Chromium oxide and zirconium oxide composite coating and preparation method thereof

A composite coating and zirconia technology, applied in the coating, metal material coating process, liquid chemical plating, etc., can solve the problem of lack of composite hydrogen/deuterium/tritium penetration coating, inability to completely cover complex shape parts, Insufficient permeation barrier ability and other problems, to achieve excellent hydrogen/deuterium/tritium permeation resistance, improve thermal compatibility, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

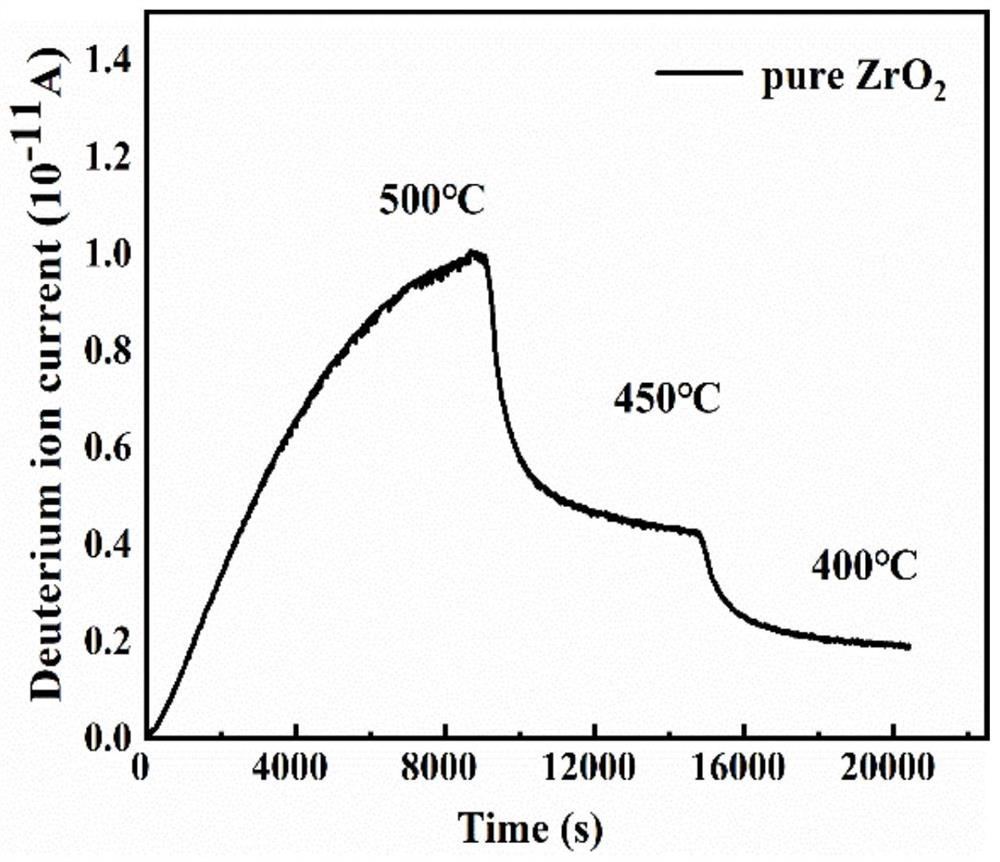

[0029] A pure ZrO 2 Hydrogen / deuterium / tritium permeation barrier coating, prepared by:

[0030] 1. Polish the 321L stainless steel to a mirror surface, deionize it with ethanol for 15 minutes, and clean it with acetone.

[0031] 2. Weigh 3 g of zirconium acetate, add 50 ml of absolute ethanol, 2.5 ml of acetone, and 50 μL of glacial acetic acid, place it on a magnetic stirrer and stir for about 10 hours until it is fully dissolved and become clear and transparent, and stand for 24 hours to obtain a zirconium sol.

[0032] 3. The dipping and pulling process is completed with a pulling machine. The pulling speed is uniform throughout the process. The pulling speed is set to 400 μm / s. After pulling, the wet sol and the substrate are placed together at 80 °C for drying for 1 hour, and kept at 400 °C for 30 minutes. , after cooling, the second layer is pulled up, and the previous operation is repeated for a total of three times, and finally heat treatment is performed, and the te...

Embodiment 2

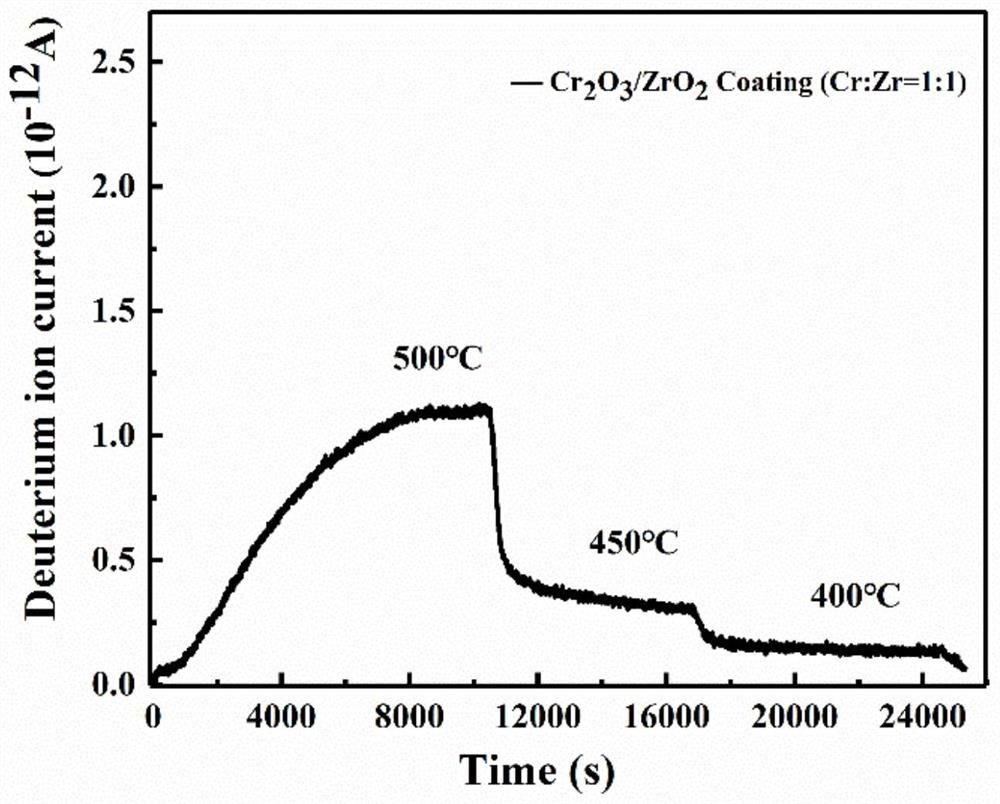

[0034] A Cr with a Cr and Zr molar ratio of 1:1 2 O 3 / ZrO 2 The composite hydrogen / deuterium / tritium permeation barrier coating is prepared by the following methods:

[0035] 1. Polish the 321L stainless steel to a mirror surface, deionize it with ethanol for 15 minutes, and clean it with acetone.

[0036] 2. Weigh 3g of zirconium acetate, add 50ml of absolute ethanol, 2.5ml of acetone, and 50μl of glacial acetic acid, place it on a magnetic stirrer and stir for about 10h until it is fully dissolved and become clear and transparent, and stand for 24h to obtain a zirconium sol; then add to it 1.23g of chromium acetate, ultrasonic for 0.5h or magnetic stirring for about 1h, to obtain a mixed sol.

[0037] 3. The dipping and pulling process is completed with a pulling machine. The pulling speed is uniform throughout the process. The pulling speed is set to 400 μm / s. After pulling, the wet sol and the substrate are placed together at 80 °C for drying for 1 hour, and kept at 40...

Embodiment 3

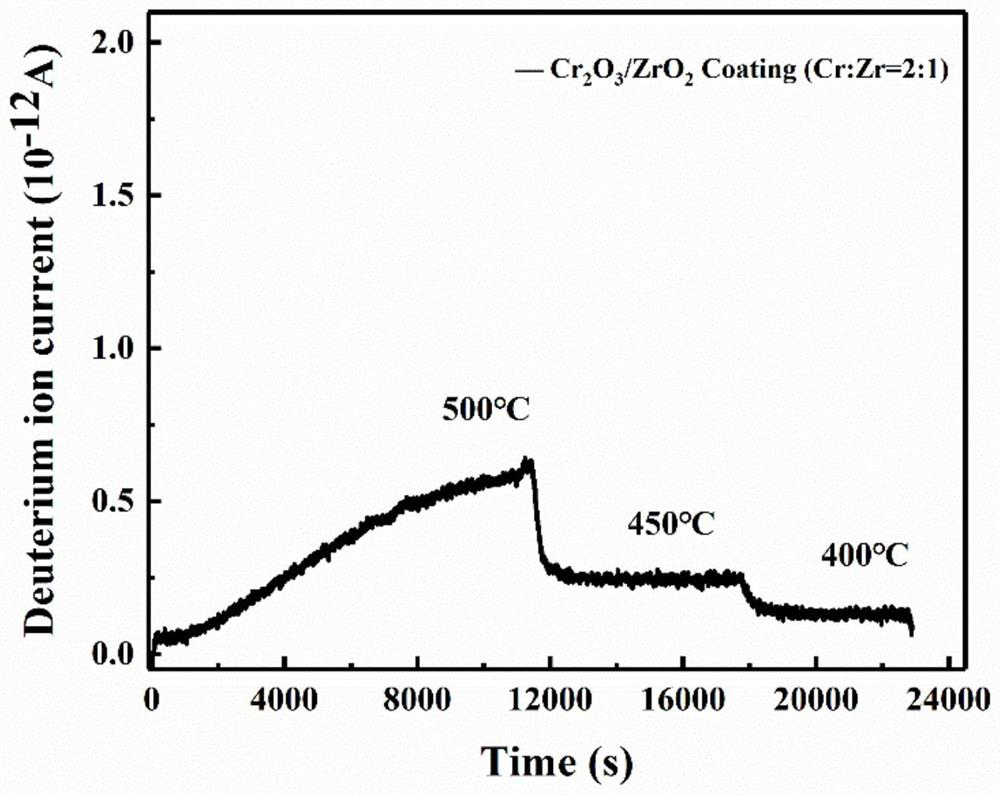

[0039] A Cr with a Cr and Zr molar ratio of 2:1 2 O 3 / ZrO 2 The composite hydrogen / deuterium / tritium permeation barrier coating is prepared by the following methods:

[0040] 1. Polish the 321L stainless steel to a mirror surface, deionize it with ethanol for 15 minutes, and clean it with acetone.

[0041] 2. Weigh 3 g of zirconium acetate, add 50 ml of absolute ethanol, 2.5 ml of acetone, and 50 μl of glacial acetic acid, place it on a magnetic stirrer and stir for about 10 hours until it is fully dissolved and become clear and transparent, and stand still for 24 hours to obtain a zirconium sol; 2.46 g of chromium acetate was added, and the mixture was ultrasonicated for 0.5 h or magnetically stirred for about 1 h to obtain a mixed sol.

[0042] 3. The dipping and pulling process is completed with a pulling machine. The pulling speed is uniform throughout the process. The pulling speed is set to 400 μm / s. After pulling, the wet sol and the substrate are placed at 80 °C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com