A curved glass coating device, coating process and coating product

A technology of curved glass and coating device, applied in the direction of coating, can solve the problems of uneven coating and poor printing of curved 3D glass, and achieve the effect of improving the appearance yield, avoiding over-plating, and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

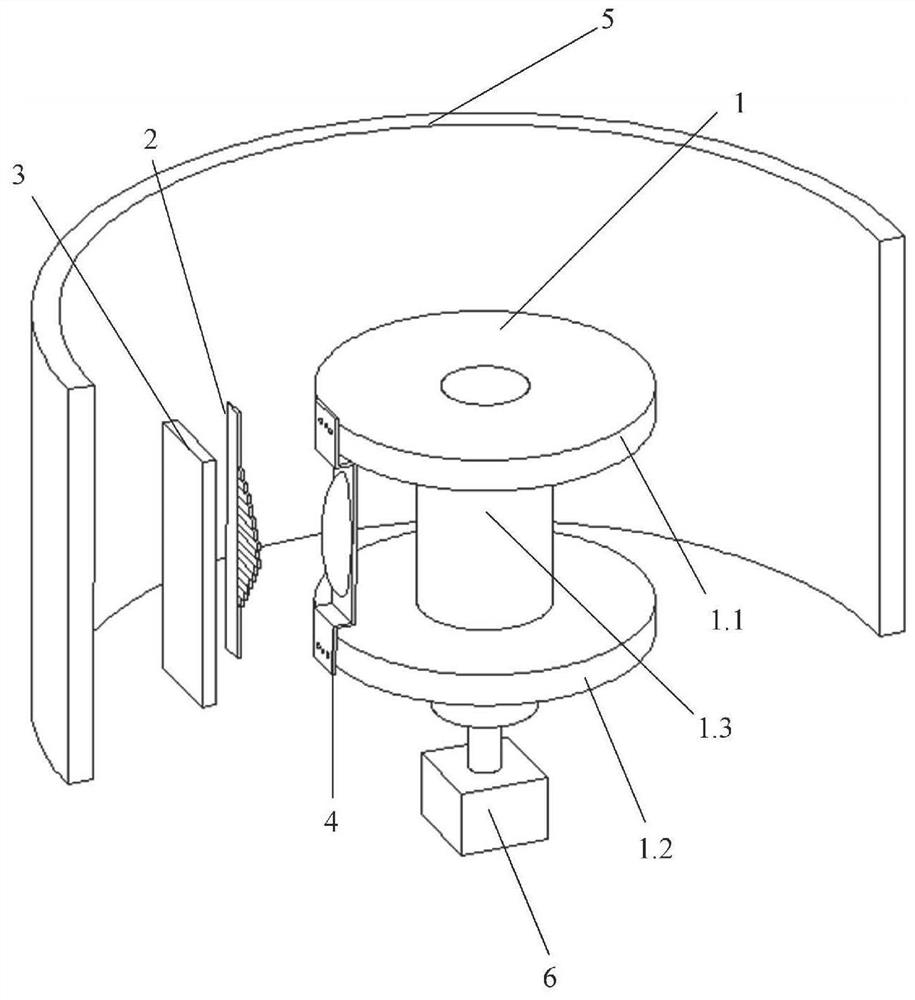

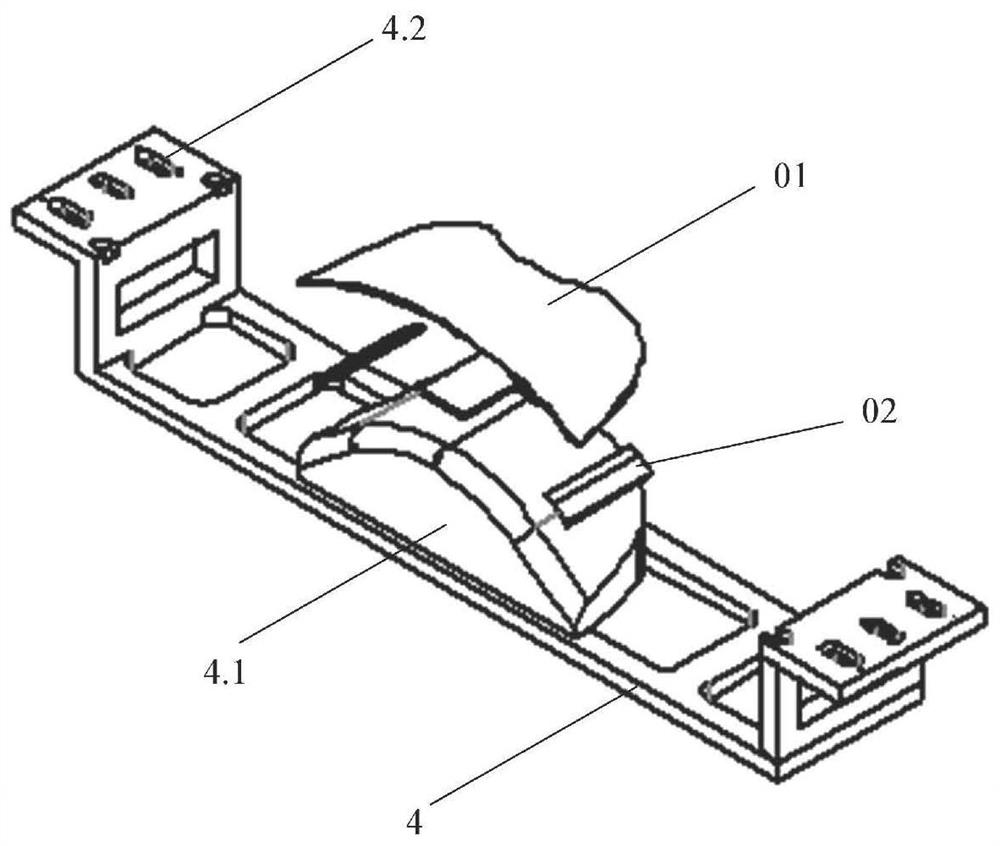

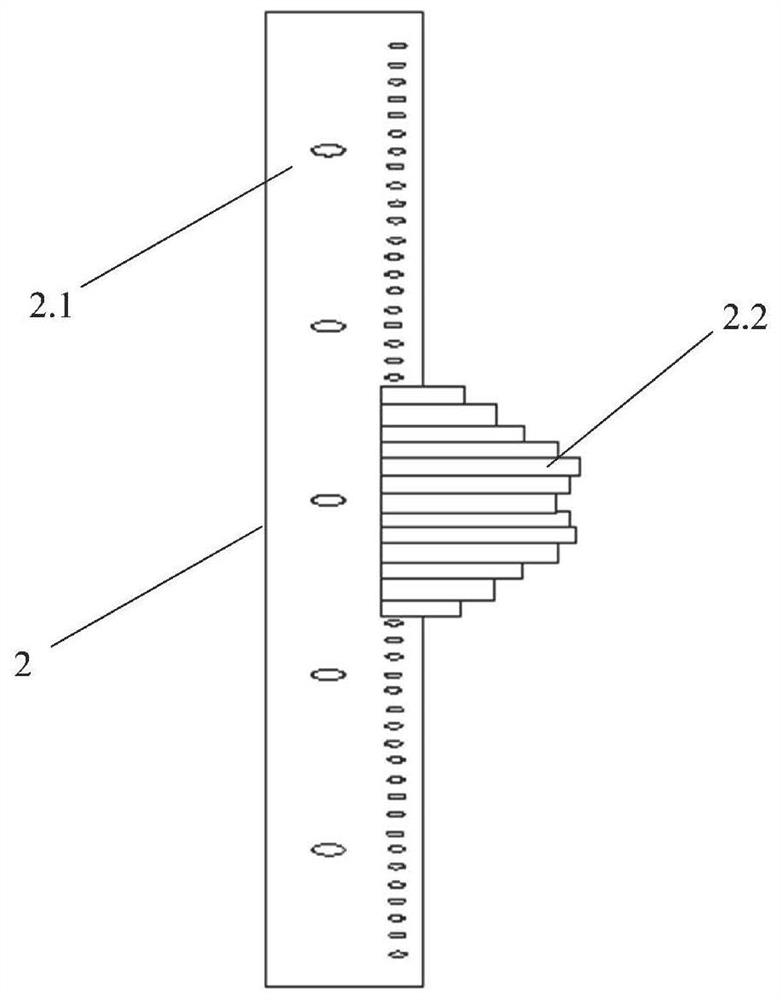

[0038] see figure 1 , a curved glass coating device, comprising a coating device body 5, a rotatably arranged workbench 1, a motor 6 for driving the movement of the workbench 1, a hanging plate 4 arranged on the workbench 1, and the The hanging plate 4 is facing the target spray head 3 and the correction component 2 arranged between the hanging plate 4 and the target spray head 3, and the workbench 1 is vertically arranged in the middle of the coating device body 5 , the workbench 1 includes an upper plate 1.1 and a lower plate 1.2 arranged up and down, welded by a fixed rod 1.3 between the upper plate 1.1 and the lower plate 1.2, and the direction of the axis of rotation of the workbench 1 is parallel to its own length direction ( That is, the direction where the fixed rod 1.3 is located); the two ends of the hanging board 4 in the length direction are fixedly arranged with the workbench 1, see Figure 1~2 , the hanging board 4 includes a projection 4.1 arranged in the middl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com