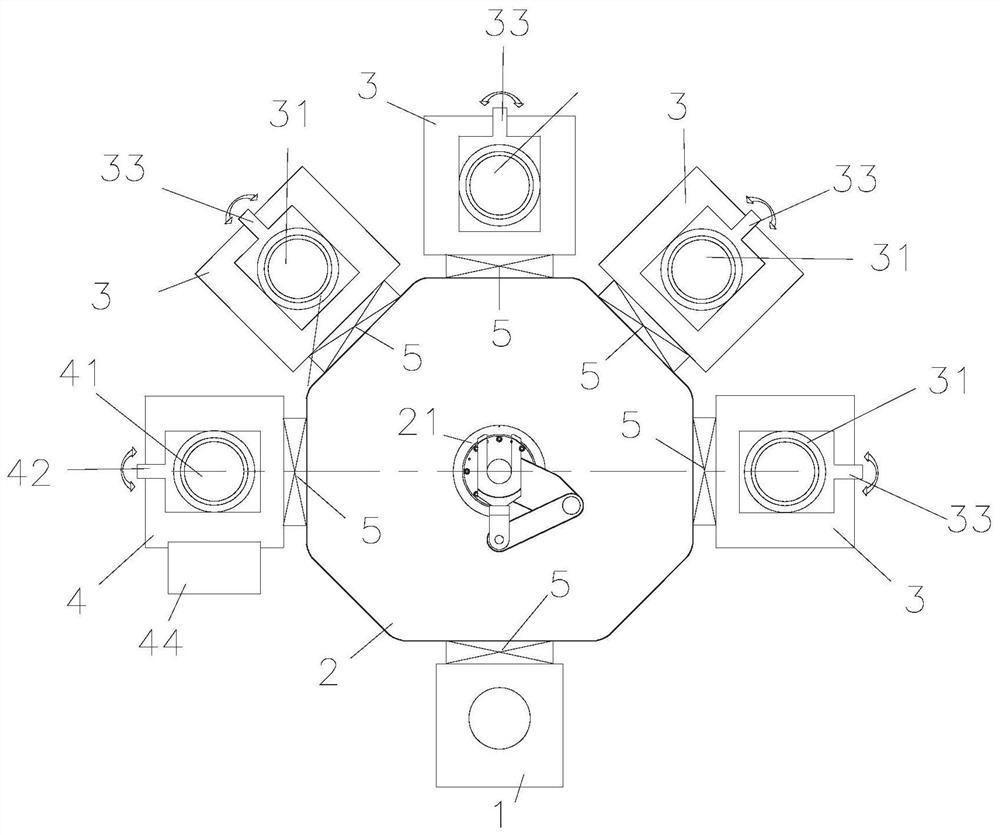

RGB-LED full-automatic fluorescent powder glue high-speed intelligent coating device and method

PendingCN108962798ARealize closed-loop controlImprove Coating IntelligenceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputer control systemEngineering

The invention discloses a RGB-LED full-automatic fluorescent powder glue high-speed intelligent coating device, the intelligent coating device includes a lower computer and an upper computer control system; the lower computer comprises a machine frame, a fluorescent powder glue feeding mechanism, a conveying mechanism, a coating movement module, a fluorescent powder glue thickness measuring mechanism, and a lower computer controller, the fluorescent powder glue feeding mechanism presses the mixed fluorescent powder glue into a spray head in the coating movement module through air pressure, theconveying mechanism conveys the chip array and fixes the chip array on the coating position, and the spraying head on the coating movement module is used for coating the chip at the coating position,the fluorescent powder glue thickness measuring mechanism is used for detecting the coating thickness of the current chip array, and the lower computer controller is connected with the upper computercontrol system. The device is high in automation degree, and has the functions of coating feedback control and online setting control parameters, the purpose of high-precision control on the coatingthickness of the fluorescent powder glue can be achieved, and the RGB-LED coating precision and coating efficiency of the LED can be effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

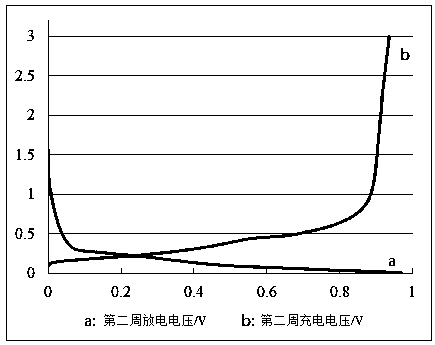

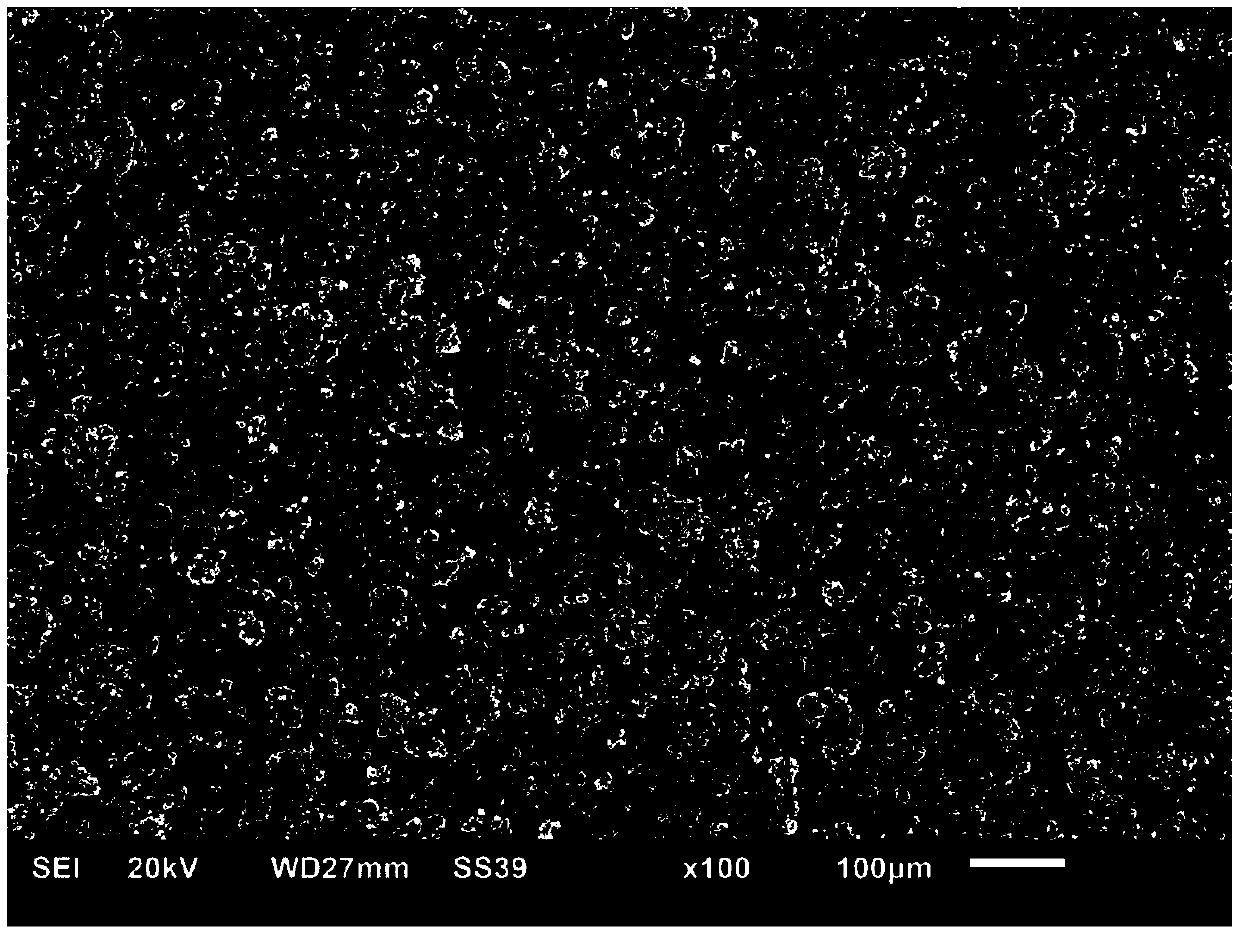

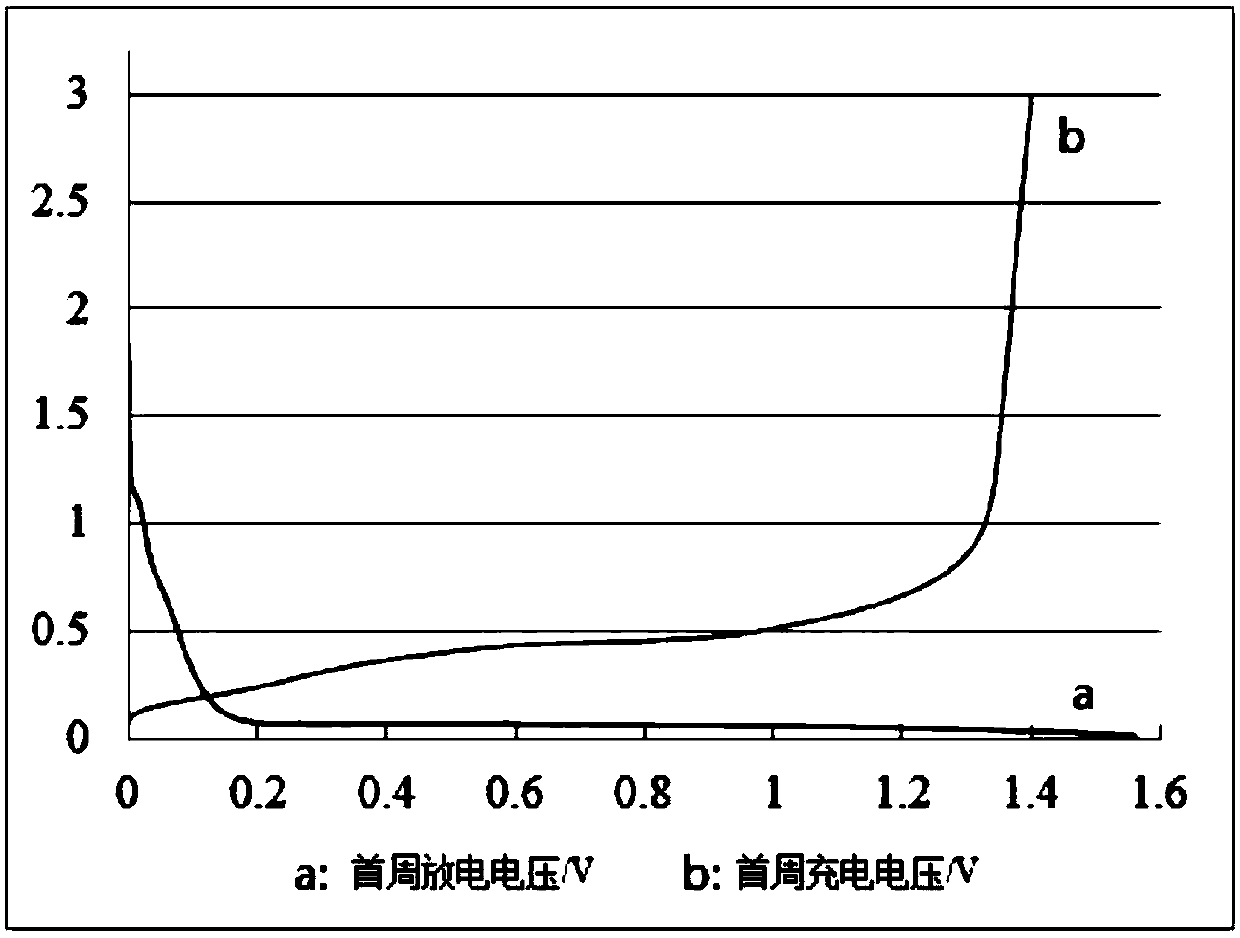

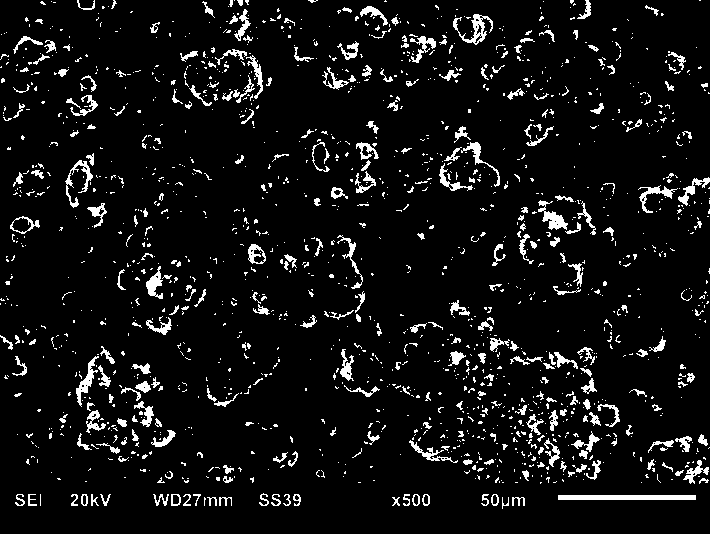

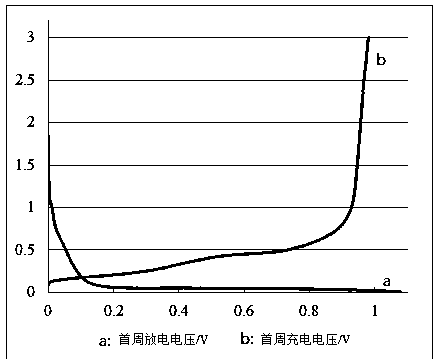

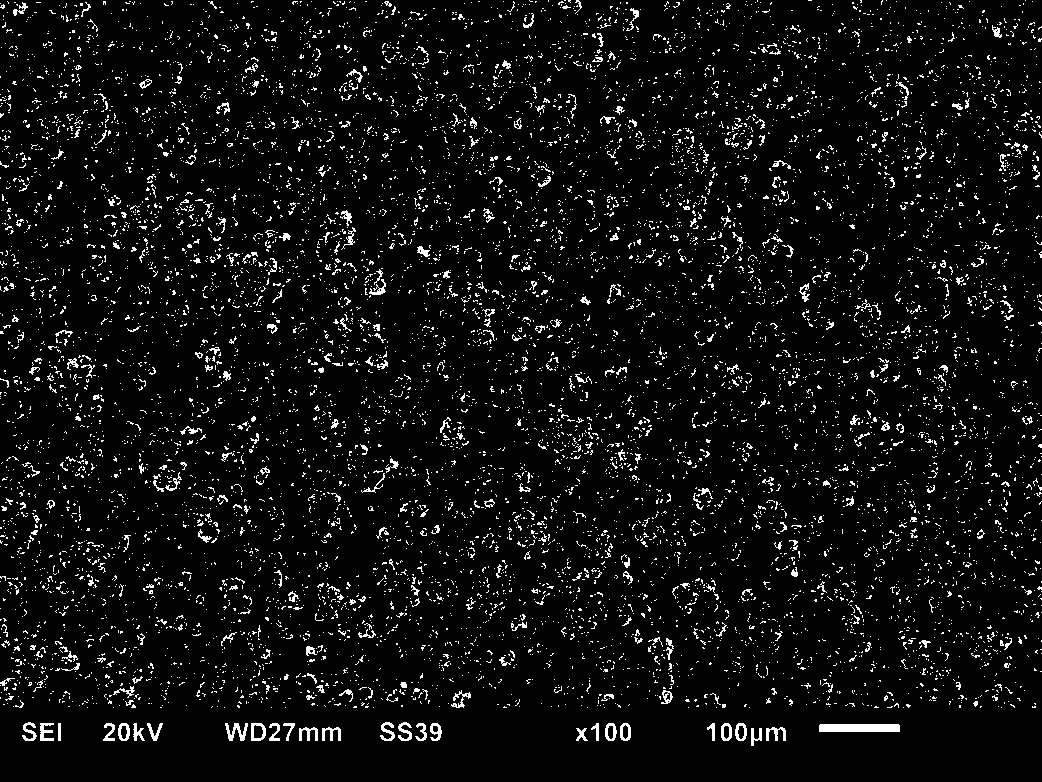

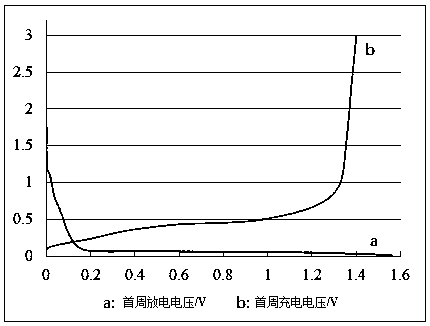

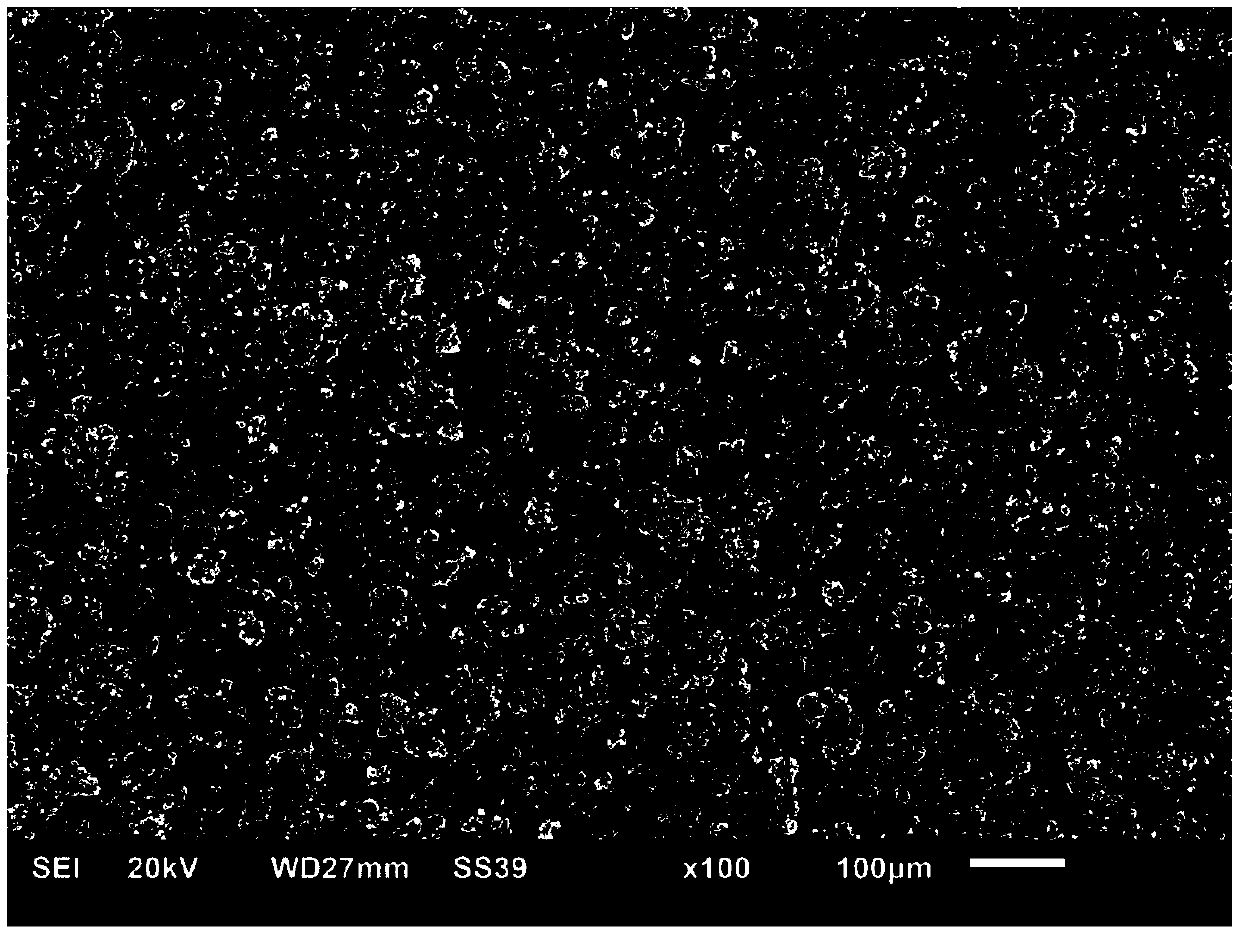

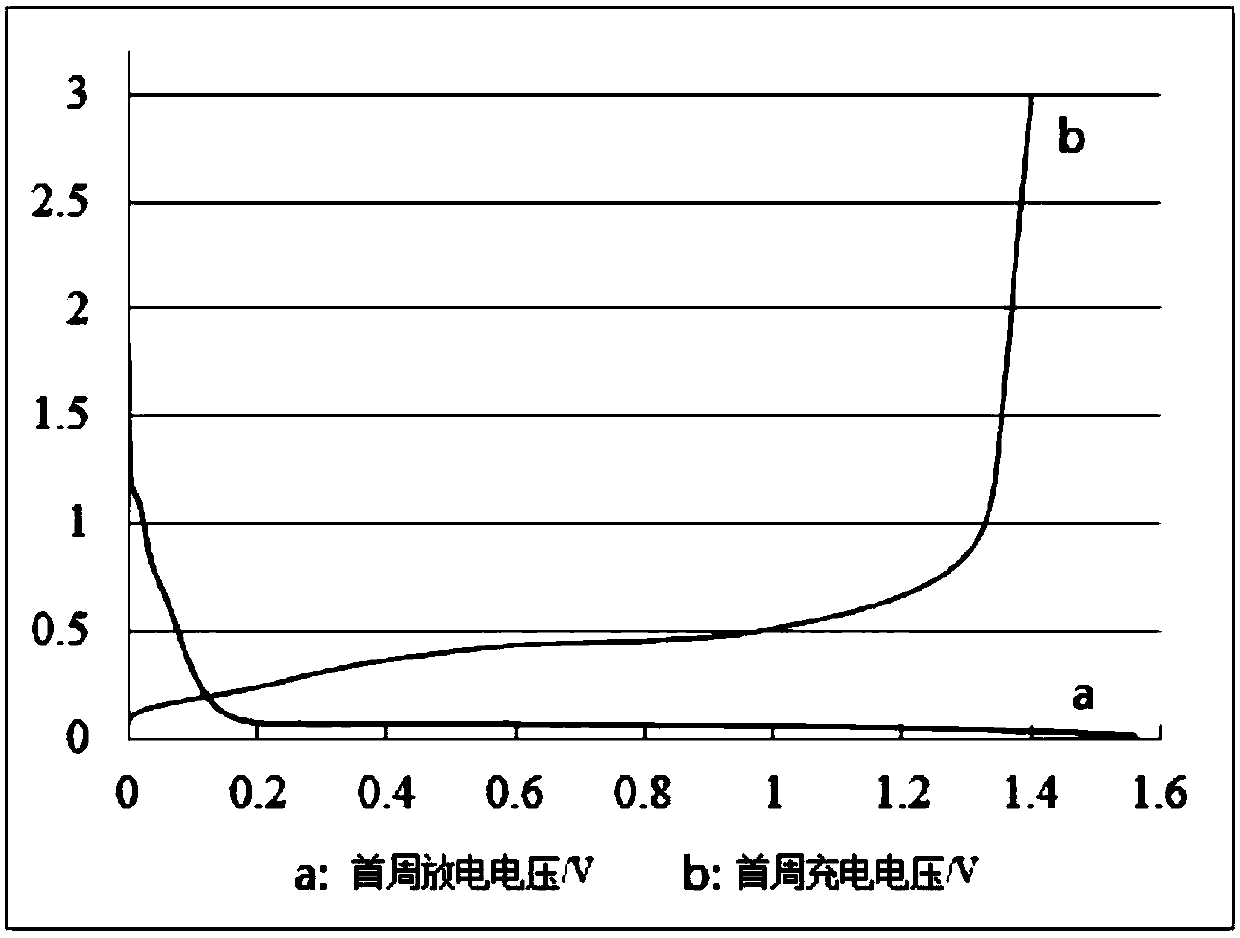

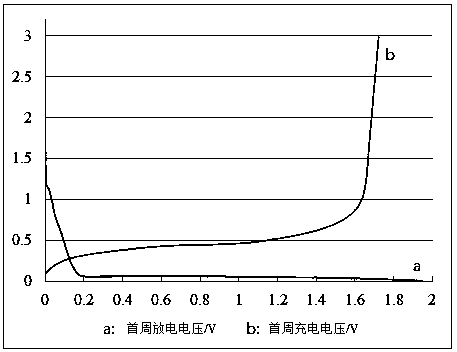

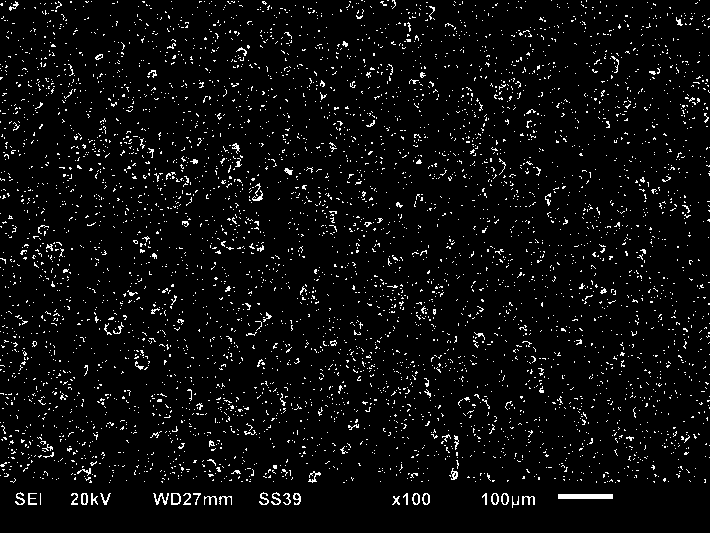

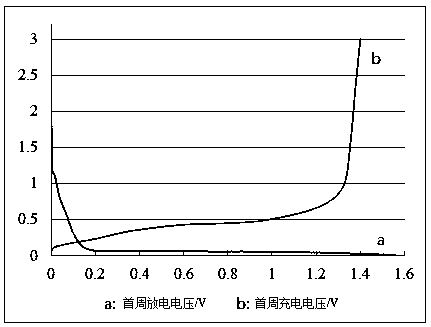

Copper-aluminum-silicon alloy nano cathode material of lithium battery and preparation method thereof

ActiveCN107790712AUnique structureImprove conductivityMaterial nanotechnologyTransportation and packagingSilicon alloyNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nano cathode material of a lithium battery and a preparation method thereof, and belongs to the technical field of cathode materials of the lithium battery. The adopted technical scheme is that the copper-aluminum-silicon alloy nano cathode material of the lithium battery comprises the following raw materials in parts by weight: 42 to 46 parts of silicon, 50 to 58 parts of copper, 5 to 15 parts of aluminum and 0 to 3 parts of impurities; the copper-aluminum-silicon alloy nano cathode material integrally comprises a multi-defect structurewith pores, shrinkage cavities, shrinkage porosities, dislocation, vacancy and holes; and the particle size is smaller than or equal to 80 <mu>m. The copper-aluminum-silicon alloy nano cathode material can be applied to the technical field of cathode materials of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

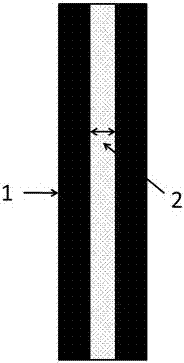

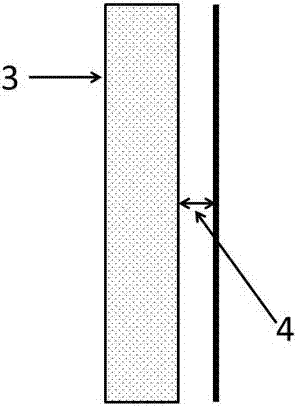

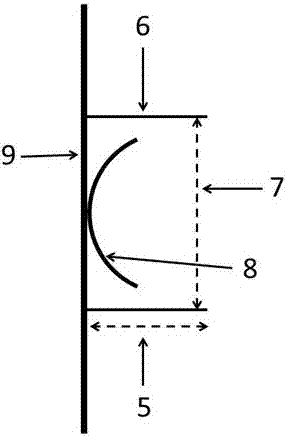

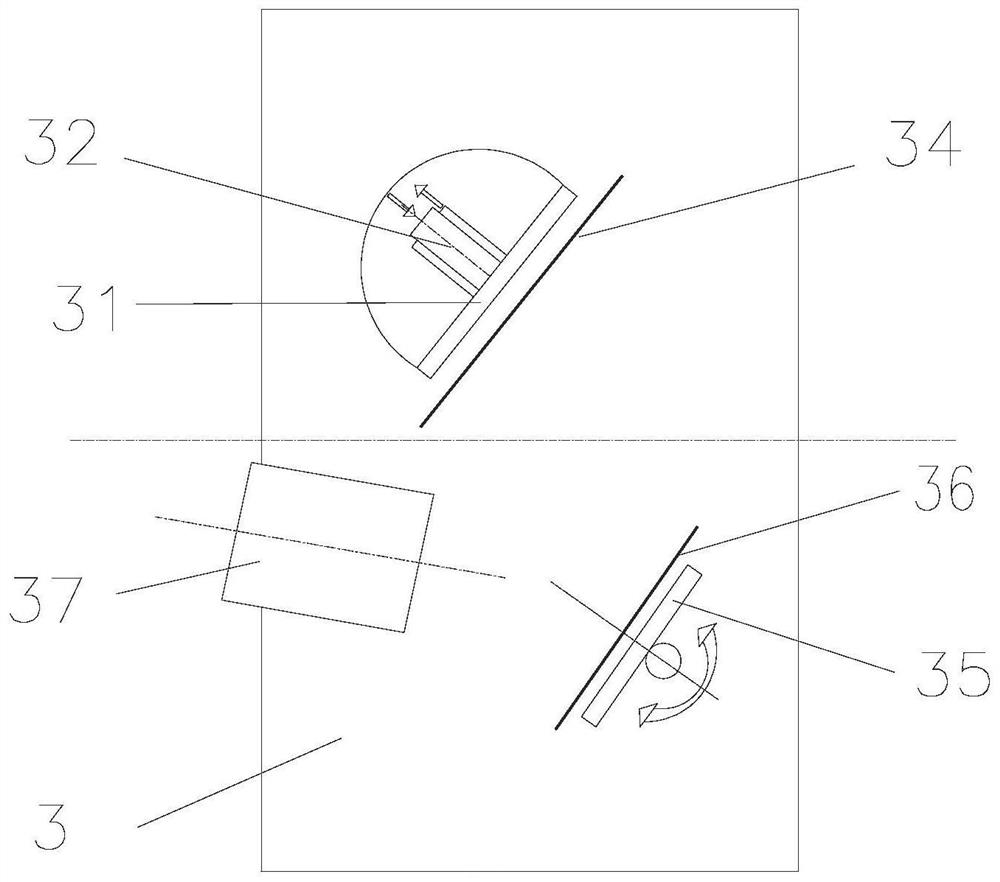

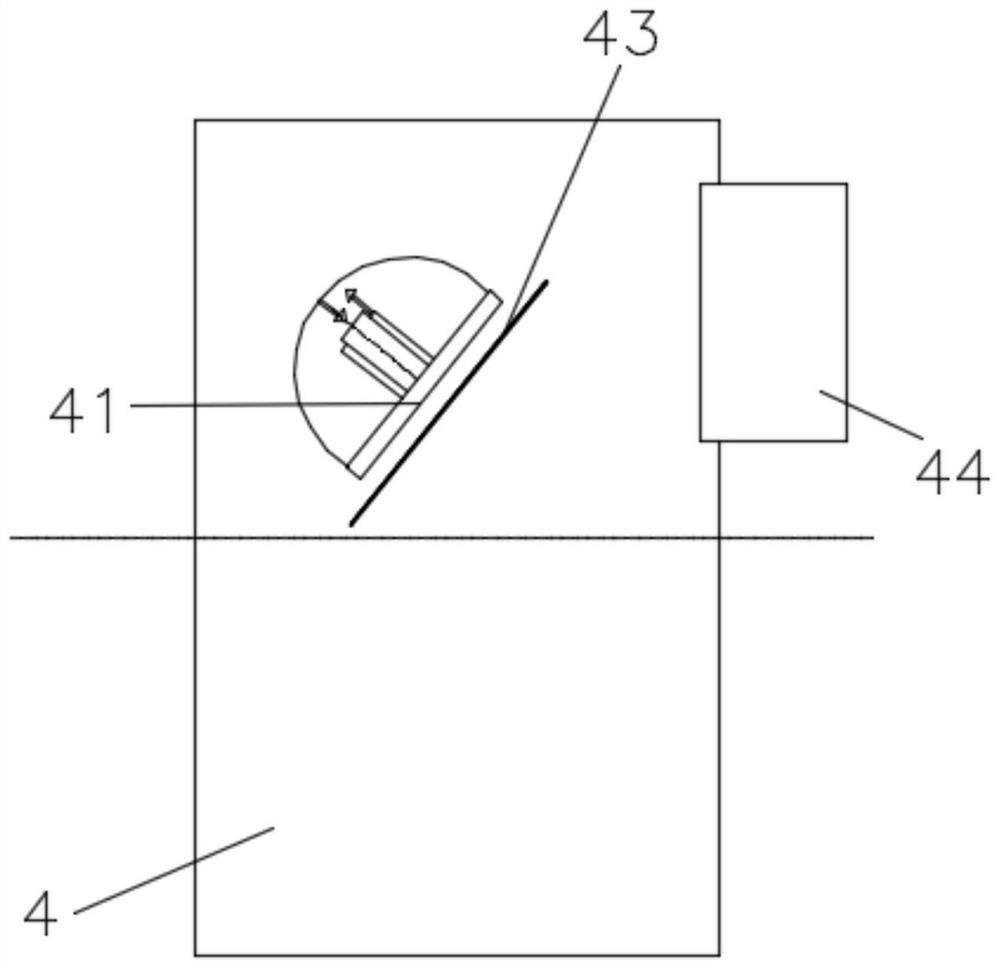

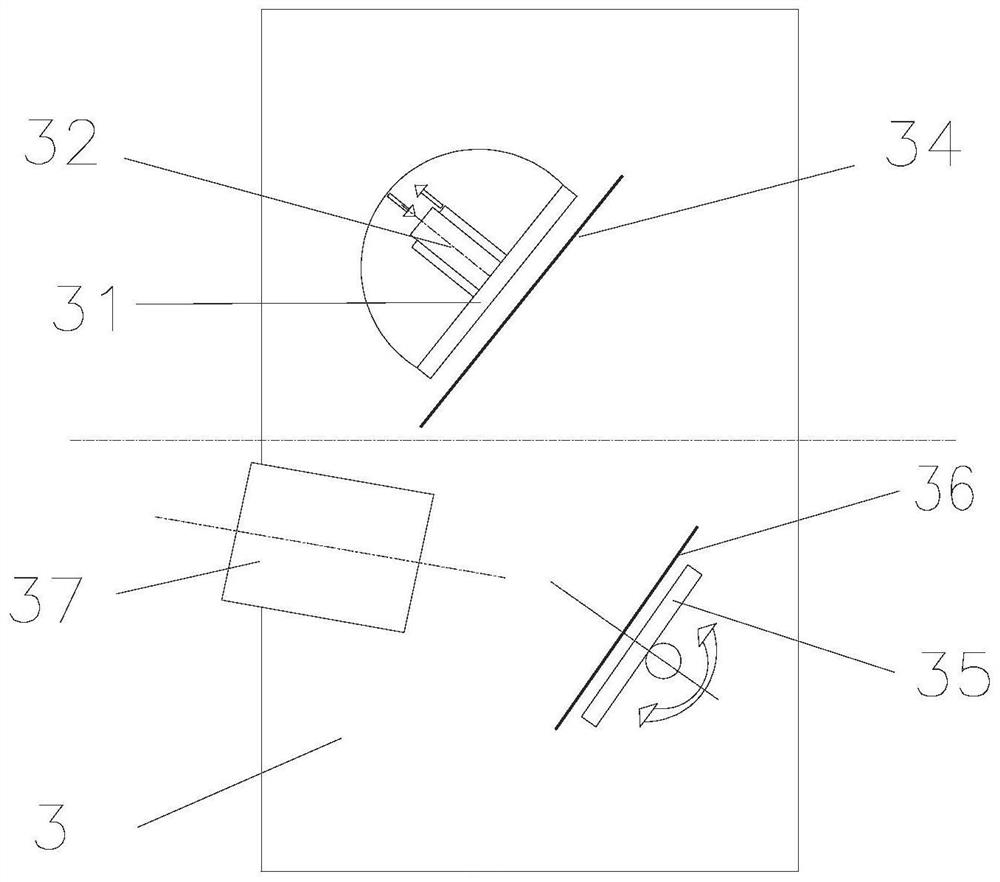

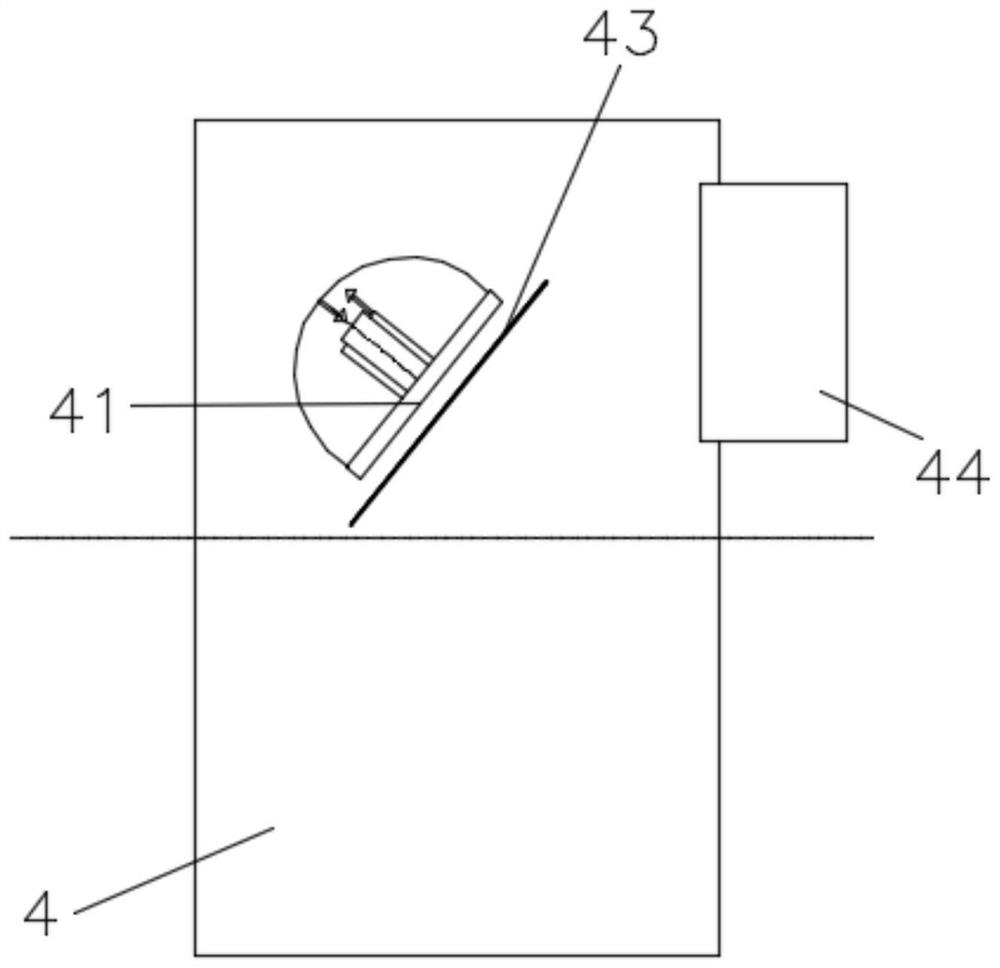

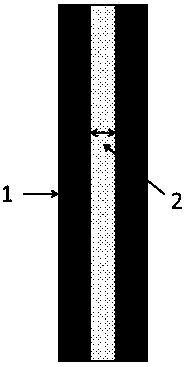

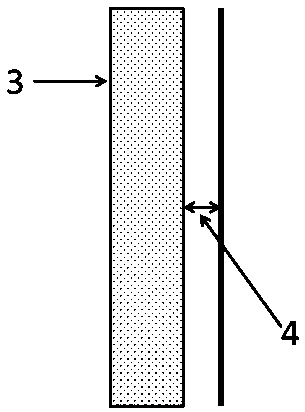

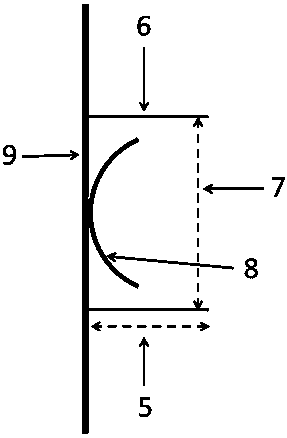

Method for improving coating film quality of linear magnetron sputtering target gun on concave column face substrate

ActiveCN106987817AMeet the needs of regularityImprove film qualityVacuum evaporation coatingSputtering coatingEngineeringLarge size

The invention relates to a method for improving the coating film quality of a linear magnetron sputtering target gun on a concave column face substrate. A mask mounted in front of the target gun and partition boards mounted at the positions, located on the two symmetric positions of a sample, of a sample frame are used for limiting the distribution angle of sputtered particles, in the horizontal and vertical direction, of the large-size linear magnetron sputtering target gun, the incident angle, inclined bombardment of the substrate, of the sputtered particles is reduced, the side effect of the sputtered particles which bomb the substrate in an inclined manner on the film forming quality is reduced, and the thin film quality of the concave column face substrate is improved.

Owner:TONGJI UNIV

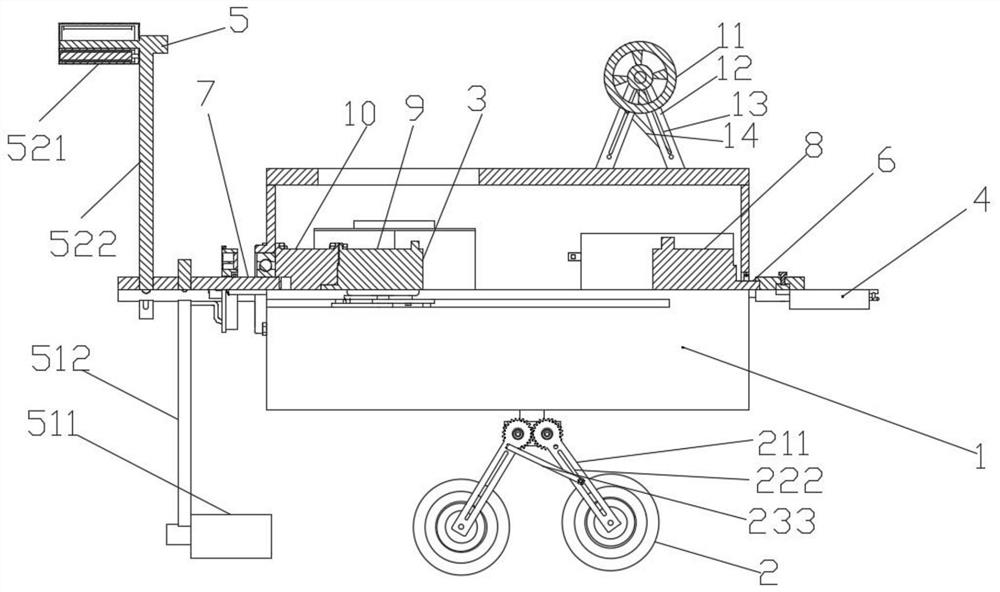

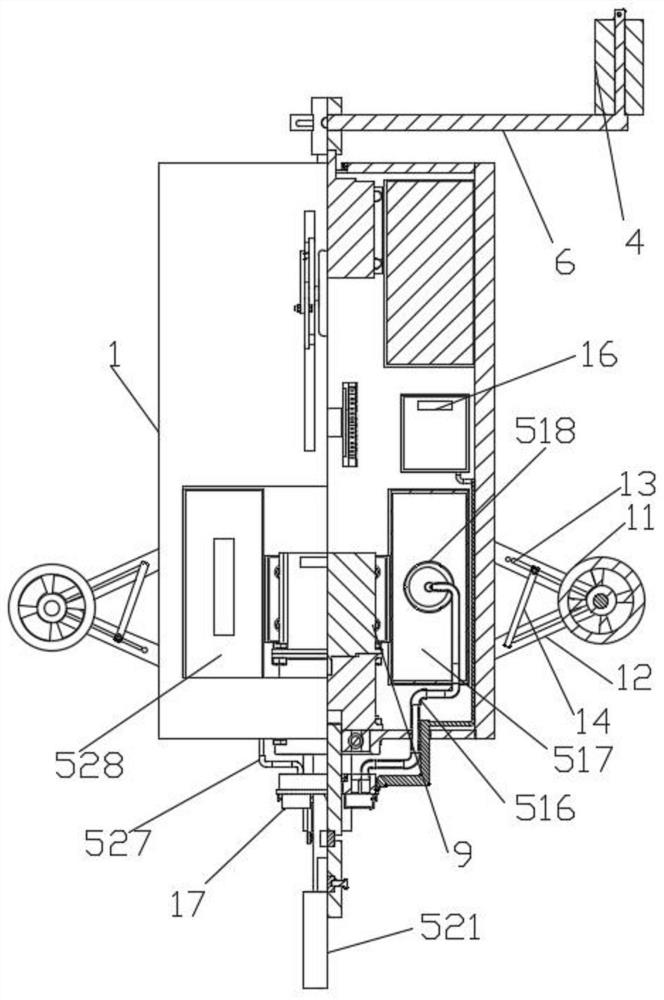

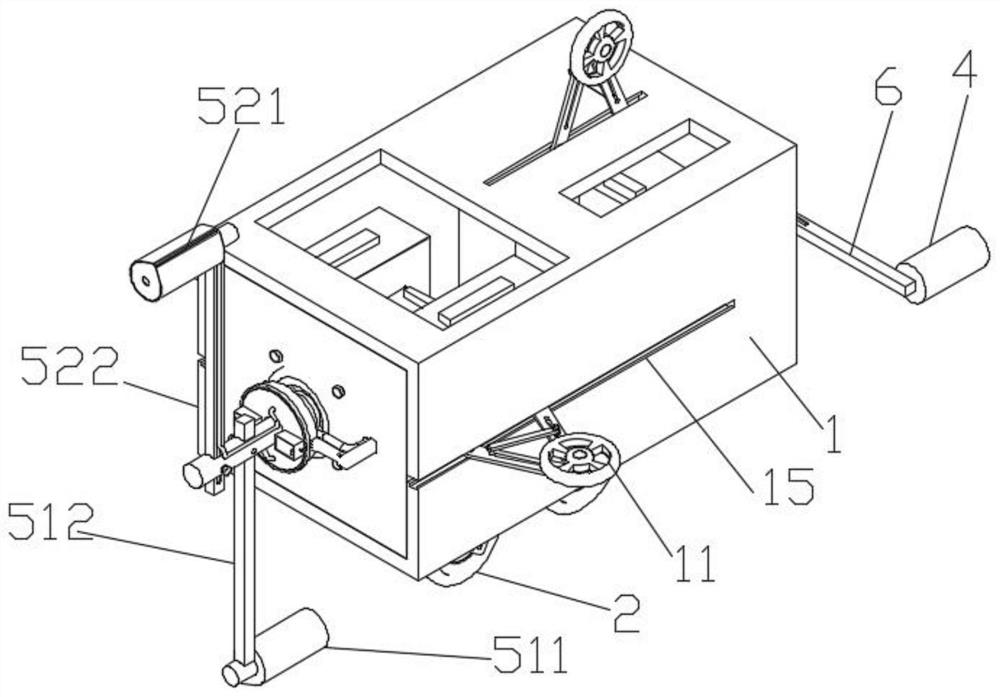

Method suitable for coating large-diameter metal pipe by molding powder to manufacture composite pipe

InactiveCN104259041AImprove bindingCuring stabilityLiquid surface applicatorsCoatingsHigh pressure waterHigh pressure

The invention relates to a method suitable for coating a large-diameter metal pipe by molding powder to manufacture a composite pipe. The method is characterized by comprising the following steps: (1) rotating the pipeline at a certain speed in the shot blasting process, and performing shot blasting at set speed; (2) degreasing the metal pipe in a striking way by adopting a high-pressure water gun and by virtue of a degreasing agent; (3) drying the degreased metal pipe in a high-temperature environment; (4) uniformly spraying the molding powder onto the metal pipe through a paint shaking sieve, and driving the metal pipe to rotate at a given constant speed by a metal pipe carrier cart; and (5) solidifying the molding powder on the metal pipe under a high temperature condition in a large-sized kiln-type heating device, driving the metal pipe with the plastic coating to rotate at a constant speed in the large-sized kiln-type heating device by the carrier cart, and thus preparing a finished product composite pipe. The method has advantages of large binding force, large attaching force, uniformity in coating and smoothness and attractiveness of surface, and the coating requirement of the large-diameter metal pipe can be met.

Owner:JILING YULINGLONG STEEL PIPE STEEL STRUCTURE MFG

Ion beam coating equipment and coating method thereof

ActiveCN112899633AAchieve transshipmentImprove adhesionFinal product manufactureVacuum evaporation coatingIsolation valveIon beam

The invention discloses ion beam coating equipment and a coating method thereof. The ion beam coating equipment comprises a transfer chamber and a substrate loading and unloading chamber, a coating chamber and a cleaning chamber which are connected to the transfer chamber, isolation valves are arranged among the substrate loading and unloading chamber, the coating chamber and the cleaning chamber, and a transfer mechanism is arranged in the transfer chamber. According to the film coating method, the equipment is adopted for coating treatment. In the ion beam coating equipment, the substrate loading and unloading chamber is used for storing different types of substrates, the transfer chamber is used for transferring the substrates among the substrate loading and unloading chamber, the coating chamber and the cleaning chamber, the coating chamber can be used for coating a plurality of substrates at the same time and can also be used for preparing various types of film layers, and the cleaning chamber is used for removing dirt and oxides on the surfaces of the substrates, and the adhesive force between the film and the substrate is improved. According to the ion beam coating equipment, continuous cleaning and continuous coating of the substrate can be achieved, continuous production can be achieved, the production efficiency can be improved, the production cost can be reduced, and the requirements of the substrate (such as an infrared device) for the large-size, low-damage and low-temperature coating process can be met.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

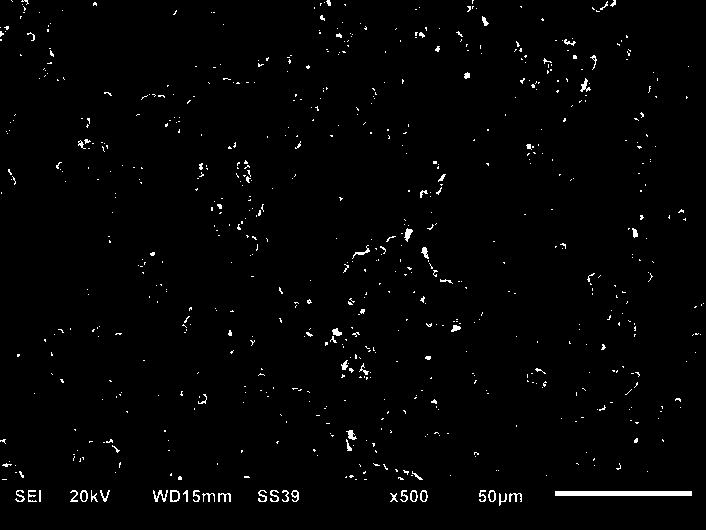

Method for preparing copper-aluminum-silicon alloy powder by water atomization and application of method

ActiveCN107732190AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesMolten stateSilicon alloy

The invention relates to a method for preparing copper-aluminum-silicon alloy powder by water atomization and application of the method, and belongs to the technical field of preparation of a lithiumbattery negative electrode material. The invention provides a high-performance lithium battery copper-aluminum-silicon alloy nanometer negative electrode material prepared by employing a water atomization method and application of the copper-aluminum-silicon alloy nanometer negative electrode material. The method comprises the steps of 1, starting a tundish system of an atomization system, whereinthe inner diameter of a tundish nozzle selects 6-14 millimeters; 2, adjusting a tapping temperature of molten-state copper-aluminum-silicon alloy to be 1,300-1,700 DEG C; and 3, pouring liquid-statemetal to a tundish, adjusting water atomization pressure to be 300-450Mpa, and performing water atomization powder preparation, wherein the copper-aluminum-silicon alloy comprises the constituents based on parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of other impurity. The method can be widely applied to the field of preparation of the lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Preparation method of high-transmittance silicon rotary sputtering target material

PendingCN113481477AImprove transmittanceReduce use costMolten spray coatingVacuum evaporation coatingSputteringPolycrystalline silicon

The invention provides a preparation method of a high-transmittance silicon rotary sputtering target material. The method comprises the following steps that a 6N polycrystalline silicon heavily doped raw material and a 5N polycrystalline silicon high-resistance raw material are crushed into powder to obtain a 6N polycrystalline silicon semi-finished product raw material and a 5N polycrystalline silicon semi-finished product raw material, and the 6N polycrystalline silicon semi-finished product raw material and the 5N polycrystalline silicon semi-finished product raw material are mixed and diluted to prepare high-purity silicon powder with a low impurity content. In this way, a content of impurities, especially B, of the target material prepared through spraying is reduced, a transmittance of the target material in a coating process is improved, an LAB value is greater than or equal to 93%, the use cost of customers is reduced, and coating requirements of the customers on large-size products are met.

Owner:WUHU YINGRI TECH CO LTD

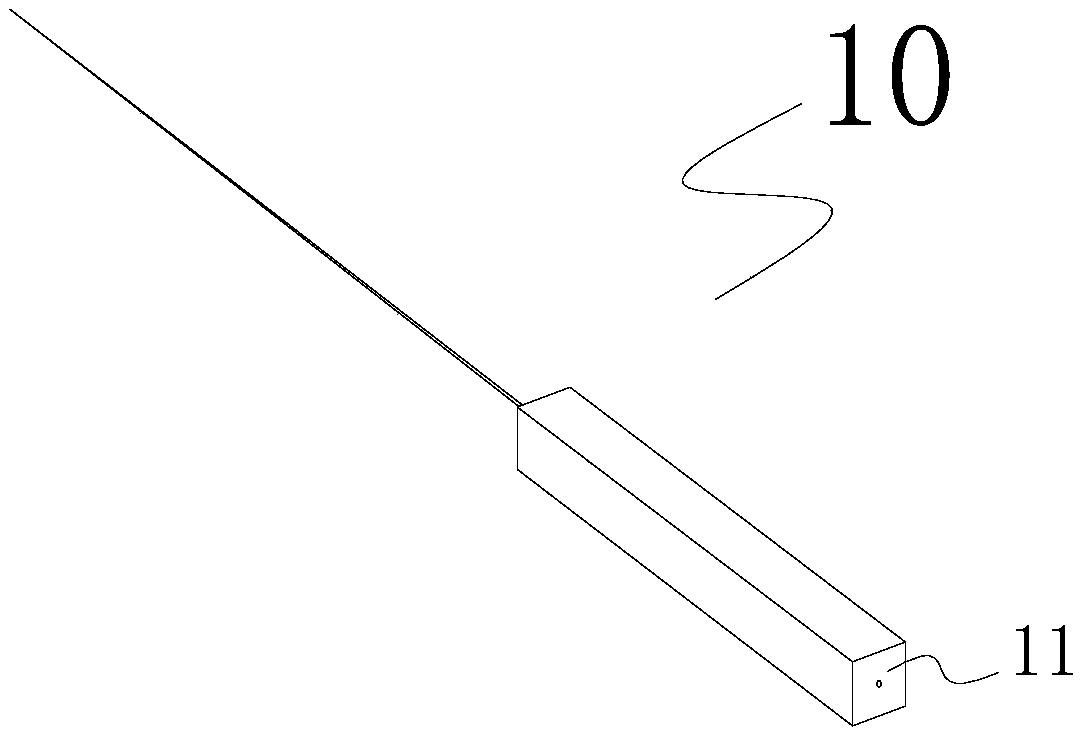

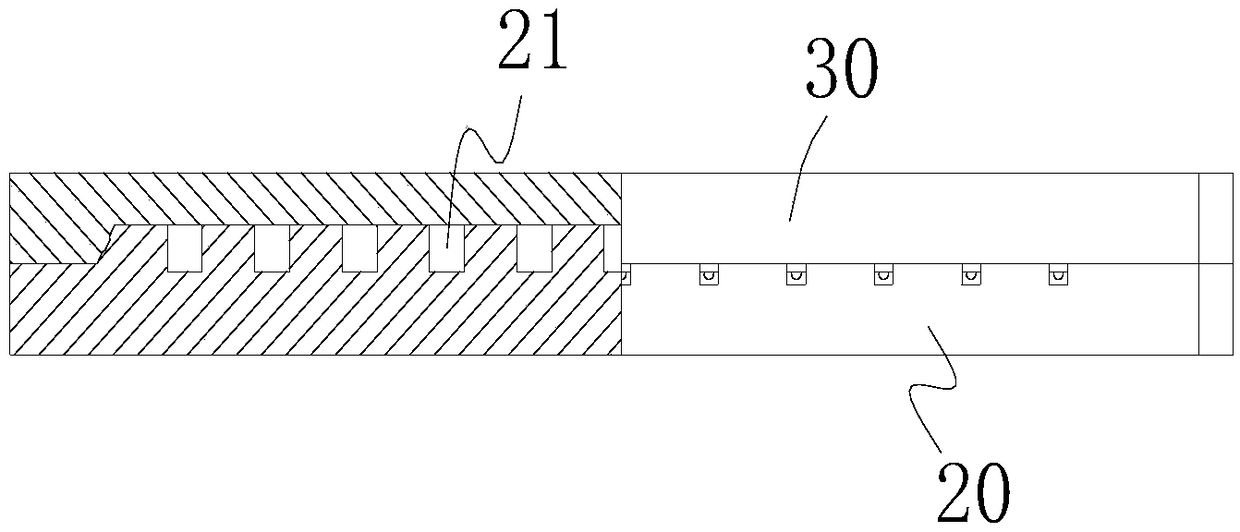

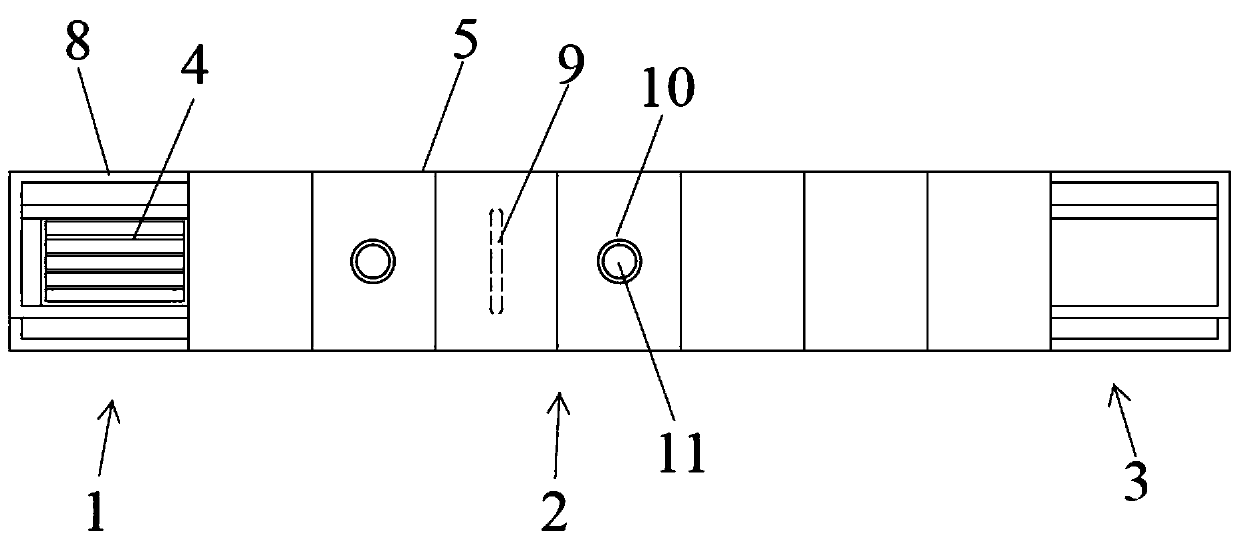

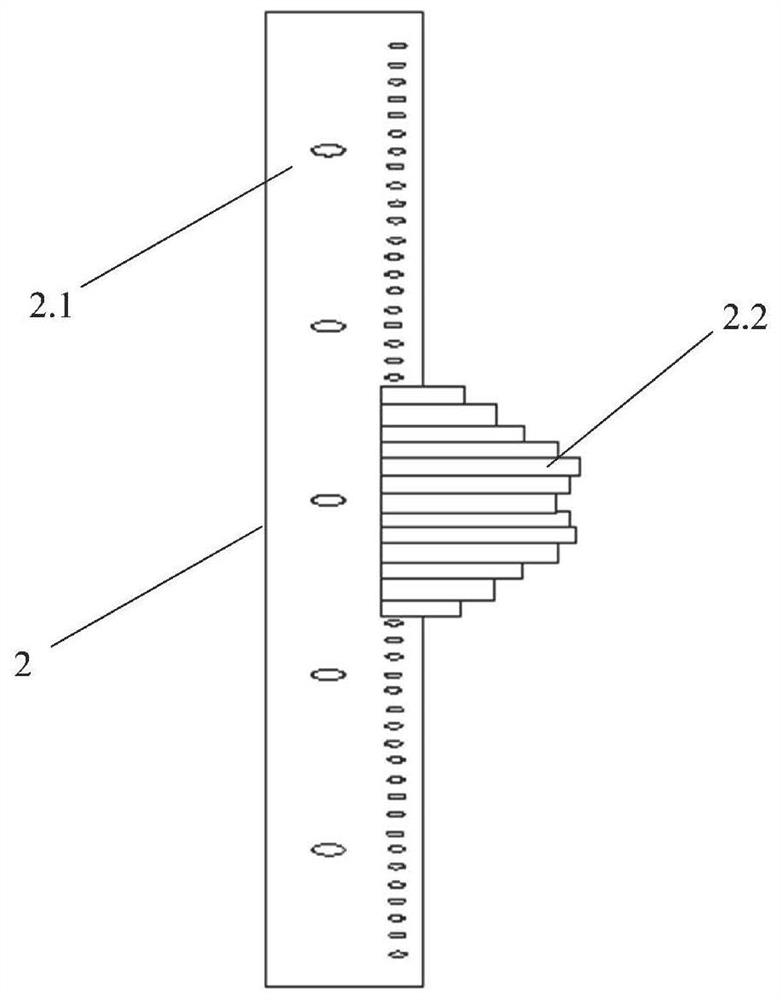

Tool used for optical fiber capillary tube film coating

PendingCN109440076ANot easy to bendNot easy to breakVacuum evaporation coatingSputtering coatingFiberEngineering

The invention discloses a tool used for optical fiber capillary tube film coating. The tool is characterized by comprising a tool body; the tool body is of a cuboid structure and is composed of a baseand a cover plate covering the base; the tool body is provided with multiple product grooves matched with optical capillary tubes in appearance in the positions of covering faces of the base and thecover plate; the multiple product grooves are formed in the length direction of the tool body; each product groove is provided with an optical fiber limiting end and a capillary tube limiting end connected with the optical fiber limiting end; the optical fiber limiting ends are sealed in the tool body; and the limiting ends of the capillary tubes are opened and communicate with external media. Bymeans of the tool used for optical fiber capillary tube film coating, the optical fibers are not likely to be bent and fractured during film coating of the optical capillary tubes, the product qualityof the optical capillary tubes is improved, the tool can be used for batched film coating, the film coating efficiency of the optical capillary tubes is improved, and the film coating requirement forcapillary tube tail fibers is met.

Owner:SUZHOU TFC OPTICAL COMM CO LTD

Copper-aluminum-silicon alloy material and application thereof

InactiveCN107732191AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesLithium electrodeCopper

The invention relates to a copper-aluminum-silicon alloy material and application thereof, and belongs to the technical field of alloy material. The defect of the prior art is overcome, and a high-performance copper-aluminum-silicon alloy material of a lithium battery and application of the copper-aluminum-silicon alloy material are provided. The copper-aluminum-silicon alloy material provided bythe technical scheme comprises the following constituents based on parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurity. The copper-aluminum-silicon alloy material can be widely applied to the field of a lithium ion battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

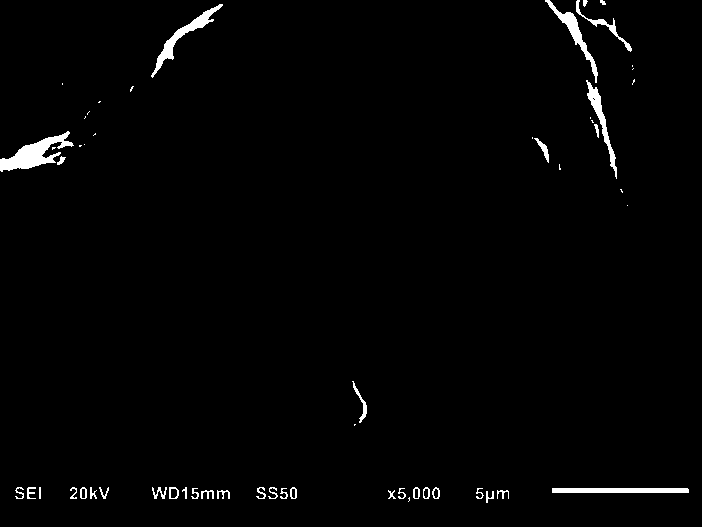

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of negative electrode material

InactiveCN107732197AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesSilicon alloyNickel–lithium battery

The invention discloses a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the negative electrode material, and belongs to the technical field of the negative electrode material of the lithium battery. According to the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the negative electrode material provided by the invention, a technical scheme is adopted as follows: the copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials in parts by weight: 37-42 parts of silicon, 55-62 parts of copper, 4-15 parts of aluminum and 0-3 parts of impurities; and the overall alloy nanomaterial comprises a multi-defect organization structure of air pores, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain diameter is less than or equal to 80[mu]m. The invention can be applied to the technical field of the negative electrode material of the lithium battery.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminium-silicon alloy nano negative electrode material of lithium battery and preparation method thereof

InactiveCN107779661AUnique structureImprove conductivityMaterial nanotechnologyCell electrodesSilicon alloyCopper

The invention discloses a copper-aluminium-silicon alloy nano negative electrode material of a lithium battery and a preparation method thereof, and belongs to the technical field of lithium battery negative electrode materials. The used technical solution is as follows: the copper-aluminium-silicon alloy nano negative electrode material of the lithium battery is formed by the following raw materials by weight: 22-27.5 parts of silicon, 60-70 parts of copper, 0.5-5 parts of aluminium, and 0-5 parts of impurities; and the alloy nano material contains multi-defect tissue structures of pore, contraction cavity, shrinkage porosity, dislocation, vacancy and cavity, and the particle size is less than or equal to 80 um. The copper-aluminium-silicon alloy nano negative electrode material can be applied to the technical field of the lithium battery negative electrode materials.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

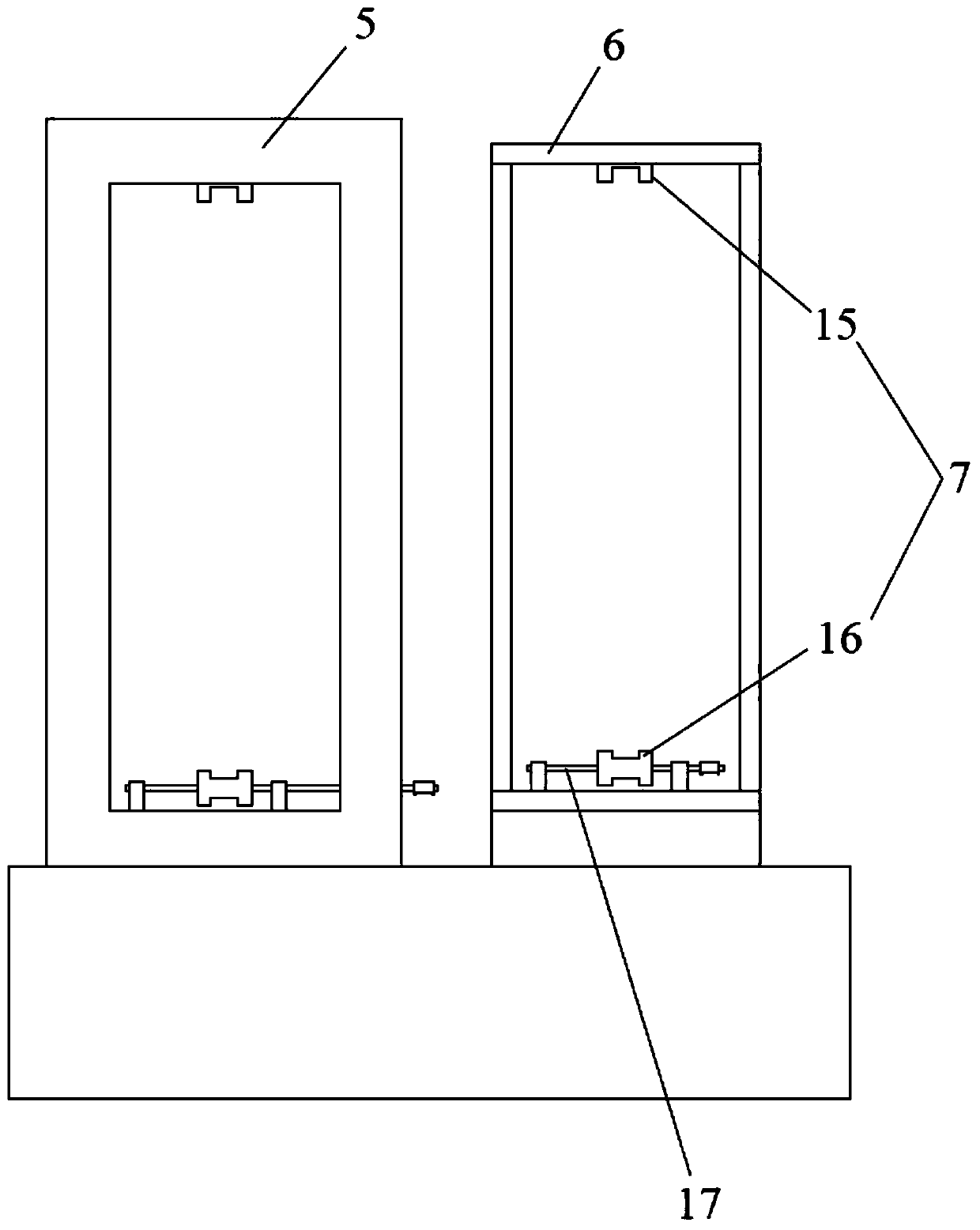

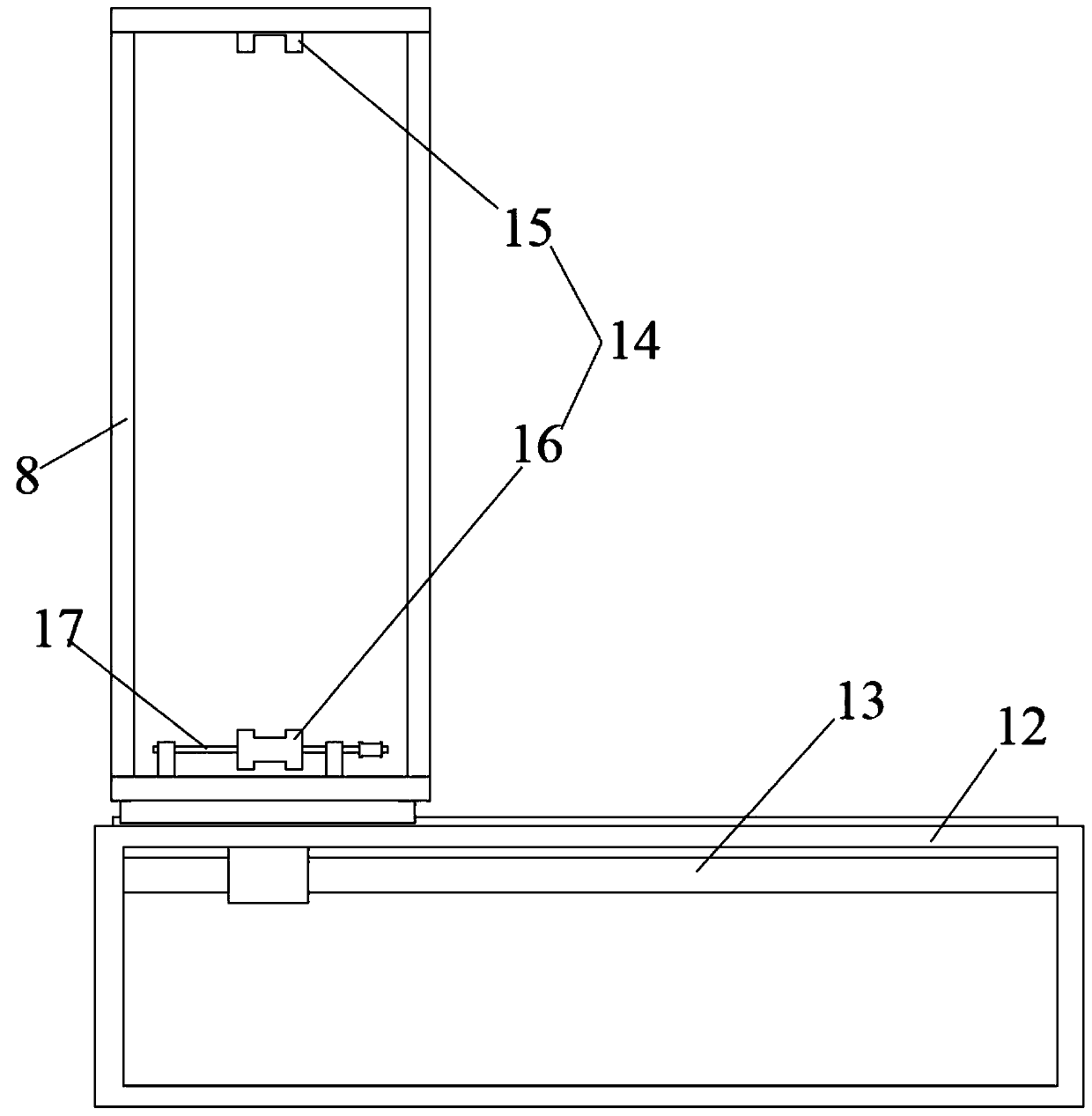

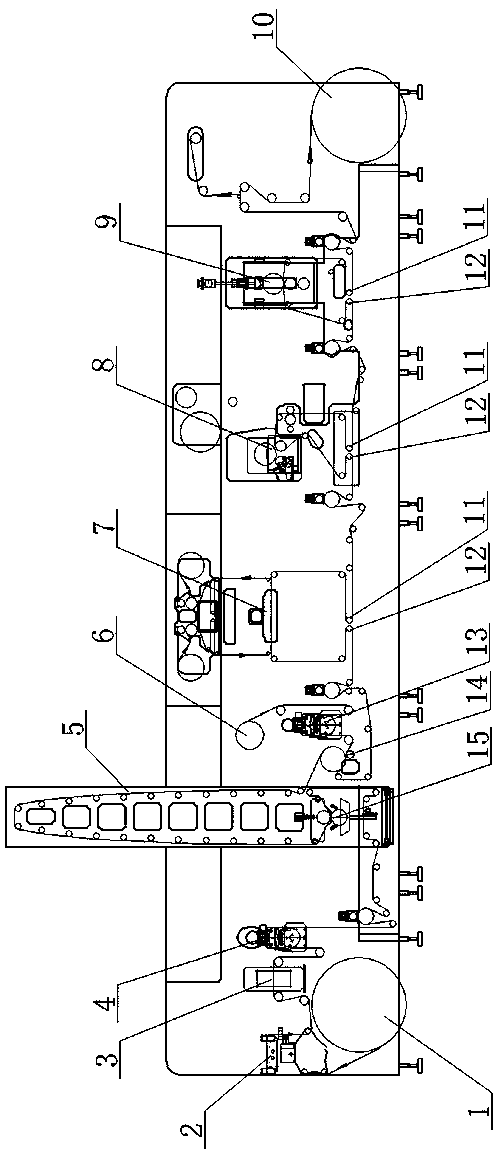

Production line for plastic back cover film coating

PendingCN109778134ANot hurtAvoid manual handlingVacuum evaporation coatingSputtering coatingProduction lineBiochemical engineering

The invention discloses a production line for plastic back cover film coating. The production line comprises a feeding area, a film coating area, a discharging area and a movable frame. A treatment box and a circulating frame are arranged in the film coating area. First transmission rails are arranged in the treatment box and the circulating frame, the treatment box and the circulating frame are arranged in parallel, and transferring frames are arranged in the feeding area and the discharging area. The movable frame is moved between the treatment box and the circulating frames through the transferring frames. An ion source is arranged in the position, on one side of the feeding area, of the treatment box, a cold pump is arranged outside, the cold pump is connected with the interior of thetreatment box in a communicating manner, and a molecular pump is arranged on the cold pump. The transferring frames are arranged on a transferring base, and lead screw transmission assemblies are arranged between the transferring base and the transferring frames. Second transmission rails are arranged in the transferring frames. According to the production line, a low-temperature film coating process can be achieved, the yield of subsequent film coating can be guaranteed, a circulating function is achieved, and the production efficiency is improved.

Owner:张家港市铭斯特光电科技有限公司

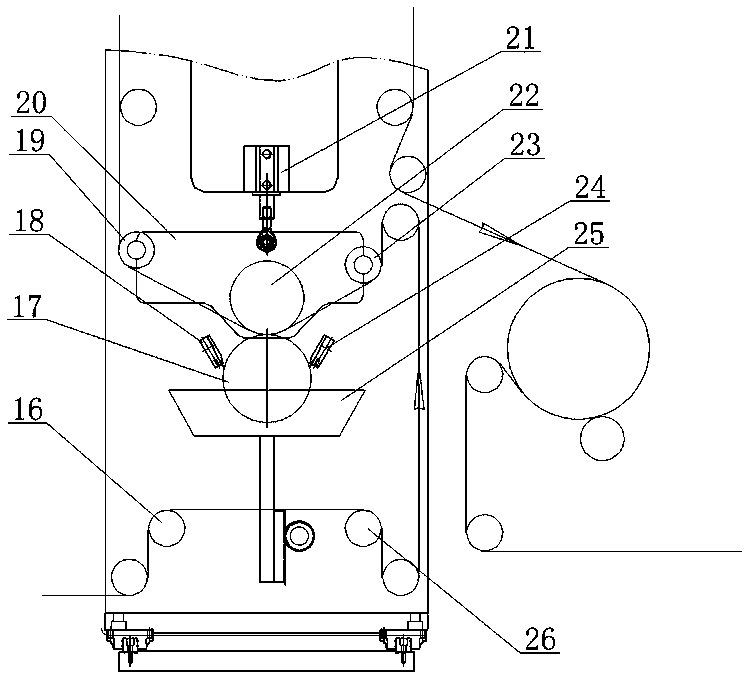

Multifunctional printing post-processing equipment

InactiveCN108724928AThickness optionalCompact structureRotary pressesOther printing apparatusElectricityWind component

The invention discloses multifunctional printing post-processing equipment. The multifunctional printing post-processing equipment is characterized by comprising a first unwinding component, a deviation rectifying component, a dedusting component, a first corona component, a composite component, a coating component, a flat gold stamping component, an intermittent flexographic printing component, an intermittent round die cutting component and a winding component; a second unwinding component is arranged above the composite component; a second corona component is arranged between the second unwinding component and the composite component; and a vertical oven is arranged on the upper portion of the coating component adjacently. The multifunctional printing post-processing equipment is simpleand compact in structure, can provide the multifunctional post-processing procedure for printed products to achieve multiple types of the printed products, and is good in product quality, thereby meeting the higher and higher packaging market requirements.

Owner:浙江力冠机械有限公司

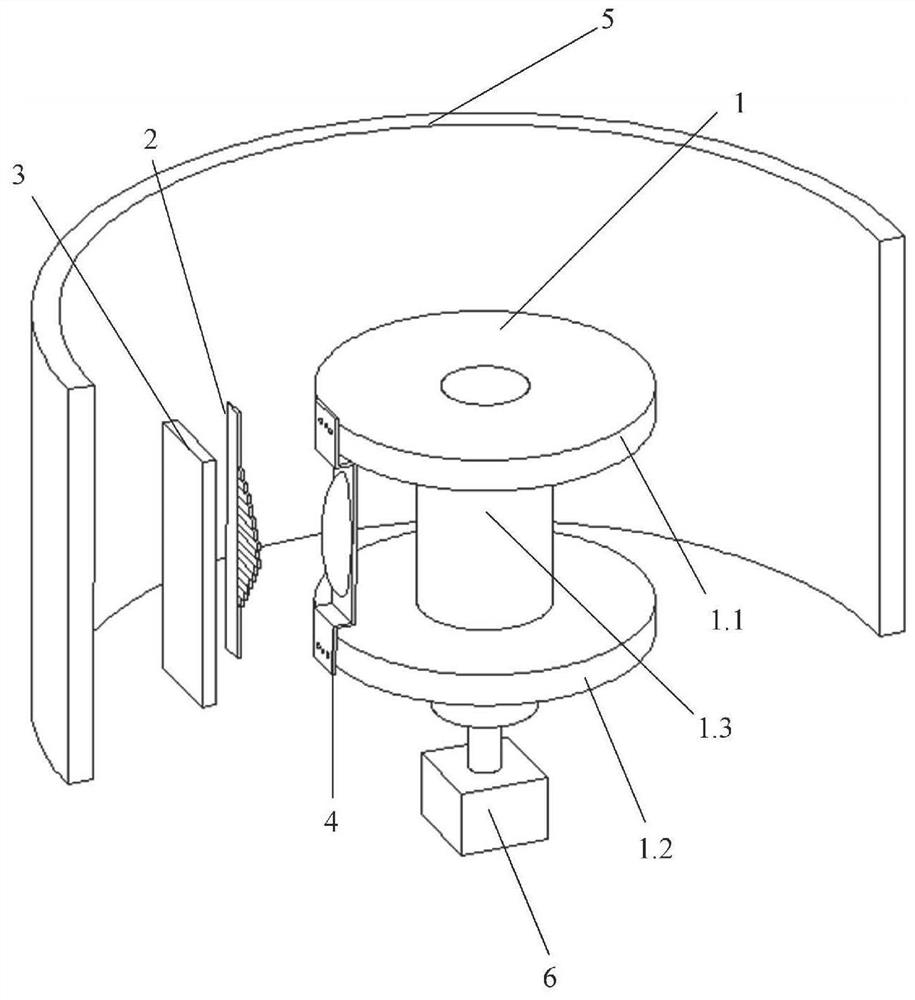

A curved glass coating device, coating process and coating product

The invention provides a curved glass coating device, a coating process and a coating product, which include a rotatable workbench, a power source for driving the workbench, a hanging plate set on the workbench, and a hanger The plate is opposite to the target spray head and the correction component arranged between the hanging plate and the target spray head, the rotation axis direction of the worktable is parallel to its own length direction; The end is fixed with the workbench, and the hanging plate includes a bump set in the middle for placing the curved glass, and the bump and the curved glass are fixedly connected by an adhesive member, and the correction part includes a correction plate and a tooth piece arranged in the same plane And the plane is perpendicular to the line connecting the spraying center of the nozzle of the target material and the geometric center of the bump. The coating device of the invention has simple structure, simplified coating process steps and convenient operation. The spectral wavelength of the coating product is 380-1100nm, the light transmittance is greater than 94%, and the film thickness is uniform.

Owner:LENS TECH

Vibration aging treatment method of copper-aluminum-silicon nano alloy material and application of vibration aging treatment method

InactiveCN107760921AStress reliefImprove performance consistencySecondary cellsNegative electrodesAlloyCopper

The invention discloses a vibration aging treatment method of a copper-aluminum-silicon nano alloy material and application of the vibration aging treatment method, and belongs to the technical fieldof lithium battery cathode material preparation. To overcome defects of the prior art, the invention provides the vibration aging treatment method of the copper-aluminum-silicon nano alloy material and application of the vibration aging treatment method. According to the technical scheme, the vibration aging treatment method is implemented after a step of vacuum drying after steps of blending, smelting, powdering, separation and screening, dried copper-aluminum-silicon nano alloy powder is subjected to vibration aging treatment, an electromagnetic vibration aging instrument is adopted, the electromagnetic vibration efficiency is 3000-5000Hz, and the vibration time is 24-150 hours; a copper-aluminum-silicon nano alloy comprises the following components in parts by weight: 22-70 parts of silicon, 20-70 parts of copper, 0.5-15 parts of aluminum and 0-5 parts of impurities, and the particle size of the alloy is less than or equal to 80mu m. The vibration aging treatment method can be widely applied to the field of lithium battery cathode materials.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of copper-aluminum-silicon alloy nanometer negative electrode material

InactiveCN107706386AUnique structureImprove conductivityCell electrodesSilicon alloyNickel–lithium battery

The invention relates to a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material, and belongs to the technical field of a lithium battery negative electrode material. The invention provides a high-performance copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and a preparation method of the high-performance copper-aluminum-silicon alloy nanometer negative electrode material. The copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery comprises the following raw materials based on parts by weight: 32-39 parts of silicon, 54-59 parts of copper, 1-8 parts of aluminum and 0-5 parts of impurity, the whole alloy nanometer material comprises a multi-defect tissue structure of air holes, shrinkage holes, shrinkage porosity, dislocation, vacancy and holes, and the grain is smaller than orequal to 80 micrometers. The copper-aluminum-silicon alloy nanometer negative electrode material can be applied to the technical field of a lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Copper-aluminum-silicon alloy nanometer negative electrode material of lithium battery and preparation method of copper-aluminum-silicon alloy nanometer negative electrode material

InactiveCN107732189AUnique structureImprove conductivityCell electrodesDislocationNickel–lithium battery

The invention relates to a copper-aluminum-silicon alloy nanometer negative electrode material of a lithium battery and a preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material, and belongs to the technical field of a lithium battery negative electrode material. The invention provides a high-performance copper-aluminum-silicon alloy nanometer negative electrode material of the lithium battery and the preparation method of the copper-aluminum-silicon alloy nanometer negative electrode material. The copper-aluminum-silicon alloy nanometer negative electrodematerial of the lithium battery comprises the following raw materials based on parts by weight: 50-70 parts of silicon, 20-40 parts of copper, 0.5-10 parts of aluminum and 0-5 parts of impurity, thealloy nanometer material integratedly comprises a multi-defect tissue structure of air holes, shrinkage holes, shrinkage porosity, dislocation, vacancies and holes, and the grain size is smaller thanor equal to 80 micrometers. The copper-aluminum-silicon alloy nanometer negative electrode material can be applied to the technical field of the lithium battery negative electrode material.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

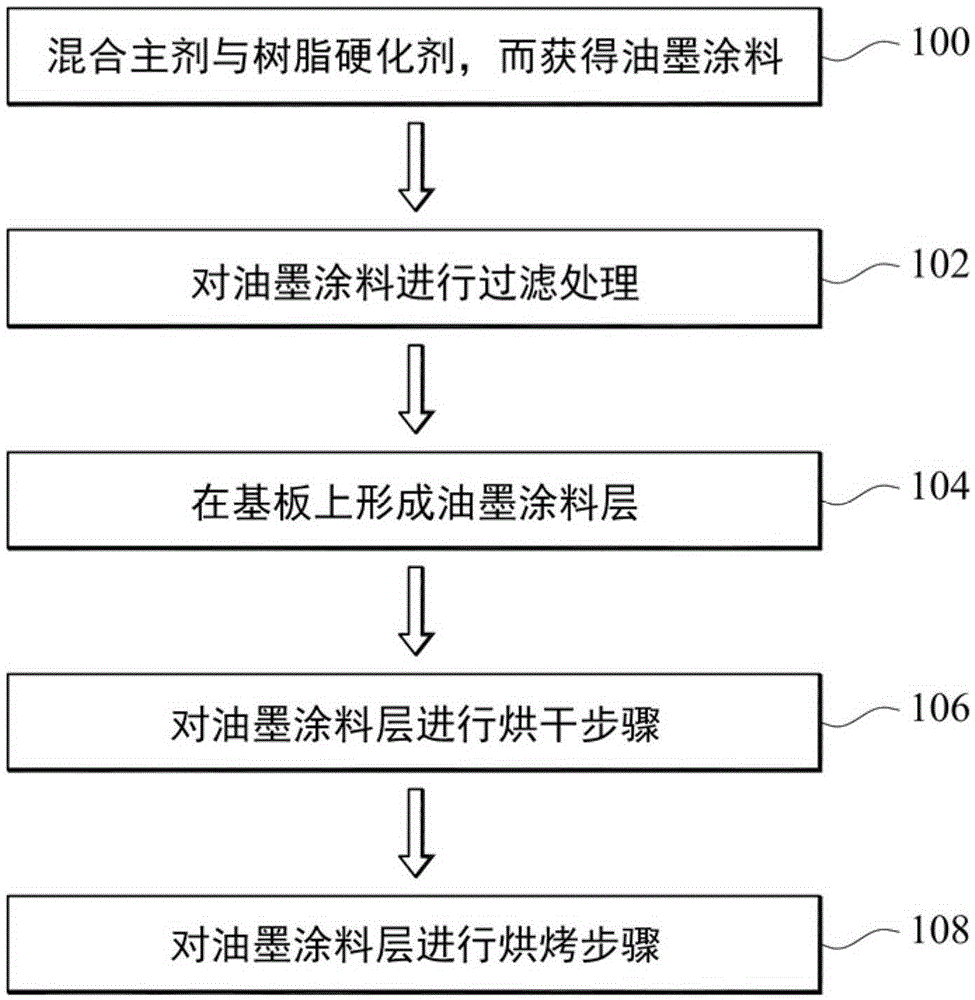

Resin hardening agent of coating film, ink coating film composition and ink coating film manufacturing method

The invention relates to a resin hardening agent of a coating film, an ink coating film composition and an ink coating film manufacturing method. According to the present invention, the resin hardening agent of the coating film comprises 0.1-99.8 wt% of a silicon oxygen resin, 0.1-99.8 wt% of a silicon oxygen coupling agent resin, and 0.1-99.8 wt% of an organic solvent; with the resin hardening agent, the coating film can have advantages of high hardness, wear resistance and temperature resistance, and the chromatic aberration value of the coating film after the reflow soldering is less than 1; the dielectric constant of the ink coating film can be adjusted, such that the application in the capacitive fingerprint identification device is easily achieved; and the ink coating film production can be completed only requiring the single-channel film plating process, such that the ink coating film production process is simple and easy to perform, the production cost can be reduced, and the production capacity can be improved.

Owner:洪昭南

A kind of ion beam coating equipment and coating method thereof

ActiveCN112899633BAchieve transshipmentImprove adhesionFinal product manufactureVacuum evaporation coatingIsolation valveIon beam

The invention discloses an ion beam coating equipment and a coating method thereof. The equipment comprises a transfer chamber, a chip loading and unloading chamber, a coating chamber and a cleaning chamber connected to the transfer chamber, and an isolation valve is arranged between them. The transfer chamber is provided with a transfer mechanism. The coating method adopts the above-mentioned equipment for coating treatment. In the present invention, the loading and unloading chamber is used to store different types of substrates, the transfer chamber realizes the transfer of the substrates between the loading and unloading chamber, the coating chamber and the cleaning chamber, and the coating chamber can realize the Coating multiple substrates at the same time can also realize the preparation of various types of film layers, cleaning the chamber, removing dirt and oxides on the surface of the substrate, and improving the adhesion between the film and the substrate. The ion beam coating equipment of the invention can realize continuous cleaning and continuous coating of substrates, can realize continuous production, improve production efficiency, reduce production costs, and can meet the requirements of substrates (such as infrared devices) for large-size, low-damage and low-temperature coating processes. Require.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

A Method for Improving the Coating Quality of Linear Magnetron Sputtering Target Gun on Concave Cylindrical Substrate

ActiveCN106987817BMeet the needs of regularityImprove film qualityVacuum evaporation coatingSputtering coatingEngineeringLarge size

The invention relates to a method for improving the coating film quality of a linear magnetron sputtering target gun on a concave column face substrate. A mask mounted in front of the target gun and partition boards mounted at the positions, located on the two symmetric positions of a sample, of a sample frame are used for limiting the distribution angle of sputtered particles, in the horizontal and vertical direction, of the large-size linear magnetron sputtering target gun, the incident angle, inclined bombardment of the substrate, of the sputtered particles is reduced, the side effect of the sputtered particles which bomb the substrate in an inclined manner on the film forming quality is reduced, and the thin film quality of the concave column face substrate is improved.

Owner:TONGJI UNIV

A pulsed ion source coating extraction device

ActiveCN113186504BBeam stabilizationExtended durationVacuum evaporation coatingSputtering coatingIon beamPulse power supply

The invention relates to a pulsed ion source coating extraction device, comprising a pulsed electrode, a cathode target and an anode; the anode comprises an outer cylinder and an inner anode ring; the cathode target and the outer cylinder are connected; the anode ring is connected to the outer cylinder; An insulating material is arranged between the outer cylinders; the cathode target is cylindrical, inserted into the outer cylinder, and located above the anode ring in the outer cylinder; the center line of the cathode target passes through the central hole of the anode ring; the cathode target is connected to the drive The motor is driven and connected to drive the cathode target to feed to the anode ring; a pulse electrode is sleeved on the outer side of the ion emission end of the cathode target, and the exposed end of the cathode target extends out of the pulse electrode, and a pulse electrode is arranged between the cathode target and the pulse electrode. Insulating sleeve; the anode ring is connected to the positive pole of the power supply, the cathode target is connected to the negative pole or ground of the power supply, and the pulse electrode is connected to the pulse power supply. The ion beam extracted by the ion source of the invention can be continuous, the quality of the extracted ion beam is improved, and the distribution is uniform.

Owner:BEIJING NORMAL UNIVERSITY

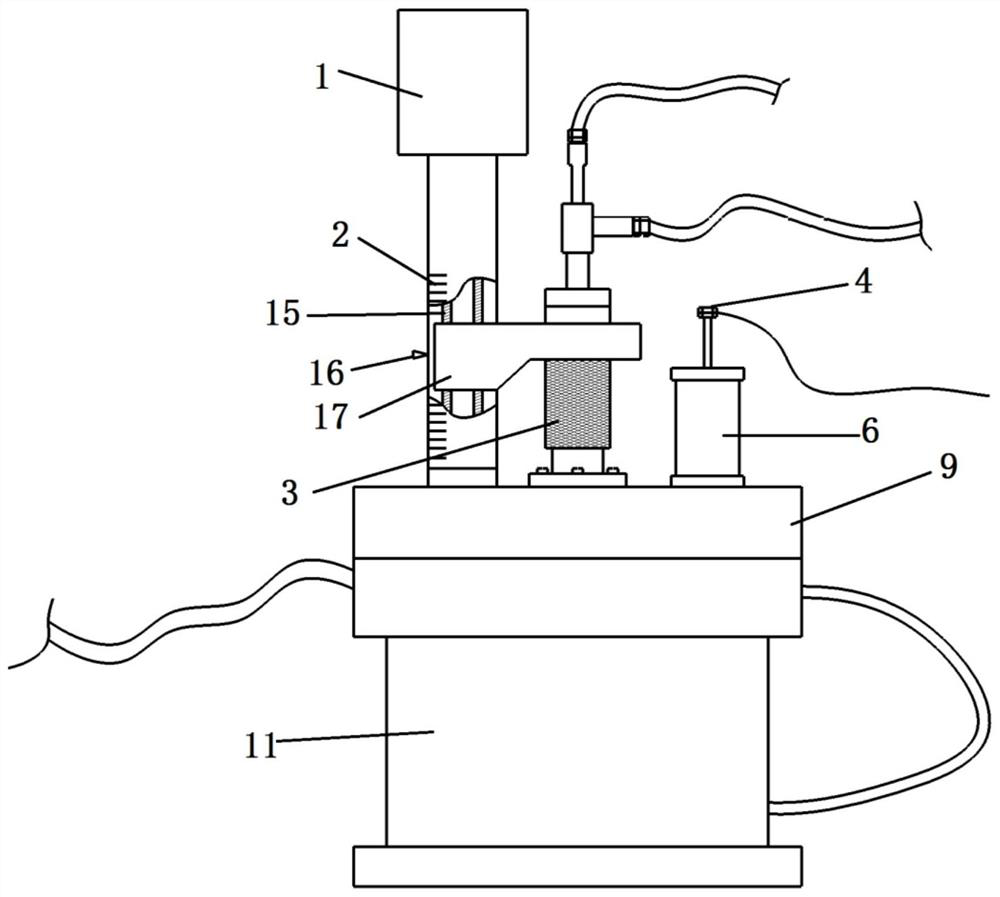

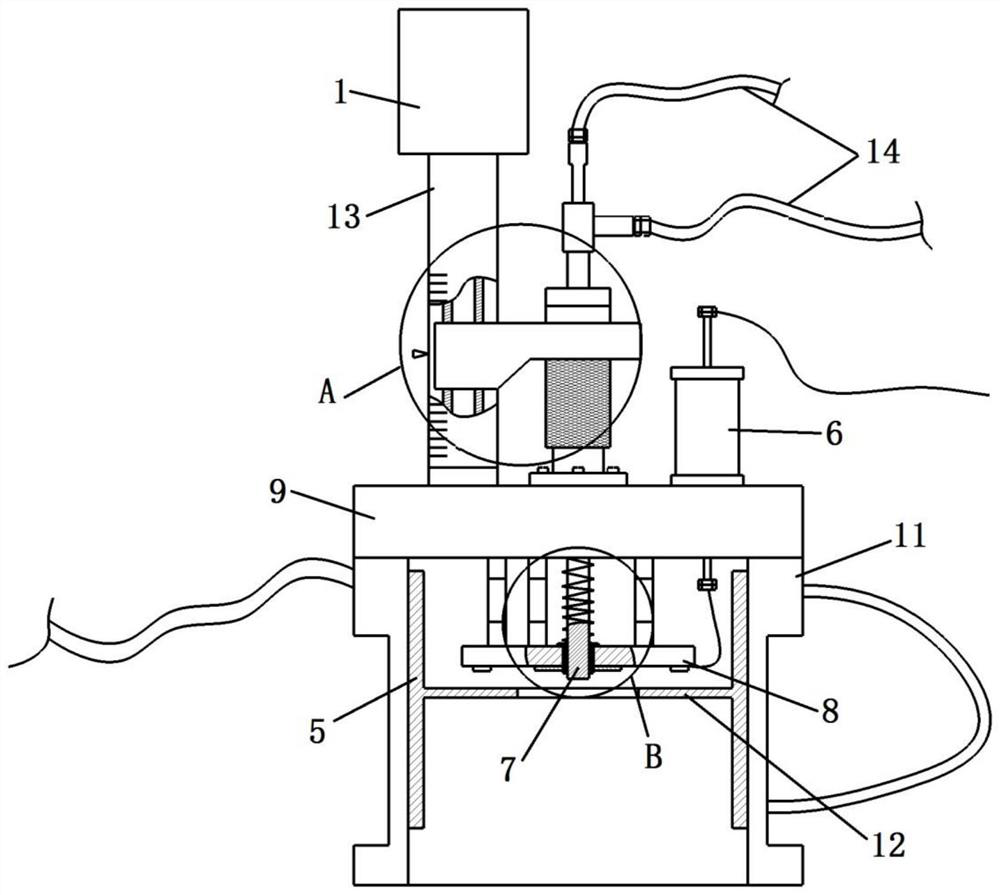

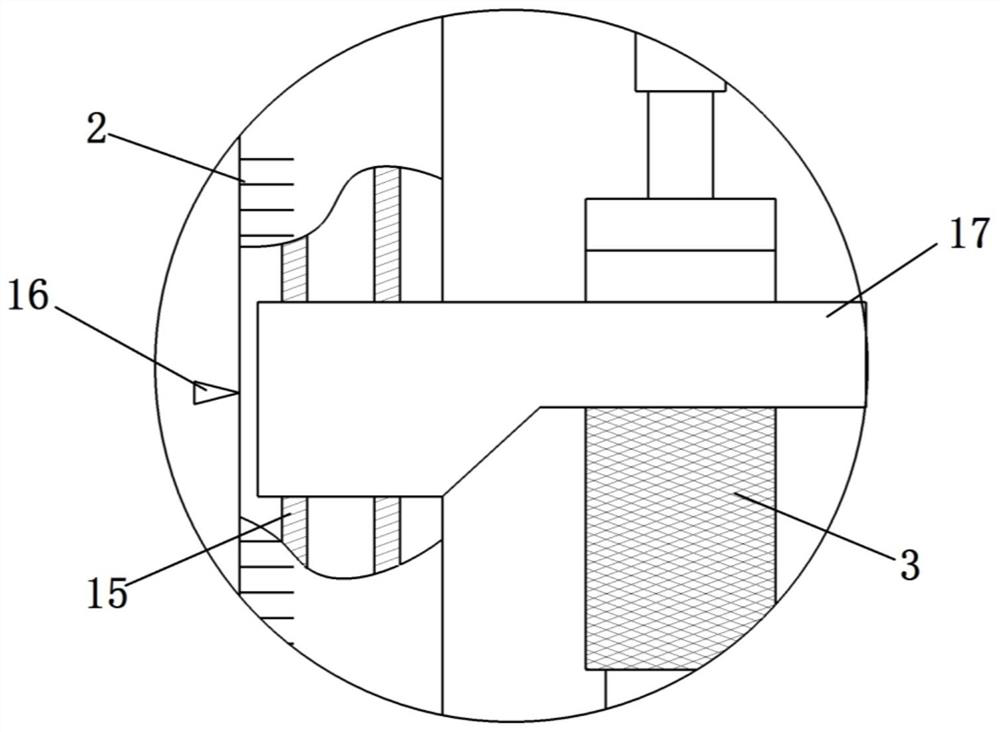

Pipeline inner wall coating device

ActiveCN112275513AImprove coating efficiencyPrevent excessive speedHollow article cleaningSpray boothsMechanical engineeringCoating

The invention discloses a pipeline inner wall coating device, and belongs to the technical field of pipeline coating. The pipeline inner wall coating device comprises a shell, wheels are connected tothe outer bottom surface of the shell, a rotating device is arranged in the shell, two ends of the rotating device extend out of the shell, the end, outside the shell, of the rotating device is connected with a cleaning device, and the other end of the rotating device is connected with a coating mechanism for coating the inner wall of a pipeline. By arranging the rotating device, the cleaning device and the coating mechanism can be driven to work, the situation of missing coating of the inner wall of the pipeline is avoided, and the coating effect can be guaranteed by conducting cleaning and then conducting coating.

Owner:HEFEI UNIV OF TECH

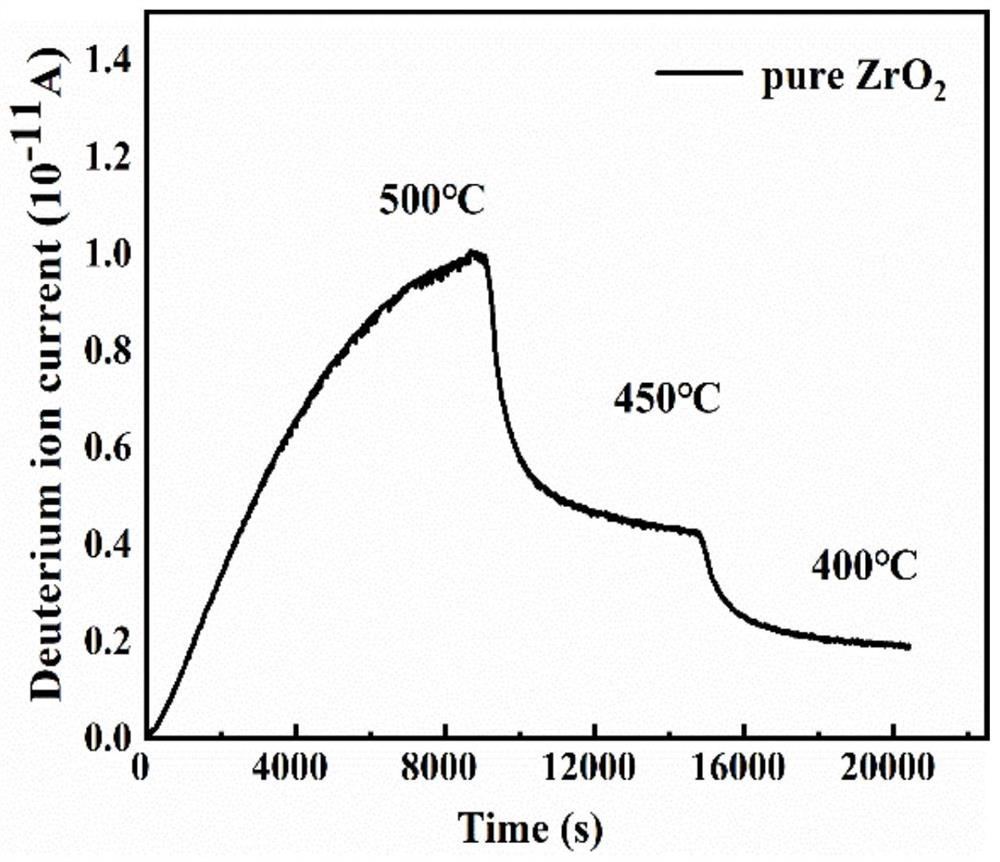

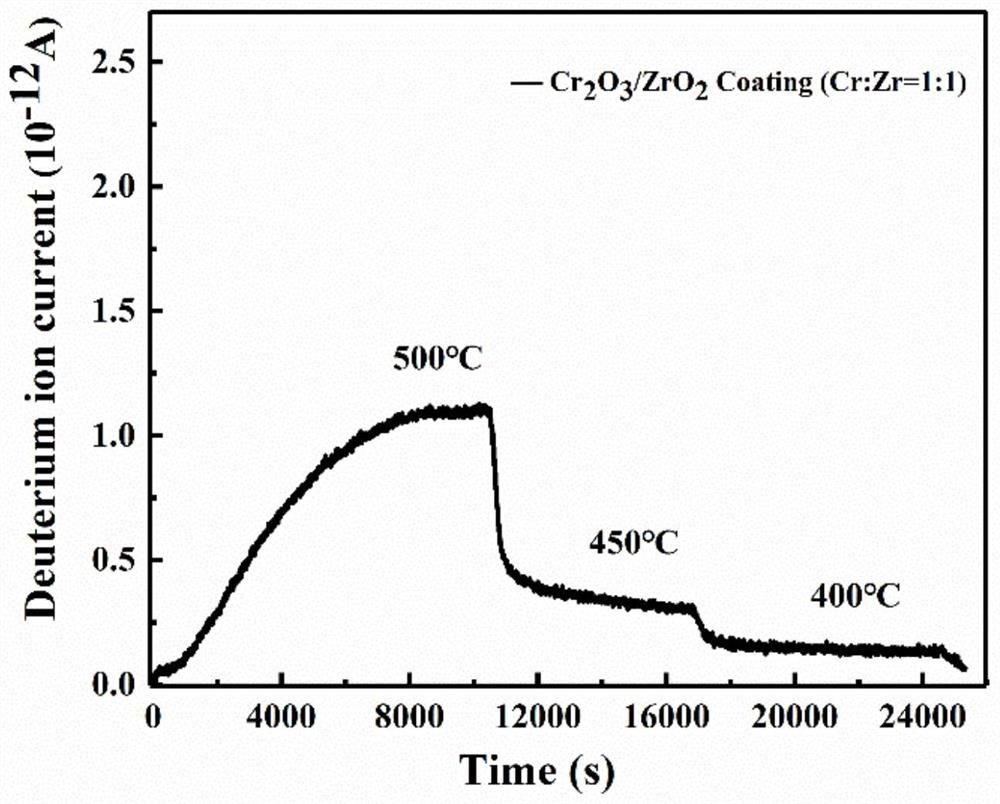

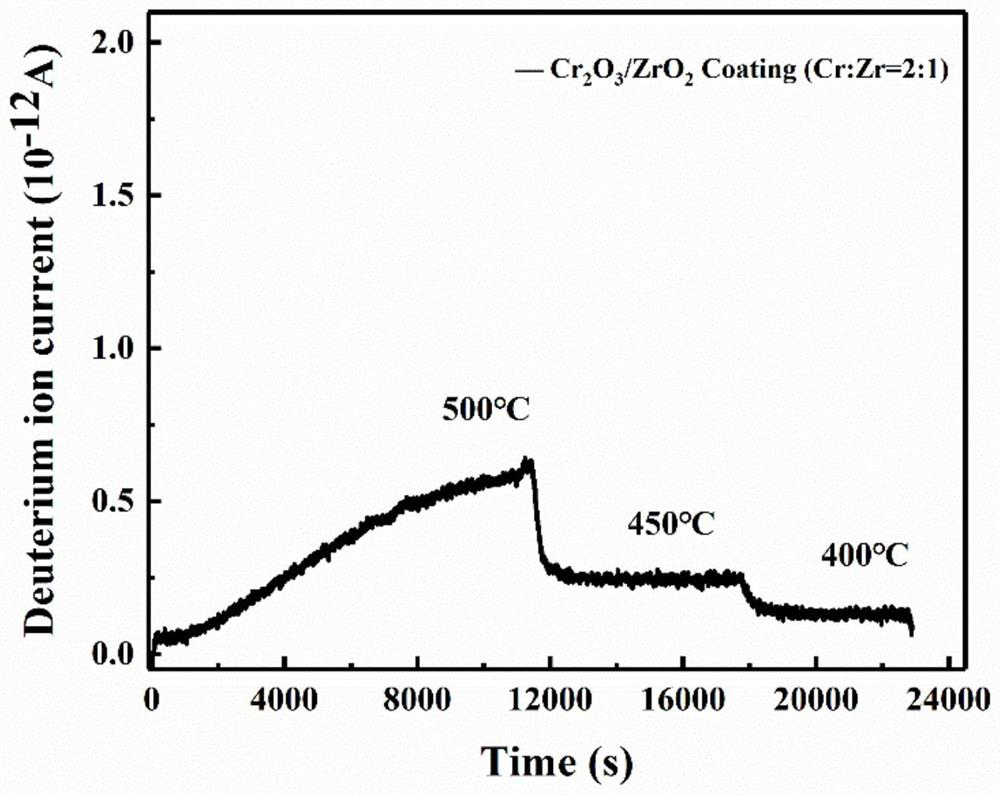

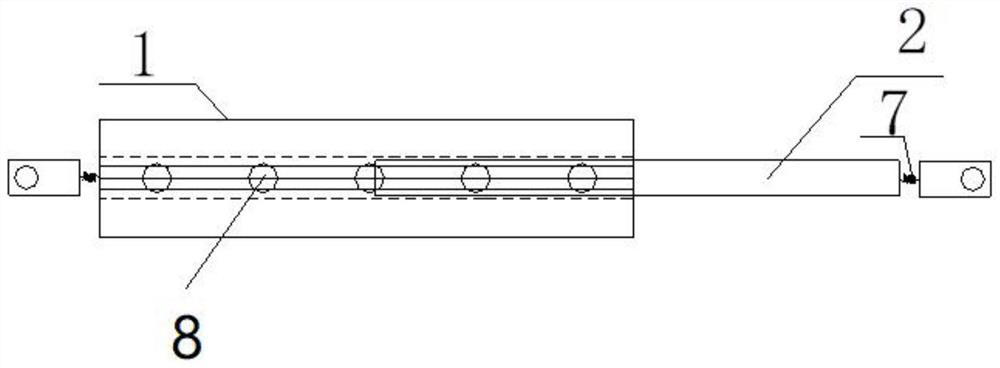

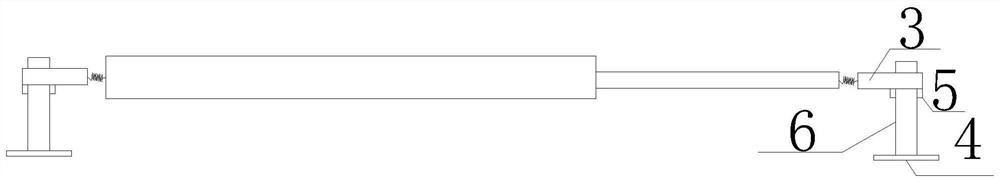

Chromium oxide and zirconium oxide composite coating and preparation method thereof

ActiveCN114686862AExcellent resistance to hydrogen permeationImprove toughnessLiquid/solution decomposition chemical coatingPhysical chemistryTwo phase composite

The invention provides a chromium oxide and zirconium oxide composite coating and a preparation method thereof. The chromium oxide and zirconium oxide composite coating can be suitable for resisting hydrogen and permeation of isotopes thereof in various hydrogen related fields such as fusion reactor cladding module structure materials and hydrogen storage devices. The composite coating is a single-layer composite coating or a multi-layer gradient composite coating, each layer is formed by compounding Cr2O3 and ZrO2, the composite coating combines the hydrogen / deuterium / tritium permeation resistance characteristics of zirconium oxide and chromium oxide, on the basis that the hydrogen / deuterium / tritium resistance performance of the single-phase zirconium oxide coating is improved, the good toughness of the zirconium oxide coating is reserved, and the service life of the zirconium oxide coating is prolonged. The preparation process combining sol-gel with dip-coating can be suitable for coating the surface of a material with a complex structure, and the practical value of the composite coating is greatly improved. The whole process method is simple, healthy, environmentally friendly and suitable for large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

Simple fixed tool fracture for unconventional lens coating

The invention provides a simple fixed tool fixture for unconventional lens coating. The simple fixed tool fracture comprises a sleeve, the sleeve comprises a through groove, a drawing piece capable ofsliding along the through groove is arranged in the through groove, the two ends of the drawing piece are each connected with a connecting piece through an elastic piece, and a pressing piece is fixed to each connecting piece. By means of the tool fixture, the size of the fixture can be automatically adjusted, so that the requirements of lenses of different specifications can be met.

Owner:苏州欣恒高科光电科技有限公司

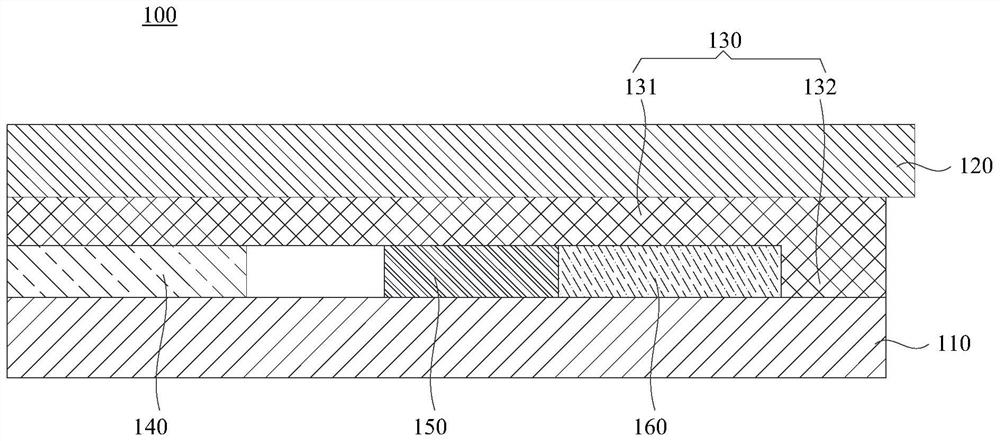

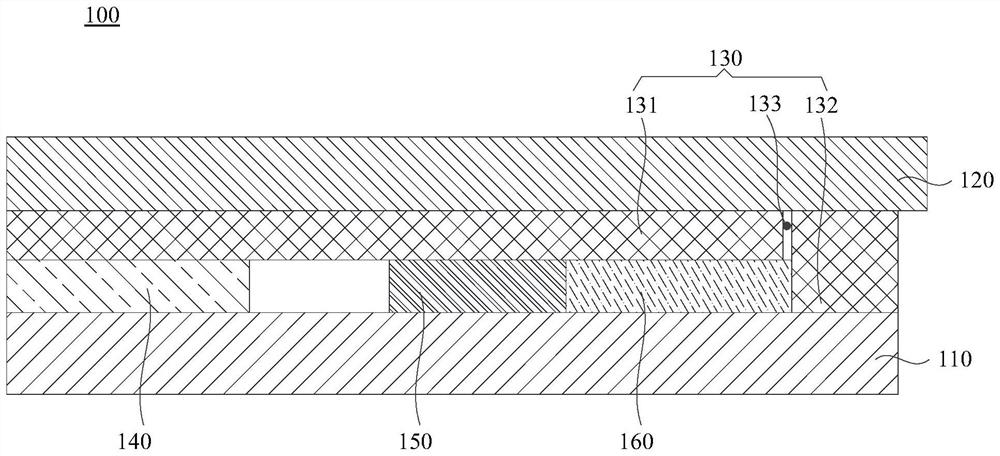

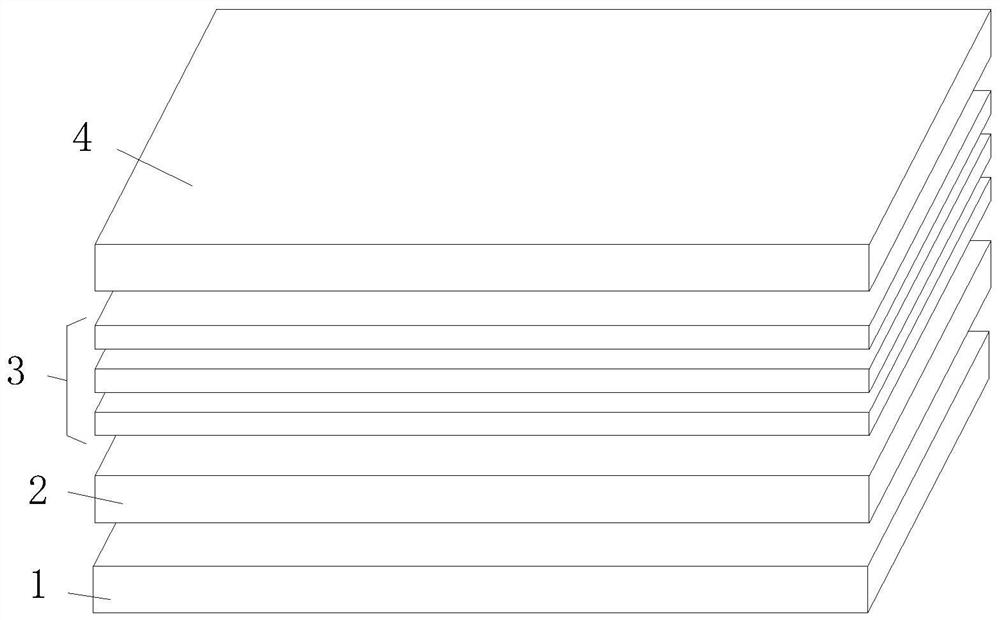

Display module and electronic equipment

PendingCN114299825AImprove drop resistanceAvoid breakingSolid-state devicesIdentification meansEngineeringMechanical engineering

The invention provides a display module and electronic equipment, relates to the technical field of display equipment, and is used for solving the technical problem that the anti-falling capacity of a frame area of the display module is poor, the display module comprises a screen body, a bonding layer and a packaging cover plate which are sequentially arranged in a stacked mode, the bonding layer comprises semi-solid glue, and the bonding layer is used for bonding the screen body and the packaging cover plate; the bonding layer comprises a first transparent bonding part and a second transparent bonding part, the orthographic projection of the first transparent bonding part on the screen body covers the display area, and the orthographic projection of the second transparent bonding part on the screen body covers the frame area; wherein the thickness of the second transparent bonding part is greater than that of the first transparent bonding part. The display module is used for improving the anti-falling capability of the frame area of the display module.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

A pipe inner wall coating device

ActiveCN112275513BPrevent leakageGuaranteed coating effectHollow article cleaningSpray boothsEngineeringStructural engineering

Owner:HEFEI UNIV OF TECH

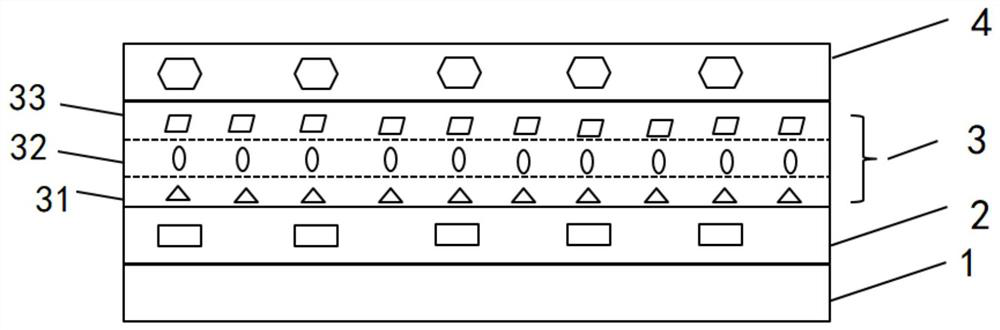

High-mirror-surface leopard print synthetic leather and preparation method thereof

InactiveCN112813697AImprove performanceReduce manufacturing costTextiles and paperManufacturing cost reductionPolymer science

The invention discloses high-mirror-surface leopard print synthetic leather which comprises a base cloth layer, a wet-process polyurethane layer, a dry-process polyurethane layer and a high-mirror-surface layer, wherein the surface of the top of the base cloth layer is coated with the wet-process polyurethane layer, and the surface of the top of the wet-process polyurethane layer is coated with the dry-process polyurethane layer. The invention also discloses a preparation method of the fabric. The preparation method comprises the following steps: step 1, preparing base cloth; step 2, coating wet-process polyurethane; step 3, coating dry-process polyurethane; and step 4, spraying a high mirror surface. By synchronously improving materials, components and the preparation process, the product performance is improved, and meanwhile the manufacturing cost is reduced. Through cooperation of leopard print release paper and the high-mirror-surface layer, the high-mirror-surface leopard print synthetic leather which is bright in gloss, high in refractive index and high in thickness is prepared, and the high-mirror-surface leopard print synthetic leather has good moisture permeability and air permeability, is soft, full and light in hand feeling, is richer in style and appearance of natural leather, and is low in cost and easy to popularize.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

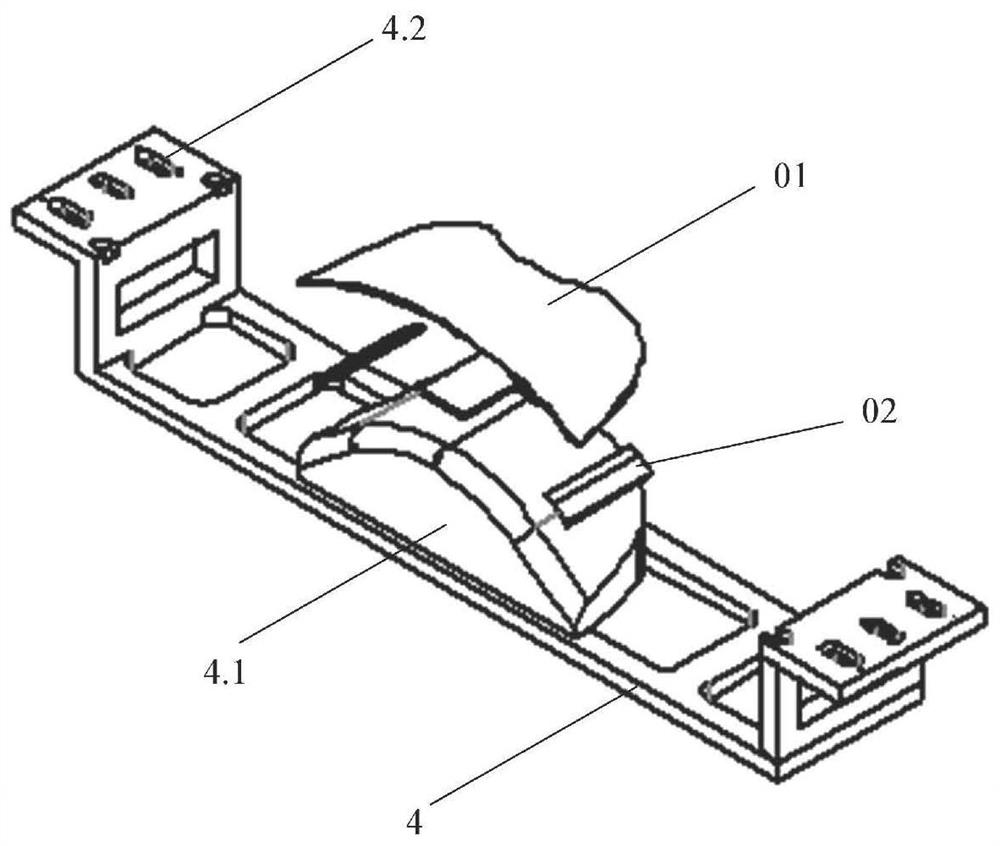

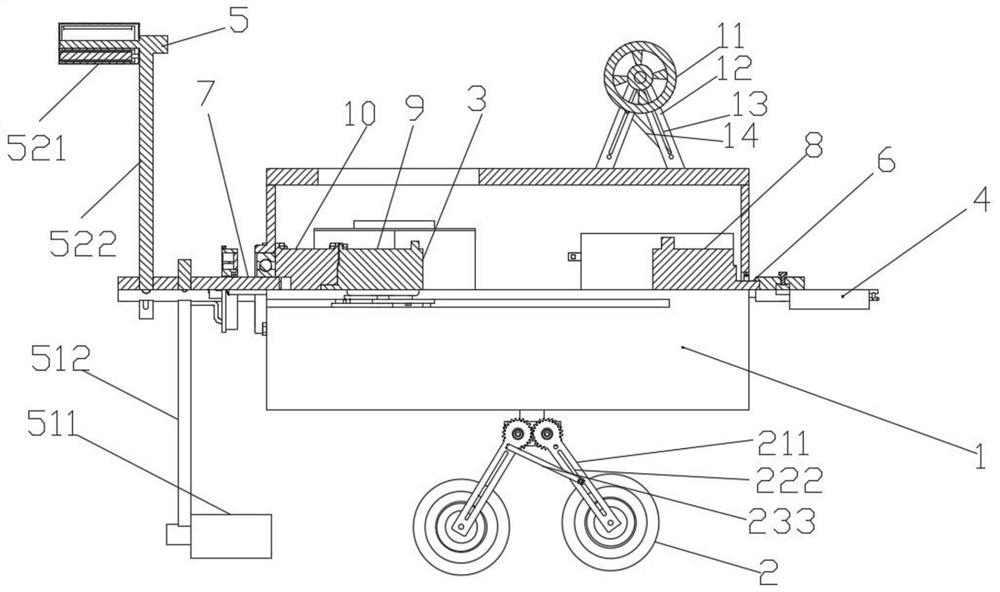

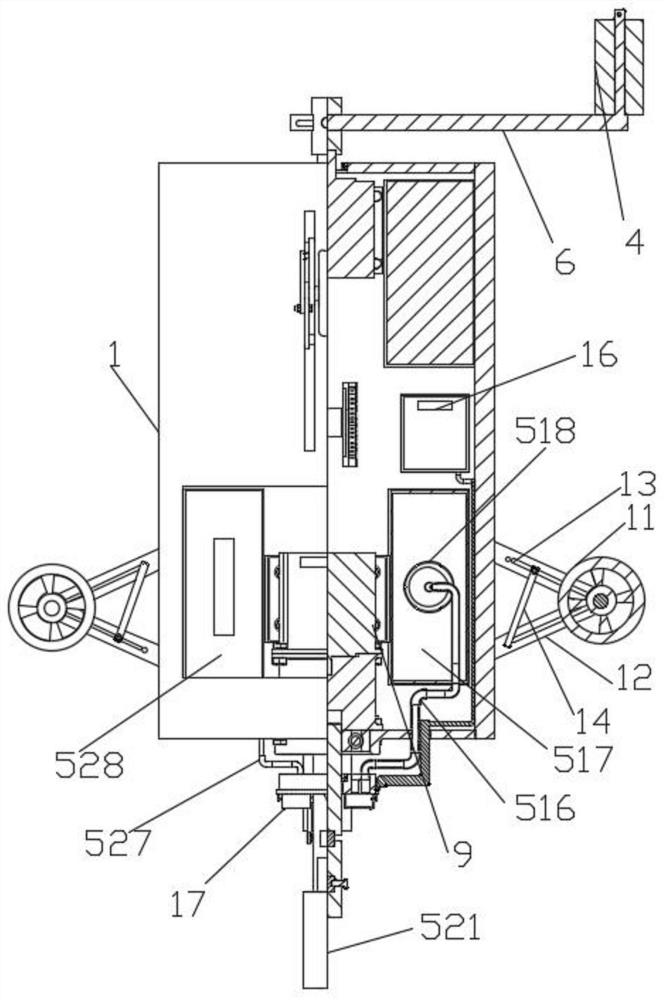

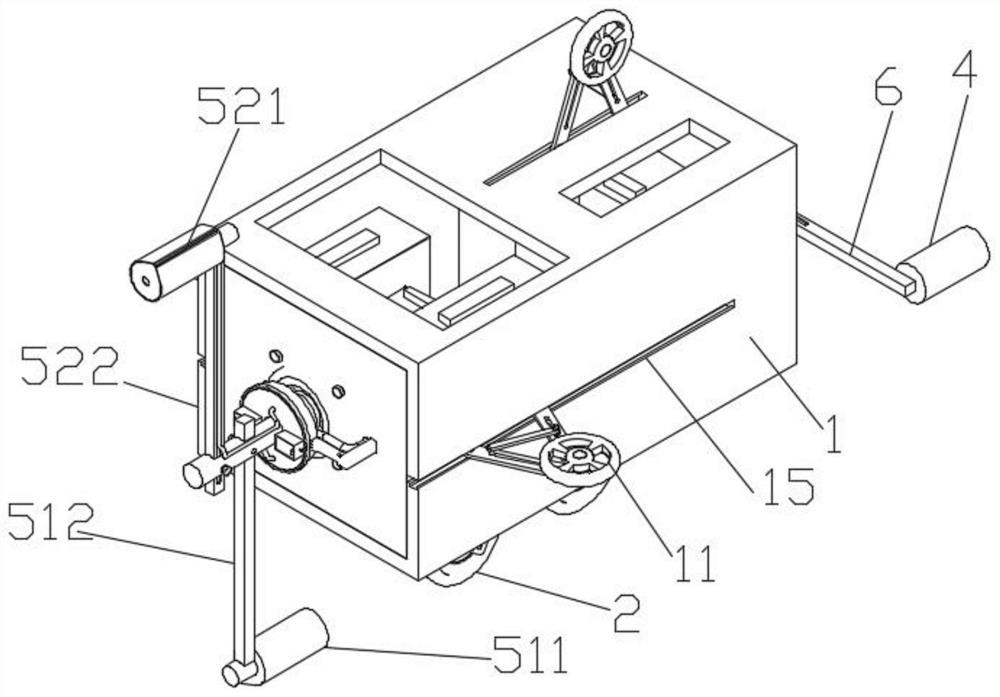

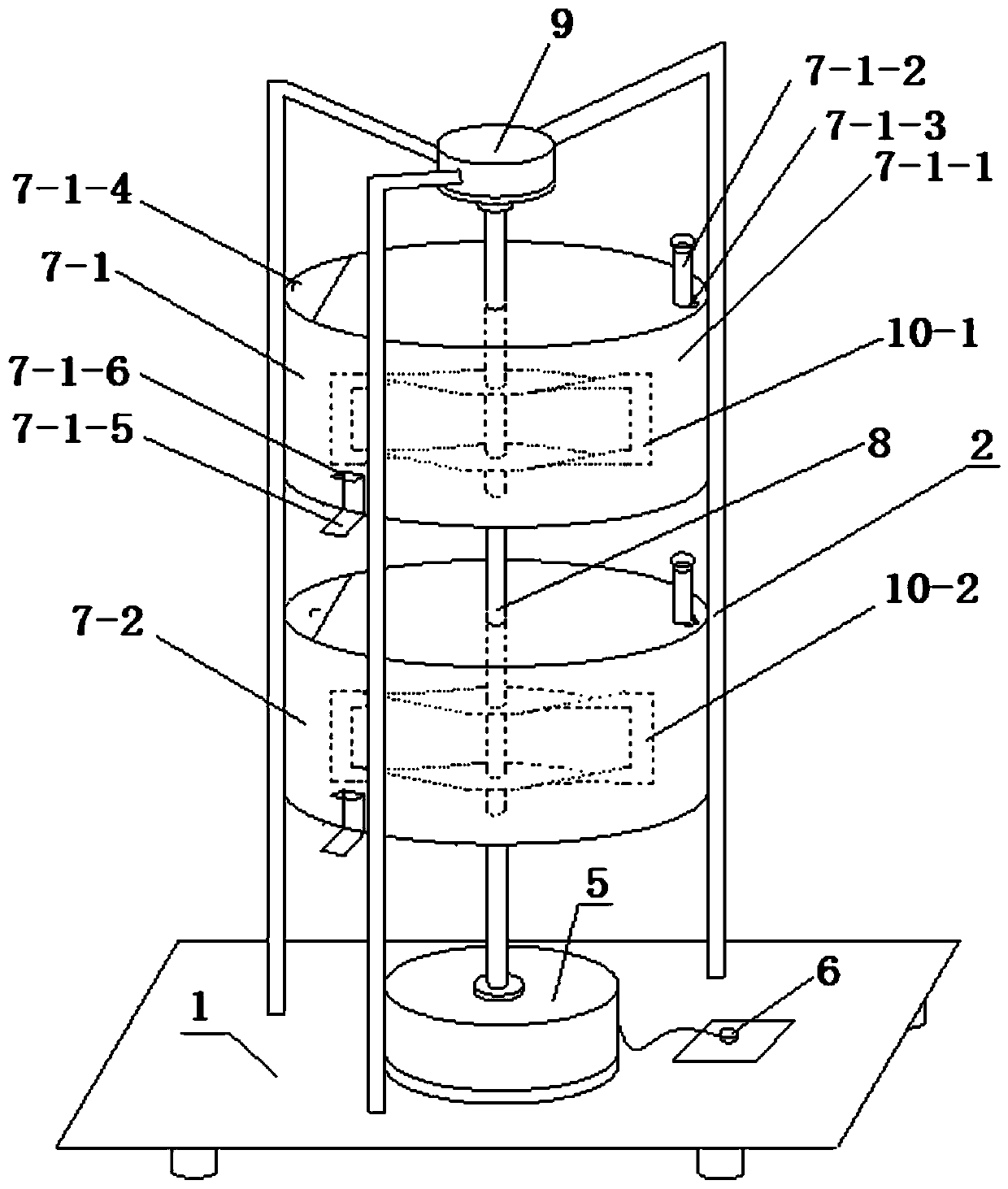

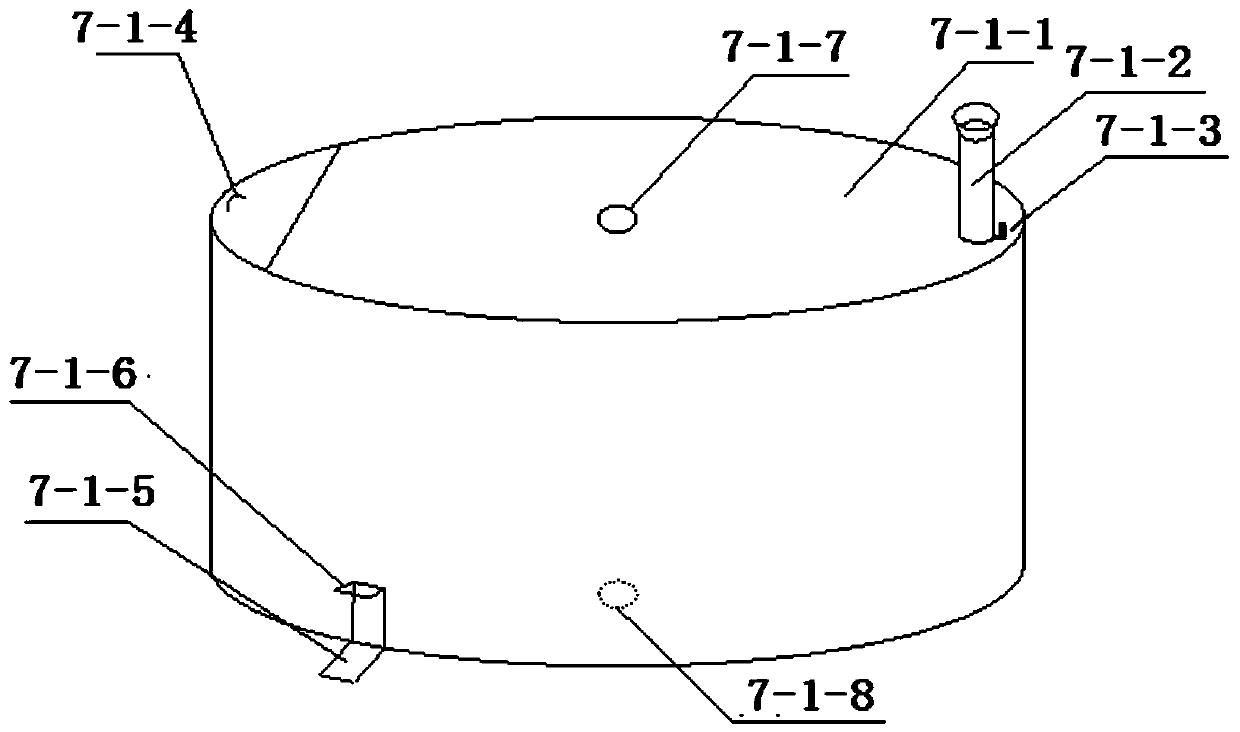

Small-sized seed coating device

PendingCN109983879AGood coating effectCause damageSeed coating/dressingDrive shaftAgricultural engineering

The invention discloses a small-sized seed coating device, and belongs to the field of agricultural scientific research. The problems that in agricultural breeding work, traditional manual seed coating efficiency is low, and operators are easily harmed are solved. A triangular fixing framework of the device is vertically arranged above a base, two stirring buckets are fixed to the triangular fixing framework, a motor is arranged in the center of the base, a transmission shaft is connected to the output end of the motor, two stirring devices are arranged on the transmission shaft and arranged in the stirring buckets, and the upper end of the transmission shaft and a bearing arranged in the center of the upper end of the triangular fixing framework are assembled. The small-sized seed coatingdevice has the advantages of being simple in structure, low in manufacturing cost, easy and convenient to maintain, capable of saving labor and high in working efficiency. The small-sized seed coating device is widely applicable to coating for seeds of various crops such as maize, soybeans, wheat and peanuts.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com