Patents

Literature

45results about How to "Avoid affecting the coating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

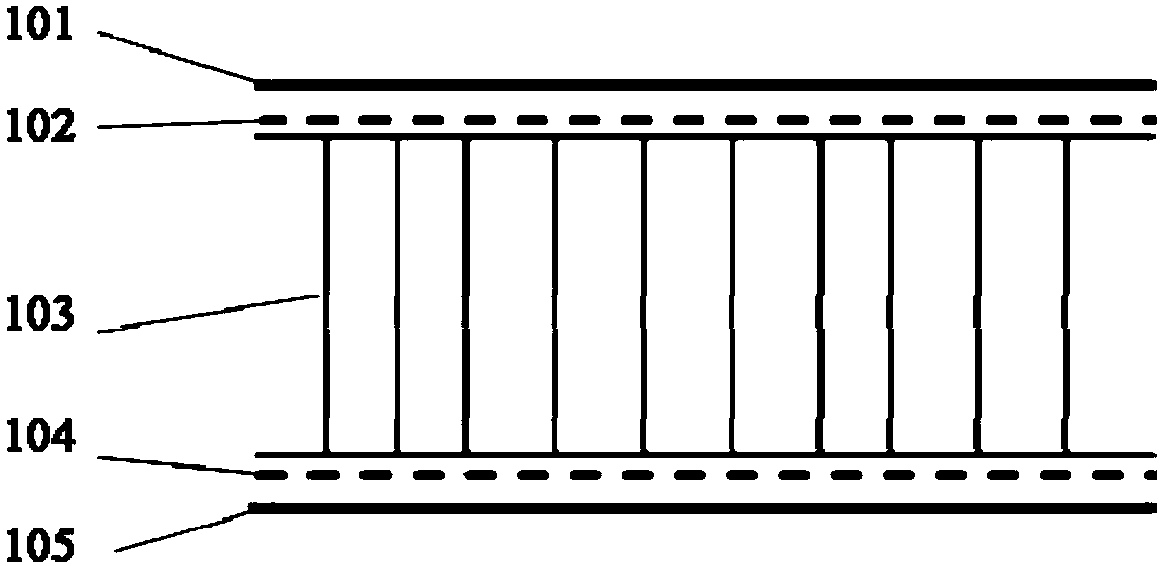

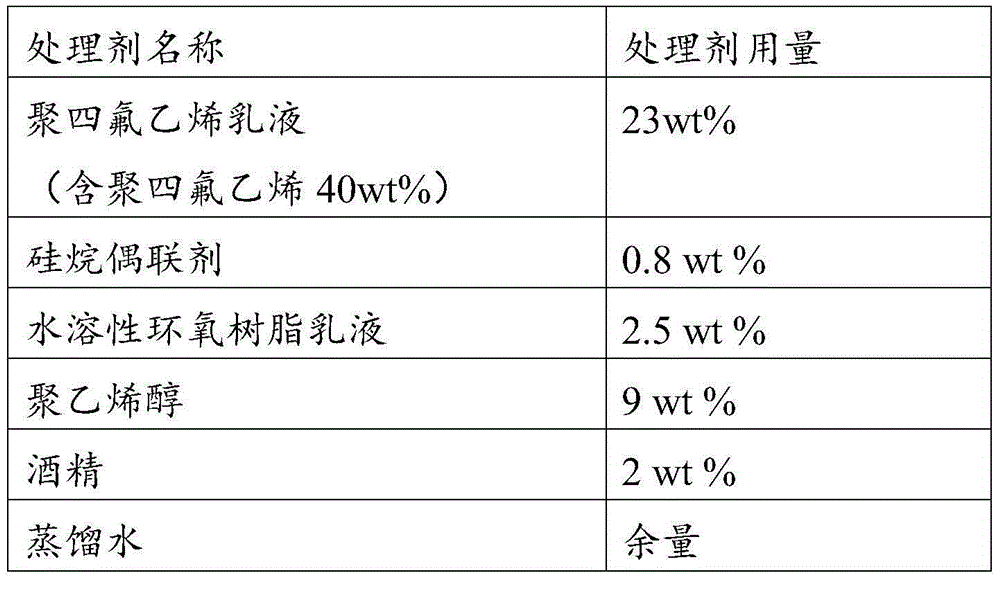

Manufacturing method for high-accuracy coating filter material

InactiveCN102512877AGood acid and alkali resistanceImprove water resistanceSynthetic resin layered productsGlass/slag layered productsFiberLoss strength

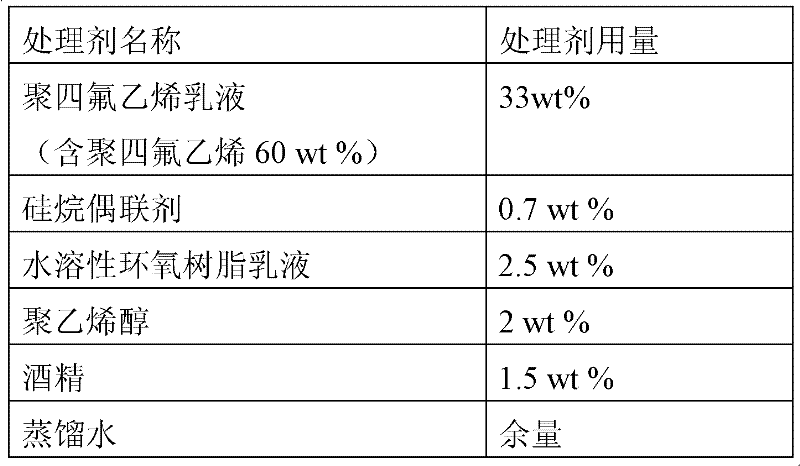

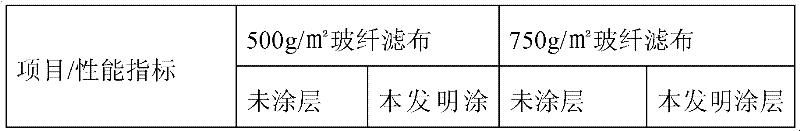

The invention provides a manufacturing method for a high-accuracy coating filter material, which has the advantages of good binding effect between the filter material and PTFE (Polytetrafluoroethylene) and capability of improving the performance of the filter material. The method comprises the following steps of: (1) thermal cleaning treatment, performing the thermal cleaning treatment on the filter material and removing various auxiliary agents on the surface of the filter material through high temperature; (2) dipping treatment, performing PTFE dipping treatment on the filter material which is subjected to the thermal cleaning treatment; (3) sequentially performing baking, drying and thermal forming treatment on the filter material which is subjected to the dipping treatment; (4) performing coating treatment on the filter material which is subjected to thermal forming; and (5) sequentially performing volatile treatment, baking treatment, sintering treatment and thermal forming treatment on the filter material which is subjected to the coating treatment. In the manufacturing method for the high-accuracy coating filter material, the thermal cleaning treatment is performed before the filter material is subjected to the dipping treatment, so that a wire drawing impregnating agent remained on the surfaces of fibers can be effectively removed, meanwhile, no loss strength of a textile is guaranteed; and the acid and alkali resistance, water resistance, oxidation resistance, wear resistance and folding resistance of the filter material are effectively improved, and the service life of the filter material is prolonged.

Owner:辽宁鸿顺环保新材料有限公司

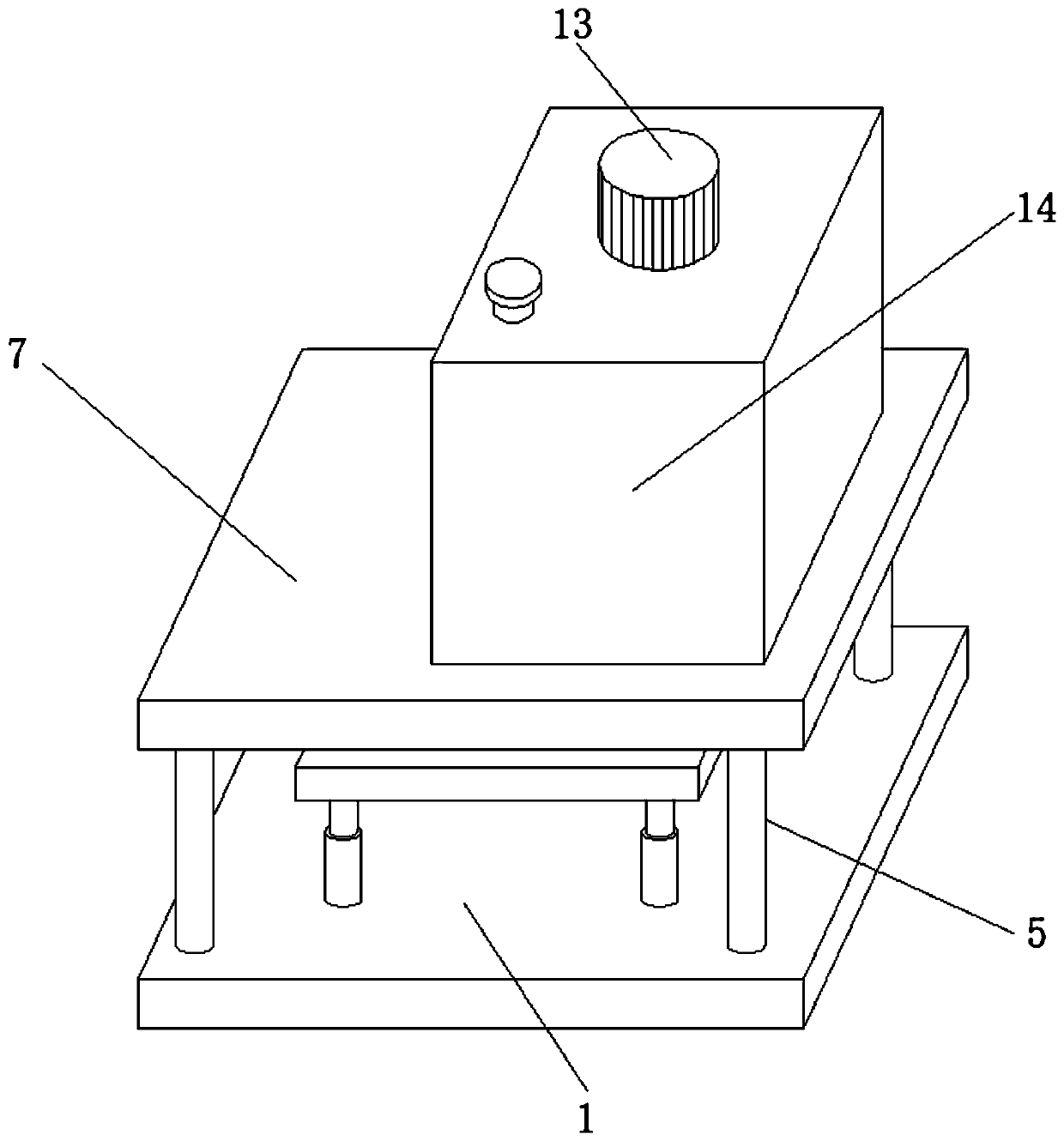

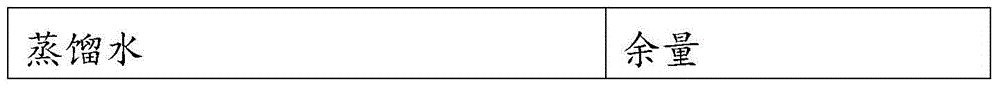

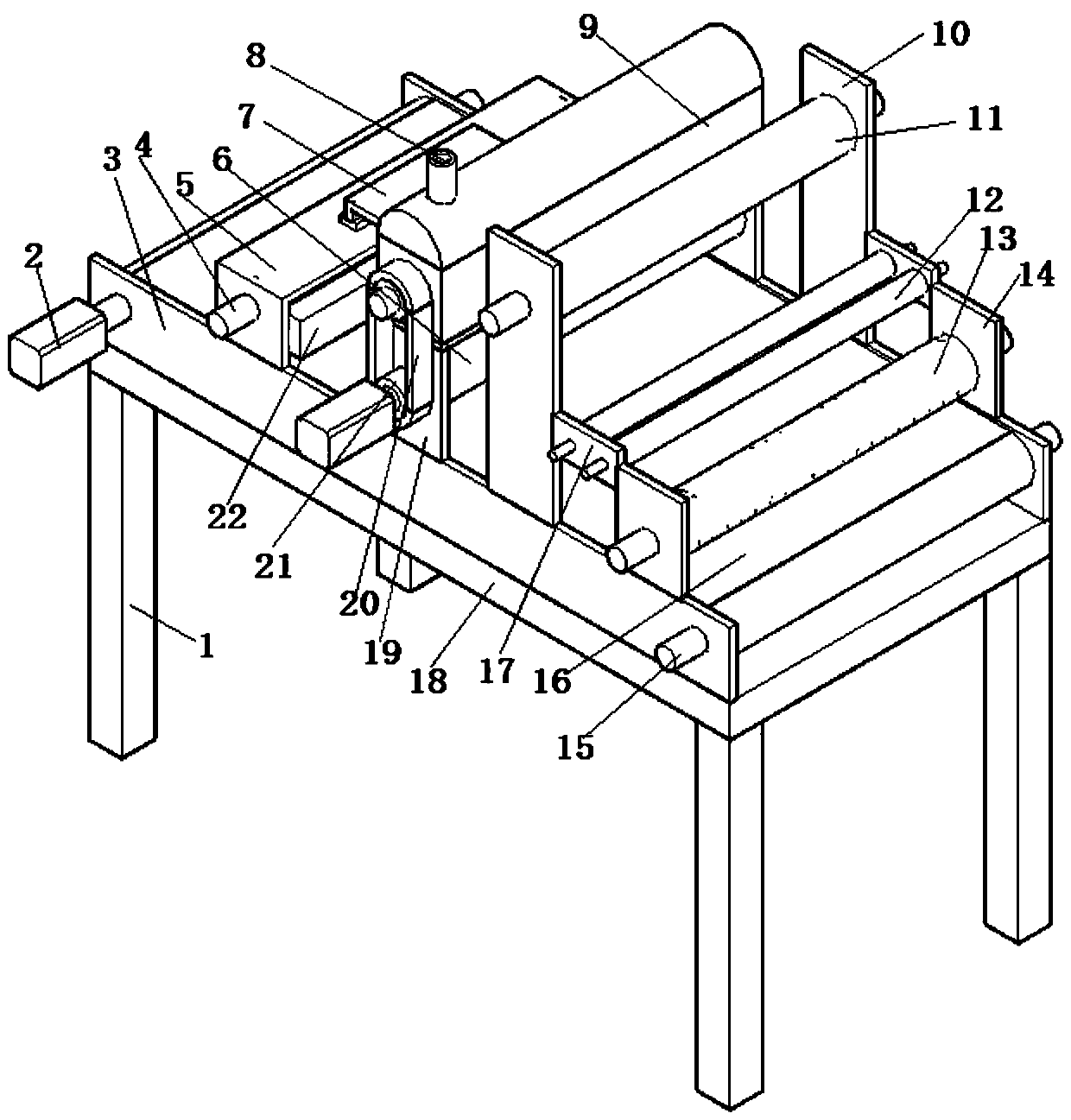

Film coating equipment used in plaster production, and application method thereof

ActiveCN108372076AAdjust the size of the gapAdjustable thicknessLiquid surface applicatorsCoatingsEngineeringFilm-coated tablet

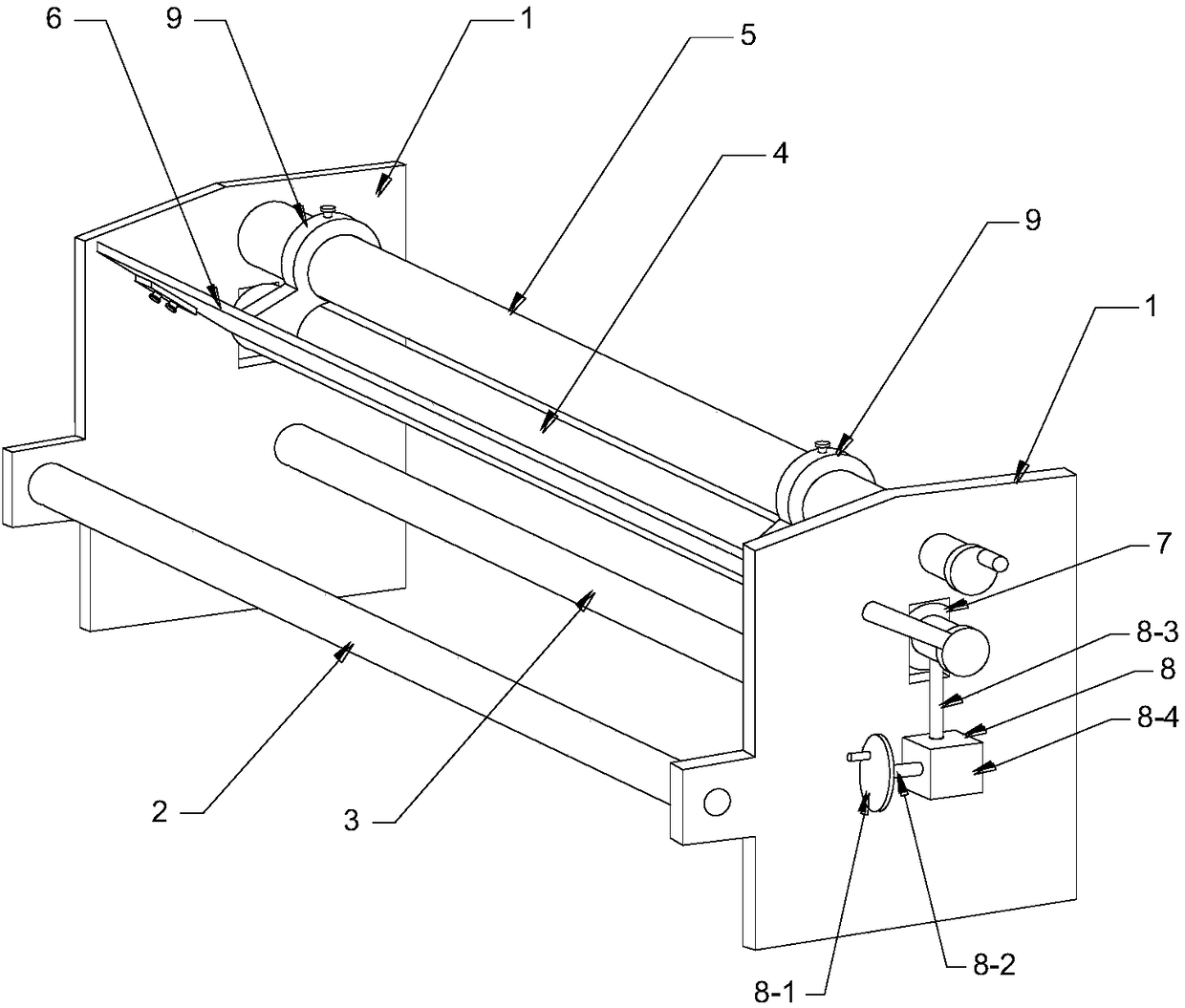

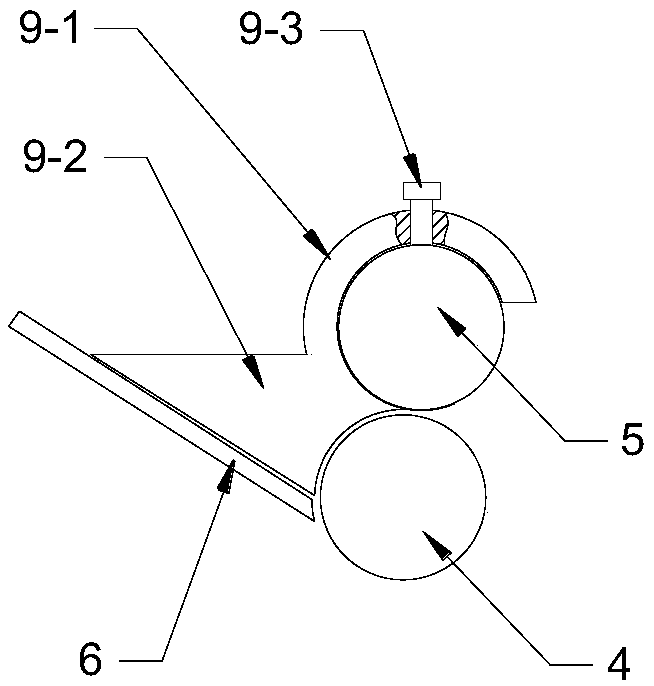

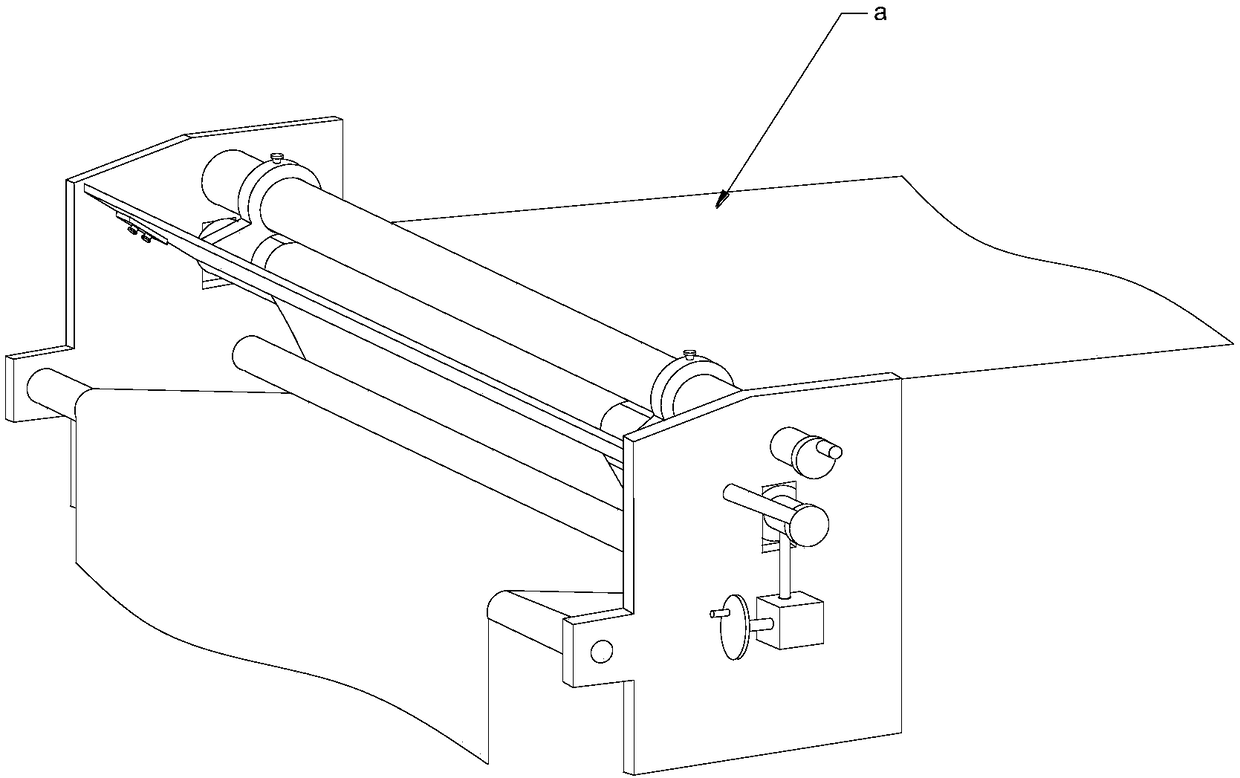

The invention discloses a film coating equipment used in plaster production, and applications thereof. The film coating equipment used in plaster production comprises a machine frame, a gluing lower roller, a gluing upper scraping roller, and a discharge plate; the gluing lower roller, the gluing upper scraping roller, and the discharge plate are transversely arranged on the machine frame; the gluing upper scraping roller is arranged above the gluing lower roller; the discharge plate is arranged on the feed inlet side of the gluing lower roller and the feed inlet side of the gluing upper scraping roller; a gap is arranged between the bottom end of the discharge plate and the gluing lower roller, so that cloth to be coated can be delivered through; a discharge gap is left between the gluinglower roller and the gluing upper scraping roller; slidable mounting is adopted by the end parts of the gluing lower roller; lower gluing roller adjusting devices which are used for acting on the twoends of the gluing lower roller, and adjusting the vertical position of the gluing lower roller are arranged on two side plates respectively; and film width adjusting blocking plates which are used for adjusting film coating width are arranged on the gluing lower roller and the gluing upper scraping roller. The film coating equipment is reasonable in design, excellent in control performance, highin production efficiency, convenient in operation, convenient to clean, and is an ideal plaster film coating equipment.

Owner:JINZHOU ZIJIN PHARMA

Gluing device for packaging box production

ActiveCN110918396AApply evenlyEasy to useLiquid surface applicatorsBox making operationsPaperboardRubber mat

The invention discloses a gluing device for packaging box production. The gluing device comprises a bottom plate, wherein stand columns are welded at the four corners of the outer wall of the top of the bottom plate, and a top plate is welded to the outer wall of the top of the stand columns; an electric sliding rail is connected to the outer wall of the bottom of the top plate through bolts, a sliding block is slidably connected to the inner wall of the electric sliding rail, vertical rods which are distributed equidistantly are welded to the outer wall of the bottom of the sliding block, andbrushes are connected to the outer walls of the bottoms of the vertical rods in a bonding mode; and a glue storage box is connected to the outer wall of the top of the top plate through bolts, and aglue adding pipe is welded to the outer wall of the top of the glue storage box. According to the gluing device for the packaging box production, the brushes on the vertical rods can continuously moveleft and right, and glue body flowing to a paperboard is evenly spread, so that the using effect is better, and the paperboard can be firmly adsorbed on a sucker; and meanwhile, a rubber pad on the sucker can increase the friction force with the paperboard, so that the fixing is stabler, it is guaranteed that the paperboard does not shake during coating, and the gluing effect of the device is further improved.

Owner:株洲蓝海包装有限公司

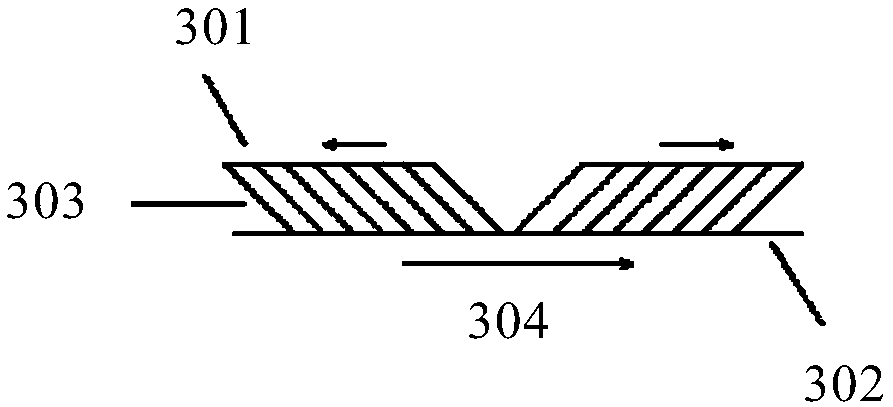

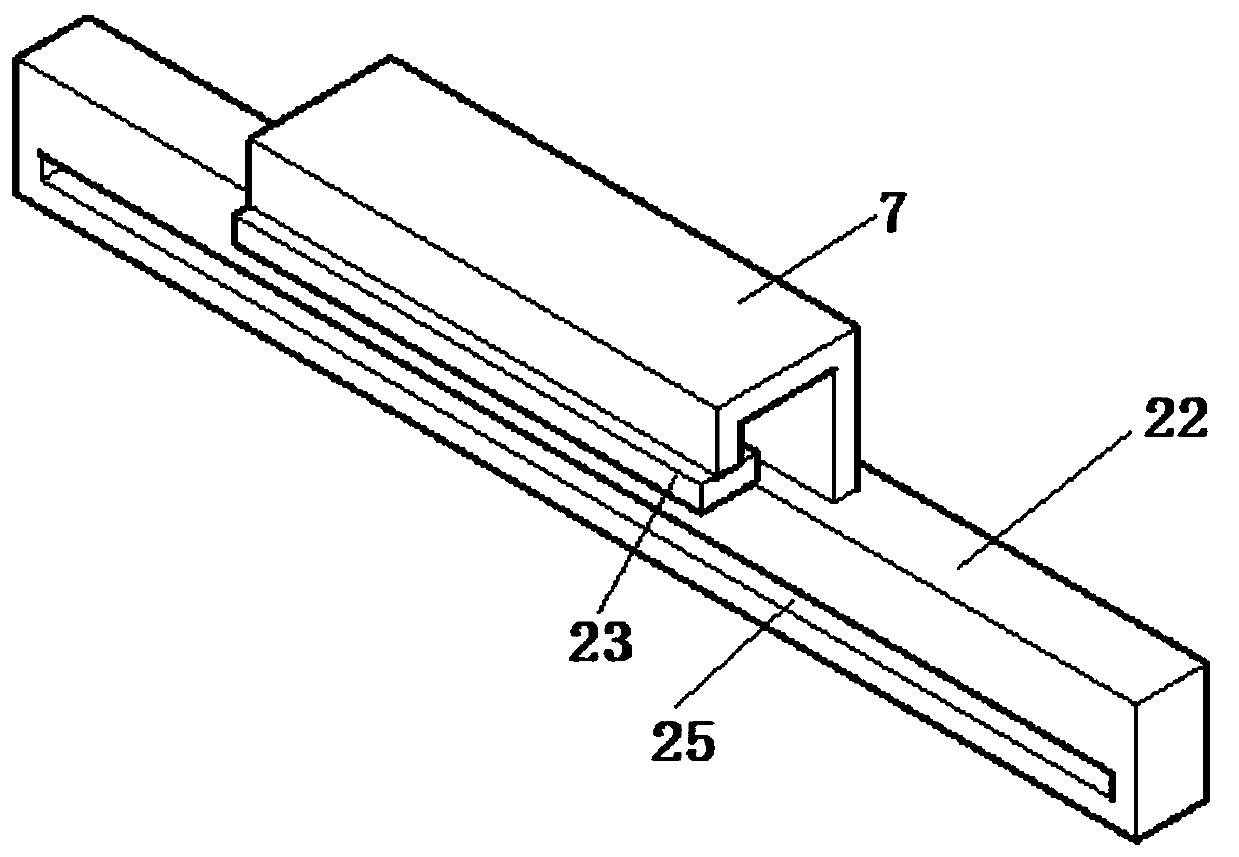

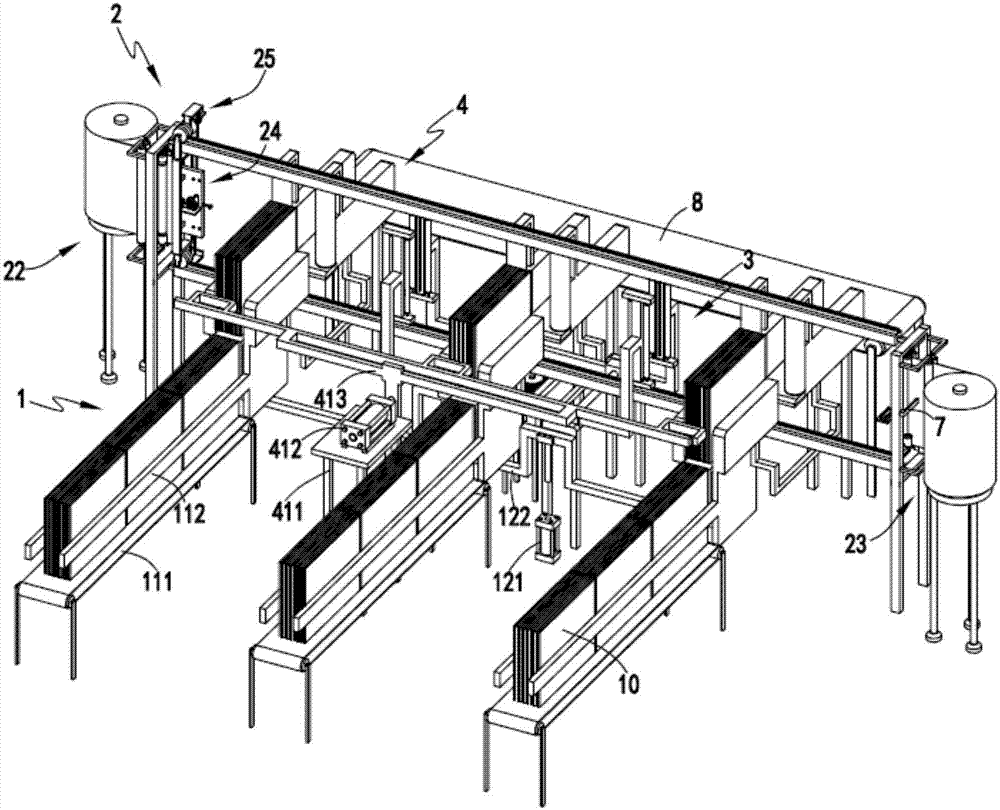

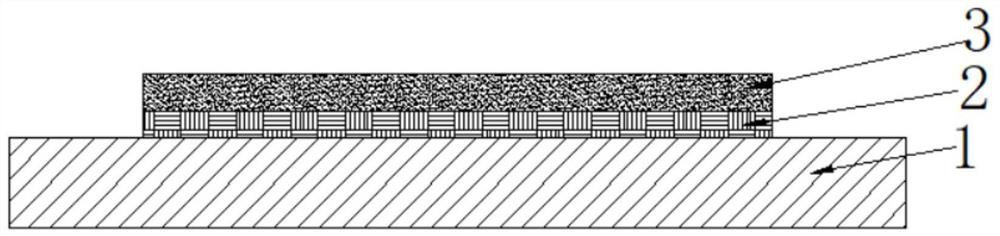

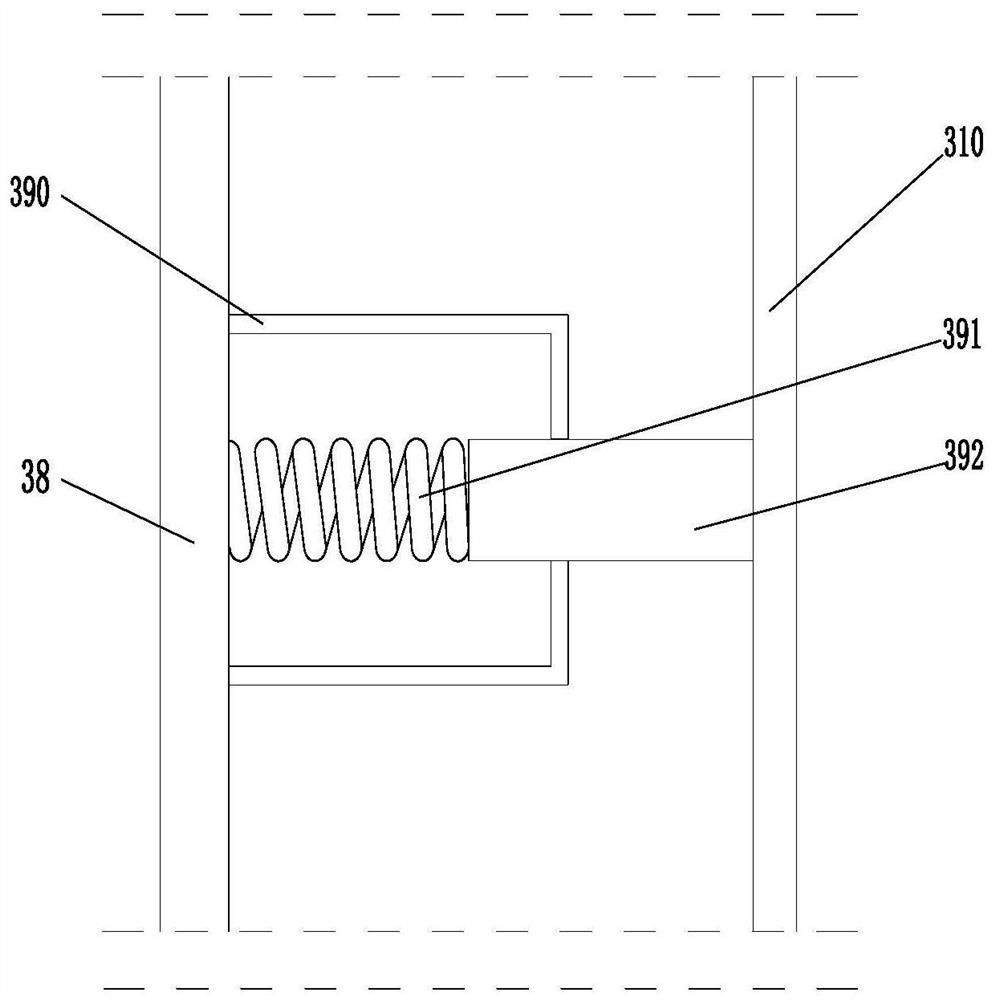

Three-dimensional spacer fabric reinforced space membrane material, preparation method and processing device thereof

ActiveCN108045048ARetain propertiesReduce wearLamination ancillary operationsSynthetic resin layered productsYarnEngineering

The invention relates to a three-dimensional spacer fabric reinforced space membrane material, a preparation method and a processing device thereof. The preparation method includes: in a three-dimensional spacer fabric running process, firstly applying tension along the fabric running direction and maintaining the tension unchanged, making spacer yarns in the fabric at a vertically straight state,then disposing an opening with a length equal to the width of the fabric at the fabric top cloth surface along a direction perpendicular to the fabric running direction, letting the upper layer and lower layer of the fabric staggered horizontally and the spacer yarns at an inclined tense state, and finally compounding the composite fabric with a membrane material to obtain the three-dimensional spacer fabric reinforced space membrane material. The processing device includes a cloth feeding roll, a tension roll, a sizing mechanism, a shaping mechanism, a lamination mechanism, a post-treatmentmechanism and a collection mechanism that are arranged in sequence. The final product has a composite layer structure including a plurality of membrane materials layers and a fabric layer between themembrane material layers, and the spacer yarns in the fabric can move freely and have no adhesion. The preparation method provided by the invention is simple in process, the processing device has a simple structure, and the product has excellent mechanical properties.

Owner:DONGHUA UNIV

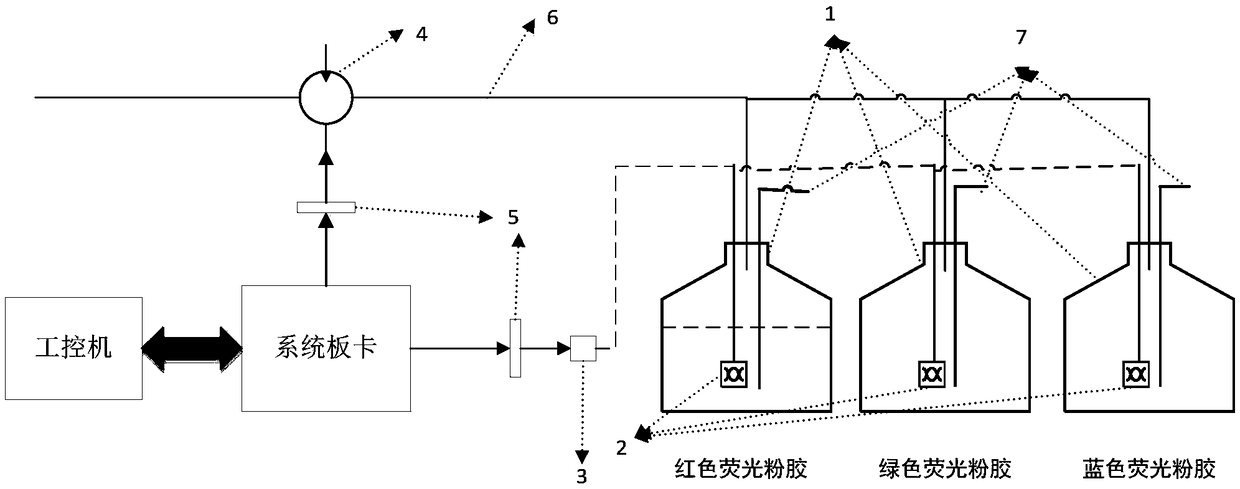

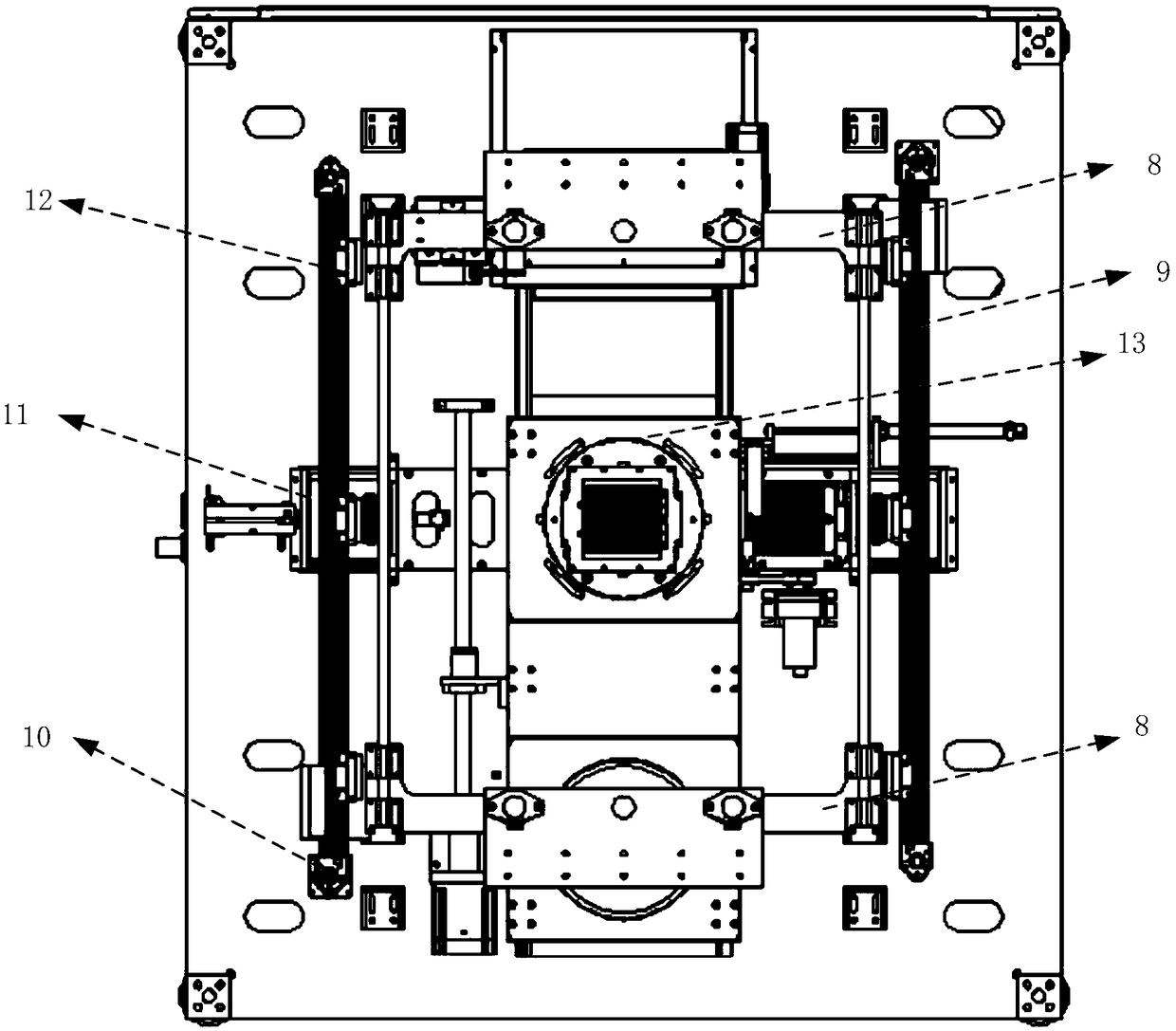

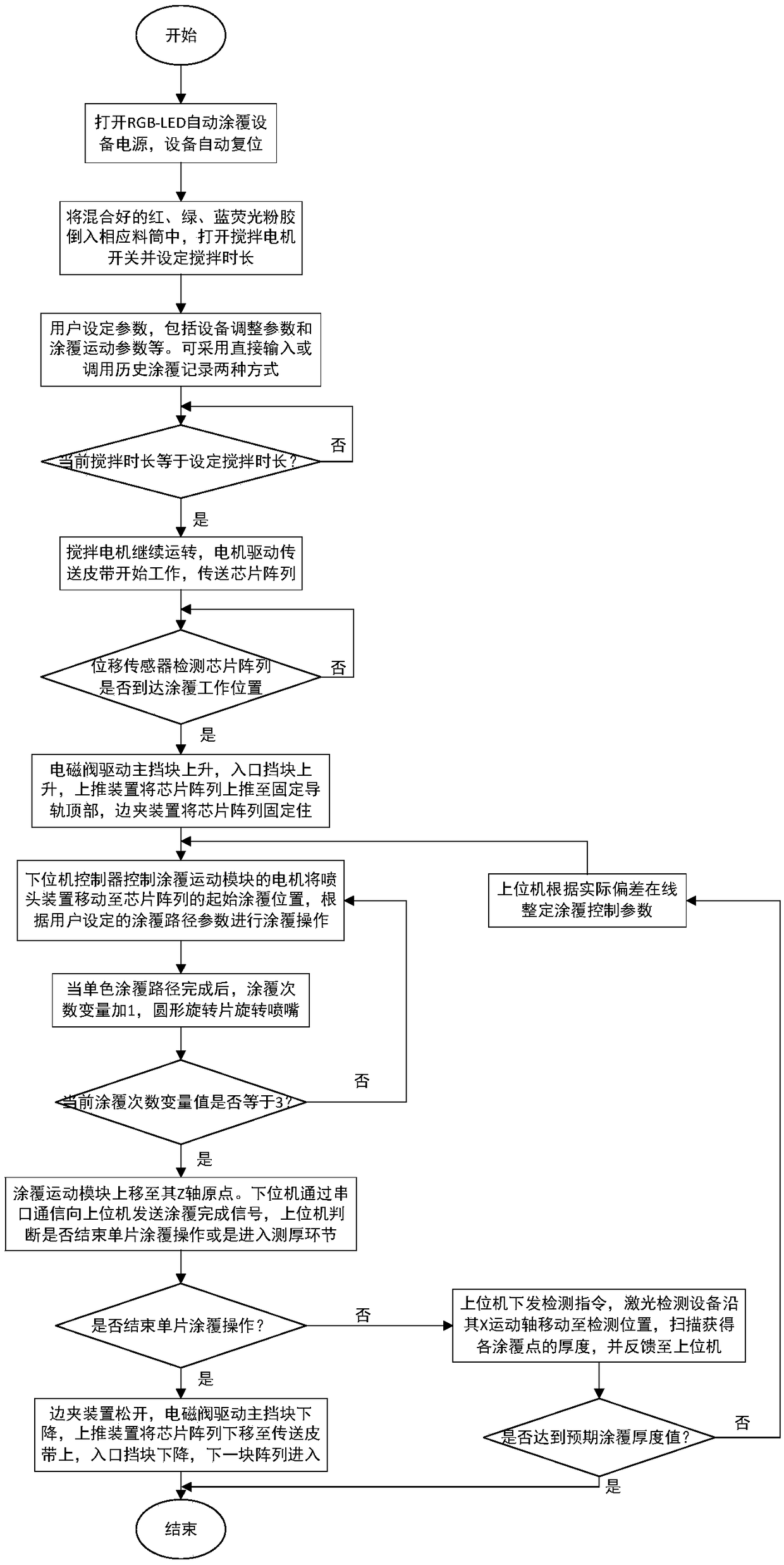

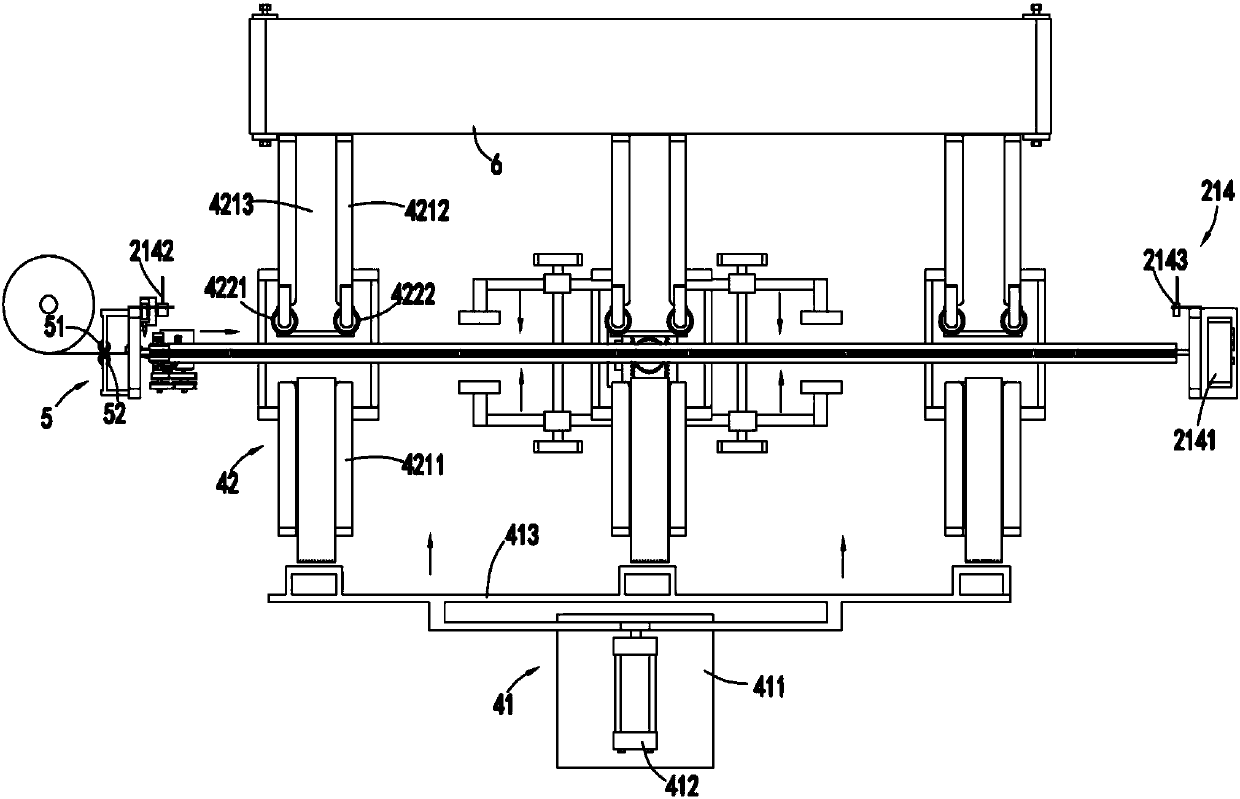

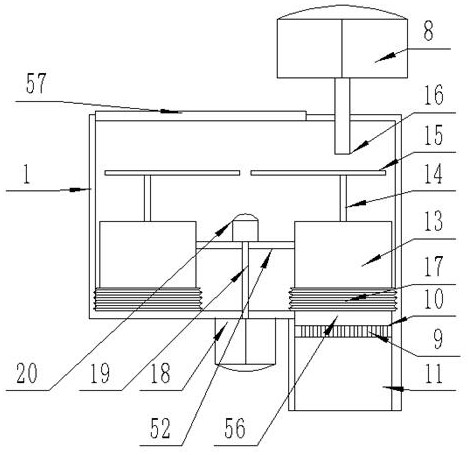

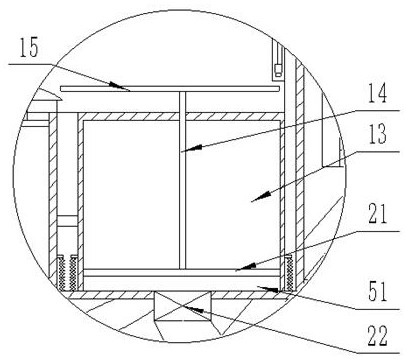

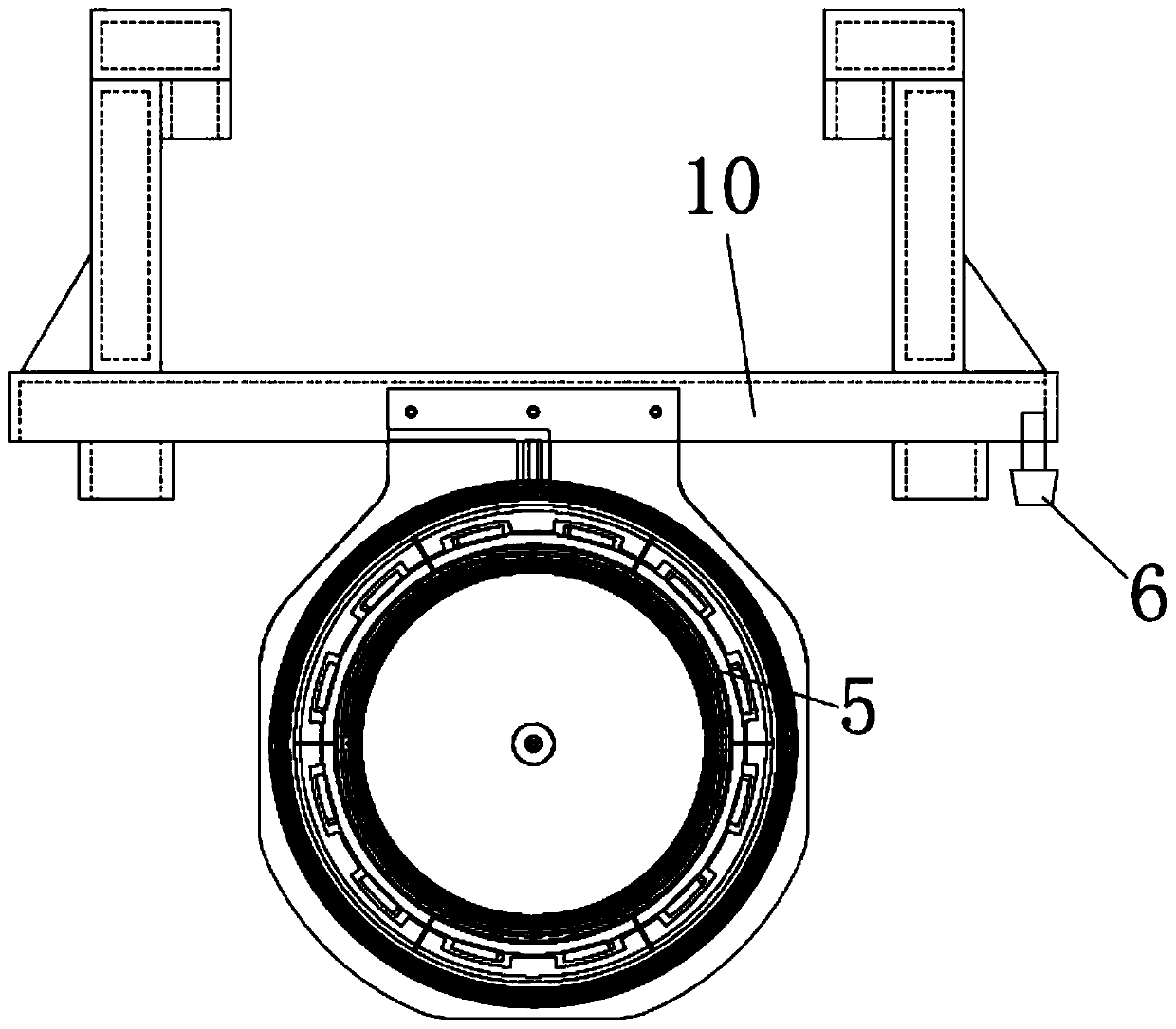

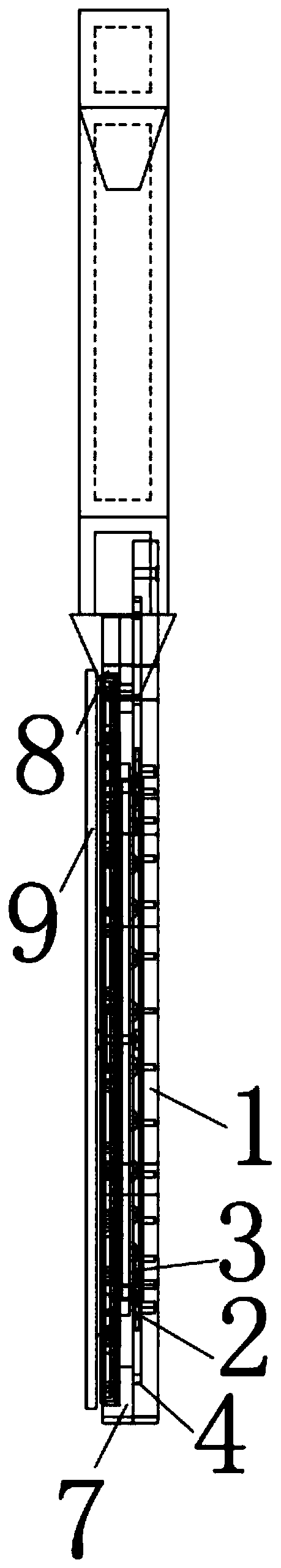

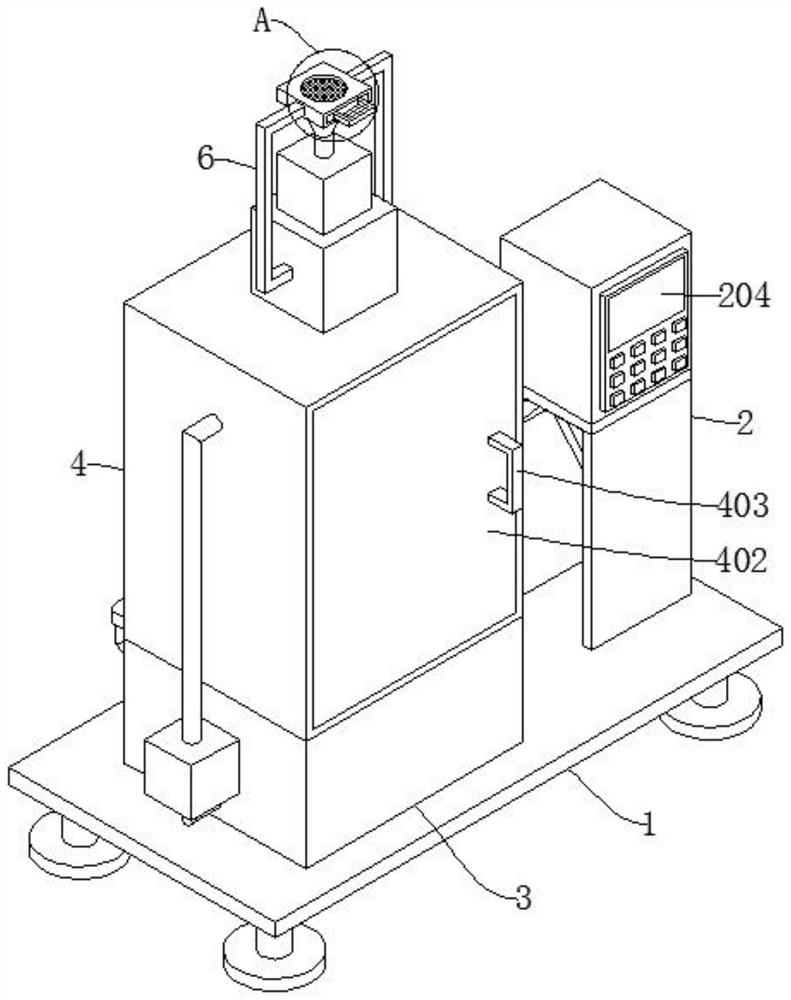

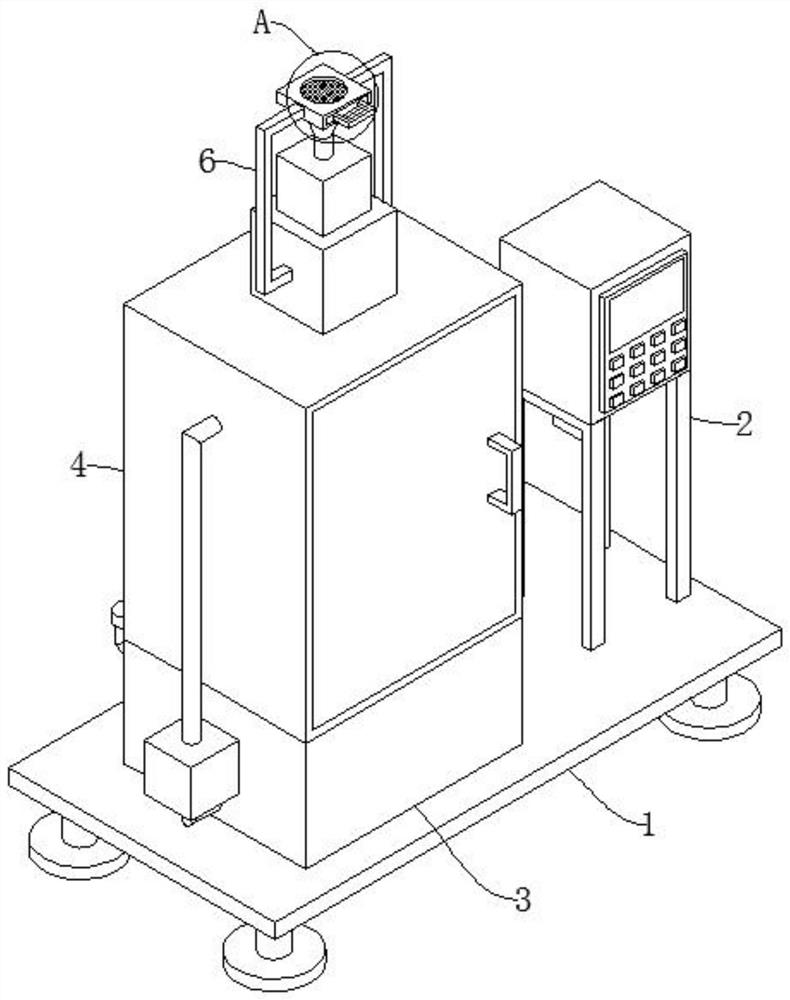

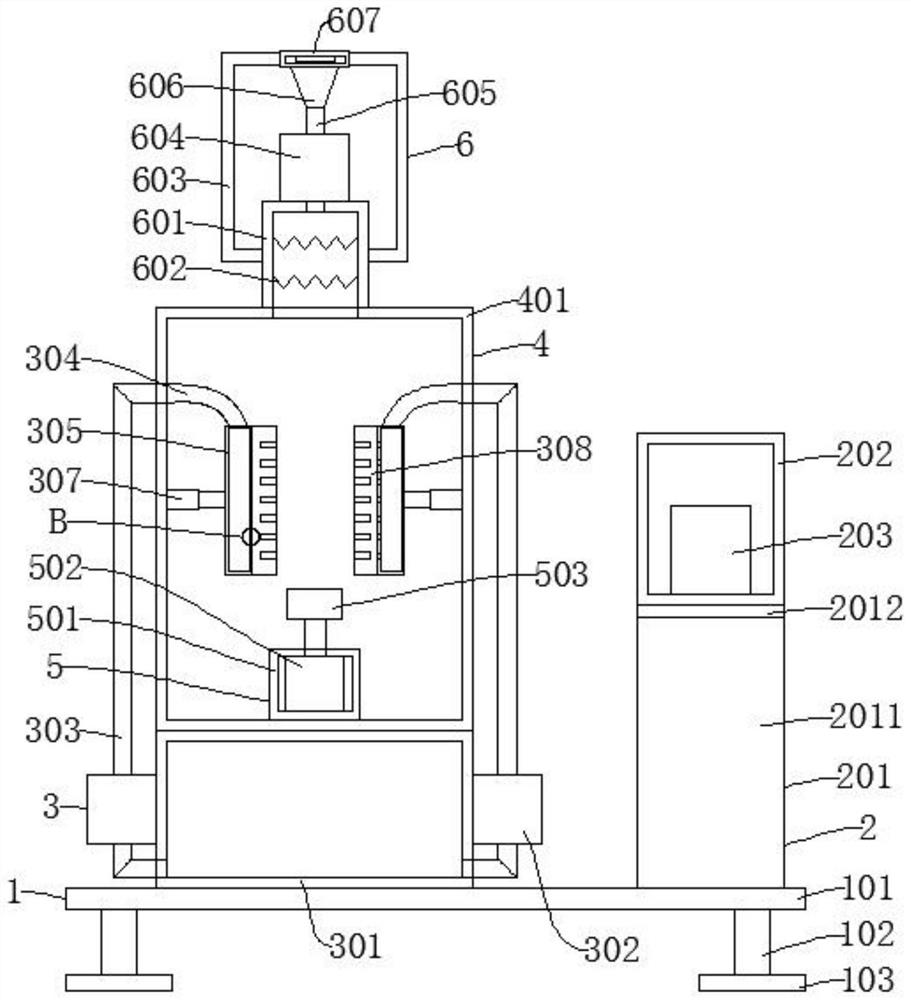

RGB-LED full-automatic fluorescent powder glue high-speed intelligent coating device and method

PendingCN108962798ARealize closed-loop controlImprove Coating IntelligenceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputer control systemEngineering

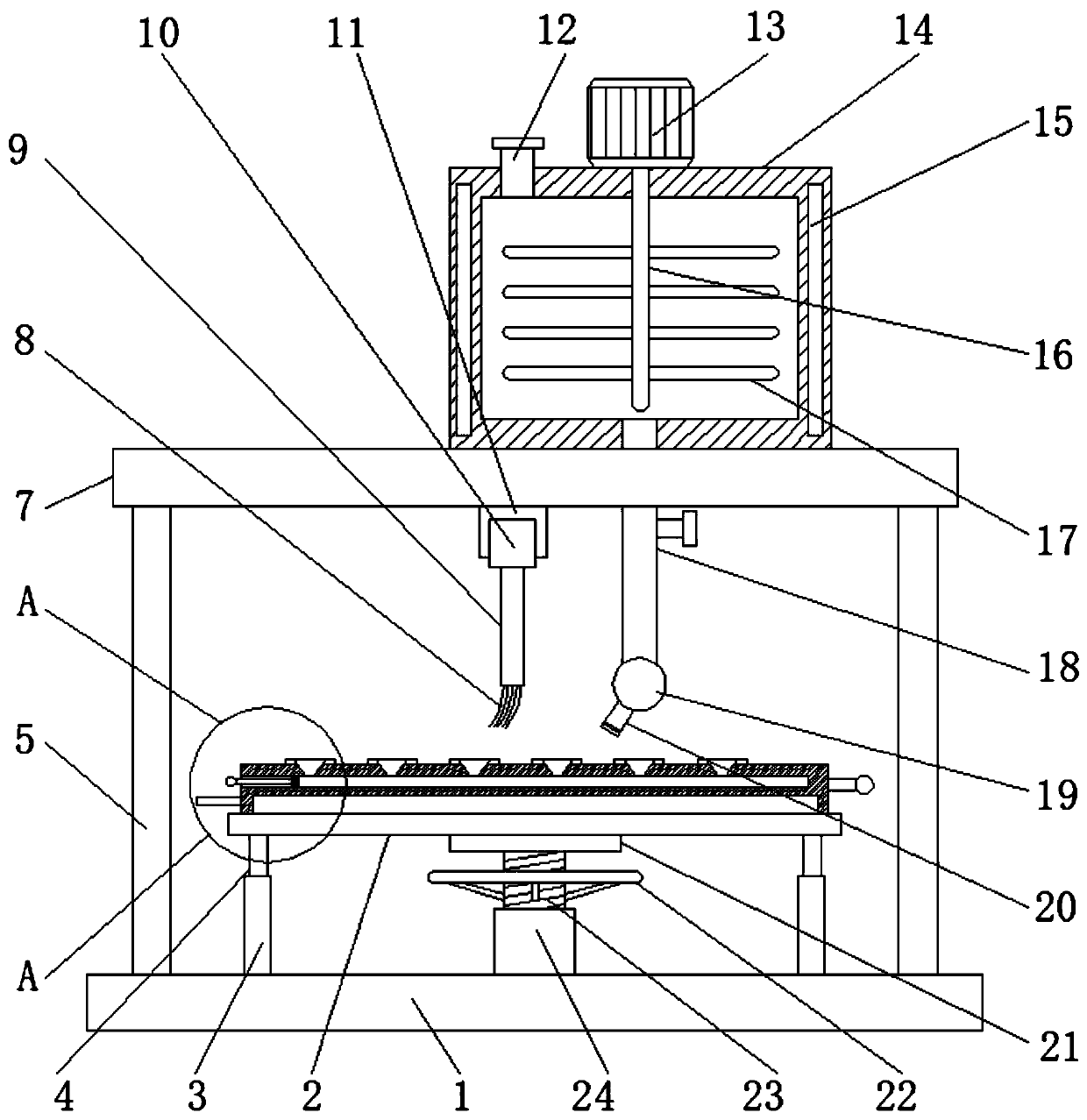

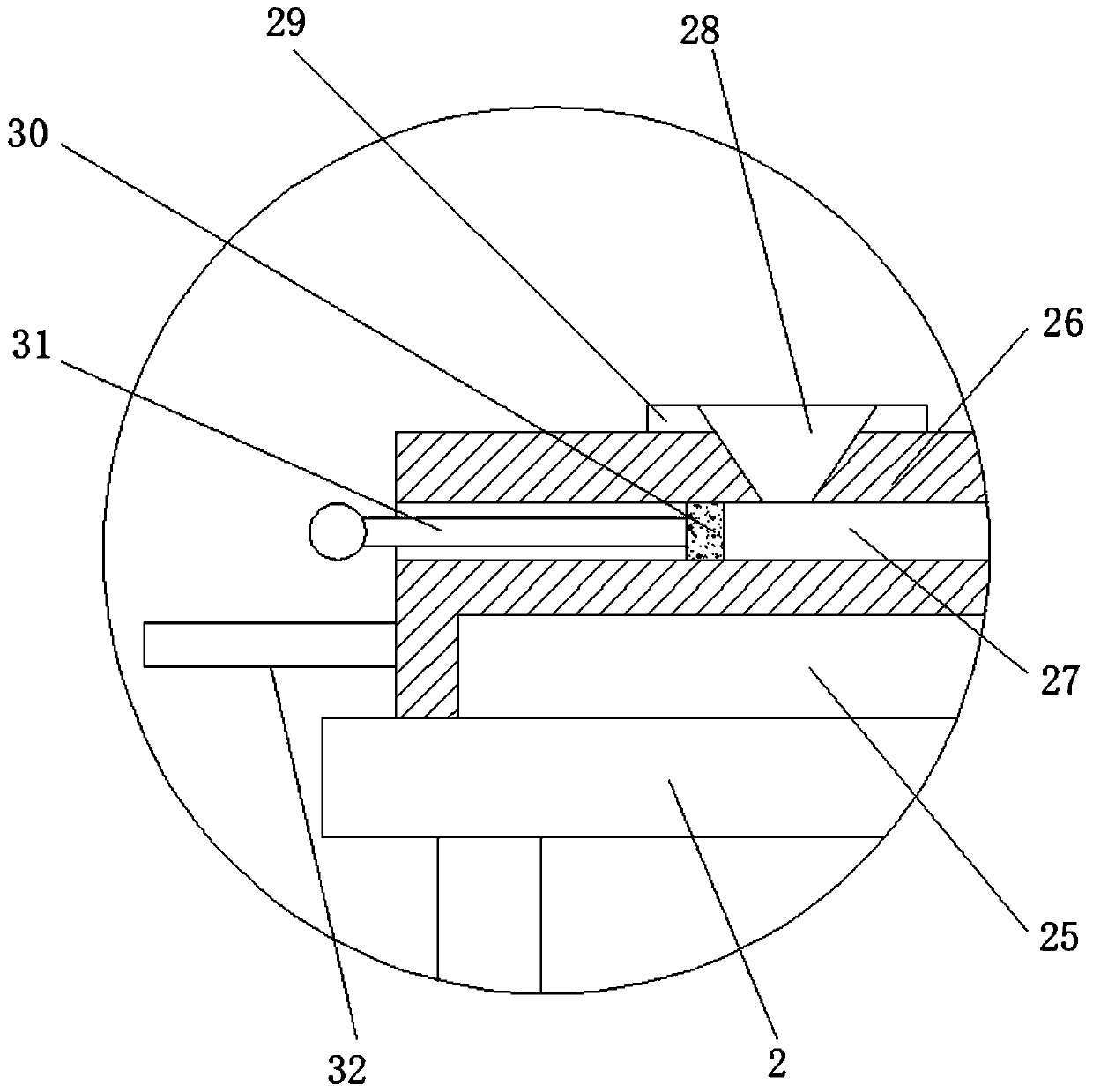

The invention discloses a RGB-LED full-automatic fluorescent powder glue high-speed intelligent coating device, the intelligent coating device includes a lower computer and an upper computer control system; the lower computer comprises a machine frame, a fluorescent powder glue feeding mechanism, a conveying mechanism, a coating movement module, a fluorescent powder glue thickness measuring mechanism, and a lower computer controller, the fluorescent powder glue feeding mechanism presses the mixed fluorescent powder glue into a spray head in the coating movement module through air pressure, theconveying mechanism conveys the chip array and fixes the chip array on the coating position, and the spraying head on the coating movement module is used for coating the chip at the coating position,the fluorescent powder glue thickness measuring mechanism is used for detecting the coating thickness of the current chip array, and the lower computer controller is connected with the upper computercontrol system. The device is high in automation degree, and has the functions of coating feedback control and online setting control parameters, the purpose of high-precision control on the coatingthickness of the fluorescent powder glue can be achieved, and the RGB-LED coating precision and coating efficiency of the LED can be effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high-precision coating filter material

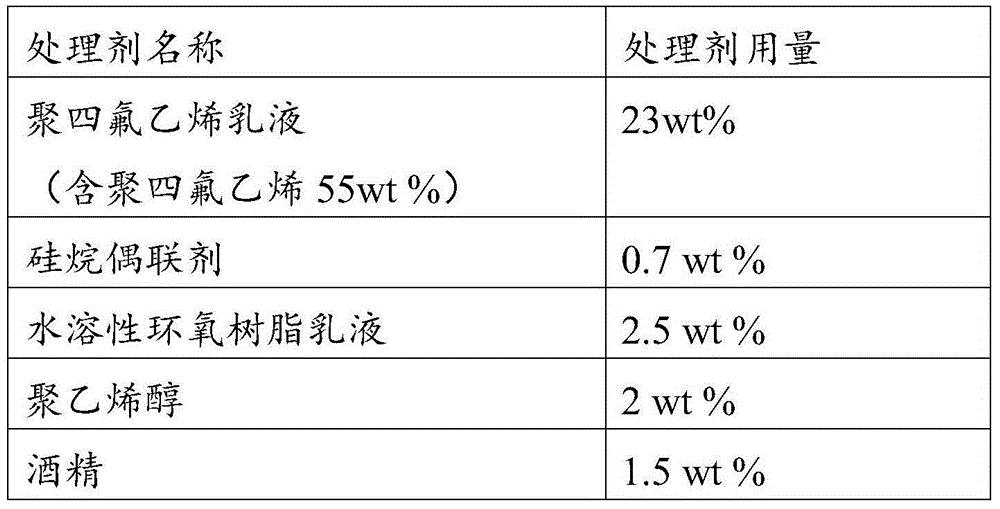

ActiveCN104436861AImprove acid and alkali resistanceExtended service lifeSynthetic resin layered productsGlass/slag layered productsPolytetrafluoroethyleneFilter material

The invention provides a preparation method of a high-precision coating filter material. According to the preparation method, the filter material can be well combined with PTFE (Polytetrafluoroethylene), and the performances of the filter material can be improved. The method comprises the following steps: (1) carrying out heat cleaning treatment, namely, performing the heat cleaning treatment on the filter material and removing various assistants on the surface of the filter material at high temperature; (2) performing immersion treatment, that is, performing PTFE immersion treatment on the filter material after heat cleaning treatment; (3) baking, drying, and carrying out heat setting on the filter material after immersion treatment sequentially; (4) coating the filter material after heat setting; and (5) performing volatilization, drying, sintering and heat setting on the filter material after coating treatment sequentially. According to the preparation method of the high-precision coating filter material, the filter material is subjected to heat cleaning treatment before immersion treatment, thus, wiredrawing impregnating compound remained on the surface of the fiber can be effectively removed, and the fabric strength can be ensured not to be lost; the acidic and alkali resistances, the water resistance, the oxidation resistance and the abrasion and folding resistances of the filter material can be effectively improved, and the service life of the filter material can be prolonged.

Owner:辽宁新洪源环保材料有限公司

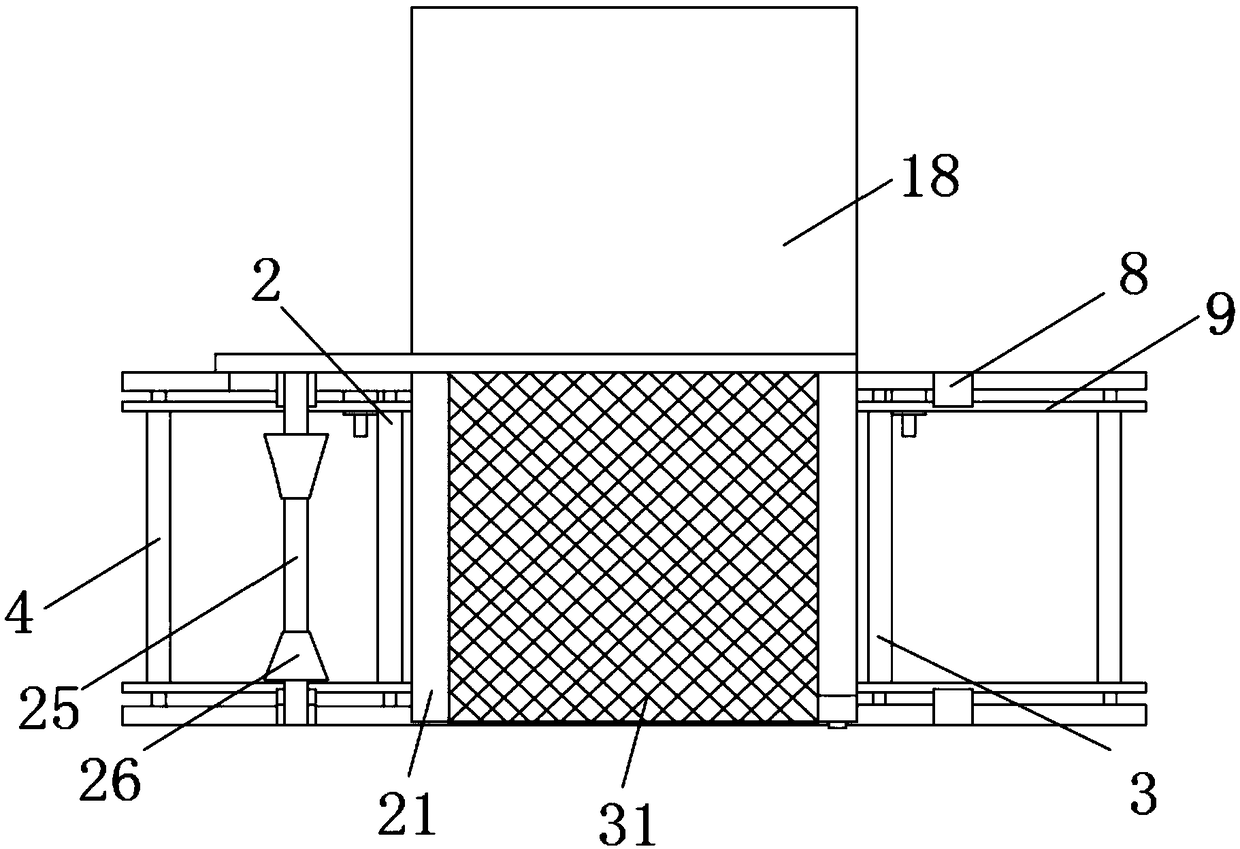

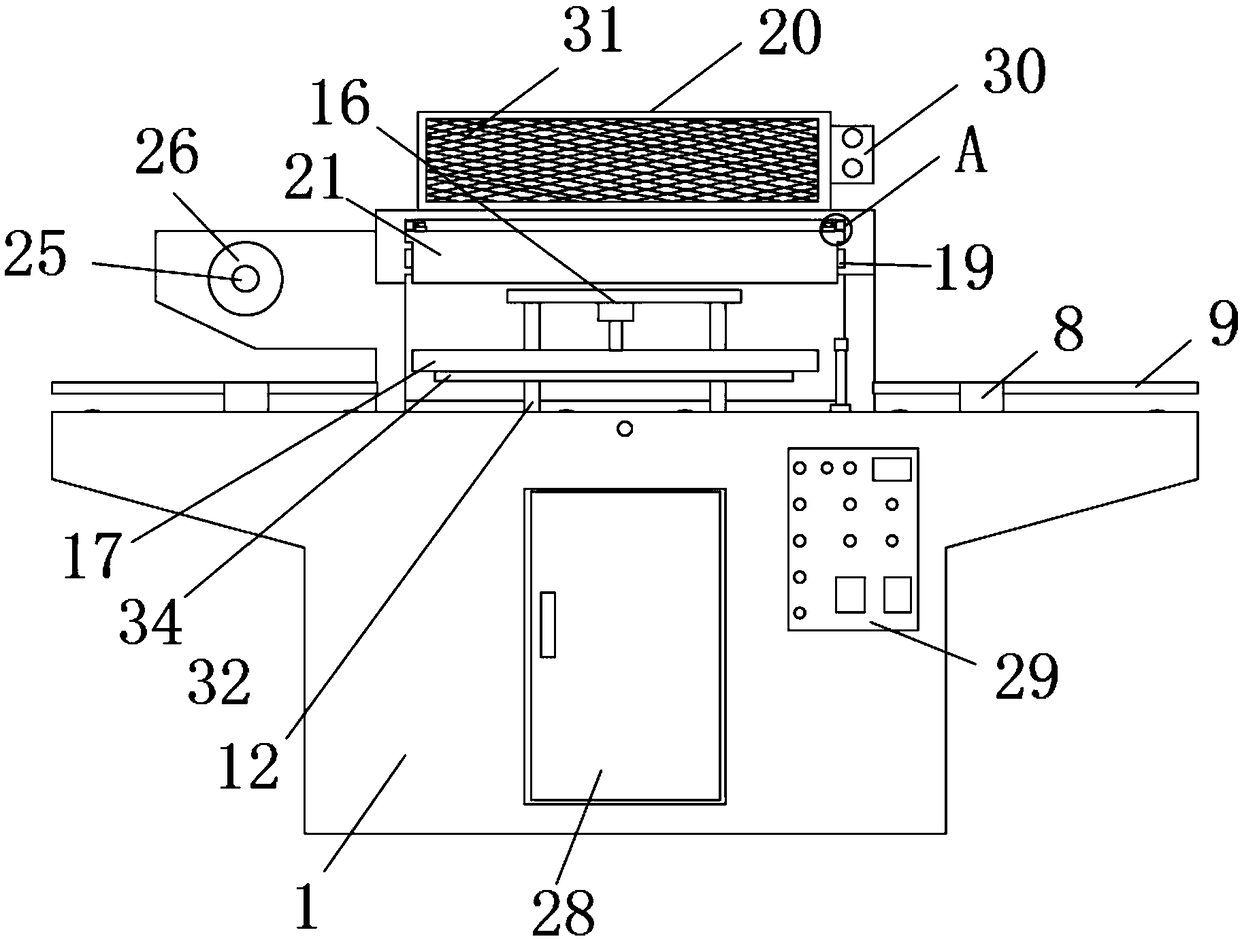

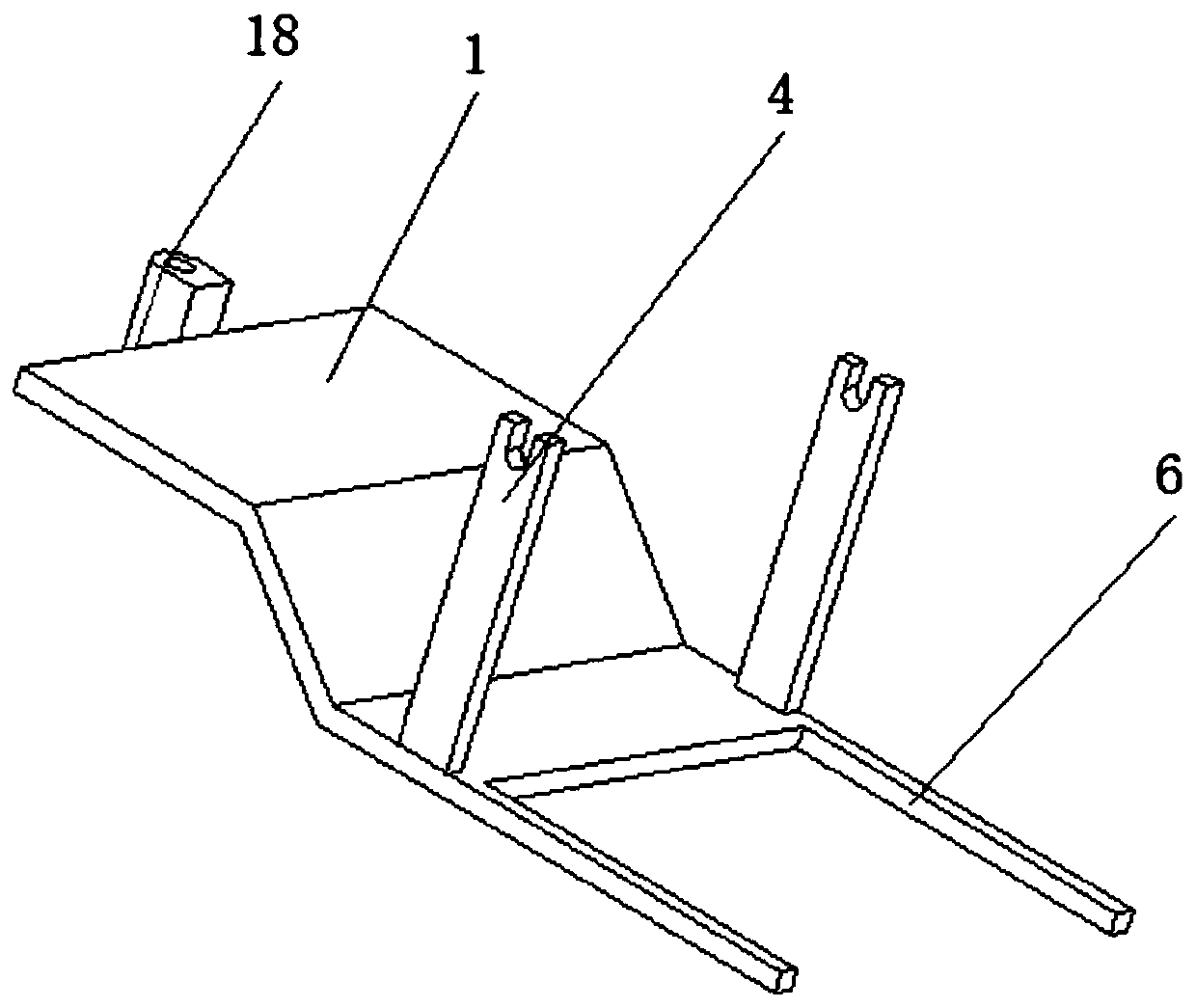

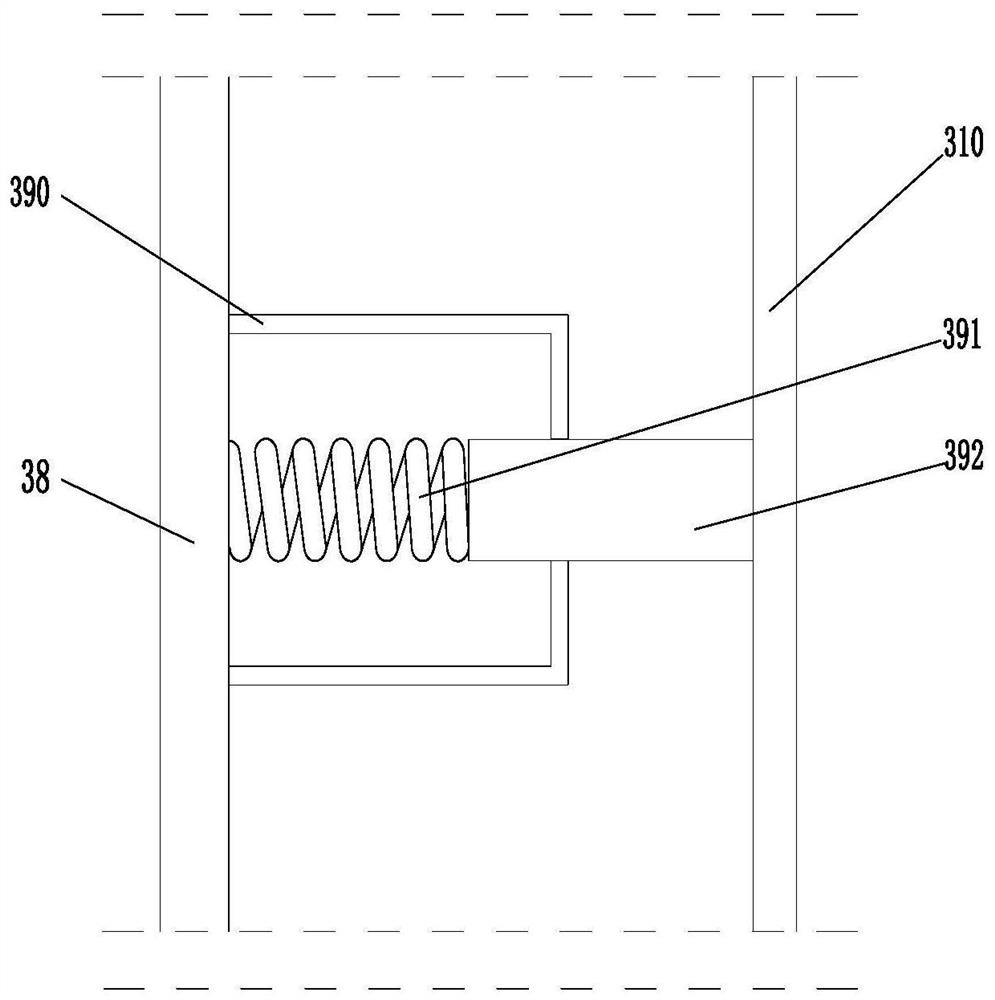

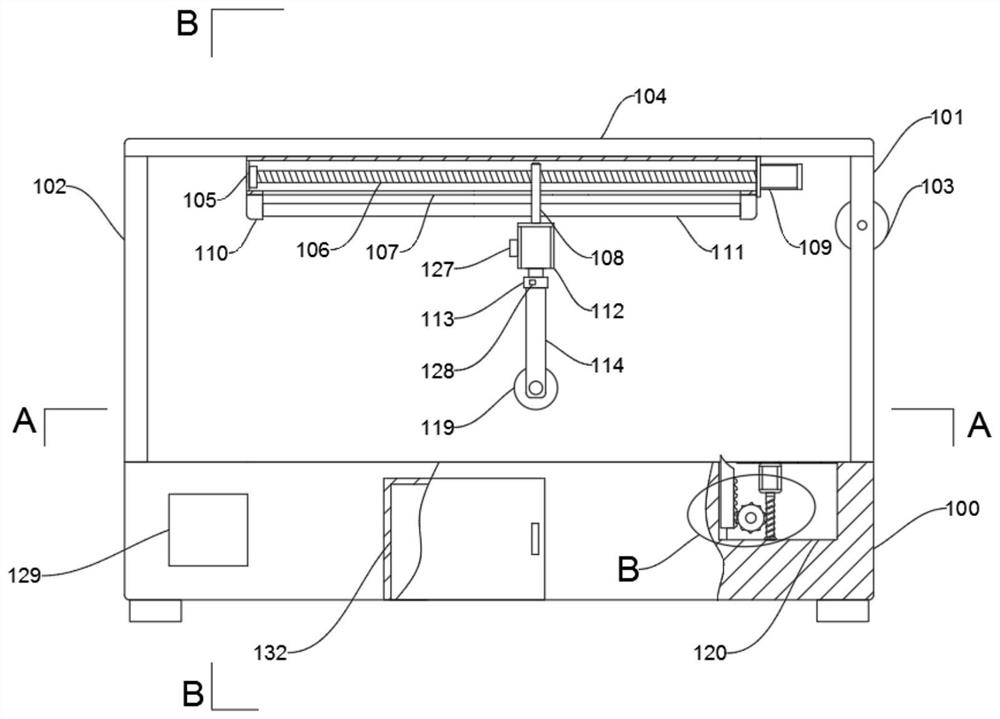

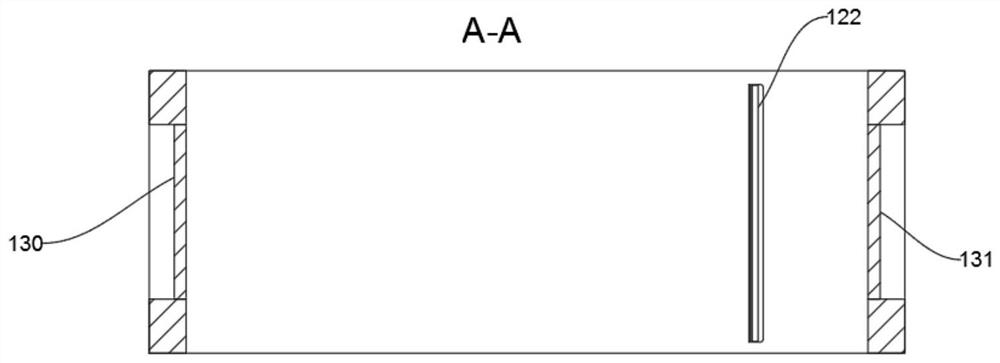

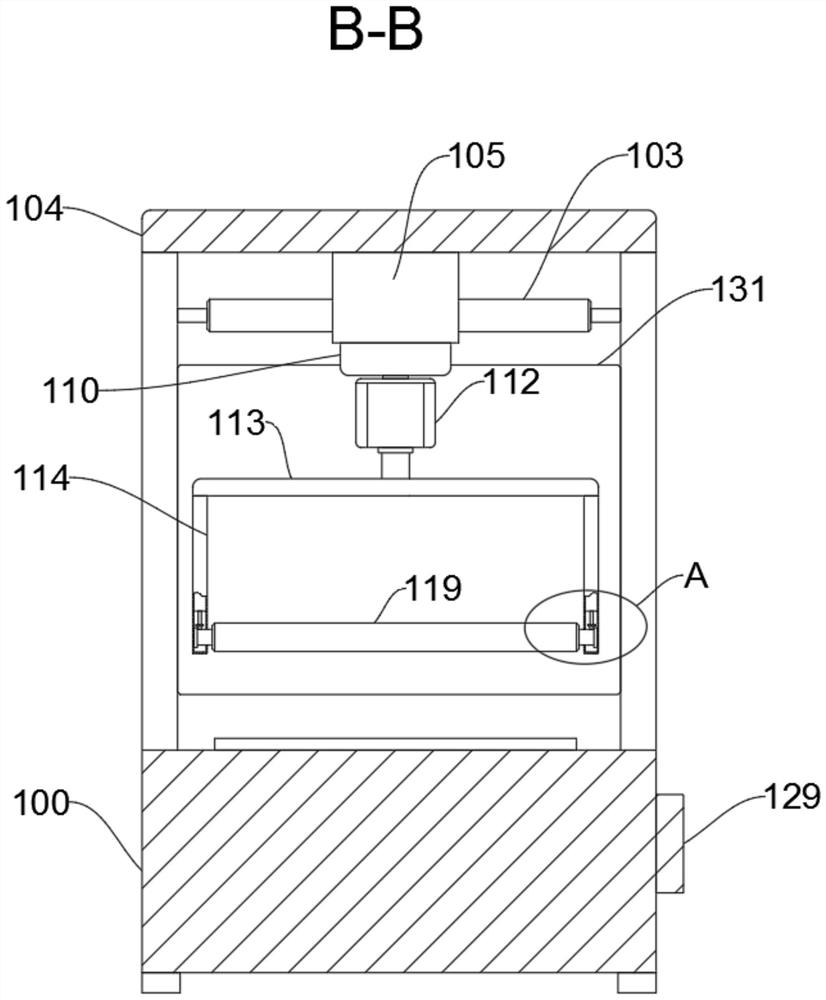

Laminating machine for color box production

InactiveCN110642068AAvoid affecting the coating effectTo achieve the purpose of dust removalLaminationLamination apparatusPaperboardDust control

The invention discloses a laminating machine for color box production. The laminating machine comprises a support, wherein a bottom plate is arranged on the support, mounting plates are arranged on the two sides of the top of the bottom plate, a conveying assembly driven by a motor is arranged between the two mounting plates, a dust removing assembly fixed to the tops of the mounting plates is arranged above the conveying assembly, a gluing assembly fixed to the tops of the mounting plates is arranged on one side of the dust removing assembly, one side of the gluing assembly is provided with an unwinding assembly fixed to the tops of the mounting plates, and one side of the unwinding assembly is provided with a film pressing assembly fixed to the tops of the mounting plates. When the laminating machine is used, a paper board is placed on a conveying belt, the paper board sequentially passes below the dust removing assembly, the gluing assembly, the unwinding assembly and the film pressing assembly in the conveying process of the conveying belt, and dust on the surface of the paper board is removed by a dust removing roller and is blown away by an air blower, so that the purpose ofdust removing is achieved.

Owner:霍山县雁江印务有限公司

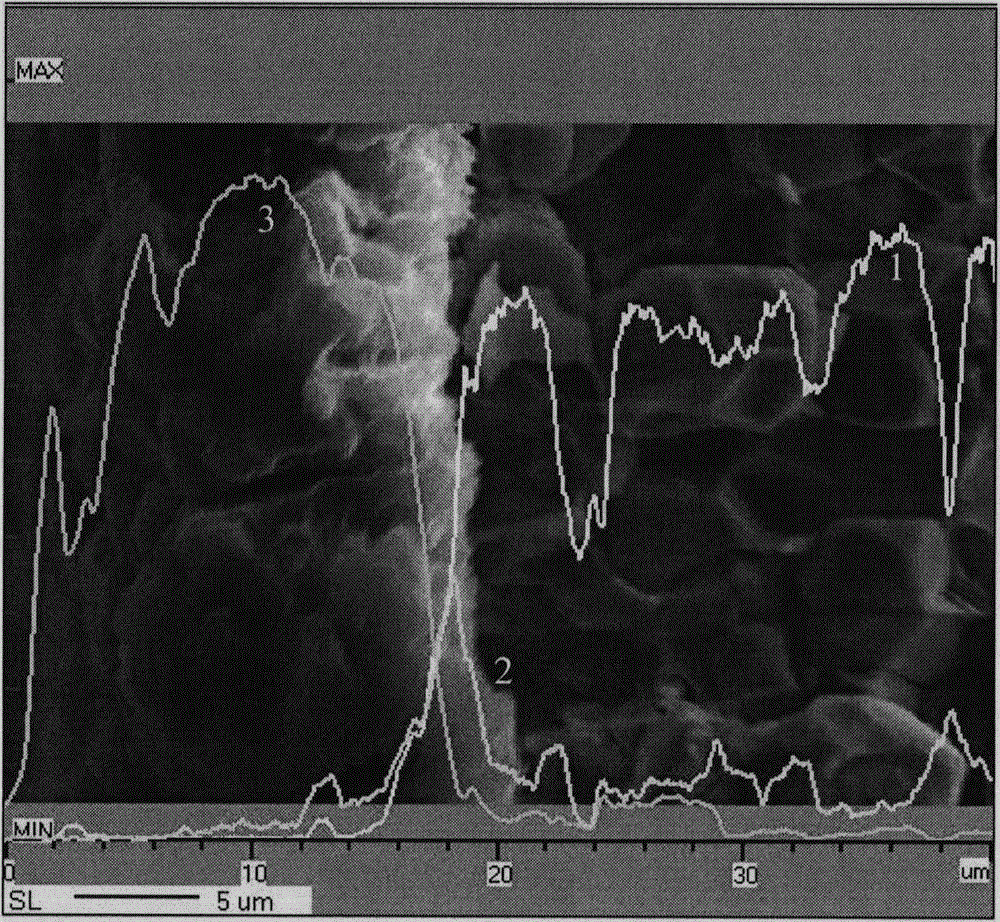

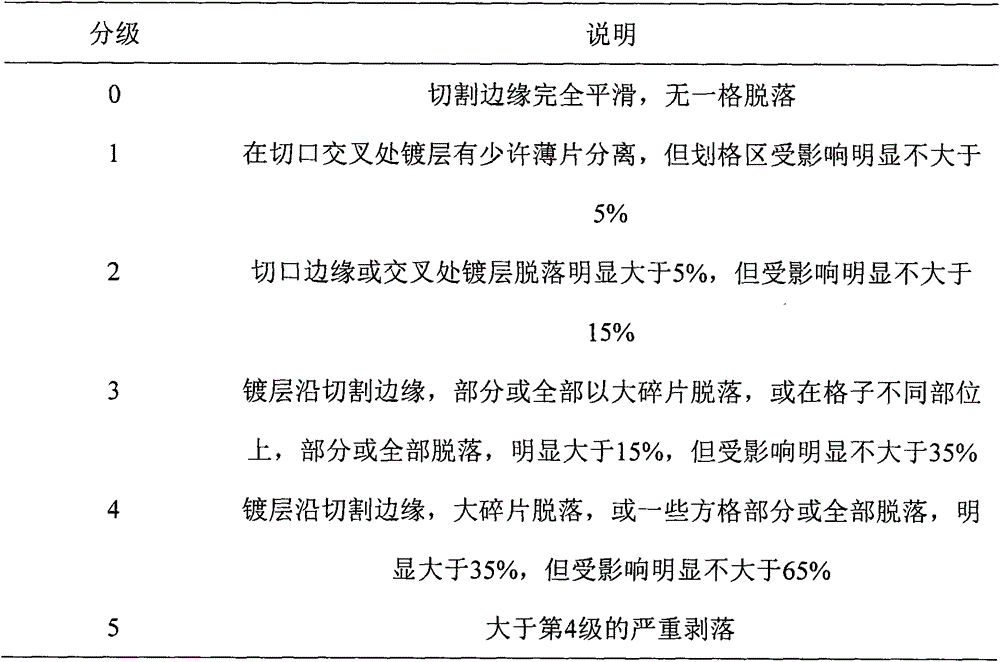

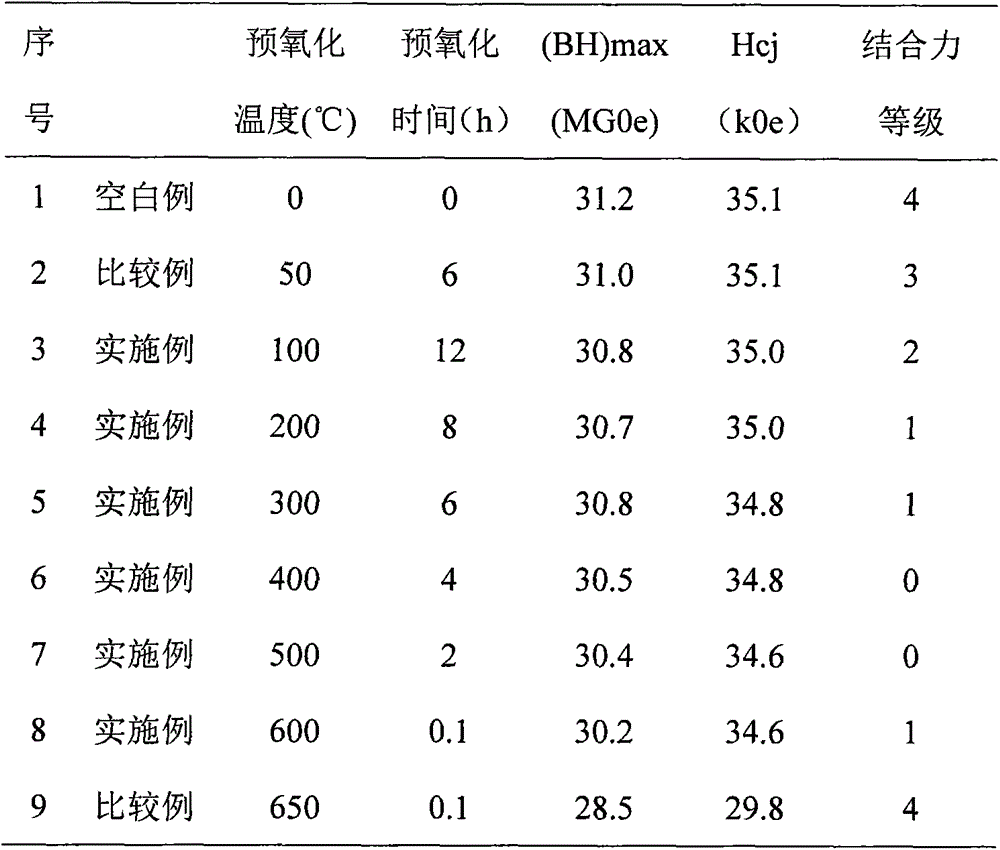

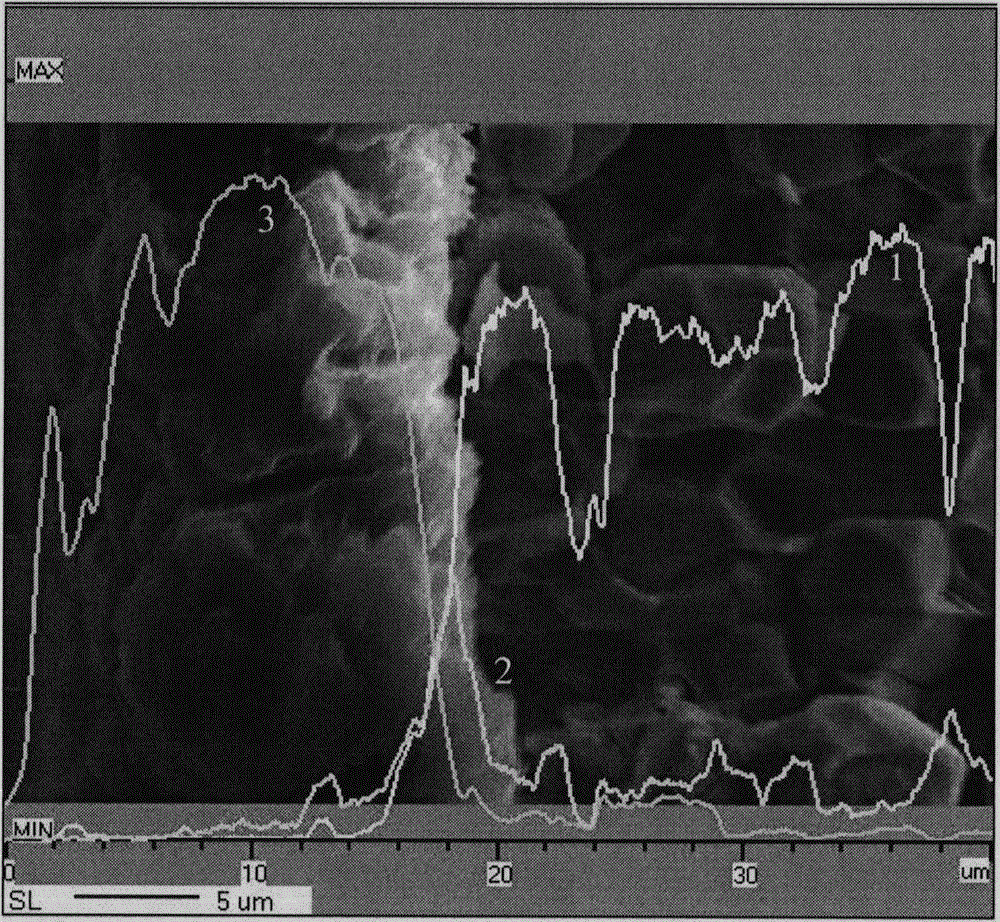

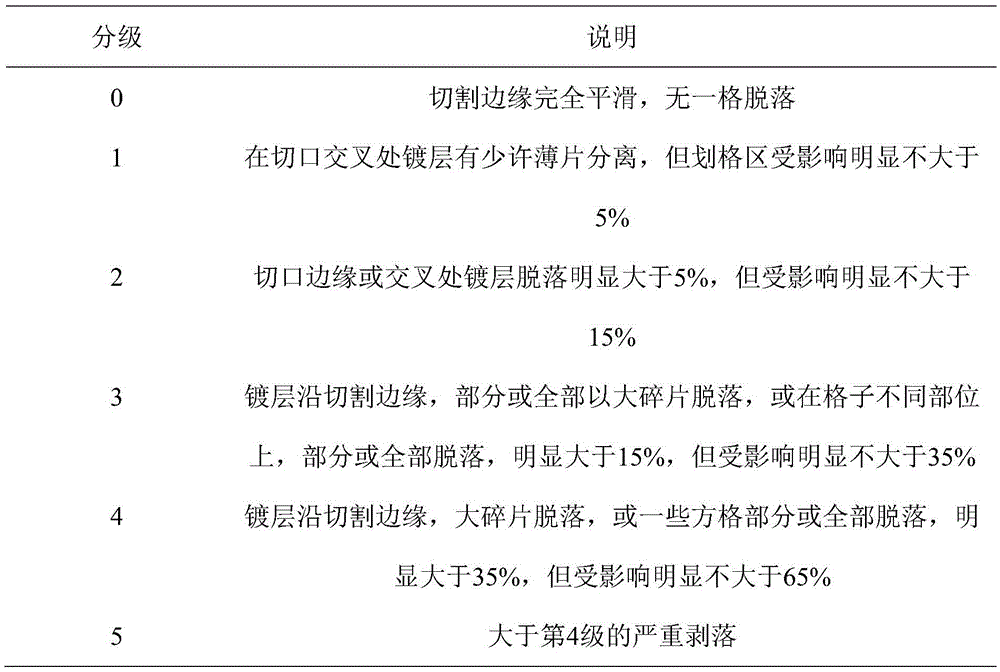

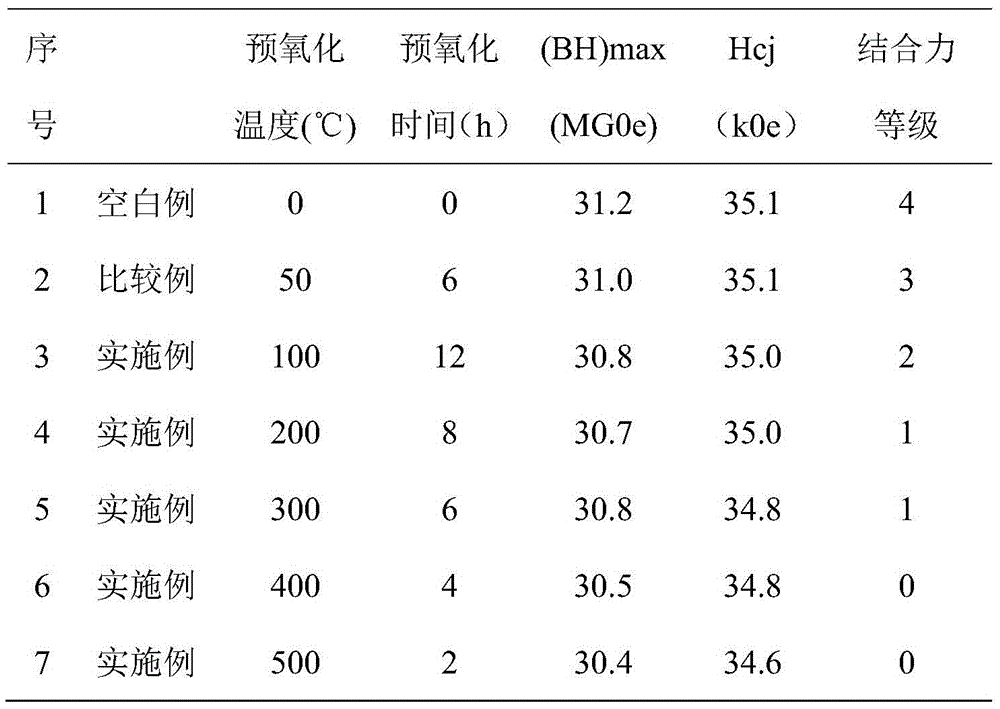

Vacuum evaporation coating method and rare earth magnet covered with evaporation coating

ActiveCN104032263AAvoid excessive oxidationOvercoming the problem of weak bindingVacuum evaporation coatingSputtering coatingRare-earth elementThin layer

The invention discloses a vacuum evaporation coating method and a rare earth magnet covered with an evaporation coating. The method includes steps of: 1) installing a rare earth magnet workpiece to a workpiece rest before pretreatment; 2) sending the workpiece rest into a reaction chamber, and performing preoxidation; 3) sending the workpiece rest to a coating chamber, vacuumizing, heating a meta evaporating material M to an evaporation temperature, and subjecting the rare earth magnet workpiece to evaporation coating; and 4) cooling, restoring to normal pressure and taking the workpiece out. According to the method, the rare earth magnet is subjected to trace oxidation in advance and is subjected to replacement by feeding M steam, thus preventing excessive oxidation of the rare earth magnet, and obtaining a dense MO distribution thin layer and an M layer firmly connected to the MO distribution thin layer.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

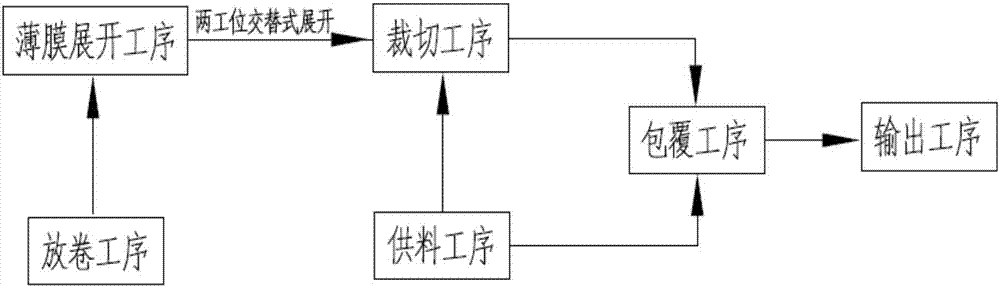

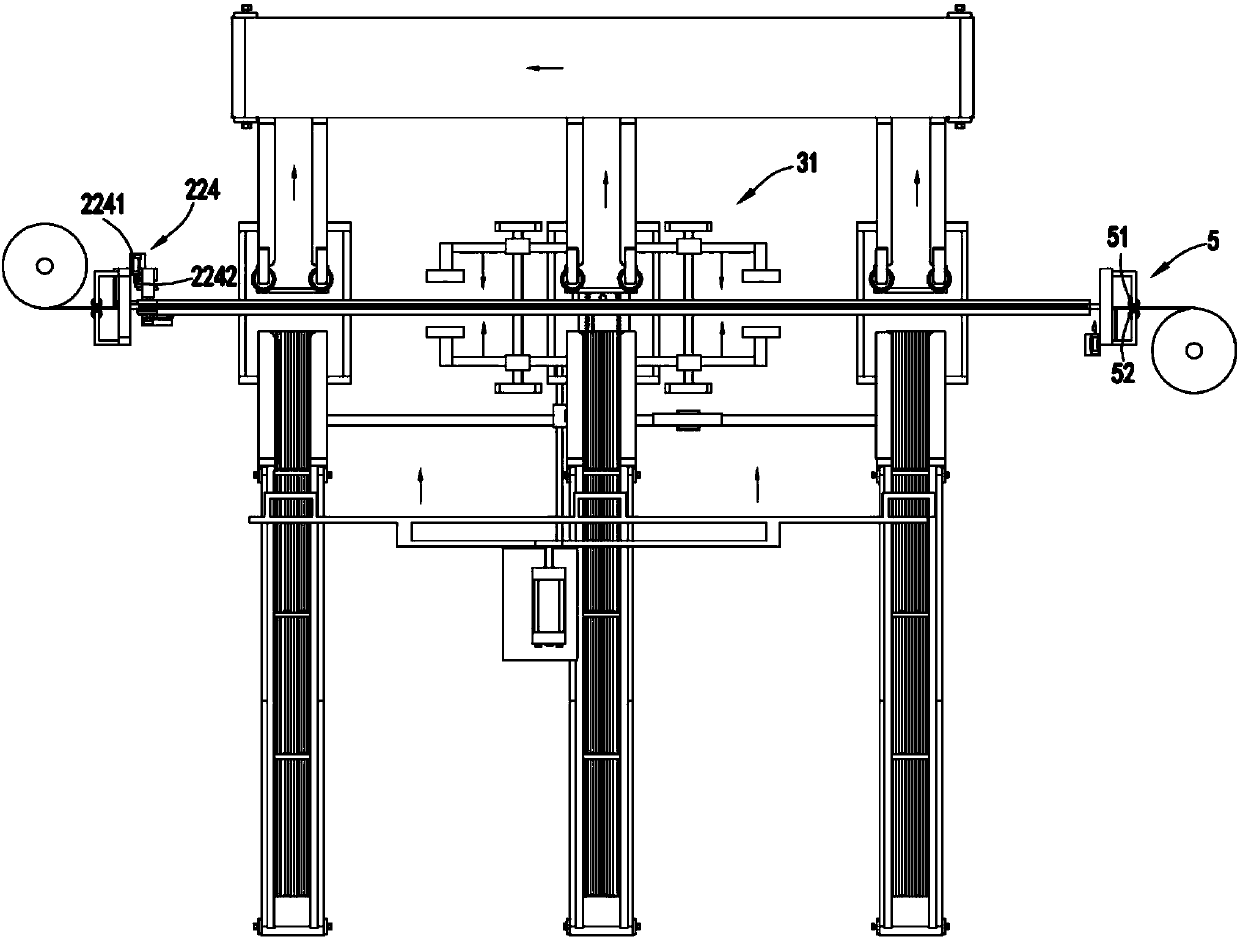

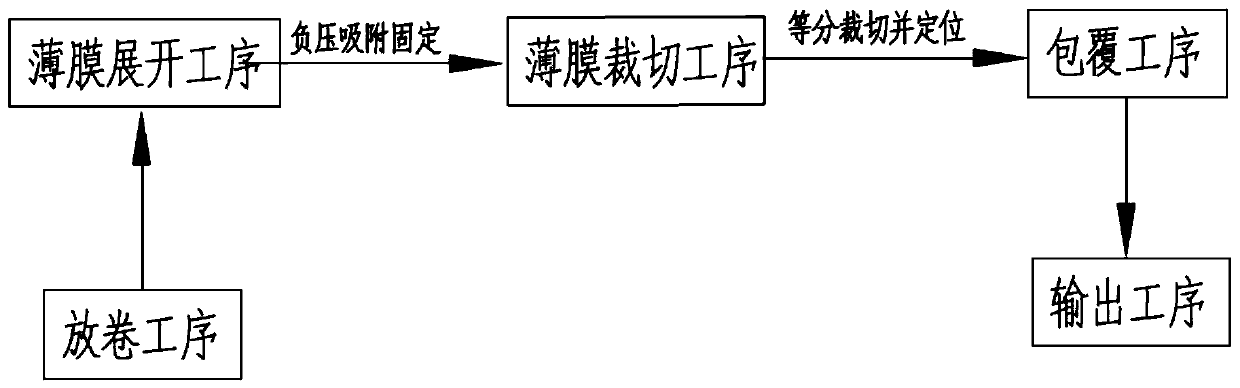

Rapid film coating process for battery pole group

ActiveCN108100336AImprove efficiencySave human effortWrapping material feeding apparatusFinal product manufactureFilm coatingEngineering

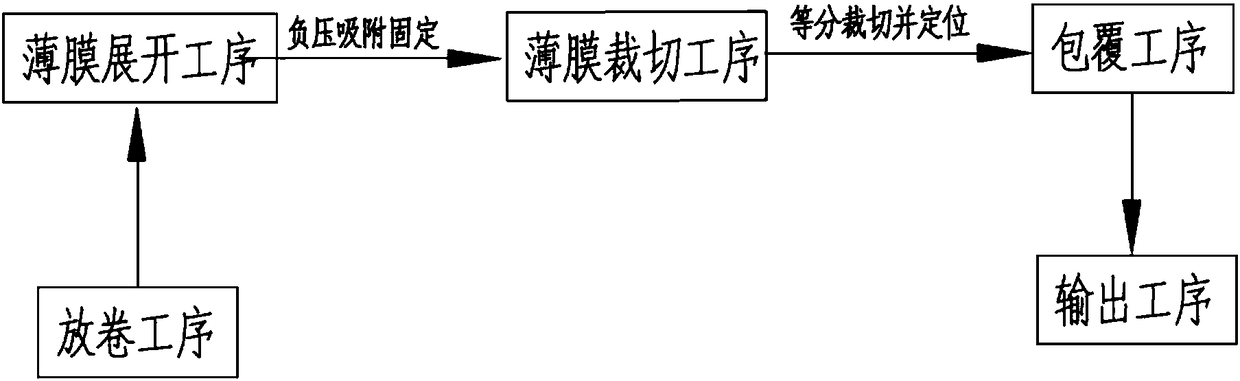

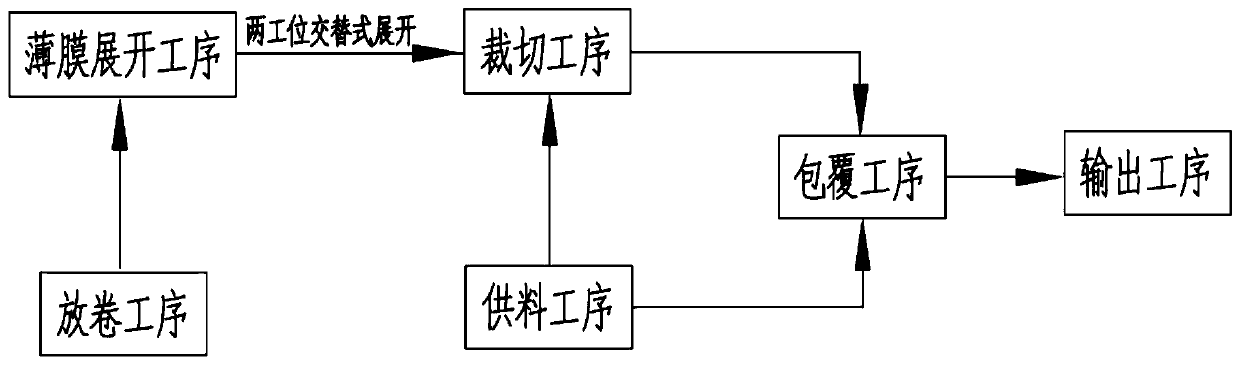

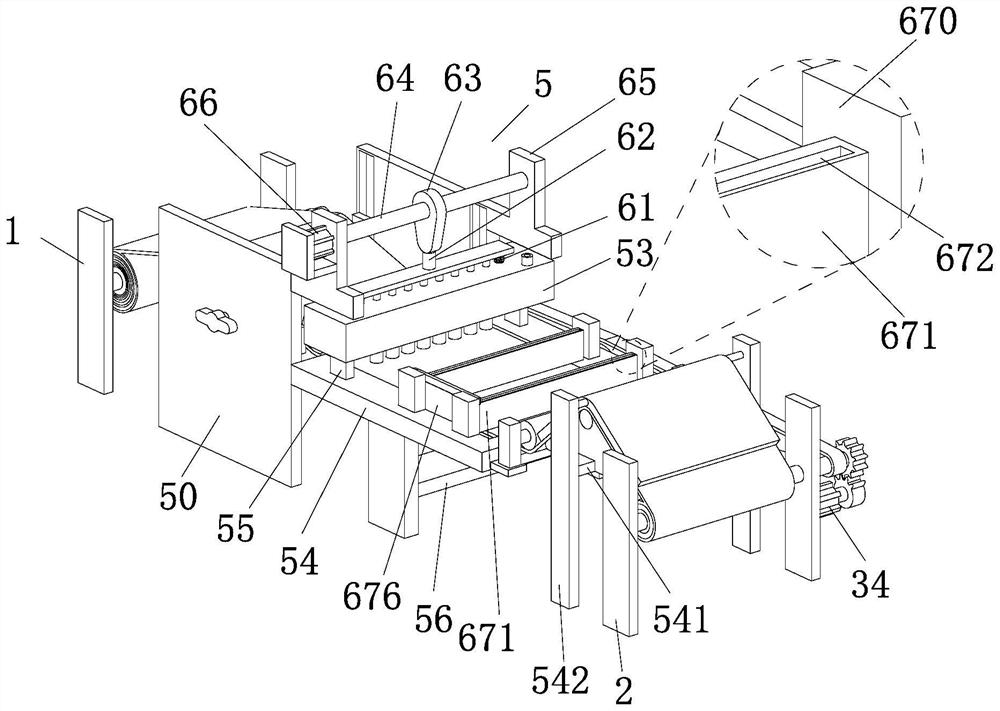

The invention relates to a rapid film coating process for a battery pole group. The rapid film coating process comprises the following steps of 1, an unreeling working procedure; 2, a thin film unfolding working procedure; 3, a thin film cutting working procedure; 4, a film coating working procedure; and 5, an output working procedure. In the step 1, a winding drum thin film is placed on an unreeling station, and a positioning mechanism is used for positioning the end part of a winding drum thin film; in the step 2, an adsorption mechanism is used for fixing the end part of a thin film at thepositioning mechanism and unfolding the thin film along a guide mechanism under the driving of a traction mechanism; in the step 3, the tail end of the thin film is cut off by a transverse cutting mechanism located at the unreeling station, cutting and positioning mechanisms positioned on the two sides of the unfolded thin film are used for equally cutting the thin film and positioning the end ofthe thin film; in the step 4, the film coating working procedure and a pole group located at the film coating station move in the direction of the thin film under the pushing of a material pushing mechanism, and the film coating mechanism is used for coating the thin film on the two sides of the polar group; and in the step 5, the polar group of the coated film is pushed to the output station to be output. According to the rapid film coating process, the problems that an existing polar group coating process is complex in process, low in coating efficiency and poor in coating effect are solved.

Owner:林浩

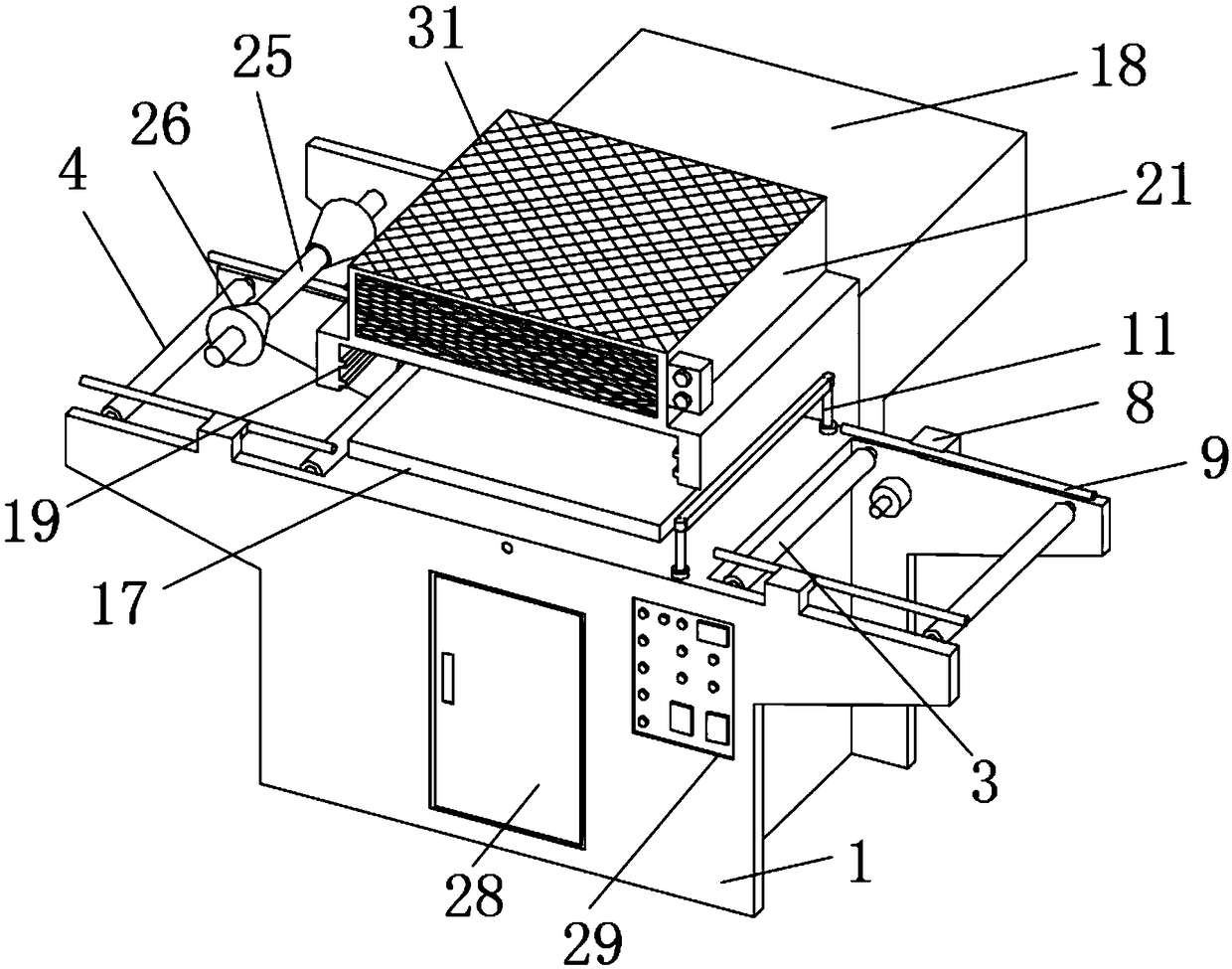

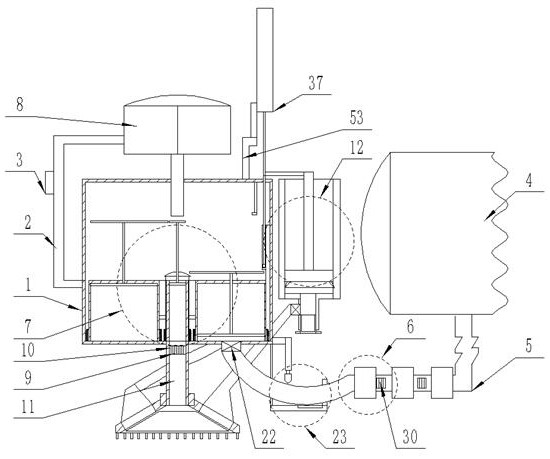

Packaging and film covering device for formed EPS foam board

ActiveCN109130434AImprove lamination efficiencyTimely coolingLamination ancillary operationsLaminationEngineeringVacuum pump

The invention discloses a packaging and film covering device for a formed EPS foam board, and relates to the technical field of foam board processing. The device comprises a machine body; a material feeding roller, a discharging roller and driven rollers are respectively and rotationally connected between opposite inner surfaces of the machine body; a conveying belt is connected to the surfaces ofthe material feeding roller and the discharging roller; vacuum suction holes are formed in one surface of the machine body; the surfaces of the vacuum suction holes communicate with a vacuum pump; one surface of the vacuum pump is fixedly connected with the machine body; one surface of the machine body is fixedly connected with adjustable pipe clamps; and a guide rod is clamped on the inner surfaces of the adjustable pipe clamps. According to the invention, the automatic film covering operation of the film covering device can be realized by the design of the material feeding roller, the discharging roller and material conveying rollers, and the film covering efficiency of the foam board is improved; and through the position design of a cooling box and a heating box, a frame can be cooledin time by a cooling mechanism after a film clamping frame is used, thereby preventing the film clamping frame from affecting the film covering effect.

Owner:丰县建鑫泡沫制品有限公司

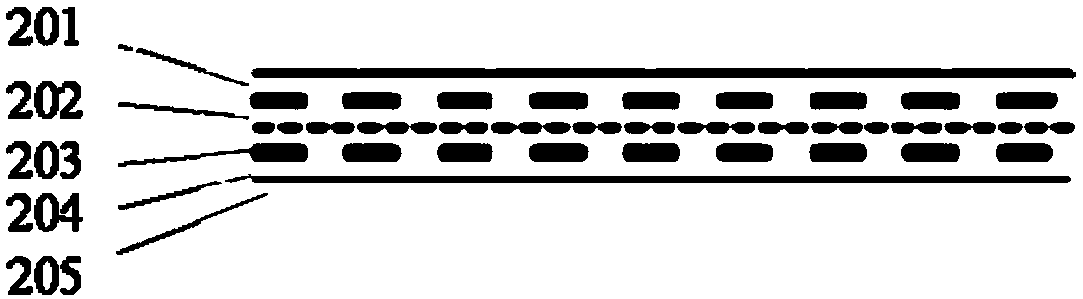

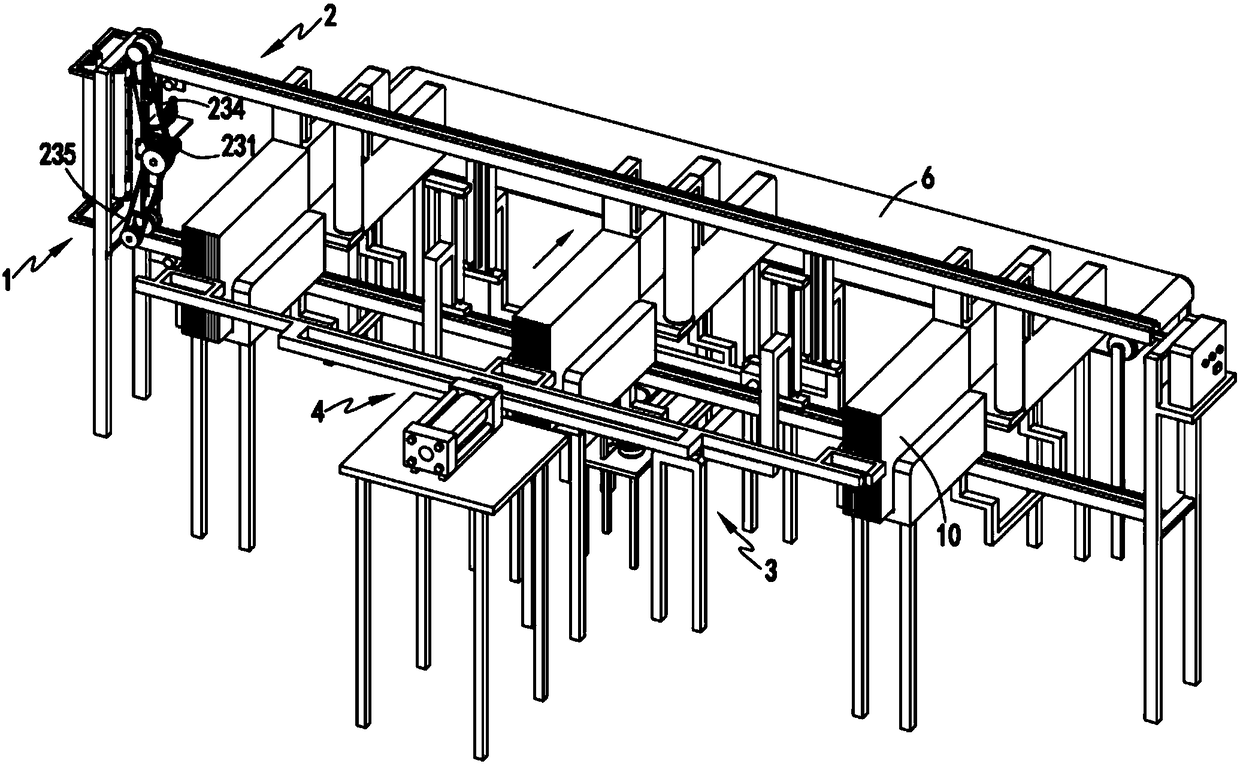

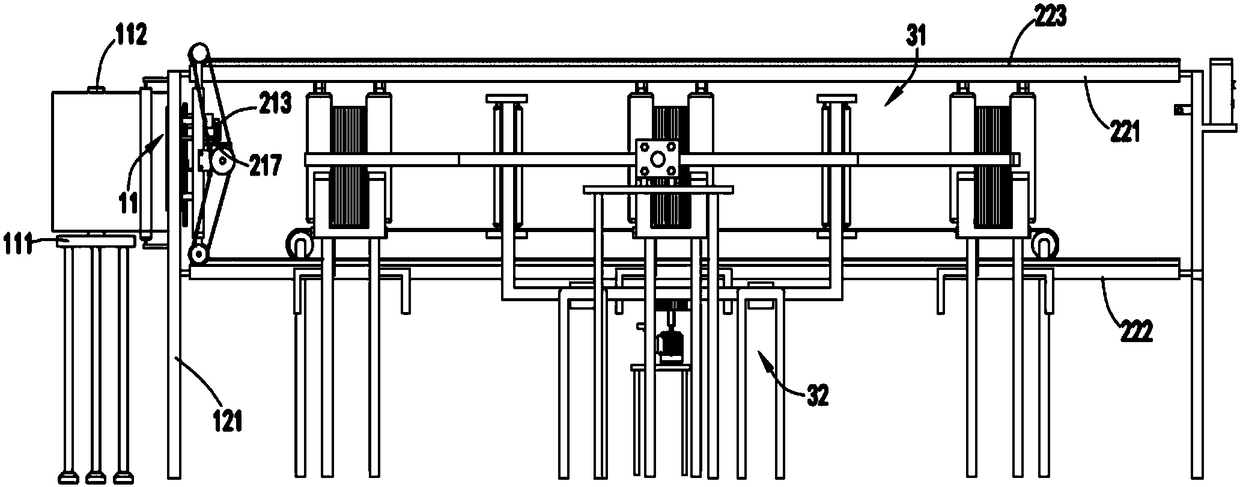

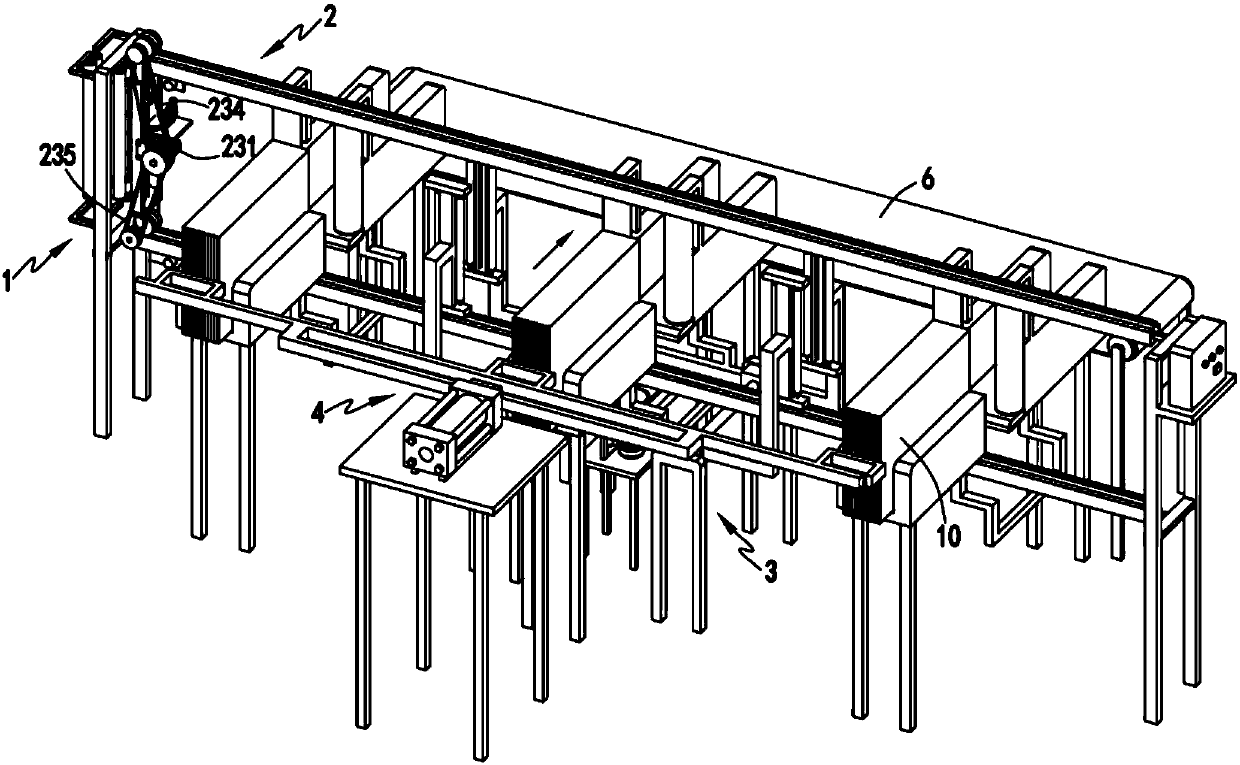

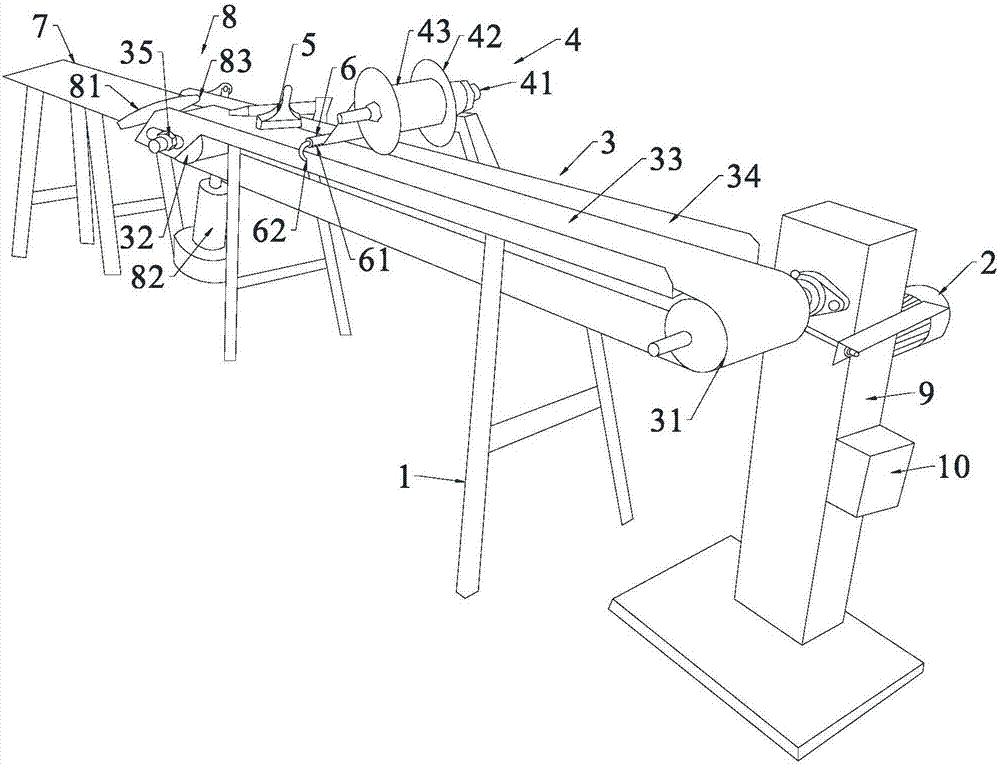

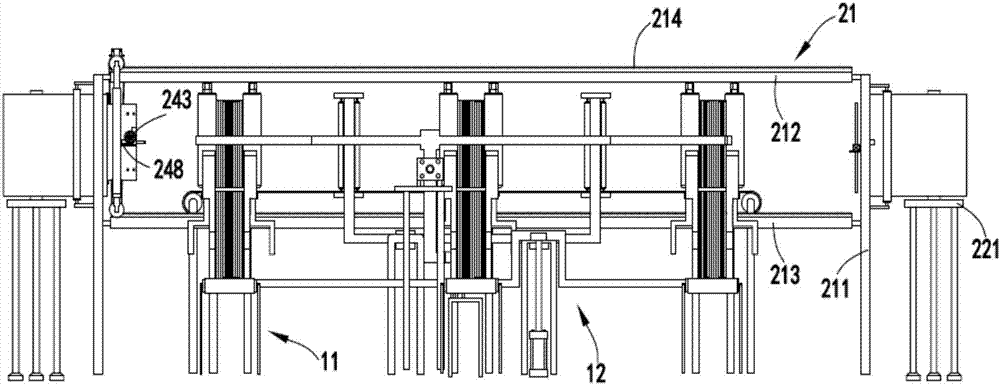

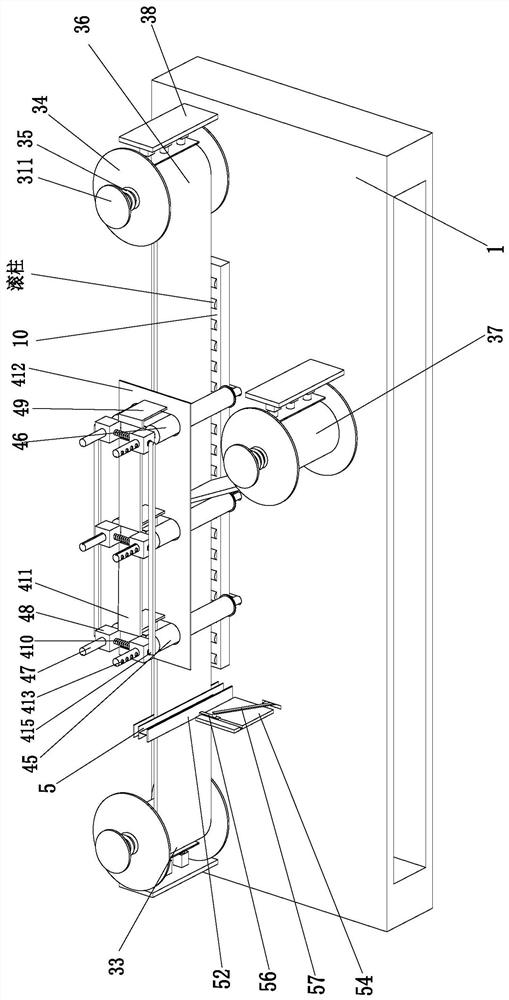

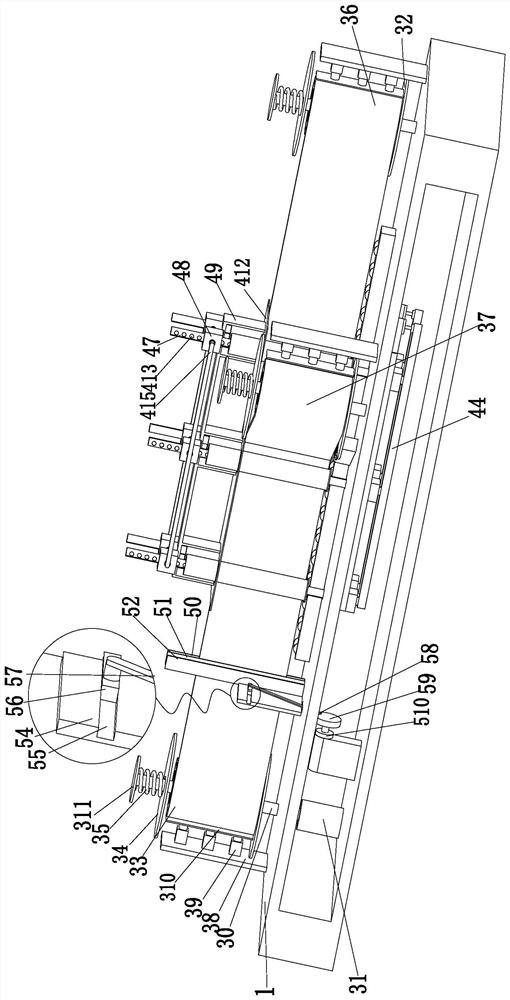

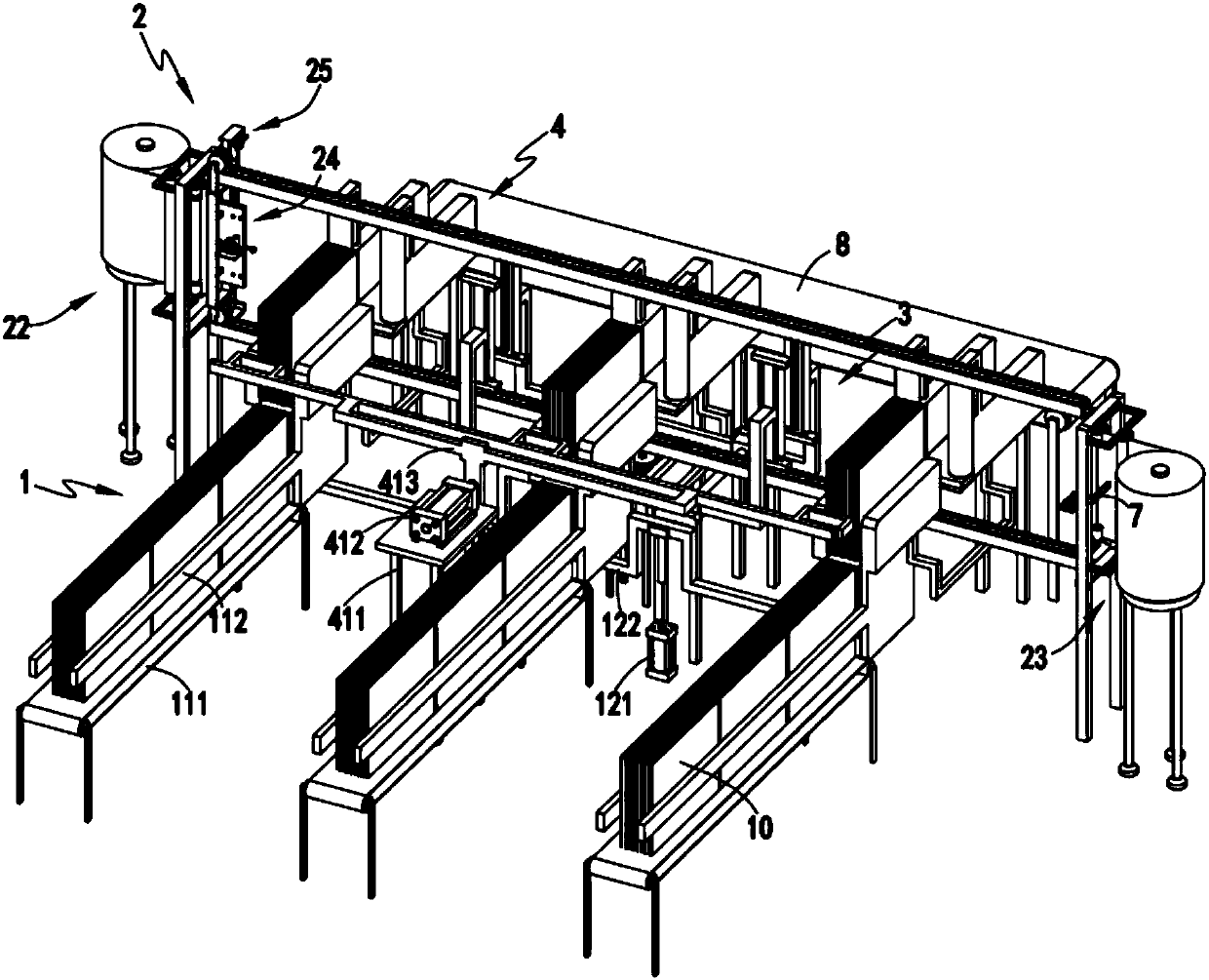

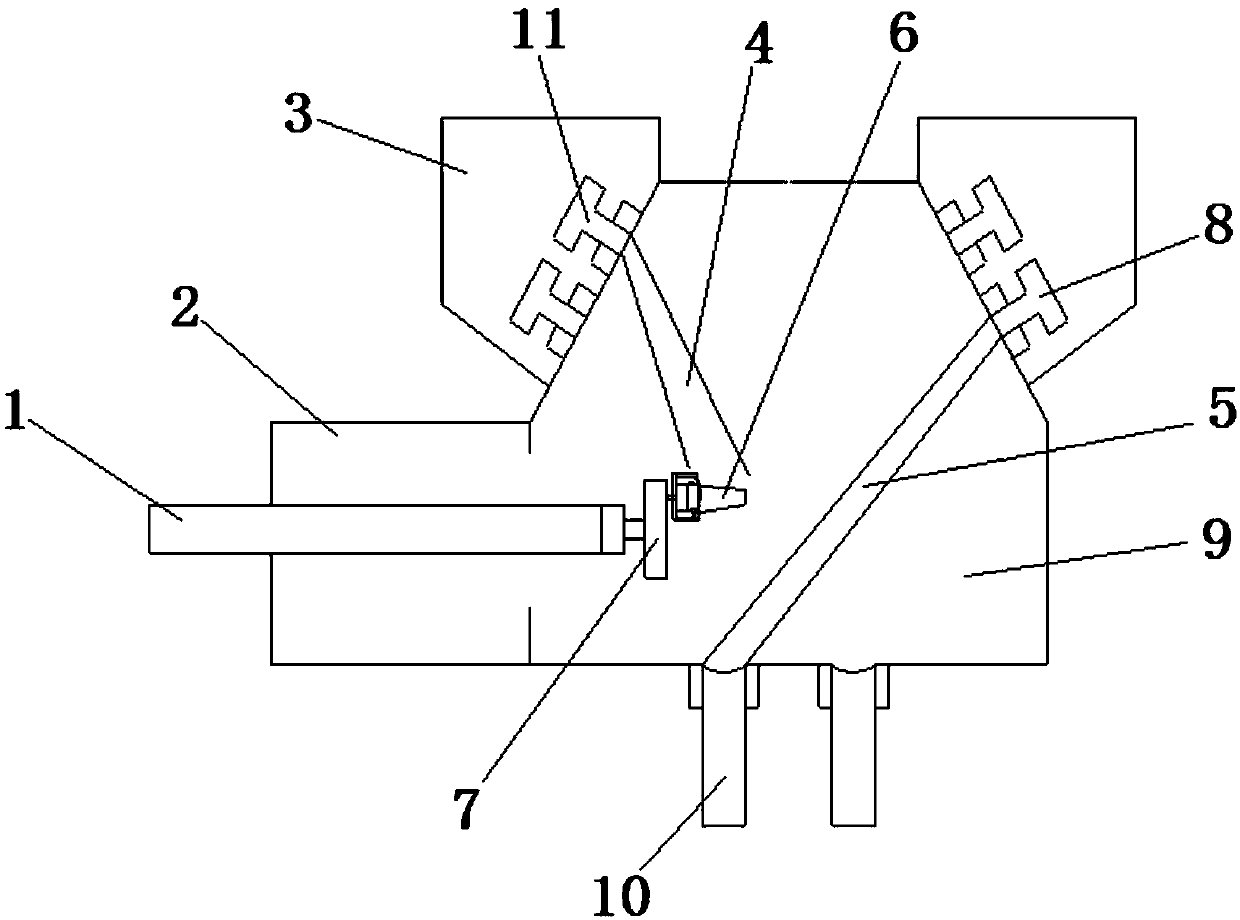

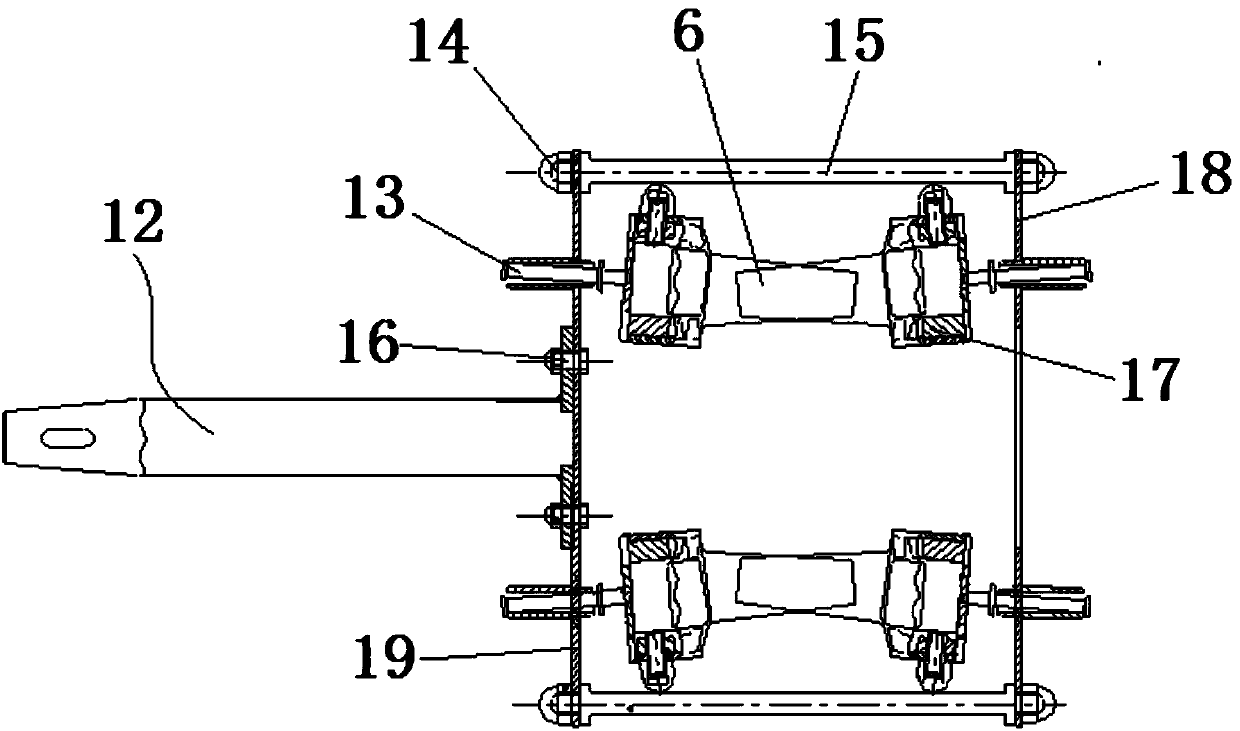

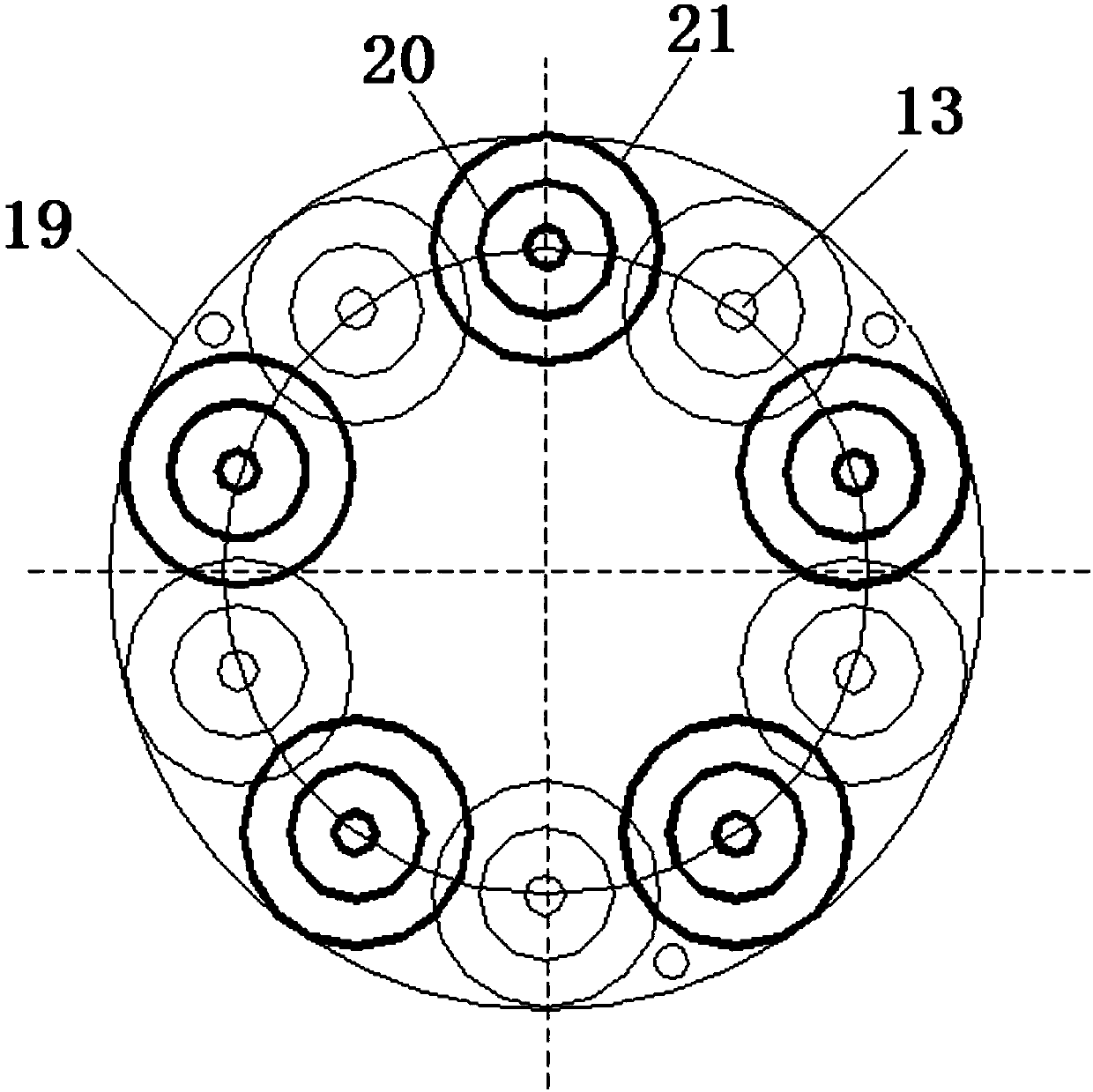

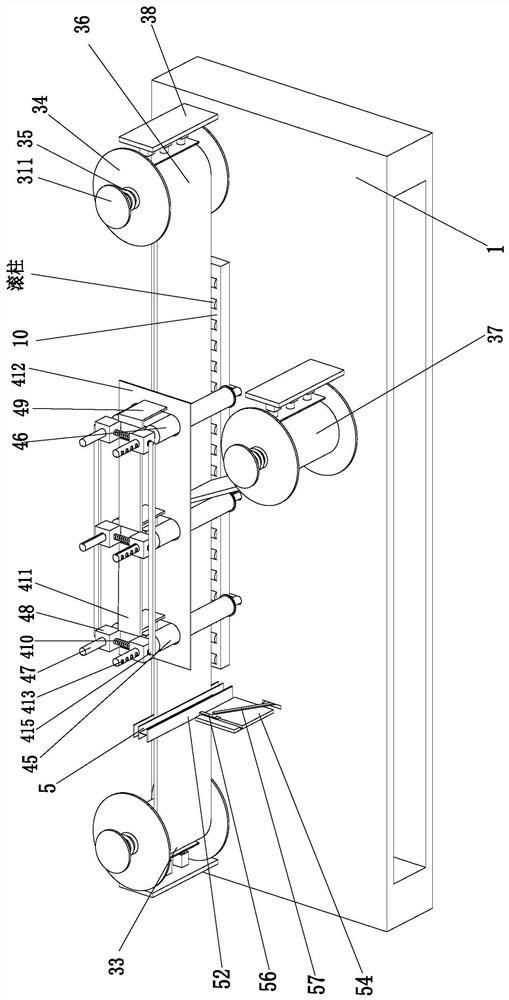

Rapid film wrapping system of battery electrode group

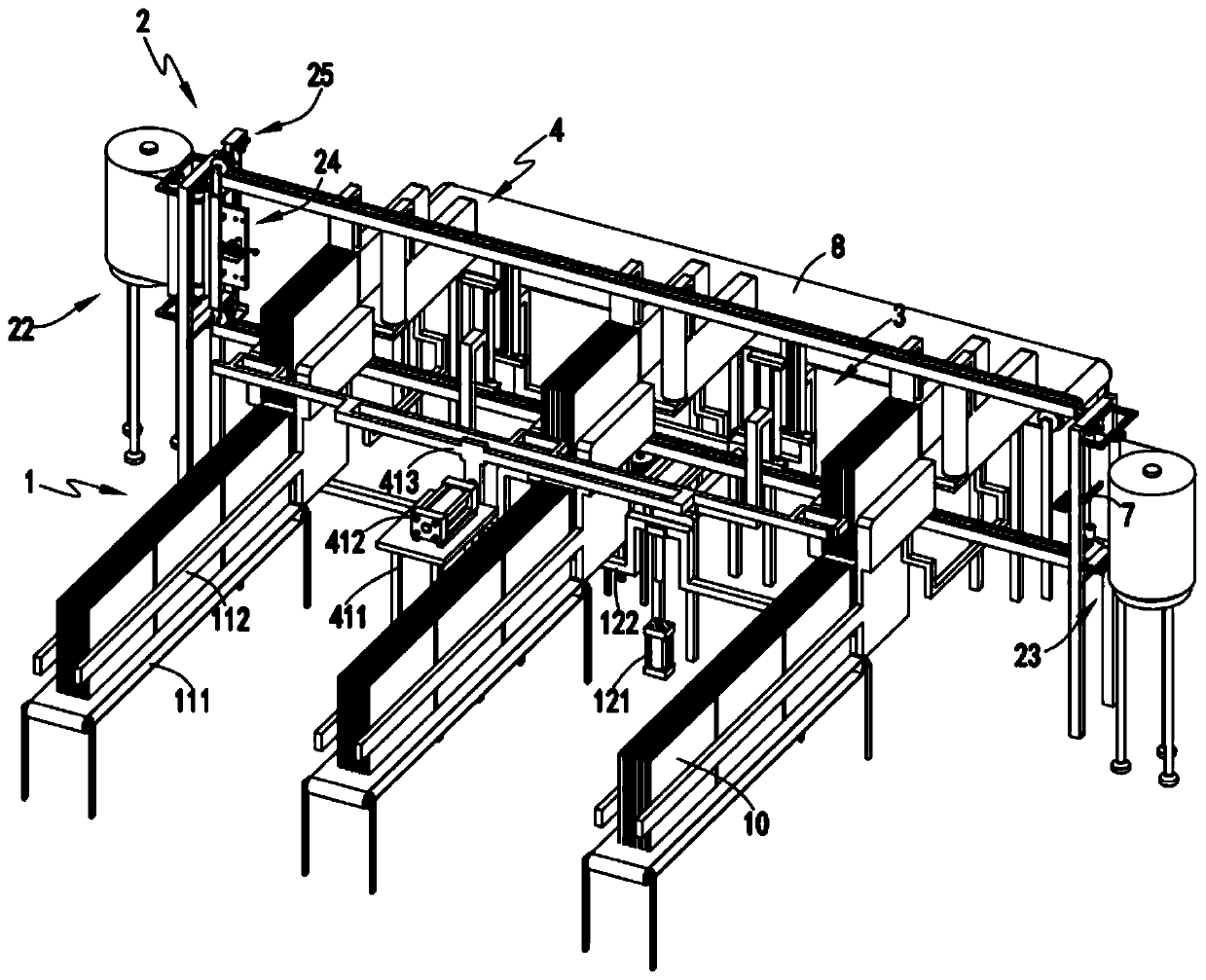

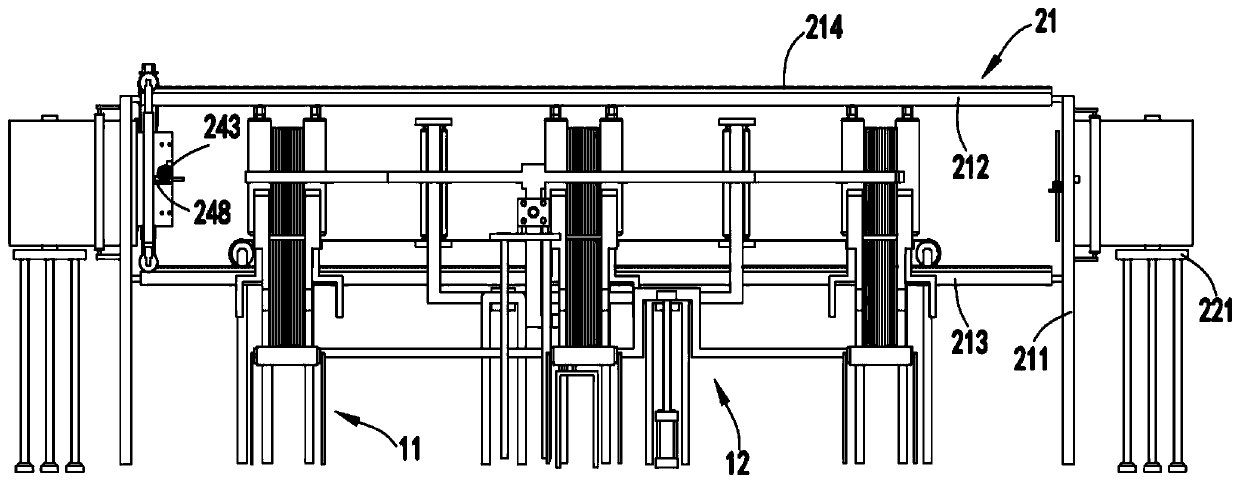

InactiveCN107863548AImprove coating efficiencyGood coating effectFinal product manufactureSecondary cells manufactureEngineeringAutomation

The invention relates to a rapid film wrapping system of a battery electrode group. The system comprises an unreeling device, a film unfolding device, a cutting device and a film wrapping device. Theunreeling device comprises an unreeling mechanism, a positioning mechanism installed on one side of the unreeling mechanism and used for positioning a film end portion, and a transverse cutting mechanism installed on one side of the positioning mechanism. The film unfolding device comprises a guide mechanism, an adsorption mechanism installed on the guide mechanism and performing adsorption on thefilm end portion of the positioning mechanism, and a hauling mechanism used for driving the adsorption mechanism and the film end portion to move along the guide mechanism to unfold a film. The cutting mechanism comprises cutting positioning mechanisms installed on the front side and the rear side of the guide mechanism, and a driving mechanism used for driving the cutting positioning mechanismsto cut the unfolded film at regular intervals. The film wrapping device comprises a material pushing mechanism and a film wrapping mechanism, the material pushing mechanism is used for pushing a to-be-wrapped electrode group to move along the film wrapping mechanism, and cooperating with the film wrapping mechanism to finish the film wrapping. The rapid film wrapping system solves the problems oflow efficiency of the electrode group film wrapping, the difficulty of achieving automation, and low quality of the film wrapping.

Owner:阜阳洁平日化有限公司

Laminating device for cover plate of injection-molded electric energy metering box

PendingCN107284735AAvoid safety hazardsImprove lamination efficiencyPackagingAgricultural engineeringInjection moulding

The embodiment of the invention discloses a laminating device for a cover plate of an injection-molded electric energy metering box. The laminating device comprises a rack, a power mechanism, a cover plate conveying mechanism, an uncoiling mechanism, a soothing mechanism and a shearing mechanism, wherein the power mechanism, the cover plate conveying mechanism, the uncoiling mechanism, the soothing mechanism and the shearing mechanism are all arranged on the rack. According to the laminating device, one end of a film is attached onto the cover plate on a cover plate transport mechanism, meanwhile, the power mechanism drives the cover plate transport mechanism to convey the cover plate, the cover plate is continually conveyed forwards, the film continually covers the cover plate which is conveyed forwards, a certain residual temperature of the cover plate subjected to primary processing is maintained, the inner layer of the film has a certain adhesive force, the film and the cover plate are tightly attached to each other without additionally arranging a pre-heating part to pre-heat the cover plate, the whole lamination process is continually and efficiently carried out, the lamination efficiency is greatly improved, and the manual labor is saved.

Owner:HANGZHOU PUAN TECH

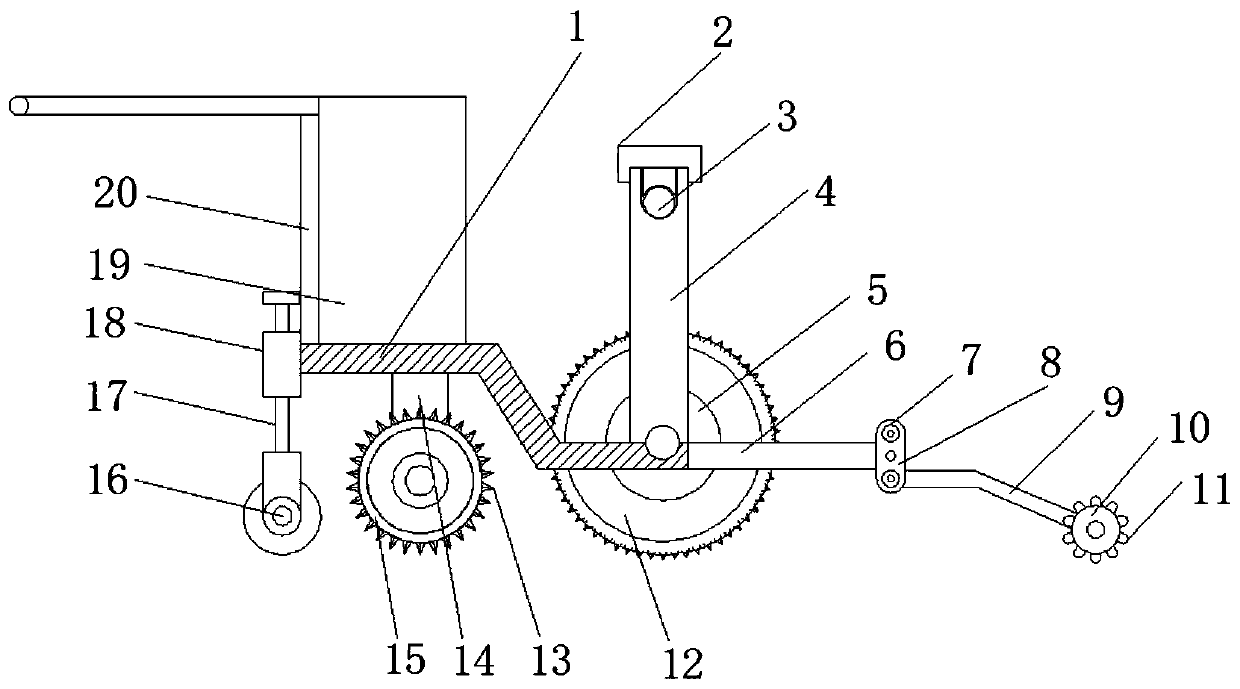

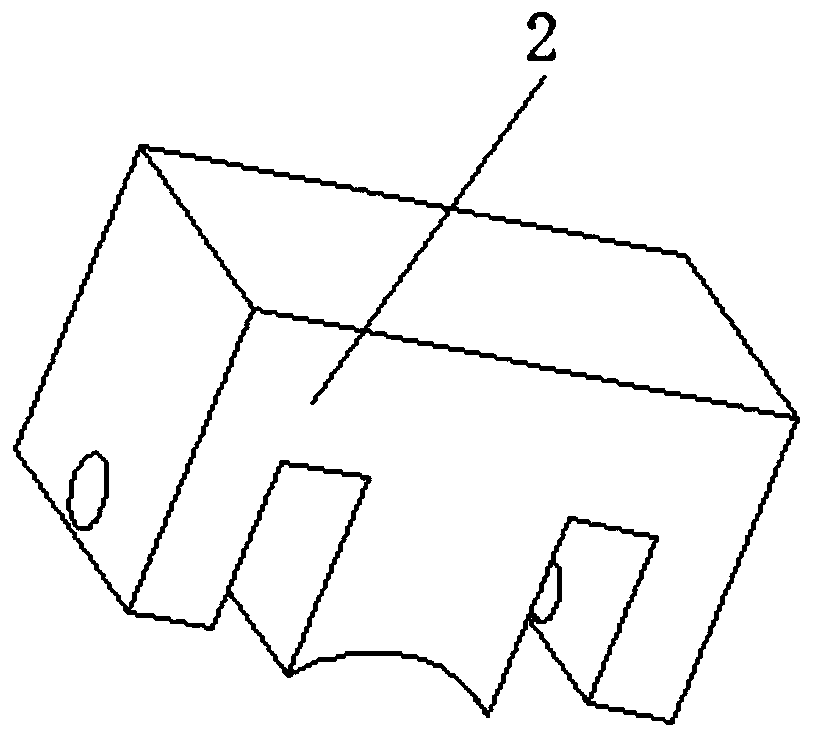

Mulching film laying device for agricultural production

InactiveCN111543228AAvoid affecting the coating effectImprove laying qualityPlant protective coveringsAgricultural scienceDrive wheel

The invention discloses a mulching film laying device for agricultural production, relates to the technical field of production tools, and aims to solve the problem that the mulching film laying efficiency and quality are affected as a mulching film laying device is prone to being damaged by soil blocks in a laying process. The device specifically comprises a rack; an operating handle of an L-shaped structure is fixedly installed at the top end of the rack; a rectangular groove is formed in the other side of the top end of the rack; vertically-arranged supporting frames are fixedly installed on the two sides of the top end of the rack; and driving motors are fixedly installed on the two sides of the rack. The direction of the device is grasped through the operating handle; the device is driven to move through the driving motors and driving wheels; a mulching film is slowly loosened in the moving process, and then mulching film laying is completed; and in the moving process of the device, a flattening roller can neaten the passing ground to press down and flatten the protruding soil blocks, so that the influence of mulching film breakage caused by sharp bulges on the mulching effectis avoided.

Owner:烟台晨烨环保节能科技有限公司

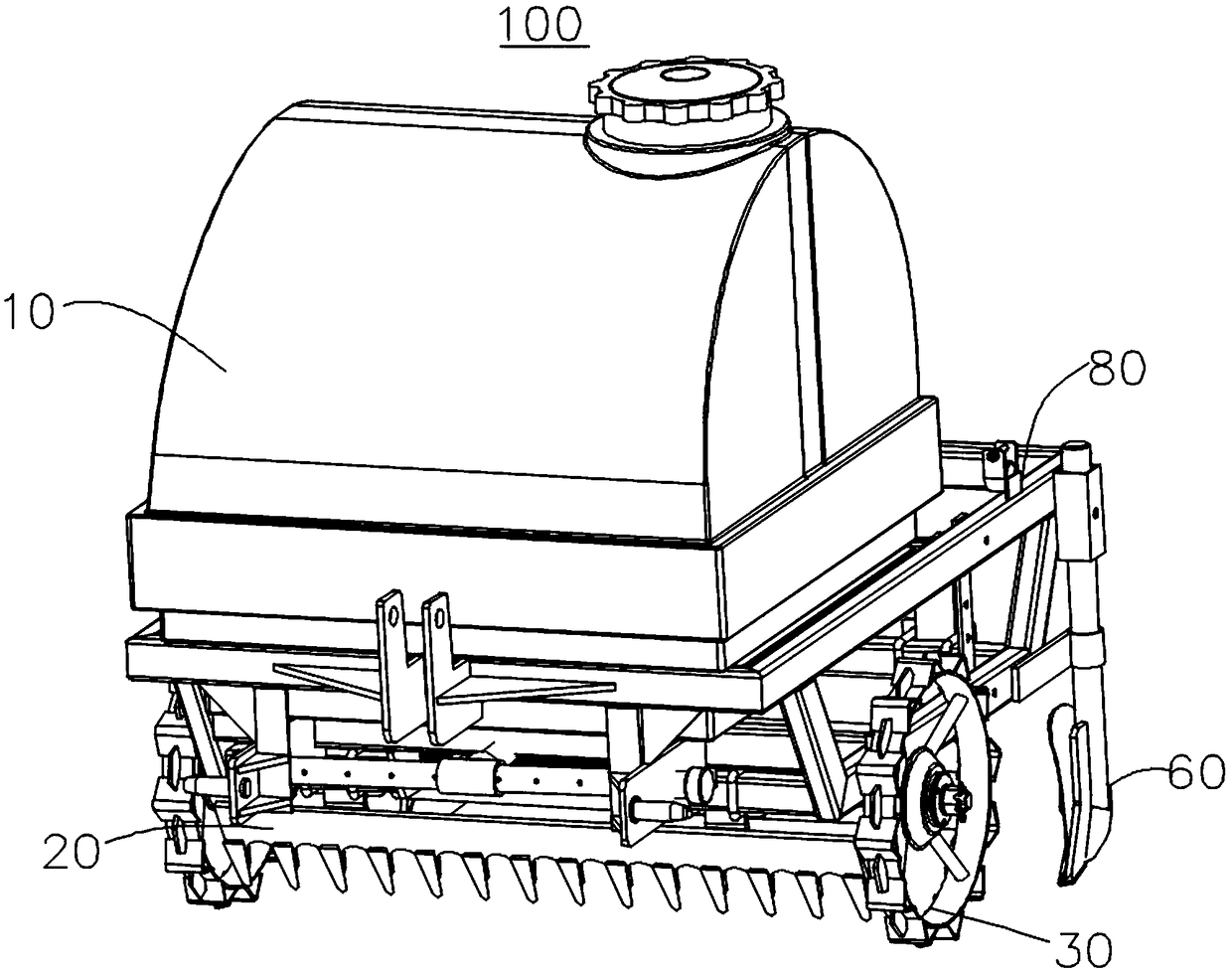

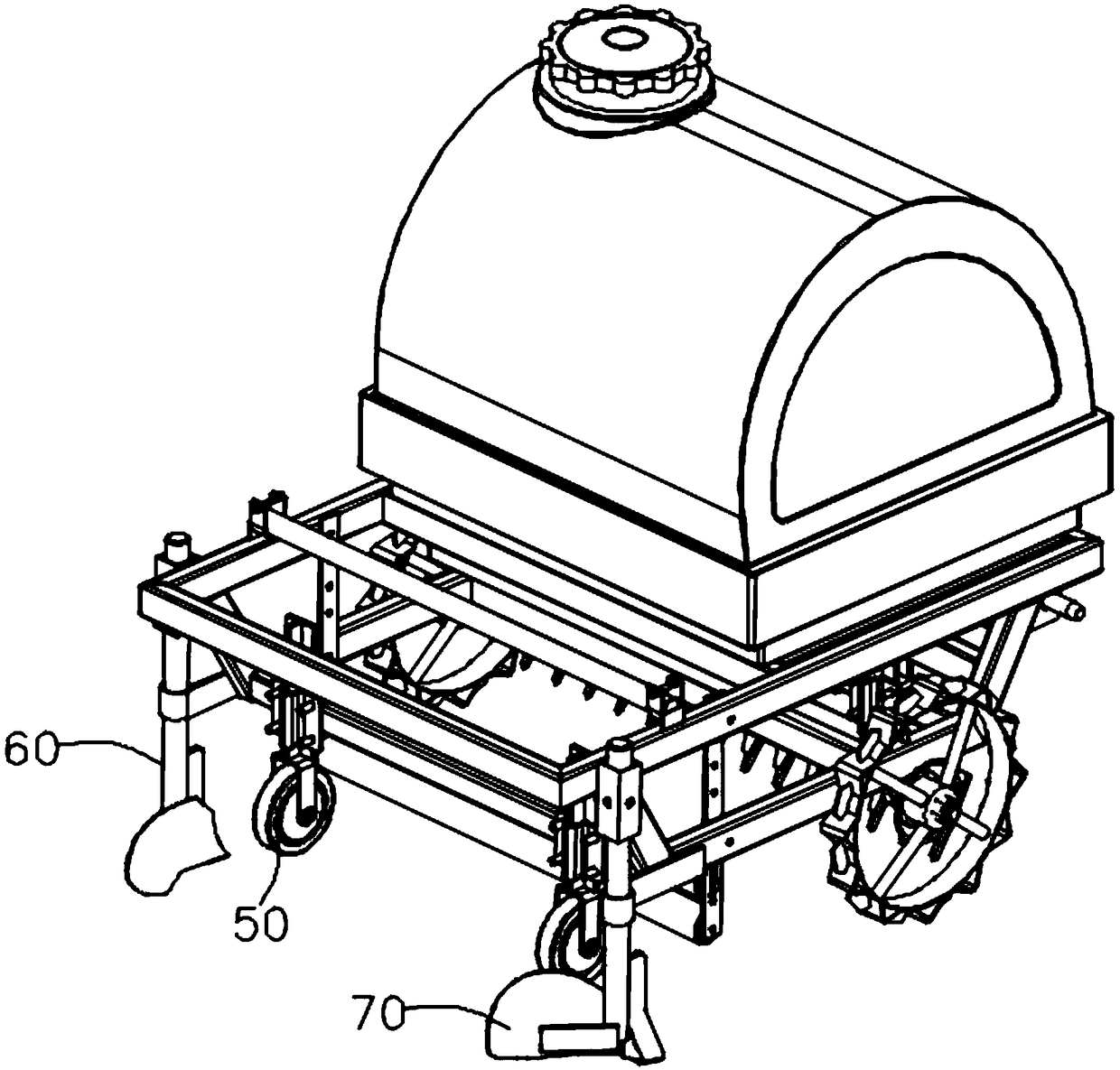

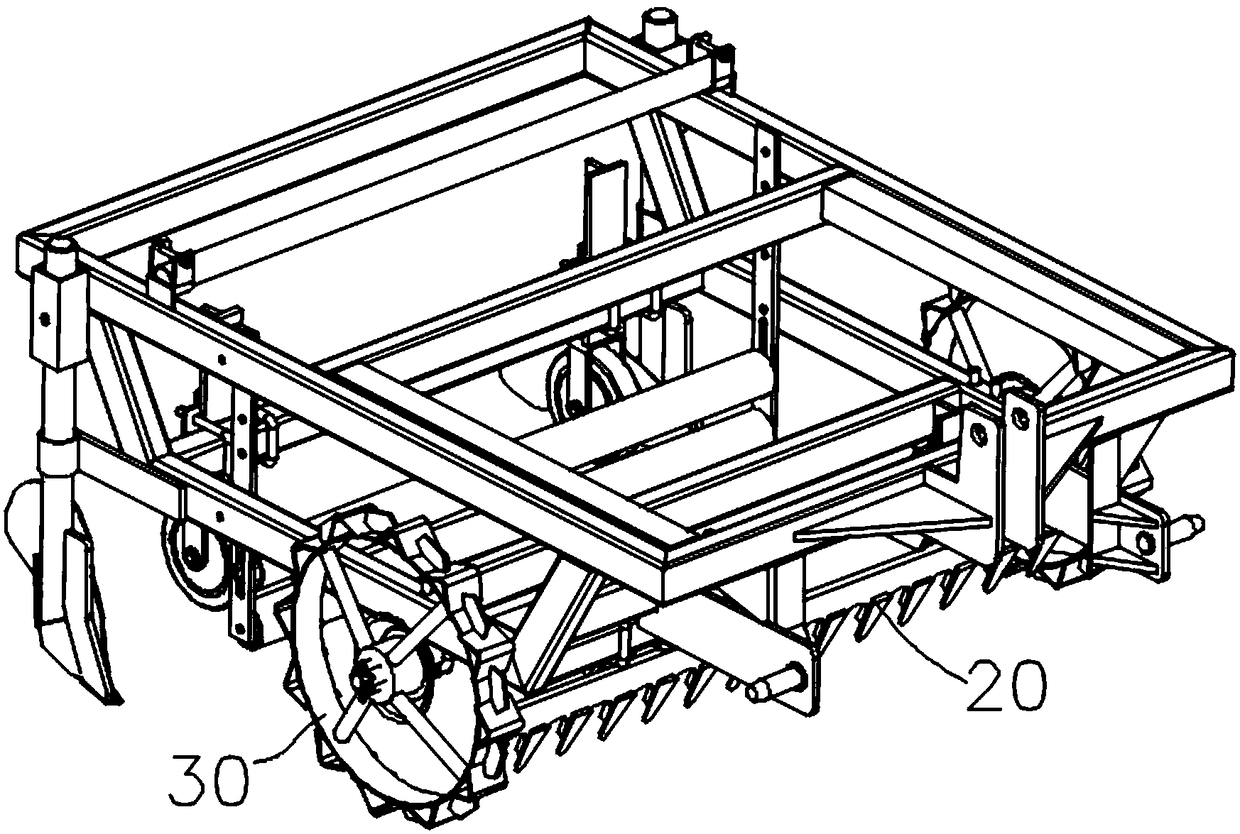

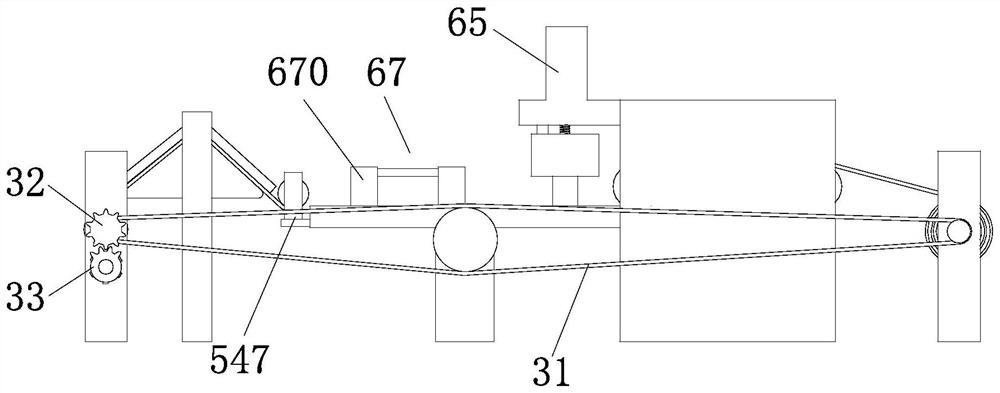

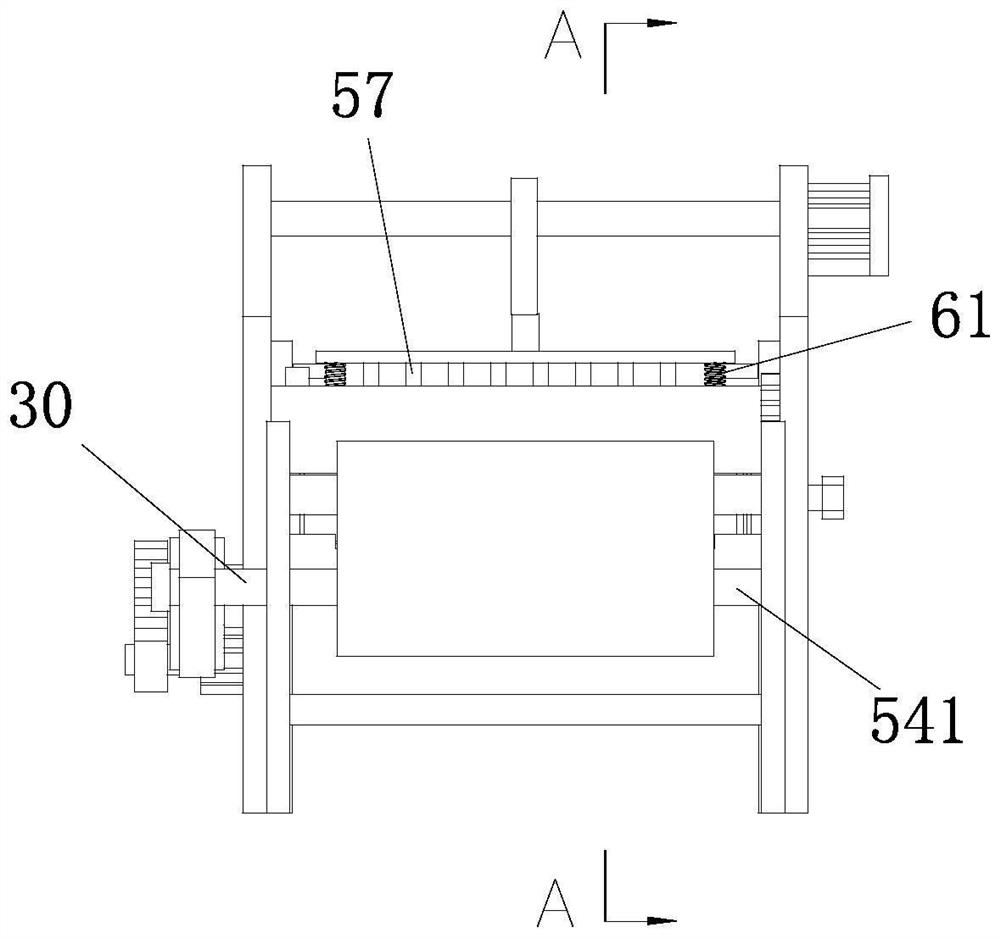

Film mulching seeder

The invention provides a film mulching seeder. The film mulching seeder comprises a watering structure, a ploughing structure, a land walking structure, a film mulching structure, a mulching film compression structure, a first soil shoveling structure, a second soil shoveling structure and a support, wherein the watering structure comprises a water tank, a first water pipe, a control valve and a second water pipe, and a plurality of watering holes are formed in the second water pipe; the ploughing structure comprises a plurality of triangular ploughing harrow teeth; the land walking structurecomprises two land walking wheels, two first withstanding pieces and two first compression plates; the film mulching structure comprises a mulching film installation roller, two fixing plates and twofilm mulching rollers; the mulching film compression structure comprises two first connecting pieces, two compression wheels and two second compression pieces; the first soil shoveling structure comprises a second connecting piece, a soil retaining piece and an arc-shaped soil shoveling piece. Seeds are scattered into loose soil, a plastic film is wound around the two film mulching rollers and attached to the soil, the compression wheels make the film tightly attached to the soil, and multiple processes comprising seeding, fertilization, irrigation, film mulching, earthing on the film and thelike can be completed through one-time operation.

Owner:广西驰胜农业科技有限公司

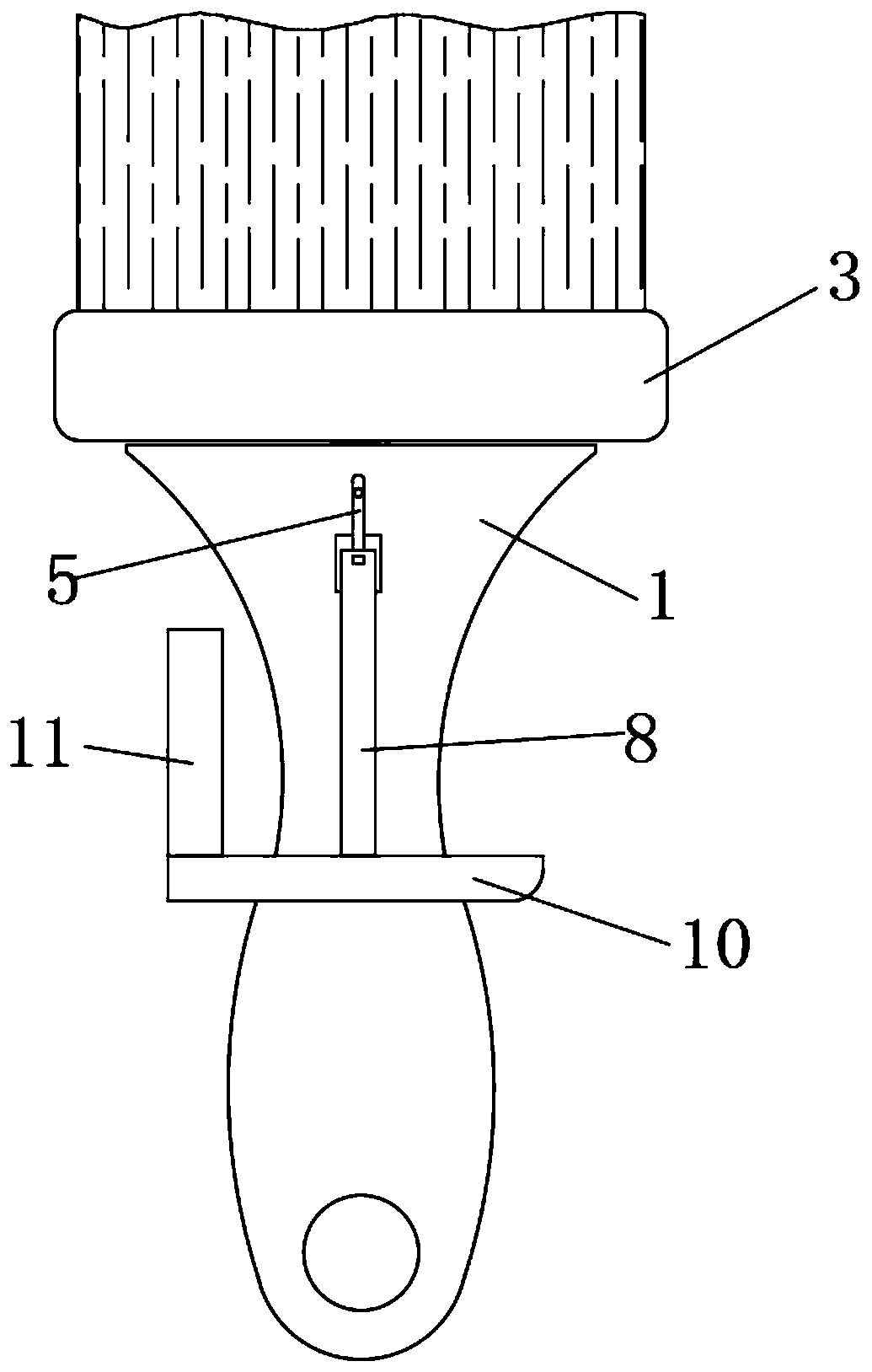

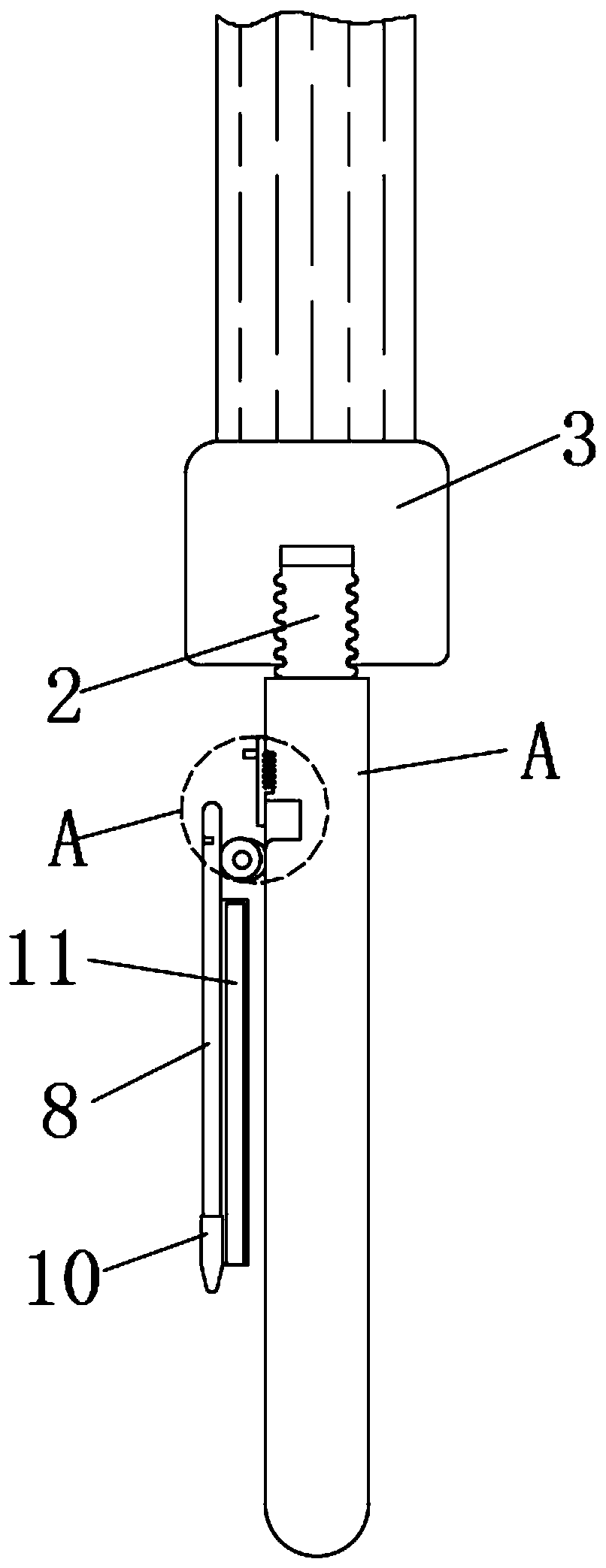

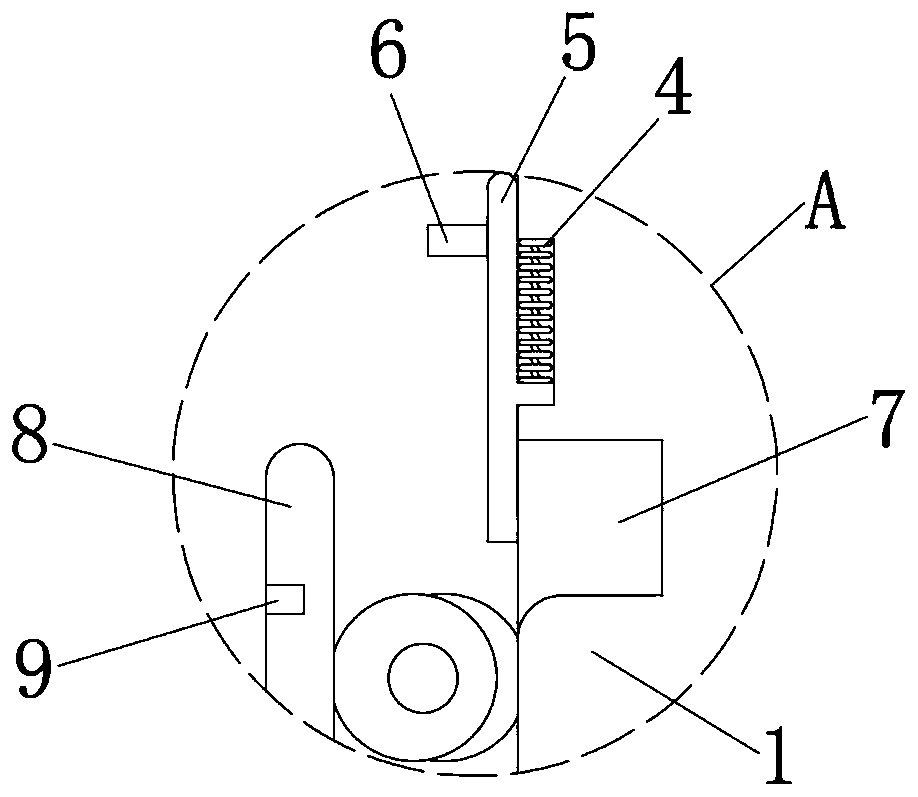

Paint brush with scraping structure

InactiveCN110811126AReduce replacement costsAvoid getting dirtyBristle carriersWorking environmentEngineering

The invention discloses a paint brush with a scraping structure. The paint brush with the scraping structure comprises a brush handle and a brush head; a threaded head is fixedly installed on the upper end of the brush handle; furthermore, the threaded head is inserted into the lower end of the brush head; a spring is fixedly arranged in the upper side of the front end of the brush handle; furthermore, one end of the spring is fixedly connected with a back protrusion block of a limiting block; a fixed block is fixedly installed on the front end of the limiting block; an empty groove is formedin the front end of the brush handle; the front end of the brush handle is hinged with a support rod; furthermore, a limiting groove is formed in the support rod; a scraping plate is welded on the lower end of the limiting groove; and furthermore, an accumulated solution groove is fixedly installed at the back of the left end of the scraping plate. According to the paint brush with the scraping structure in the invention, due to arrangement of the scraping plate, droplets on the surface of an object can be scrapped through the scraping plate, so that the problem that a coating effect is influenced by the droplets is avoided; furthermore, when being scrapped by the scraping plate, the droplets can slide down along with the scraping plate; the accumulated solution groove can receive drippingpaint below the scraping plate; and thus, accumulated paint on the scraping plate is prevented from dripping and dirtying a working environment.

Owner:靖江市新航制刷厂

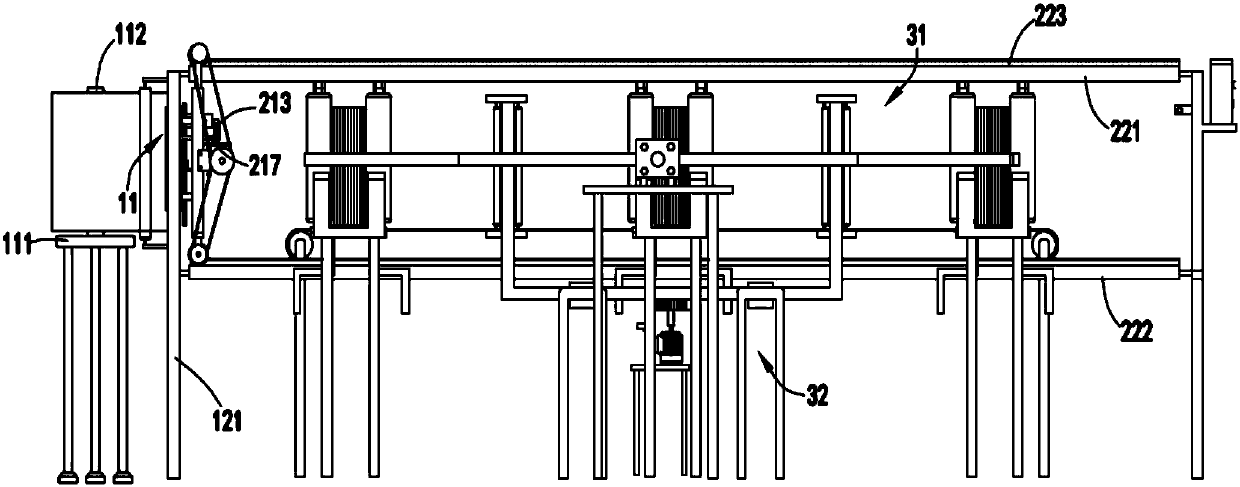

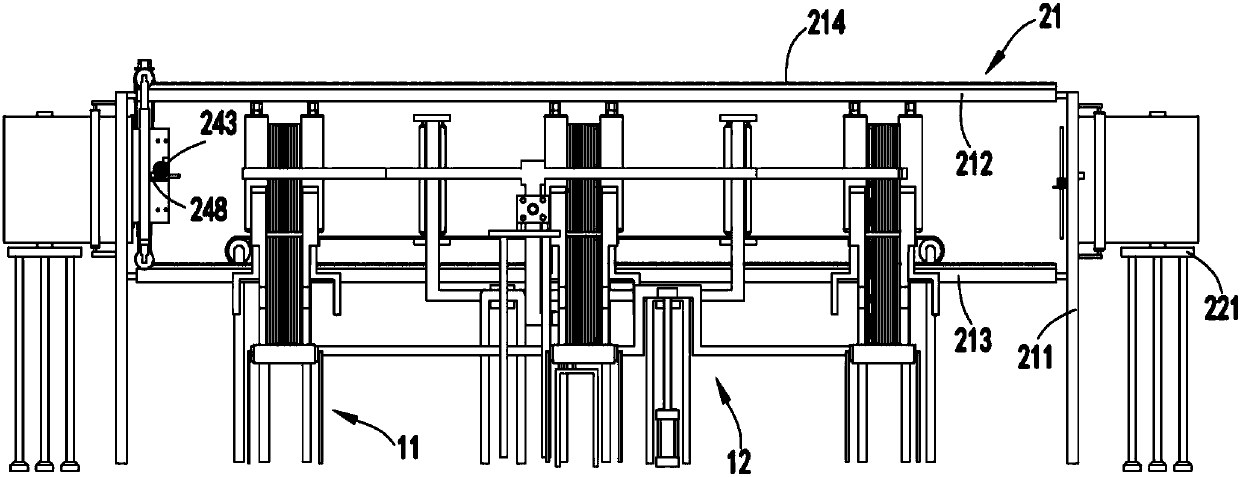

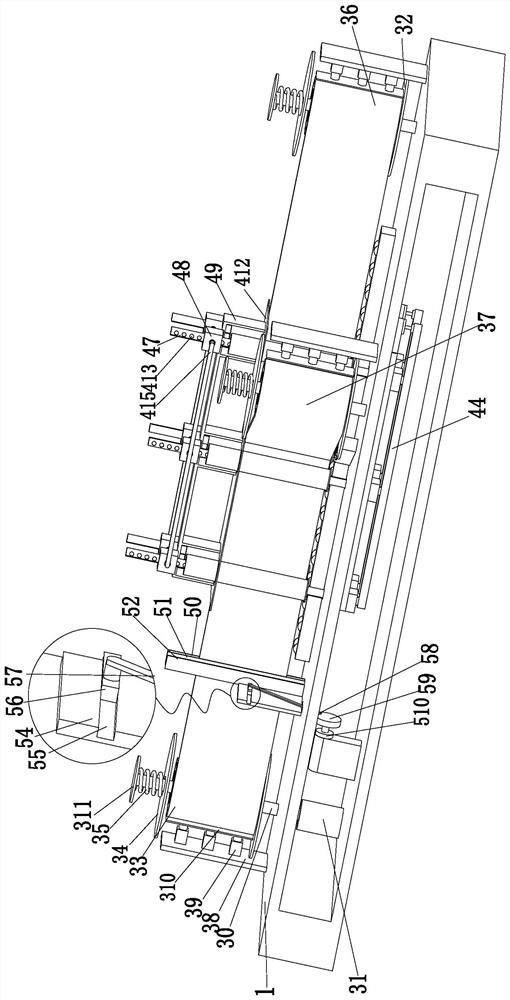

Automatic continuous type film coating technology for pole groups

ActiveCN107985652AImprove coating efficiencyGood coating effectWrapping material feeding apparatusFinal product manufactureEngineeringFilm-coated tablet

The invention relates to an automatic continuous type film coating technology for pole groups. The technology comprises processes as follows: a feeding process: the pole groups are conveyed to a feeding station and are lifted to a coating station by a lifting mechanism; an unwinding process: a roll film on a first unwinding station is unwound, and the film is limited by a limiting mechanism; a film unfolding process: the film in the station is adsorbed and fixed by an adsorption mechanism, the film is unfolded along a guiding mechanism under driving of a drawing mechanism, and when the film moves to a second unwinding station, the film is released and the operation is switched to fix the film in the second unwinding station; a cutting process: after the film is unfolded, the tail part of the film is cut off by a transverse cutting assembly, the film is subjected to equivalent cutting by a cutting mechanism and the end part of the film is limited; a coating process: after equivalent cutting, the pole groups are pushed by a pushing mechanism to move towards the film and coated with the film by a coating mechanism; an output process: the coated pole groups are output by an output station. According to the automatic continuous type film coating technology for the pole groups, the problems of low coating efficiency, poor coating quality and tedious technology in a pole group film coating process are solved.

Owner:阜阳市广联普惠自动化技术有限公司

A kind of preparation method of graphene ceramic circuit substrate

ActiveCN110628280BAvoid affecting the coating effectAnti-impact bindingVacuum evaporation coatingSputtering coatingEvaporation (deposition)Silicic acid

Owner:江苏泰芯源科技有限公司

Anti-diffusion aluminum coating spraying machine and spraying method thereof

ActiveCN112657705AAvoid affecting the coating effectImprove the pressure effectLiquid surface applicatorsLiquid spraying apparatusEngineeringAluminum coating

The invention discloses an anti-diffusion aluminum coating spraying machine and a spraying method thereof. The anti-diffusion aluminum coating spraying machine comprises a handheld barrel and a conveying pump, wherein a discharging opening is formed in the front side of a bottom plate of the handheld barrel, a square flat spraying box is vertically and fixedly connected to the lower side of the discharging opening, and a conveying hose is connected to the discharging end of the conveying pump; and a uniform discharging mechanism is arranged between a square flat spraying box and the handheld barrel. According to the anti-diffusion aluminum coating spraying machine, a pneumatic pump sprays strong-pressure airflow to the position under the pneumatic pump through a spraying pipe, and the airflow acts on outer strip-shaped pressing plates under the pneumatic pump, so that inner strip-shaped pressing plates move downwards to extrude aluminum coating in flat transition boxes, and the inner strip-shaped pressing plates and the cross section of an inner cavity of each flat transition box are identical in shape. The shape and the size of the inner cavity of each flat transition box are completely the same as those of the inner cavity of the square flat spraying box, so that the aluminum coating in the flat transition boxes is uniformly extruded and rushed into the square flat spraying box under stress, and is uniformly sprayed out from fine holes in a separation block.

Owner:重庆九海铝业有限公司

Electroplating cathode hanger

PendingCN110904492AGuaranteed StrengthEvenly distributedSealing devicesCurrent conducting devicesStructural engineeringSealant

An electroplating cathode hanger is structurally characterized in that a hanger main body is fixed below a main body upper fixing frame, a conductive block is arranged on one side of the main body upper fixing frame, a mounting groove is formed in the middle of the hanger main body, a conductive sheet is pressed in the mounting groove through a pressing plate, a fluororubber conductive sheet sealing ring covers the upper layer of the conductive sheet, and a groove is formed in the hanger main body; an electric lead is arranged in the groove and sealed and insulated through sealant, one end ofthe electric lead is connected with the conducting strip, the other end of the electric lead is led to the conductive block along the fixing frame on the body, the body cover plate is provided with agroove, an air bag is fixed in the groove in the body cover plate, and a rear cover plate covers the outer side face of the pressing plate and is fixedly connected with the body cover plate. The hanger has the advantages that the hanger main body has an anti-corrosion function, and the strength is ensured; conductive areas of the product are uniformly distributed; liquid medicine can be more effectively prevented from entering the non-plated surface of a product, and the influence on the plating effect of the product due to plating of a plating layer on the conducting strip is avoided; the service life is prolonged; the coating quality is improved; the safety is improved; increasing efficiency and quality.

Owner:吉姆西半导体科技(无锡)有限公司

Electroplating cathode hanging device

PendingCN109321963AGuaranteed StrengthAvoid enteringSealing devicesCurrent conducting devicesElectricityPower flow

The invention provides an electroplating cathode hanging device. According to the structure of the hanging device, the lower portion of a hanging device main body is provided with an installing groovematched with an electricity conducting sheet in shape, the electricity conducting sheet is installed in an installing groove in the hanging device main body in a pressing manner through a pressing plate and fixedly connected through screws, the outer surface of the electricity conducting sheet is coated with fluororubber, a protruding block is arranged on the edge of the electricity conducting sheet, an electricity conducting hook is arranged on the upper portion of the hanging device main body, the hanging device main body is provided with a groove matched with an electricity conducting linein shape, the electricity conducting line is arranged in the groove in the hanging device main body and sealed and insulated through sealing rubber, one end of the electricity conducting line is connected with the electricity conducting hook, the other end of the electricity conducting line is connected with the electricity conducting sheet, and the rear cover plate covers the outer side face ofthe pressing plate and is fixedly connected with the hanging device main body through screws. The hanging device has the advantages that the hanging device main body is light and ensures strength; liquor is effectively prevented from entering the non-plated face of a product, and the situation that the electricity conducting sheet is plated with a plating layer, and the effect of the plating layeris influenced is avoided; the situation that the electricity conducting line is exposed in the liquor and burnt out possibly is avoided, and the service life is prolonged; and the electricity conducting hook enables currents to pass smoothly, and the quality of the plating layer is improved.

Owner:吉姆西半导体科技(无锡)有限公司

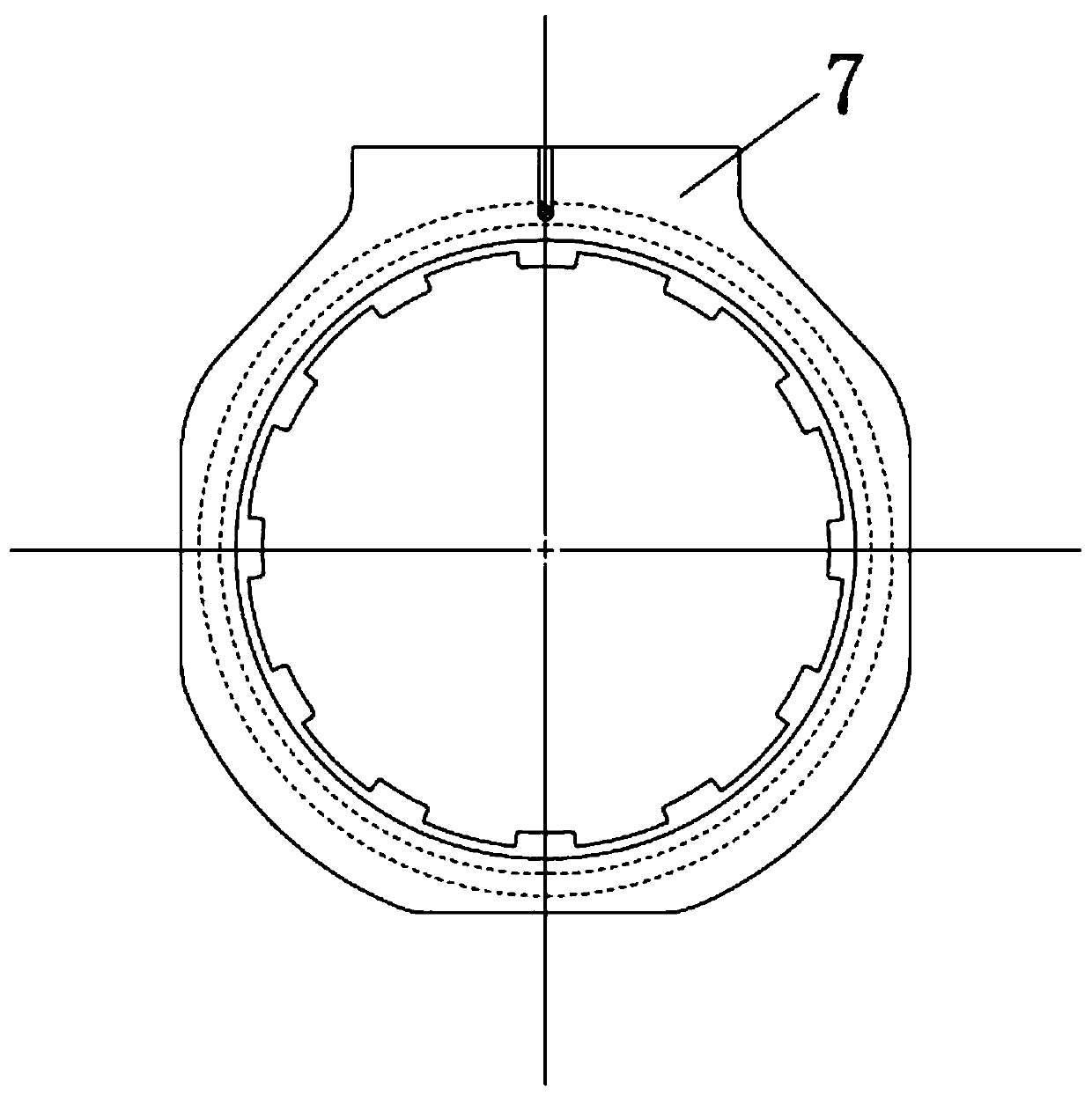

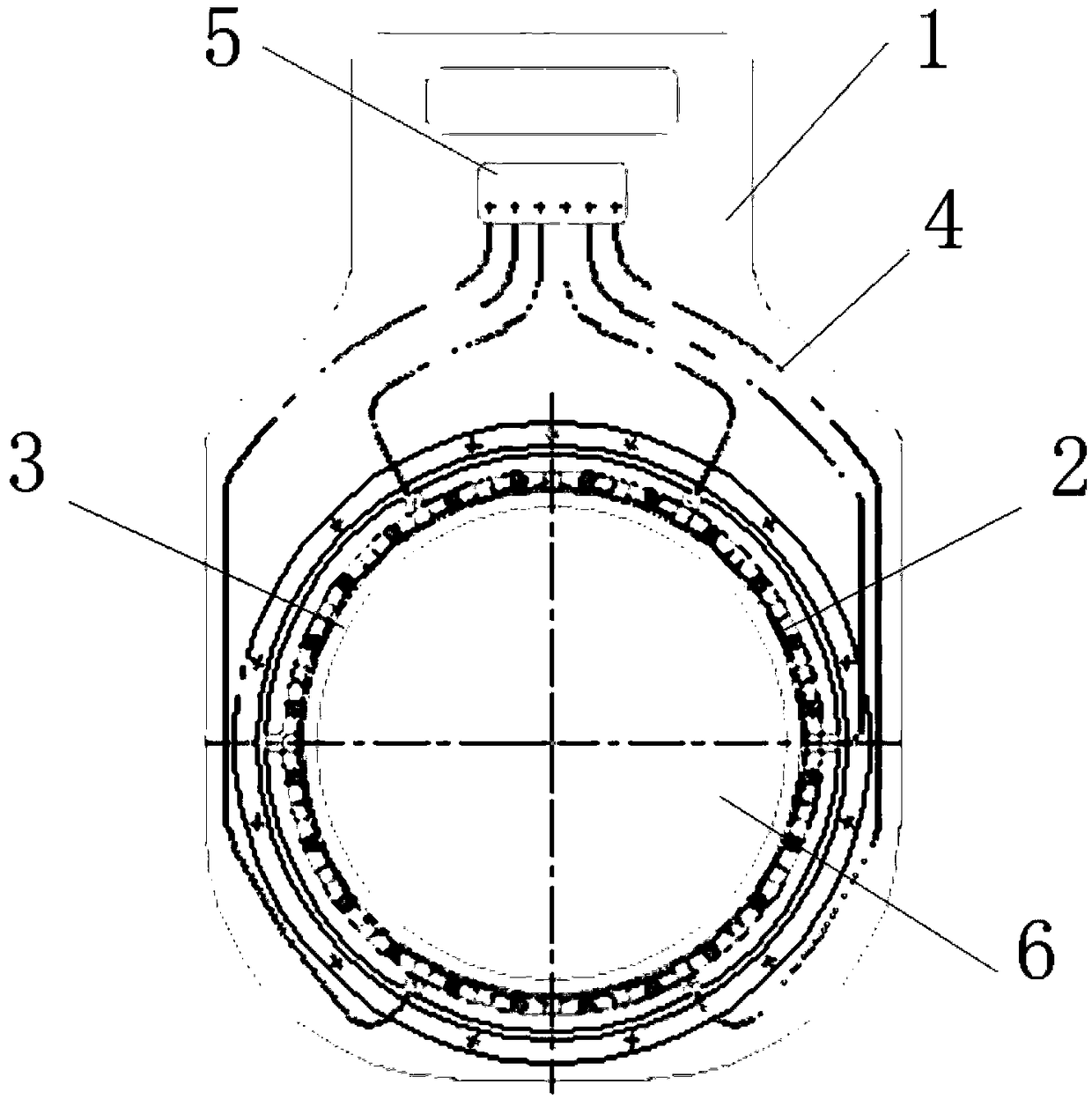

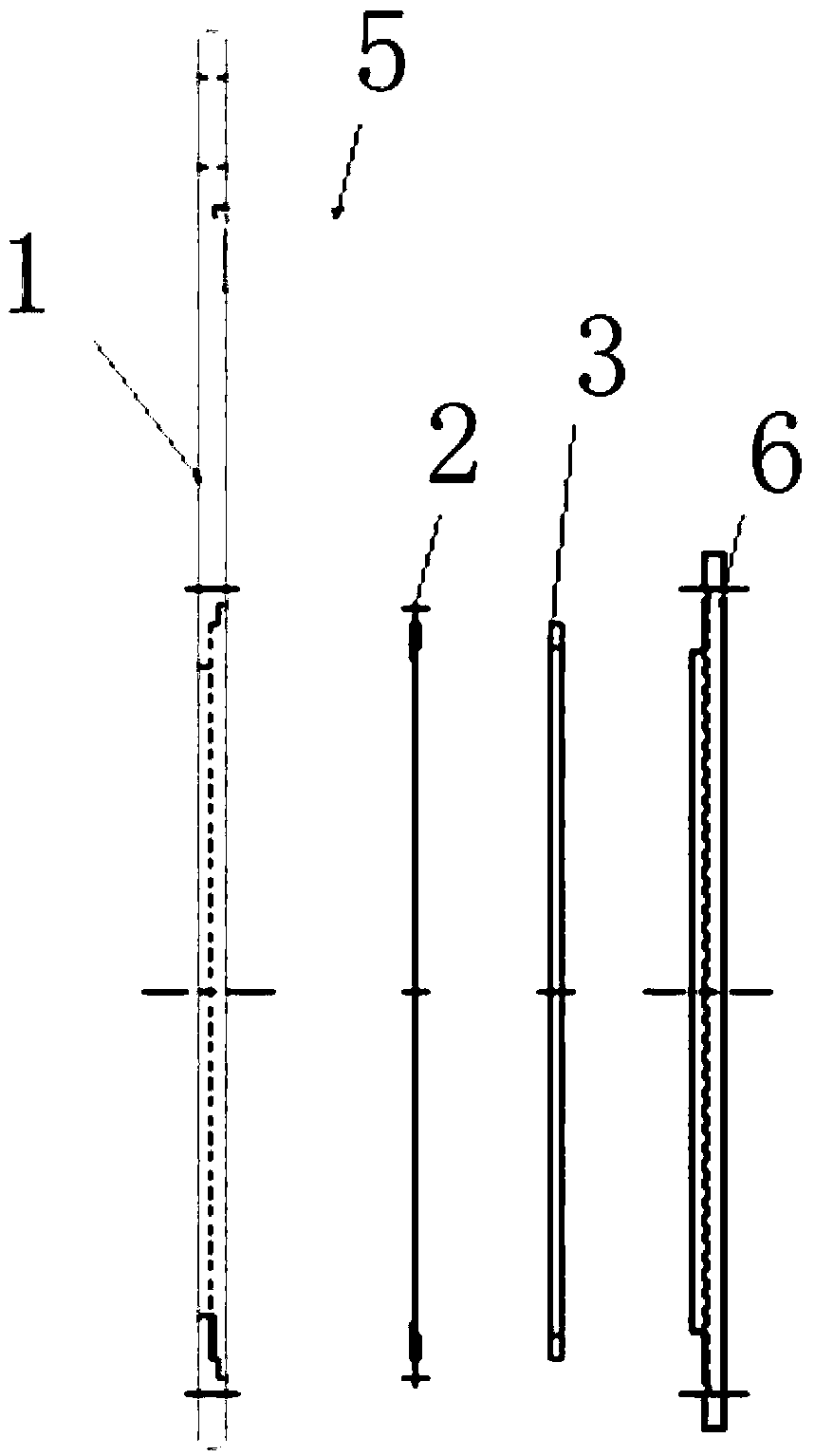

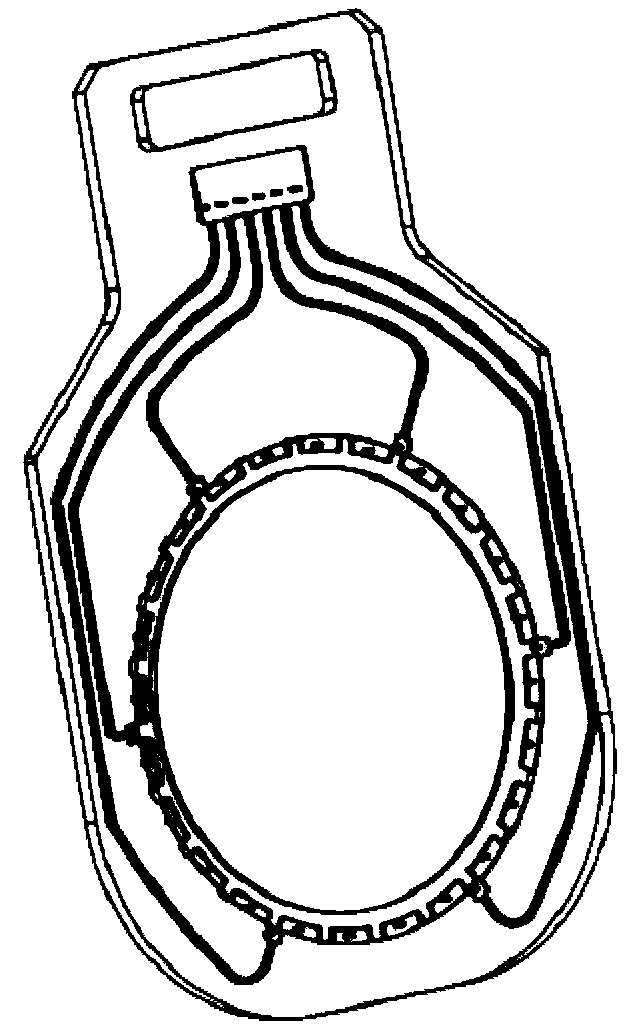

Coupling agent coating equipment for manufacturing insulator for power transmission

InactiveCN112371453AEasy to fixShorten drying timeDispersed particle filtrationPretreated surfacesActivated carbonHEPA

The invention discloses coupling agent coating equipment for manufacturing an insulator for power transmission. The coupling agent coating equipment comprises a supporting mechanism, a control mechanism used for controlling operation of a device, a coating mechanism and a closing mechanism. Through the design of a rotating mechanism, a rotating cylinder, a spring and a clamping plate, a steel anchor of the insulator can be easily fixed, and the fixing process is simple and convenient; through the arrangement of a drying mechanism, gas is filtered through a dust filter screen, the filtered gasenters a heating box under the action of an air blower, the gas is heated through an electric heating wire, the high-temperature gas acts on the surface of the insulator so as to dry a coupling agent,the time required for drying the coupling agent is shortened, and meanwhile the situation that the coating effect is influenced due to the fact that a worker touches the unsolidified coupling agent can be avoided; and through the arrangement of a purification mechanism, an HEPA filter screen and an activated carbon adsorption layer can purify harmful gas generated in the coating process, and therefore the body health of workers is prevented from being damaged.

Owner:陈鹏鹏

A method for vacuum evaporation coating and a rare earth magnet covering evaporation coating

ActiveCN104032263BAvoid excessive oxidationOvercoming the problem of weak bindingVacuum evaporation coatingSputtering coatingThin layerRare-earth magnet

The invention discloses a vacuum evaporation coating method and a rare earth magnet covered with an evaporation coating. The method includes steps of: 1) installing a rare earth magnet workpiece to a workpiece rest before pretreatment; 2) sending the workpiece rest into a reaction chamber, and performing preoxidation; 3) sending the workpiece rest to a coating chamber, vacuumizing, heating a meta evaporating material M to an evaporation temperature, and subjecting the rare earth magnet workpiece to evaporation coating; and 4) cooling, restoring to normal pressure and taking the workpiece out. According to the method, the rare earth magnet is subjected to trace oxidation in advance and is subjected to replacement by feeding M steam, thus preventing excessive oxidation of the rare earth magnet, and obtaining a dense MO distribution thin layer and an M layer firmly connected to the MO distribution thin layer.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

A kind of waterproof self-adhesive label preparation lamination processing system

ActiveCN112590386BImprove the efficiency of film processingAvoid frequent disassembly and replacementPrinting press partsAdhesiveEngineering

The invention relates to a film-coating processing system for preparing waterproof self-adhesive labels, which includes a base, an installation groove, a transmission mechanism, a film-covering mechanism and a cutting mechanism. An installation groove is opened between the front and rear sides of the base, and a transmission mechanism is arranged on the upper end of the base. , a coating mechanism is provided in the middle of the transmission mechanism, and a cutting mechanism is provided on the upper end surface of the base on the left side of the coating mechanism; Labels with a certain width are limited by lamination, so frequent disassembly of parts affects the efficiency of label lamination. When laminating labels, existing label laminating machines cannot clean the surface of the label in time, which is easy to stain the surface of the label. There are dirt and dust, etc., which make the laminated label blister and wrinkle on the surface of the label. However, the blistered label after lamination can only be scrapped and cannot be used, resulting in waste of labels and increased manufacturing costs.

Owner:湖南恒创新材料有限公司

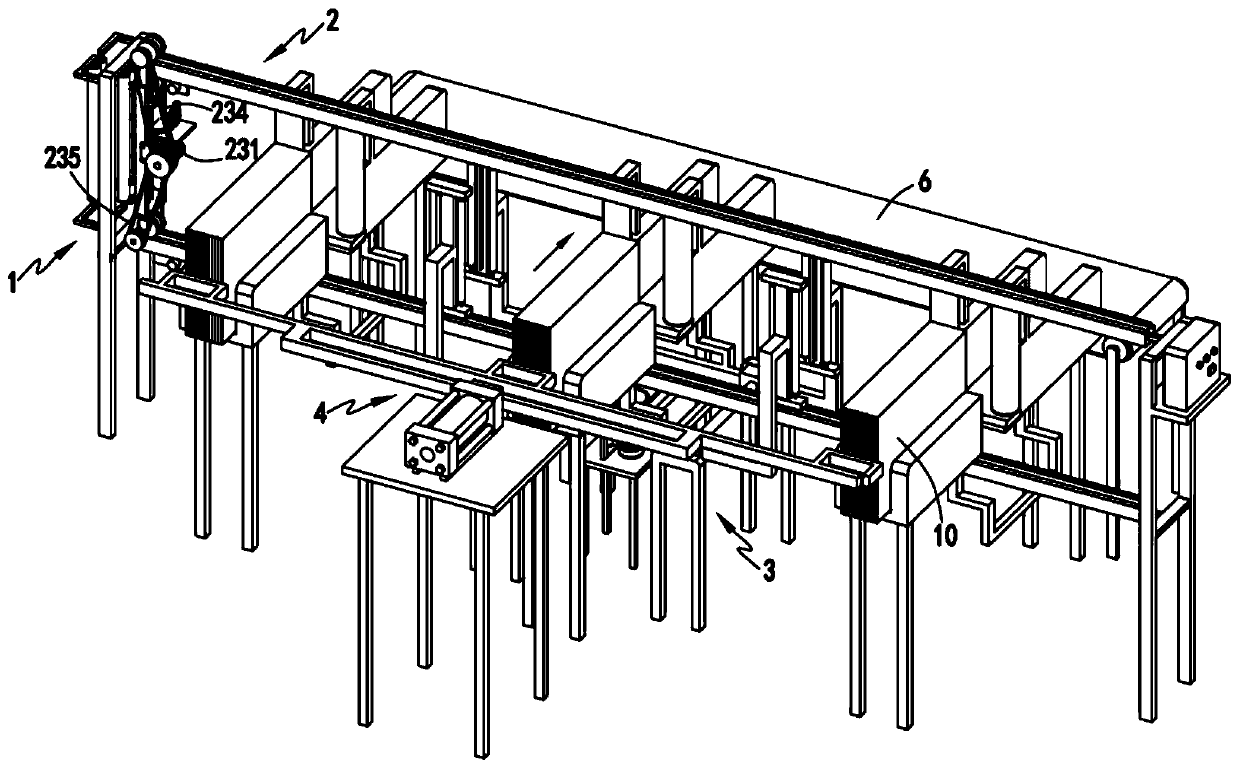

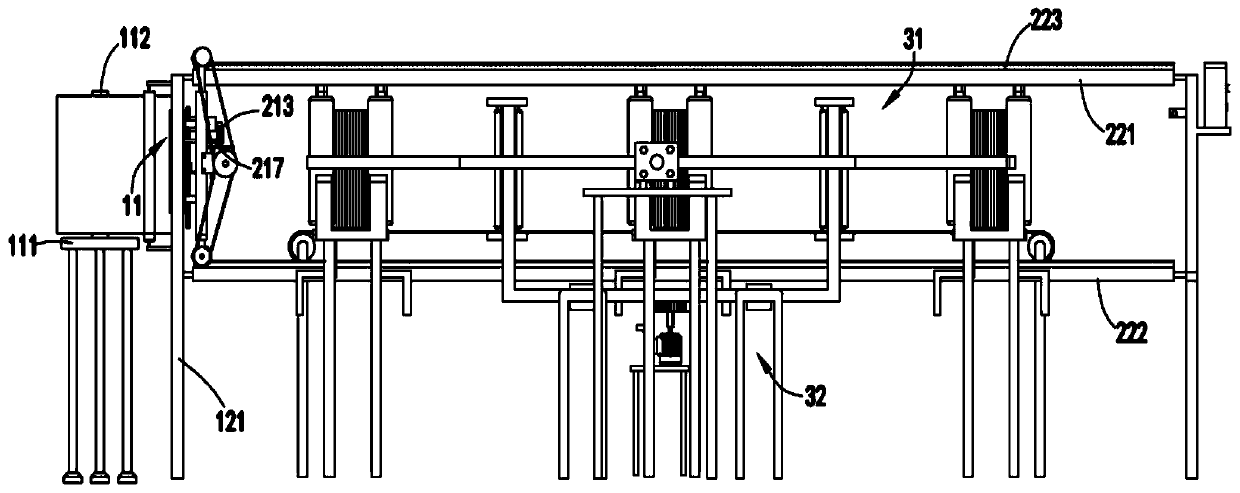

Polar group automatic continuous film coating system

InactiveCN107867574AImprove efficiencyGood coating effectFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention relates to a polar group automatic continuous film coating system. The polar group automatic continuous film coating system comprises a feeding device, a thin film unreeling device, a slitting device and a coating device, wherein the feeding device comprises a horizontal conveying mechanism and a lifting mechanism. The thin film unreeling device comprises a guide mechanism, a first unreeling mechanism, a second unreeling mechanism, an absorption mechanism and a transaction mechanism, wherein the first unreeling mechanism and the second unreeling mechanism are arranged at the twoends of the guide mechanism, the adsorption mechanism is used for adsorbing and fixing the end part of thin films on the unreeling mechanism, and the traction mechanism is used for driving the adsorption mechanism and the end part of the thin films to move along the guide mechanism. The slitting device comprises a cutting mechanism and a driving mechanism, wherein the cutting mechanism and the driving mechanism are arranged on the front side and the rear side of the guide mechanism, the cutting mechanism is driven by the driving mechanism to cut unfolded thin films at equal intervals, and theends of the thin films are limited after cutting is completed. The coating device comprises a pushing mechanism and a coating mechanism, wherein the pushing mechanism is used for pushing a polar group to move in the horizontal direction and is matched with the coating mechanism to finish coating of the polar group. The polar group automatic continuous film coating system solves the problems thatpolar group batch automatic film coating cannot be realized, the film coating efficiency is low, the labor is consumed, and the film coating effect is poor.

Owner:阜阳洁平日化有限公司

Turbine blade coating preparation device with double-side crossed clamping structure

InactiveCN107805793AEasy to processEasy to assemble and disassembleVacuum evaporation coatingSputtering coatingTurbine bladeIngot

The invention discloses a turbine blade coating preparation device with a double-side crossed clamping structure. The turbine blade coating preparation device with the double-side crossed clamping structure comprises a loading chamber and a settling chamber which communicate with each other; the clamping structure and a rotating shaft allowing the clamping structure to rotate are arranged in the loading chamber; the clamping structure extends into the settling chamber, and a pistol chamber is arranged above the settling chamber; a plurality of electronic beam pistols are arranged in the pistolchamber; a light beam of the first electronic beam pistol is emitted to the clamping structure, and a light beam of the second electronic beam pistol is emitted to an ingot under the clamping structure; the clamping structure comprises a left tool plate and a right tool plate which are connected with each other, a plurality of rotary through pipes are arranged between the left tool plate and theright tool plate in a staggered mode, and tool boxes are connected to the rotary through pipes; and the left tool plate is connected with the rotating shaft through a tool bar. The turbine blade coating preparation device with the double-side crossed clamping structure can carry out double-side crossed installation of four to twenty blades according to the requirements for dimension and designed coating areas of the working blades, the coating processing efficiency is greatly improved, and the coating processing cost is reduced.

Owner:AECC AVIATION POWER CO LTD

A rapid coating process for battery pole groups

ActiveCN108100336BImprove coating efficiencyGood coating effectWrapping material feeding apparatusFinal product manufactureElectrical batteryClassical mechanics

The invention relates to a rapid coating process for battery pole groups, which includes: 1. unwinding process, the reel film is placed at the unwinding station, and a positioning mechanism positions the end of the reel film; 2. film unfolding process, absorbing The mechanism fixes the end of the film at the positioning mechanism, and the film is unfolded along the guide mechanism under the drive of the traction mechanism; 3: Film cutting process, the cross-cutting mechanism at the unwinding station cuts off the tail end of the film, located at The cutting and positioning mechanism on both sides of the unfolded film cuts the film into equal parts and positions the end of the film; 4: Coating process, the electrode group at the coating station moves towards the direction of the film under the push of the pushing mechanism , the coating mechanism wraps the film on both sides of the pole group; five: output process, the coated pole group is pushed to the output station for output; the present invention overcomes the existing pole group coating process, which is cumbersome. Low coating efficiency and poor coating effect.

Owner:林浩

Water-proof adhesive sticker label preparation laminating processing system

ActiveCN112590386AImprove the efficiency of film processingAvoid frequent disassembly and replacementPrinting press partsAdhesiveStructural engineering

The invention relates to a water-proof adhesive sticker label preparation laminating processing system. The system comprises a base, a mounting groove, a conveying mechanism, a laminating mechanism and a cutting mechanism, wherein the mounting groove is formed between the front side face and the rear side face of the base, the conveying mechanism is arranged on the upper end face of the base, thelaminating mechanism is arranged in the middle of the conveying mechanism, and the cutting mechanism is arranged on the position, located at the left side of the laminating mechanism, of the upper endsurface of the base. The system can solve the problems that in the adhesive sticker label surface laminating processing process, in the prior art, only labels with one width can be laminated and limited, so that the label laminating efficiency is influenced by frequently disassembling parts, when an existing label laminating machine is used for laminating the labels, due to the fact that the surfaces of the labels cannot be cleaned in time, the surfaces of the labels are prone to being stained with dirt, dust and the like, the labels after laminating are blistered, wrinkles appear on the surfaces of the labels, the labels blistered after laminating can only be scrapped and cannot be used, waste of the labels is caused, and the manufacturing cost is increased are solved.

Owner:湖南恒创新材料有限公司

An intelligent coating device for reflective material processing

ActiveCN112642644BAffects cutting positionControl distanceLiquid surface applicatorsCoatingsElectric machineStructural engineering

The invention discloses an intelligent coating device for reflective material processing, which comprises a base, two left support columns and two right support columns are respectively fixedly arranged on both sides of the base, and the top ends of the left support column and the right support column A top plate is fixedly arranged, a film roller is arranged on the top of the left baffle between the two support plates, and a moving cylinder is fixedly arranged on the bottom of the top plate, and a moving motor is fixedly arranged on one side of the moving cylinder, and the guide The rod runs through the moving rod, the bottom of the moving rod is vertically provided with an electric cylinder, the film coating roller is arranged between the film coating roller rods, the inside of the base is provided with a cutter compartment, and the cutter slot is slidingly set With cutting blade. The present invention is provided with a coating roller and a pressing cylinder, the locking piece is driven to move by the pressing cylinder, the rotating shaft is fixed through the contact between the locking piece and the rotating shaft, and the coating roller is locked to avoid rotation during cutting Unexpected movement of the rollers, causing changes in the position of the film, affecting the cutting position of the cutter blades.

Owner:ZHEJIANG WINKI OPTICS CO LTD

A Jiqun automatic continuous coating process

ActiveCN107985652BImprove coating efficiencyGood coating effectWrapping material feeding apparatusFinal product manufactureEngineeringAutomation

Owner:阜阳市广联普惠自动化技术有限公司

Thermal sensitive paper producing and processing machine and thermal sensitive paper producing and processing technology

InactiveCN114150530AAvoid wastingAvoid the situationPaper/cardboardThermographyPaper productionStructural engineering

The thermo-sensitive paper production and processing machine comprises a first fixing frame, a second fixing frame, an unwinding drum, a winding drum and a coating device, the first fixing frame and the second fixing frame are symmetrically installed on the existing ground front and back, the first fixing frame is located on the left side of the second fixing frame, and the second fixing frame is located on the right side of the second fixing frame. An unwinding drum is rotatably connected between the two first fixing frames, a winding drum is rotatably connected between the two second fixing frames, and a coating device is arranged between the unwinding drum and the winding drum. The conditions that too much coating is discharged at a time, so that the coating is wasted, and the coating effect is poor can be avoided, and the function that the coating is evenly distributed on the surface of the thermo-sensitive paper can be achieved through the scraping unit in the coating device.

Owner:易春年

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com