Method for preparing hydrogen permeation preventing coating by aluminizing by adopting room temperature fused salt

A room temperature molten salt and aluminum plating technology is applied in nuclear technology and application fields to achieve the effects of maintaining mechanical properties, improving tritium resistance and eliminating voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Embodiment 1: on the tubular 1Cr18Ni9Ti austenitic stainless steel substrate surface preparation hydrogen permeable coating, the specific steps are as follows:

[0032] 1. Take a cylindrical 1Cr18Ni9Ti austenitic stainless steel substrate sample with a diameter of 60mm, a thickness of 3mm, and a height of 60mm, and first use conventional methods to degrease and remove the oxide film;

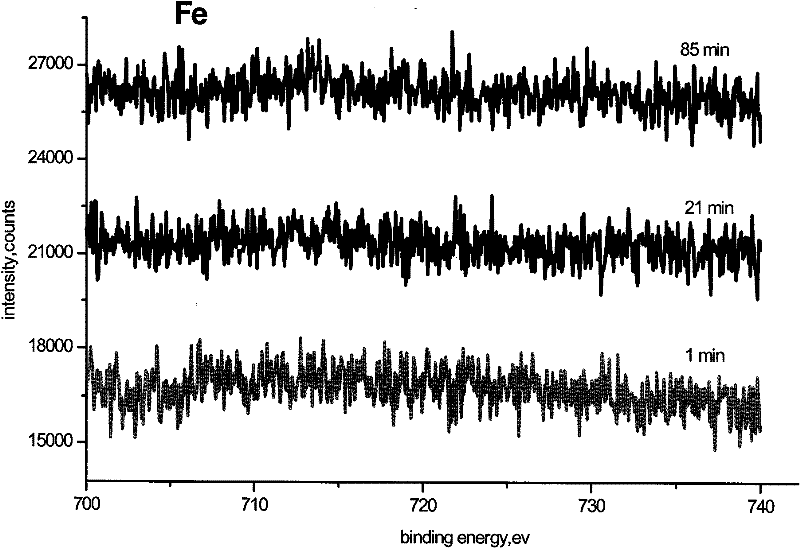

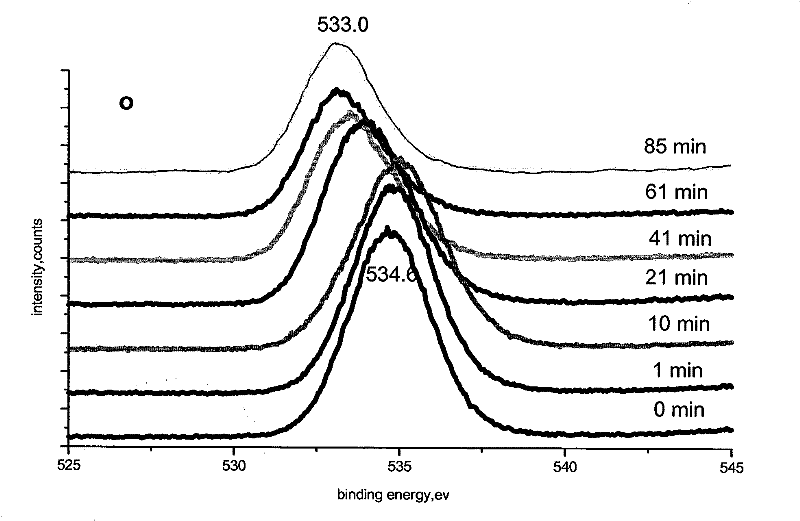

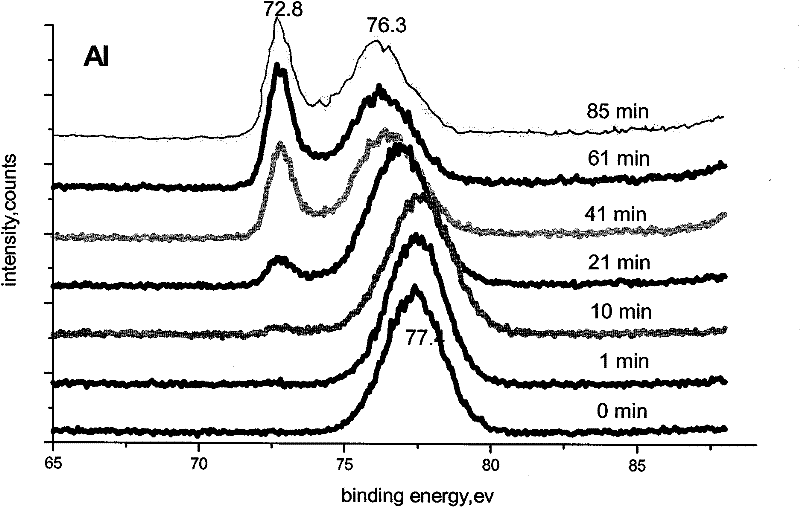

[0033] 2. Put the sample into the AlCl in the argon protection glove box 3 In a solution composed of 1-methyl-3-ethylimidazole chloride (EMIC), where AlCl 3 The molar ratio to 1-methyl-3-ethylimidazole chloride (EMIC) is 2:1. Then carry out aluminum plating at room temperature 25°C, current density 20mA / cm 2 , plating for 50min, to obtain an aluminum coating with a thickness of about 20μm, such as figure 1 As shown, the coating is well bonded to the substrate.

[0034] 3. After plating, the sample is heat-treated in an air furnace at a temperature of 750 ° C and kept for 4 hours to obt...

Embodiment 2

[0037] Embodiment 2: on the surface of the tubular HR-2 austenitic stainless steel substrate, a hydrogen-resistant permeable coating is prepared, and the specific steps are as follows: 1. get a tubular HR-2 austenitic stainless steel substrate sample with a diameter of 60 mm, a thickness of 3 mm, and a height of 60 mm. First, conventional methods are used to degrease and remove the oxide film;

[0038] 2. Put the sample into the AlCl in the argon protective glove box 3 In a solution composed of 1-methyl-3-ethylimidazole chloride (EMIC), where AlCl 3 The molar ratio to 1-methyl-3-ethylimidazole chloride (EMIC) is 2:1. Then aluminum plating is carried out at room temperature 25°C with a current density of 10mA / cm 2 , Plating for 100min, an aluminum coating with a thickness of about 20μm was obtained, and the coating was well bonded to the substrate.

[0039] 3. The sample after plating is heat-treated in an air furnace at a temperature of 750°C and held for 4 hours to obtain ...

Embodiment 3

[0042] Embodiment 3: A hydrogen permeation-resistant coating is prepared on the surface of a tubular HR-2 austenitic stainless steel substrate. The specific steps are as follows:

[0043] 1. Take a tubular HR-2 stainless steel substrate sample with a diameter of 60mm, a thickness of 3mm, and a height of 60mm, and first use conventional methods to degrease and remove the oxide film;

[0044] 2. Put the sample into the AlCl in the argon protective glove box 3 In a solution composed of 1-methyl-3-ethylimidazole chloride (EMIC), where AlCl 3 The molar ratio to 1-methyl-3-ethylimidazole chloride (EMIC) is 2:1. Then carry out aluminum plating at room temperature 25°C, current density 5mA / cm 2 , Plating for 200min, an aluminum coating with a thickness of about 20μm was obtained, and the coating was well bonded to the substrate.

[0045] 3. After plating, the sample is heat-treated in an air furnace at a temperature of 750 ° C and kept for 24 hours to obtain a Fe-Al alloy layer wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com