Multifunctional printing post-processing equipment

A processing equipment, multi-functional technology, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of poor coating quality, unreasonable structure, large size, etc., to achieve good coating quality, simple and compact structure , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

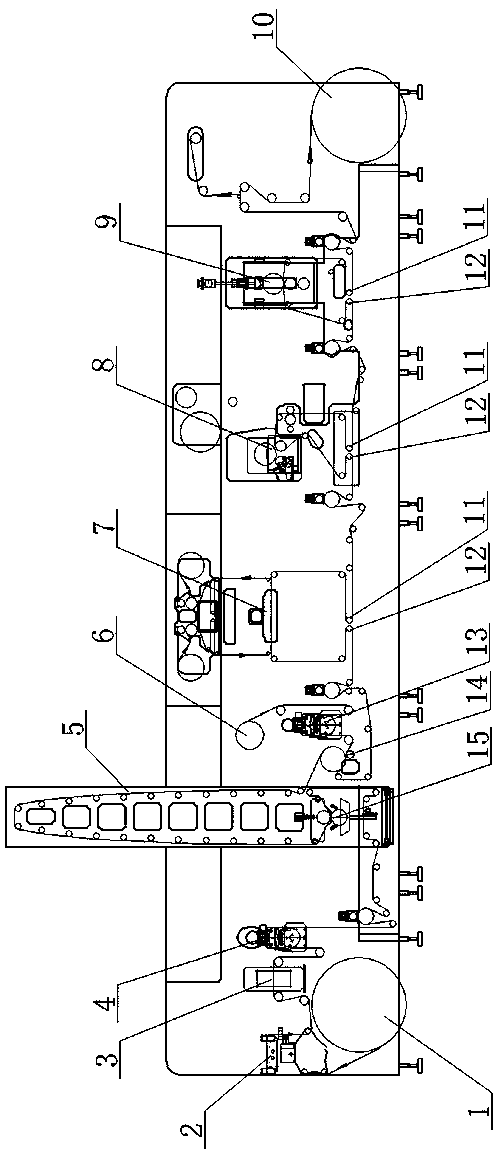

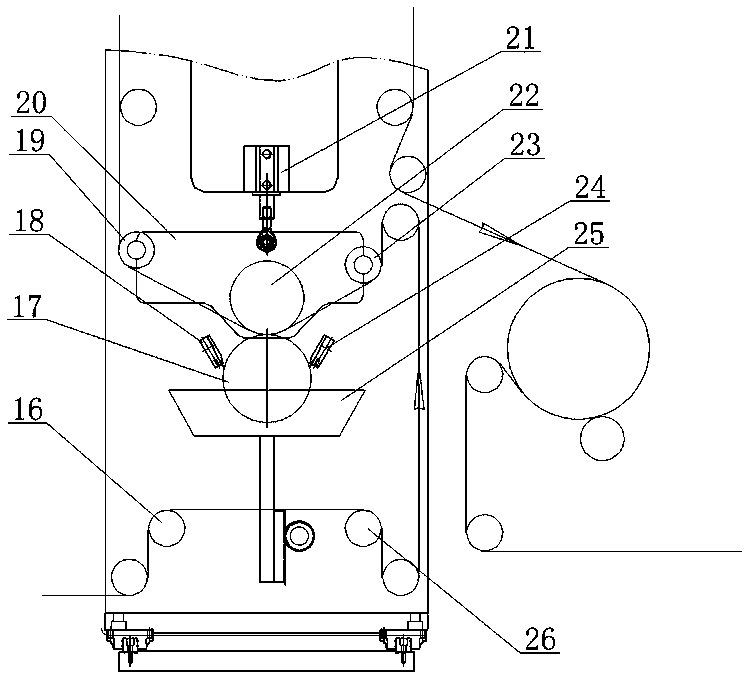

[0012] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0013] As shown in the figure, the multifunctional post-printing processing equipment of the present invention includes a first unwinding component 1, a deviation correcting component 2, a dust removal component 3, a first corona component 4, a composite component 14, a coating Cloth parts 15, flat ironing and bronzing parts 7, intermittent flexo printing parts 8, intermittent circular die-cutting parts 9 and winding parts 10, a second unwinding part 6 is arranged above the composite part 14, and the second unwinding part 6 is combined with the composite part 14. A second corona component 13 is arranged between the components 14 , and a vertical oven 5 is arranged immediately above the coating component 15 . There are front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com