Three-dimensional spacer fabric reinforced space membrane material, preparation method and processing device thereof

A technology of spacer fabric and warp-knitted spacer fabric is applied in the field of three-dimensional spacer fabric reinforced space membrane material and its preparation, which can solve the problems of poor mechanical properties, complicated process, adhesion of inner spacer wires, etc., so as to avoid low overall strength. , The effect of uniform coating and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method of the three-dimensional spacer fabric reinforced space membrane material, the specific steps are as follows:

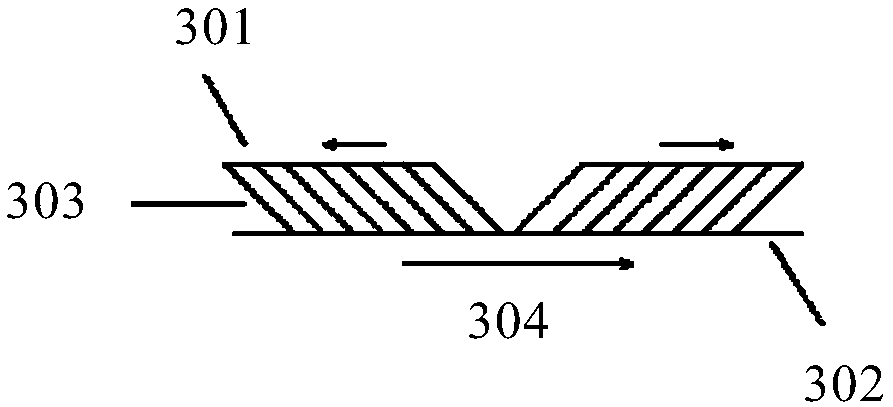

[0063] (1) Opening: The state of the opening is as follows figure 1As shown, in the running process of the three-dimensional spacer fabric, first apply tension along the fabric running direction 304 to keep the spacer yarn 303 in the fabric 2 in a vertically straight state, and then keep the tension constant on the top layer of the fabric, that is, the spacer fabric upper surface 301 The upper edge is opened in a direction perpendicular to the fabric running direction 304, the length of the opening is equal to the width of the fabric 2, and the opening of the fabric is in the shape of a "V" tear under tension, so that the upper surface 301 of the spacer fabric and the lower surface 302 of the spacer fabric The horizontal phase is staggered, the spacer wire 303 in the fabric 2 is in a state of oblique tension, and finally the opening is s...

Embodiment 2

[0076] The preparation method of the three-dimensional spacer fabric reinforced space membrane material, the specific steps are as follows:

[0077] (1) Opening: The specific method is the same as that of Example 1, wherein the running speed of the three-dimensional spacer fabric is 3.8m / min, the tension applied is 500N / m, and the pressure of the high-pressure spraying treatment is 0.7MPa.

[0078] (2) Sizing: Double-sided roller coating sizing is carried out during the fabric running from bottom to top. The fabric is pressurized by side roller coating at the sizing position, and is bent to form a certain enveloping angle. The amount of slurry coating is 160g / m 2 ;

[0079] (3) Pre-setting: Pre-setting is carried out during the bottom-up operation of the fabric, and the pre-setting temperature is 180°C;

[0080] (4) Drying and shaping: drying and shaping are carried out during the horizontal running of the fabric, the drying temperature is 170°C, and the drying speed is 4.5m / ...

Embodiment 3

[0088] The preparation method of the three-dimensional spacer fabric reinforced space membrane material, the specific steps are as follows:

[0089] (1) Opening: The specific method is the same as that of Example 1, wherein the running speed of the three-dimensional spacer fabric is 3.7m / min, the applied tension is 1000N / m, and the pressure of the high-pressure spraying treatment is 0.5MPa.

[0090] (2) Sizing: double-sided roller coating sizing is carried out during the fabric running from bottom to top. The fabric is pressurized by side roller coating at the sizing position, and is bent to form a certain enveloping angle. The amount of slurry coating is 175g / m 2 ;

[0091] (3) Presetting: Presetting is carried out during the bottom-up operation of the fabric, and the presetting temperature is 160°C;

[0092] (4) Drying and shaping: drying and shaping are carried out during the horizontal operation of the fabric, the drying temperature is 180°C, and the drying speed is 4m / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stretching force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com