Mulching film laying device for agricultural production

A technology for laying devices and mulch, which is applied to applications, botany equipment and methods, plant protection covers, etc., can solve problems affecting the efficiency and quality of mulch laying, damage, etc., to ensure the laying width, improve the tightness of lamination, and improve Effect of Lamination Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

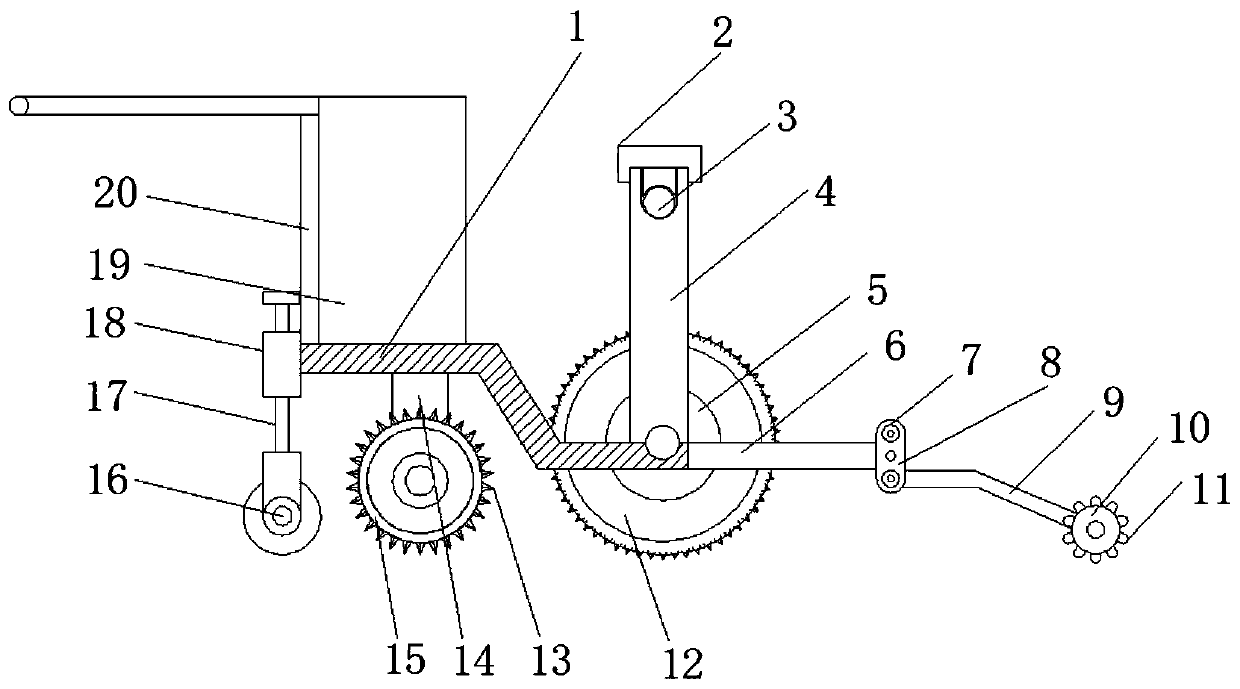

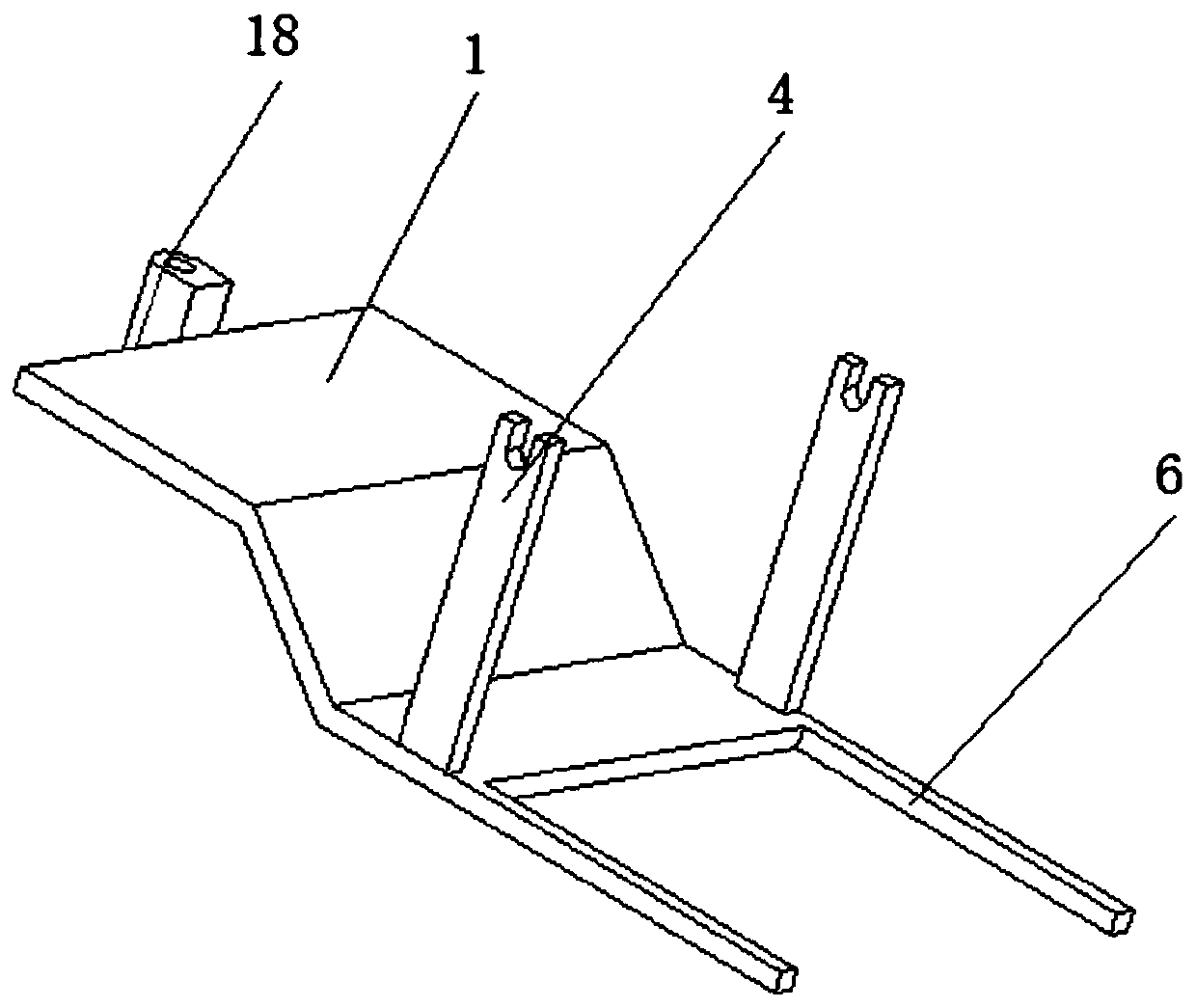

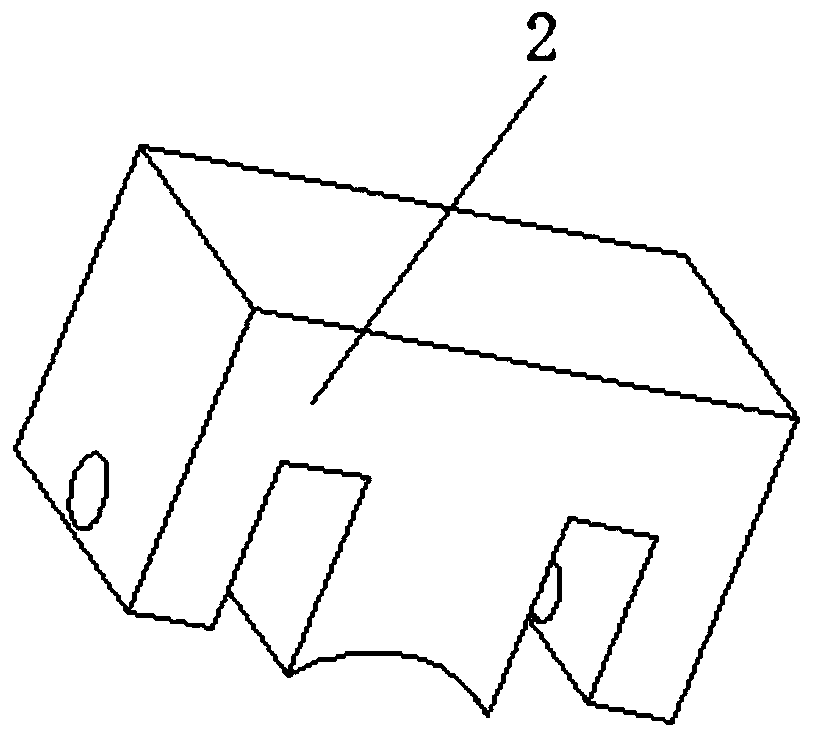

[0027] refer to Figure 1-3 , a mulch laying device for agricultural production, comprising a frame 1, an operating handle 20 of an L-shaped structure is fixedly installed on the top of the frame 1, and a rectangular groove 6 is provided on the other side of the top of the frame 1, and the top of the frame 1 Both sides of the top are fixedly installed with a vertical support frame 4, both sides of the frame 1 are fixedly equipped with a driving motor 5, and the output shaft of the driving motor 5 is fixedly equipped with a driving wheel 12. In this embodiment, the driving motor 5 Select a DC motor of matching size, the end of the frame 1 is fixedly installed with an auxiliary bracket mechanism, the inner walls of both sides of the rectangular slot 6 are fixedly installed with side plates 8, and guide rollers are installed between the two side plates 8 through bearings Wheel 7, connecting frame 14 is fixedly installed on both sides of the bottom of frame 1, and flattening rolle...

Embodiment 2

[0036] refer to figure 2 and Figure 4-5 , a mulch laying device for agricultural production. Compared with Embodiment 1 in this embodiment, the feeding mechanism includes two fixed sleeves 24 sleeved on the outside of the support frame 4, and a U is fixedly installed between the two fixed sleeves 24. The loading frame 21 of type structure, the side of the loading frame 21 is provided with the strip-shaped film outlet groove 23, and the inner bottom of the loading frame 21 is equipped with a plurality of rolling rods 22 through bearings.

[0037] When this embodiment is in use, the mulch roll can be directly placed inside the loading frame 21, and the fixed sleeve 24 is used to insert it to the outside of the two support frames 4. During the unwinding process, the mulch roll can be placed between multiple rolling rods 22. Tumbling, two film release methods, suitable for multiple mulch rolls, improving the scope of application of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com