RGB-LED full-automatic fluorescent powder glue high-speed intelligent coating device and method

A technology of phosphor powder and three primary colors, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of difficult control of RGB-LED coating thickness and low automation production efficiency, and improve coating production Efficiency, increased intelligence and precision, improved coating results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

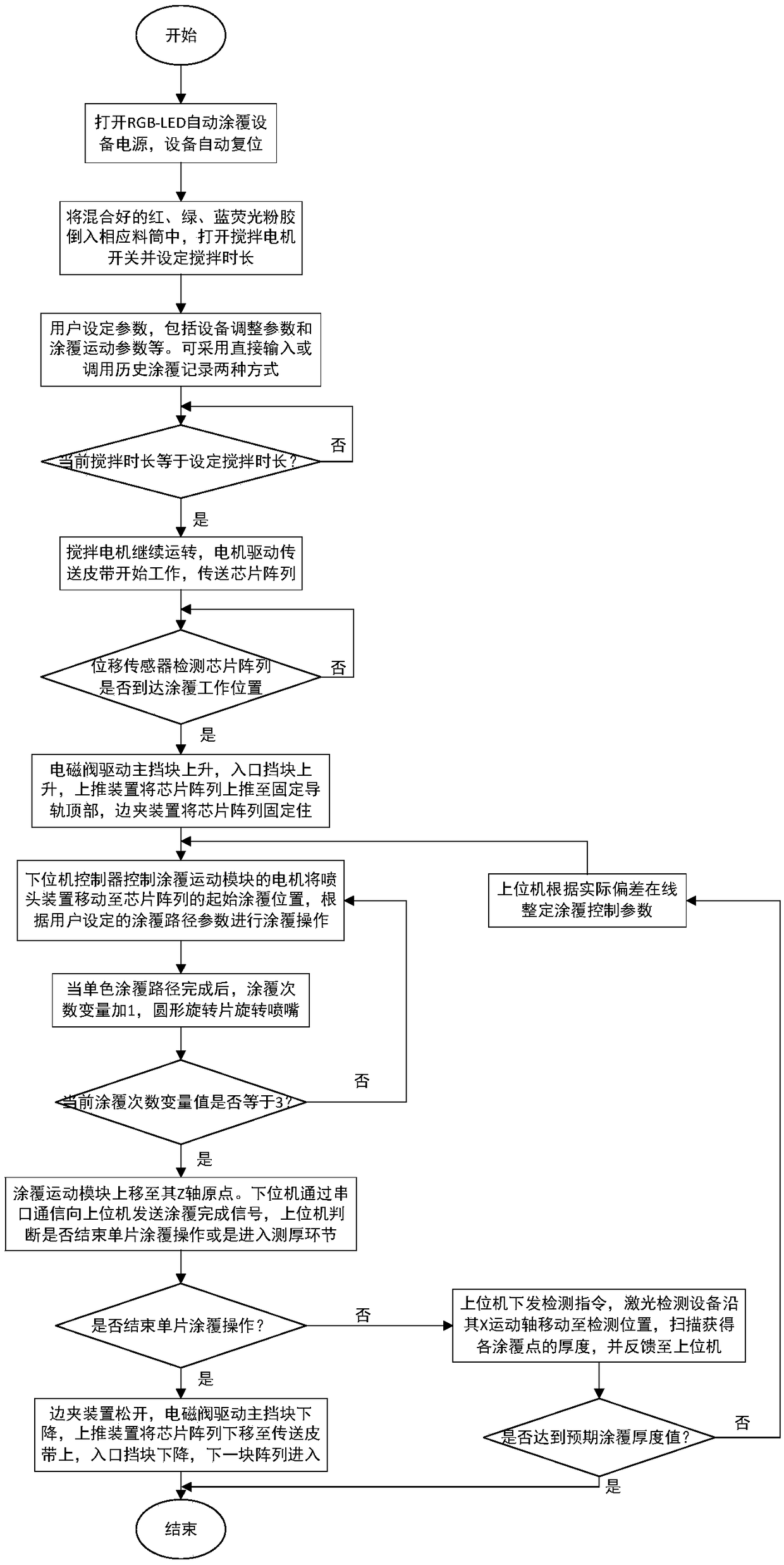

[0039] The above content has fully described the present invention. In order to have a clearer understanding of the technical features and effects of the present invention, the specific implementation modes of the present invention will now be described in detail with reference to the accompanying drawings.

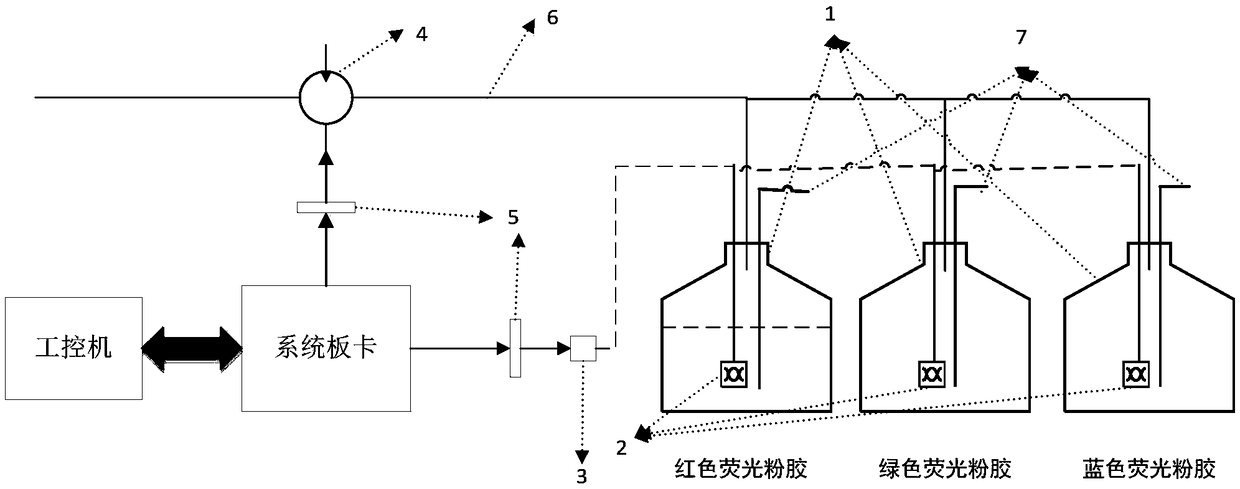

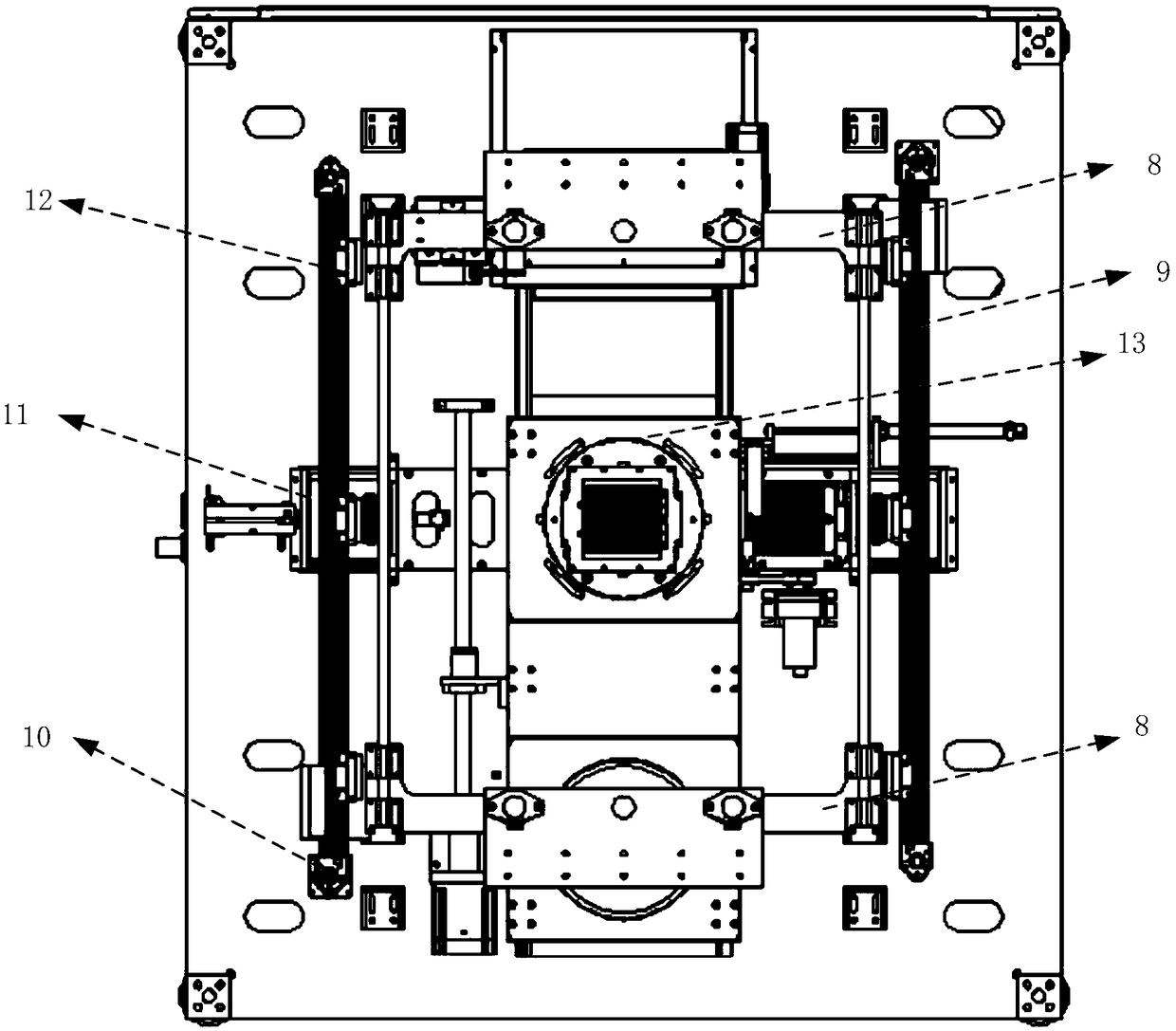

[0040] The three-primary-color RGB-LED array automatic fluorescent powder glue high-speed intelligent coating equipment of the present invention includes a lower computer and an upper computer control system. The hardware structure of the lower computer includes a frame, a phosphor glue feeding mechanism, a transmission mechanism, a coating movement module, a phosphor glue thickness measuring mechanism, and a lower computer controller. The lower computer controller is located at the lower part of the rack. The lower computer controller and the upper computer control system realize real-time data communication through the serial port, and send the control program to each mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com