A kind of preparation method of graphene ceramic circuit substrate

A circuit substrate, graphene technology, applied in vacuum evaporation plating, coating, sputtering plating and other directions, to achieve the effect of solving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

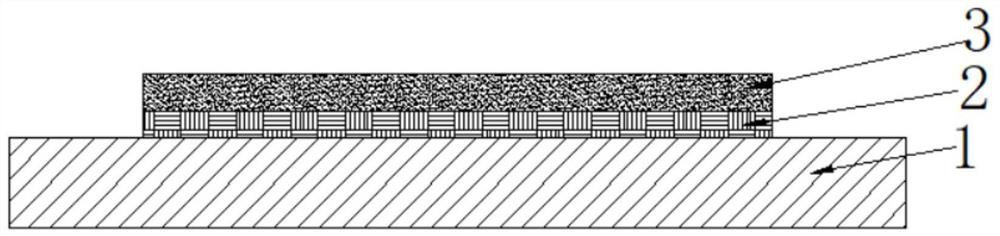

[0037] A kind of preparation method of graphene ceramic circuit board of the present invention comprises the following steps:

[0038] S1, (alumina, aluminum nitride, zirconia, etc.) before substrate 1 is sprayed, the substrate is first degreased and dried with 40g / L acetone degreaser; Clean with weak acid salt, decontaminate and activate the surface, the temperature is 19-30°C, and the time is 20-50Sec;

[0039] S2. Polish the cleaned substrate on a grinder until the plane finish is Ra<0.008um. After the polishing is completed, use the S1 method to clean it. After cleaning, dry it in an oven at 100-120°C for 10-30 minutes;

[0040] S3. Place the polished substrate in the coating chamber, turn on the vacuum pump to evacuate to 0.1-0.01pa, heat the polished substrate to 550-650°C and perform ion bombardment. The ion bombardment voltage is 200V-1kV negative high voltage, and the time is 10-40min. Then adjust The current is 30-60A to pre-melt the nickel plating material and dega...

Embodiment 1

[0045] A kind of preparation method of graphene ceramic circuit board of the present invention comprises the following steps:

[0046]S1. Before spraying the substrate, first degrease and dry it with 40g / L acetone degreasing agent; then wash it with water at a temperature of 30°C for 1min, and clean it with a weak acid salt to decontaminate and activate the surface at a temperature of 19°C and a time of 20Sec;

[0047] S2. Polish the cleaned substrate on a grinder until the plane finish is Ra<0.008um. After the polishing is completed, use the S1 method to clean it. After cleaning, dry it in an oven at 100°C for 10 minutes;

[0048] S3. Place the polished substrate in the coating chamber, turn on the vacuum pump to evacuate to 0.1pa, heat the polished substrate to 550°C and perform ion bombardment. The ion bombardment voltage is 200V negative high voltage, and the time is 10min. Melt and degas for 1 min. After the pre-melting is completed, adjust the current to 70A for evapora...

Embodiment 2

[0052] A kind of preparation method of graphene ceramic circuit board of the present invention comprises the following steps:

[0053] S1. Before spraying the substrate, first degrease and dry it with 40g / L acetone degreasing agent; then wash it with water at a temperature of 40°C for 4 minutes, clean it with a weak acid salt, decontaminate and activate the surface, the temperature is 22°C, and the time is 30Sec;

[0054] S2. Polish the cleaned substrate on a grinder until the plane finish is Ra<0.008um. After the polishing is completed, use the S1 method to clean it. After cleaning, dry it in an oven at 105°C for 15 minutes;

[0055] S3. Place the polished substrate in the coating chamber, turn on the vacuum pump to evacuate to 0.04pa, heat the polished substrate to 570°C and perform ion bombardment. The ion bombardment voltage is 400V negative high voltage, and the time is 20min. Melt and degas for 1.5min. After the pre-melting is completed, adjust the current to 80A for ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com