A preparation method of a metal hydride surface hydrogen permeation resistance layer

A hydride and permeable layer technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of difficult to prepare coatings, complex shapes, etc., to achieve improved hydrogen permeation resistance and adaptability Strong, prevent hydrogen release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

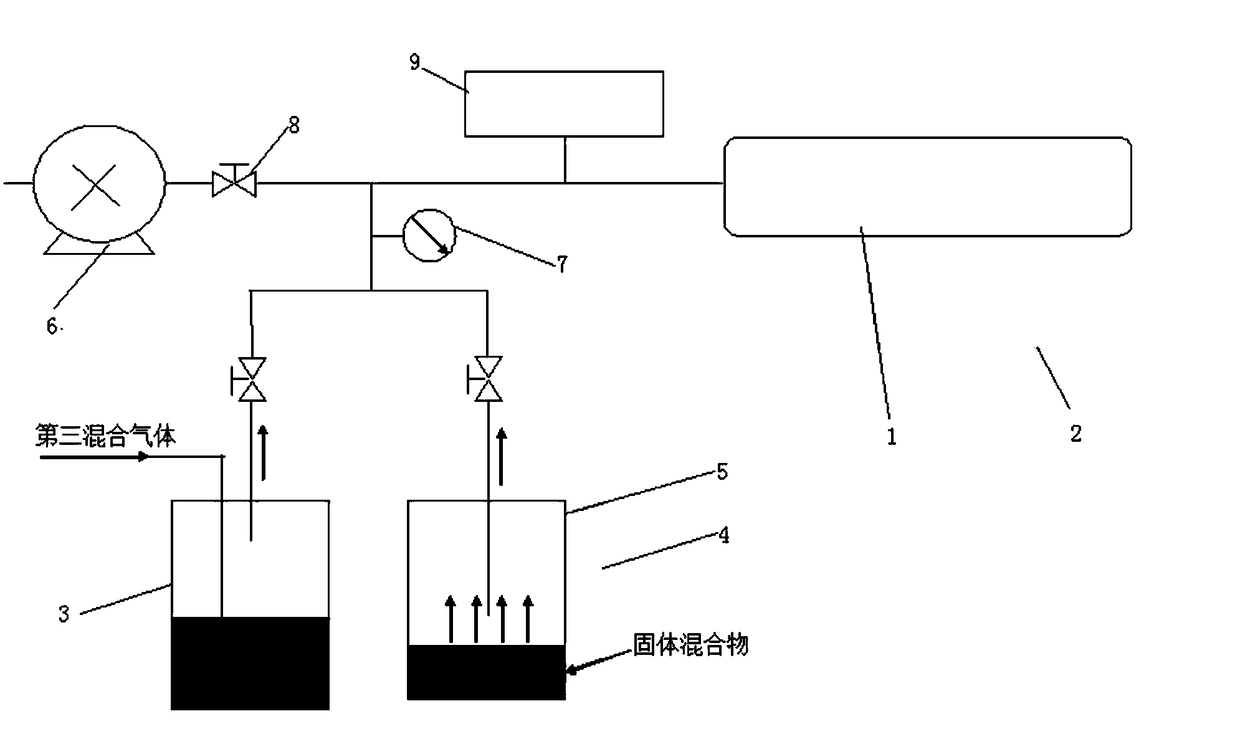

[0028] The preparation device of the hydrogen barrier permeable layer adopted in this embodiment is as follows: figure 1 shown.

[0029] 1. Degrease, clean and polish the surface of Φ20mm×20mm zirconium hydride, zirconium hydride H / Zr=1.0.

[0030] 2. Put zirconium hydride in a sealed and ventilated stainless steel vacuum reaction vessel 1, put the reaction vessel 1 into the first temperature-controlled heating furnace 2, and vacuumize the reaction vessel 1 to 2.0×10 -4 Pa.

[0031] 3. In situ reaction:

[0032] (1) In terms of volume percentage, according to CO:CO 2 :H 2 =5:80:15 ratio gas distribution, the mixed gas is distributed into water vapor through the water scrubbing device 3, and the gas flow rate is 0.2 liters / minute;

[0033] (2) The solid mixture of calcium carbonate, magnesium carbonate, and ammonium carbonate each 10kg is packed into decomposition reaction bed 5, and decomposition reaction bed 5 is inserted in the second temperature-control type heating fu...

Embodiment 2

[0039] 1. Degrease, clean and polish the surface of Φ20mm×20mm zirconium hydride, zirconium hydride H / Zr=1.6.

[0040] 2. Put zirconium hydride in a sealed and ventilated stainless steel vacuum reaction vessel, put the reaction vessel into a heating furnace, and vacuumize to 1.0×10 -4 Pa.

[0041] 3. In situ reaction:

[0042] (1) In terms of volume percentage, according to CO:CO 2 :NH 3 :N 2 :H 2 =20:35:35:5:5 ratio gas distribution;

[0043] (2) Connect the inlet valve, pass the mixed gas in (1) into the reaction vessel at a speed of 0.2 liters / minute, and open the reaction vessel outlet valve until the reaction vessel pressure reaches 0.1MPa;

[0044] (3) At the same time of constant ventilation, first raise the heating furnace from room temperature to 500°C at a rate of 300°C / hour, and keep it warm for 100 hours; then cool it down to room temperature at a rate of 10°C / hour, and the carbon-nitrogen-containing Oxygen barrier to hydrogen permeation.

Embodiment 3

[0046] 1. Degrease, clean and polish the surface of Φ20mm×20mm zirconium hydride, zirconium hydride H / Zr=1.80.

[0047] 2. Put zirconium hydride in a sealed and ventilated high-temperature-resistant glass vacuum reaction vessel, put the reaction vessel into a heating furnace, and vacuumize to 2.0×10 -4 Pa.

[0048] 3. In situ reaction:

[0049] (1) In terms of volume percentage, according to CO:CO 2 :H 2 =80:10:10 ratio gas distribution, the mixed gas is mixed with water vapor through the water scrubbing device, and the gas flow rate is 0.2 liters / minute;

[0050] (2) Calcium carbonate, magnesium carbonate, sodium carbonate each 10kg are packed into decomposition reaction bed, and reaction bed is heated up to 700 ℃ and decomposes and produces the gas containing carbon, oxygen, gas flow rate 0.1 liter / minute;

[0051] (3) the gas obtained in (1) is passed into the reaction vessel with a speed of 0.2 liters / minute; simultaneously the gas in (2) is passed into the reaction ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com