A pipe inner wall coating device

A technology for coating devices and pipes, applied in the directions of spraying devices, cleaning methods and utensils, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

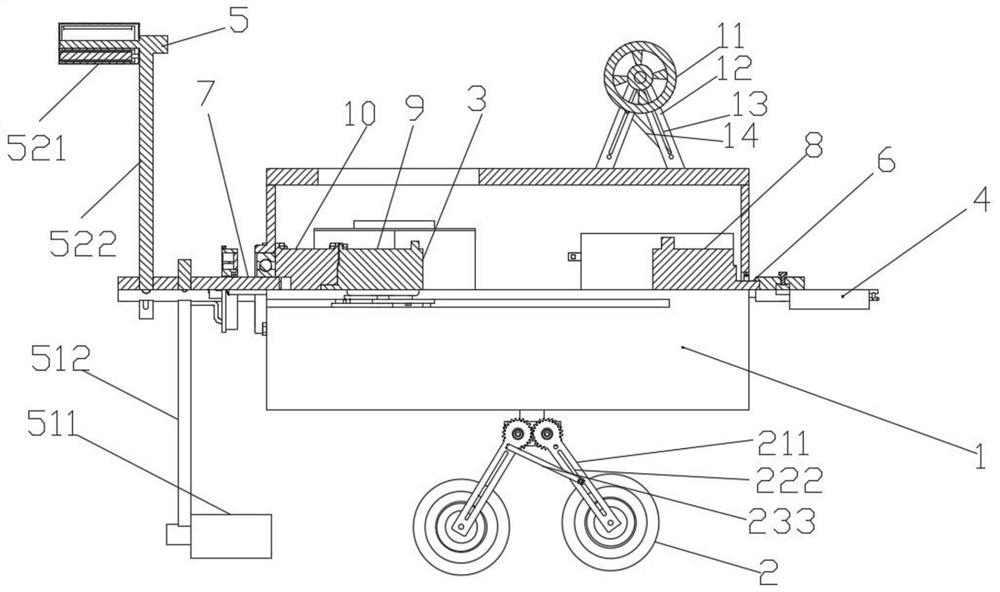

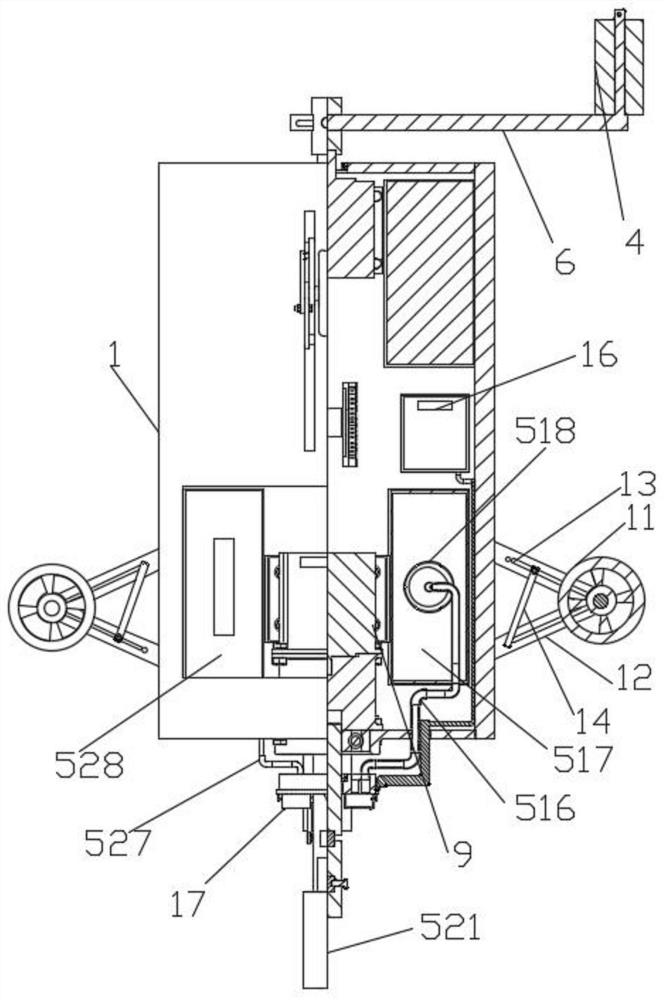

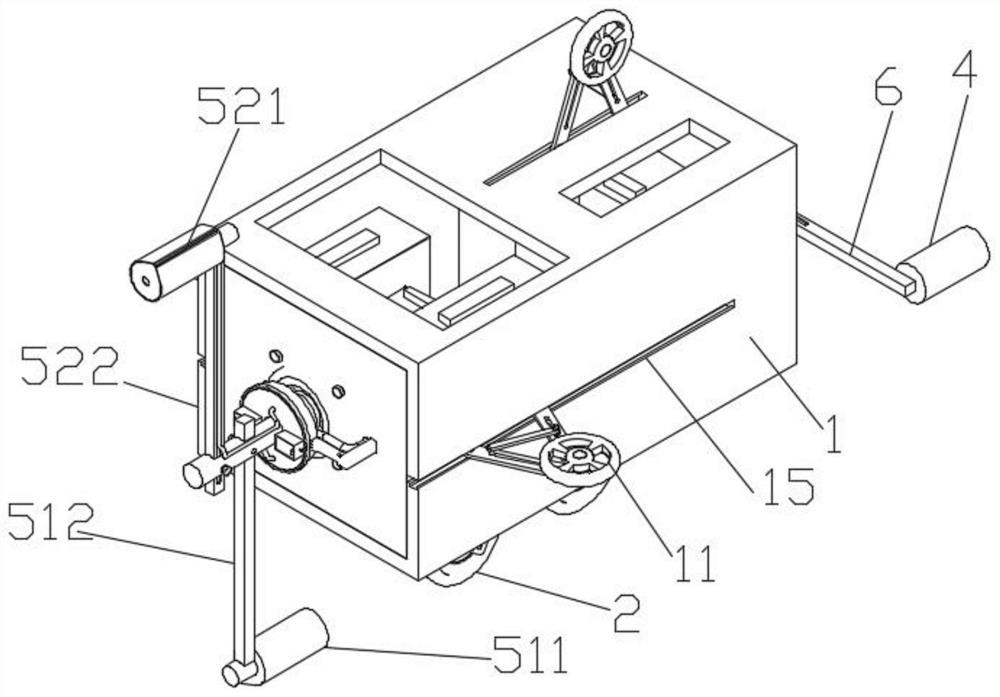

[0049] The embodiment of the present invention provides a pipe inner wall coating device, the specific structure is as follows Figure 1-Figure 3 As shown, it includes a housing 1, the outer bottom surface of the housing 1 is connected with a wheel 2, and there is a rotating device 3 inside the housing 1. Both ends of the rotating device 3 extend outside the housing 1, and one end of the rotating device 3 outside the housing 1 A cleaning device 4 is connected, and the other end of the rotating device 3 is connected with a coating mechanism 5 for coating the inner wall of the pipeline.

[0050] Working principle: Put the device into the pipe whose inner diameter is compatible with the coating device, then turn on the rotating device 3, the rotating device 3 drives the cleaning device 4 to clean the inner wall of the pipe, and the rotating device 3 drives the coating mechanism 5 to clean at the same time Coating is carried out on the inner wall of the final pipe, and then the wh...

Embodiment 2

[0052] This implementation mode is regarded as a preferred embodiment of the present invention, and the specific structure is as follows Figure 1-Figure 3 As shown, it discloses the following improvements on the basis of Embodiment 1. The rotating device 3 includes a cleaning shaft 6 and a coating shaft 7. There are a first motor 8 and a second motor 9 inside the housing 1. One end of the cleaning shaft 6 extends Connect to the first motor 8 in the housing 1, the other end of the cleaning shaft 6 is connected to the cleaning device 4, one end of the coating shaft 7 extends into the housing 1 and is connected to the second motor 9, and the other end of the coating shaft 7 Connect with coating mechanism 5.

[0053] When in use, the first motor 8 is turned on, the first motor 8 works to drive the cleaning shaft 6 to rotate, and the cleaning shaft 6 drives the cleaning device 4 to clean the pipeline. Then open the second motor 9, the second motor 9 works to drive the coating rot...

Embodiment 3

[0056] This implementation mode is regarded as a preferred embodiment of the present invention, and the specific structure is as follows Figure 1-Figure 3 As shown, it discloses the following improvements on the basis of Embodiment 2. The coating mechanism 5 includes a glue assembly 511 and a micro-nano powder assembly 521. The glue assembly 511 is disposed close to the housing 1, and the micro-nano powder assembly 521 is disposed away from the housing 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com