A kind of ion beam coating equipment and coating method thereof

A coating equipment and ion beam technology, applied in the field of ion beam coating equipment and its coating, can solve the problems of infrared device loss, inability to ensure the cleaning and coating of infrared devices, and difficulty in meeting the requirements of the deposition angle of the substrate, etc., to improve adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

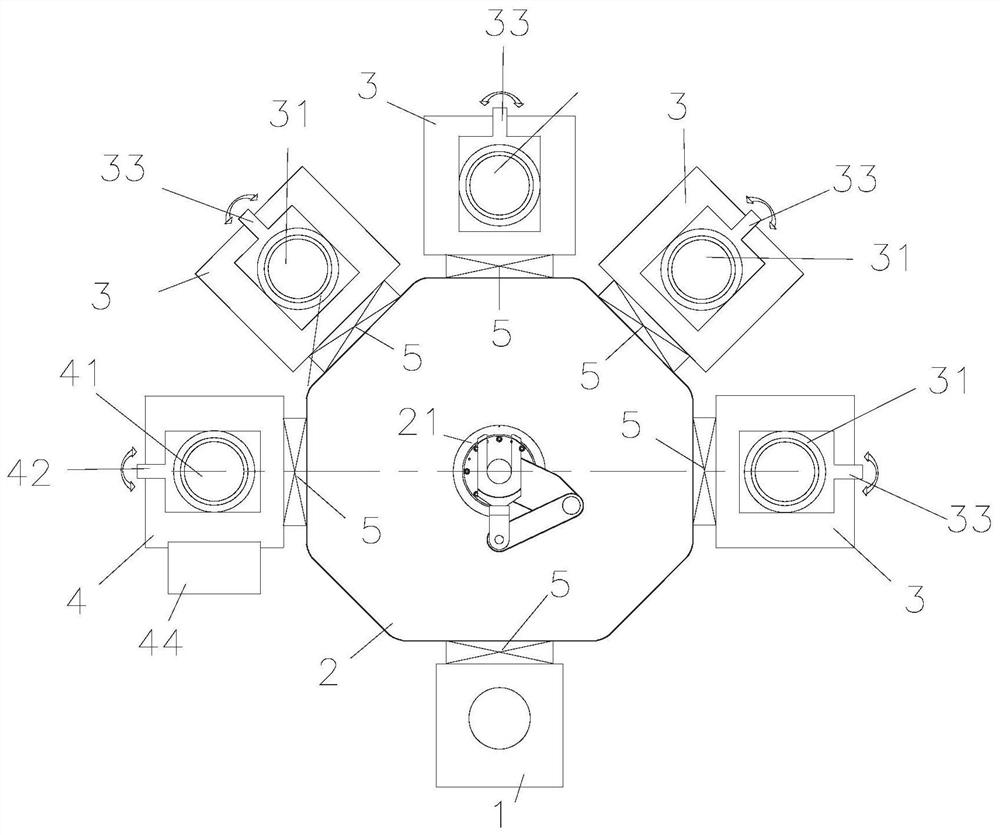

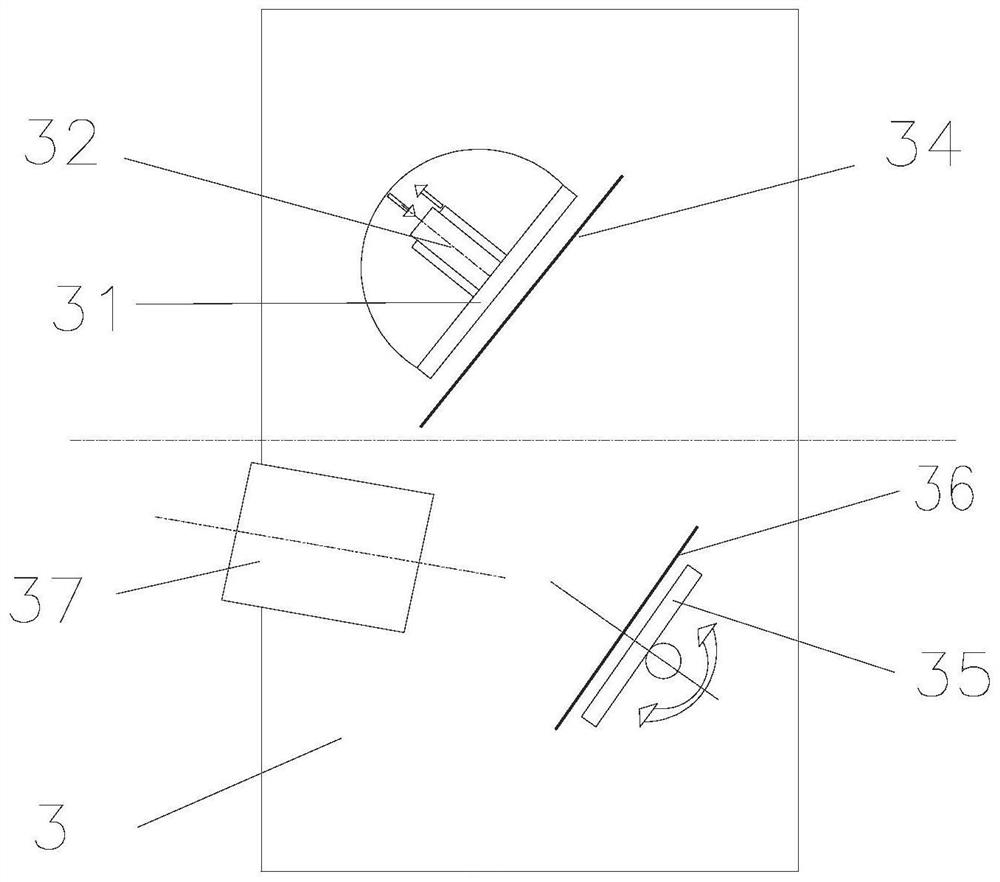

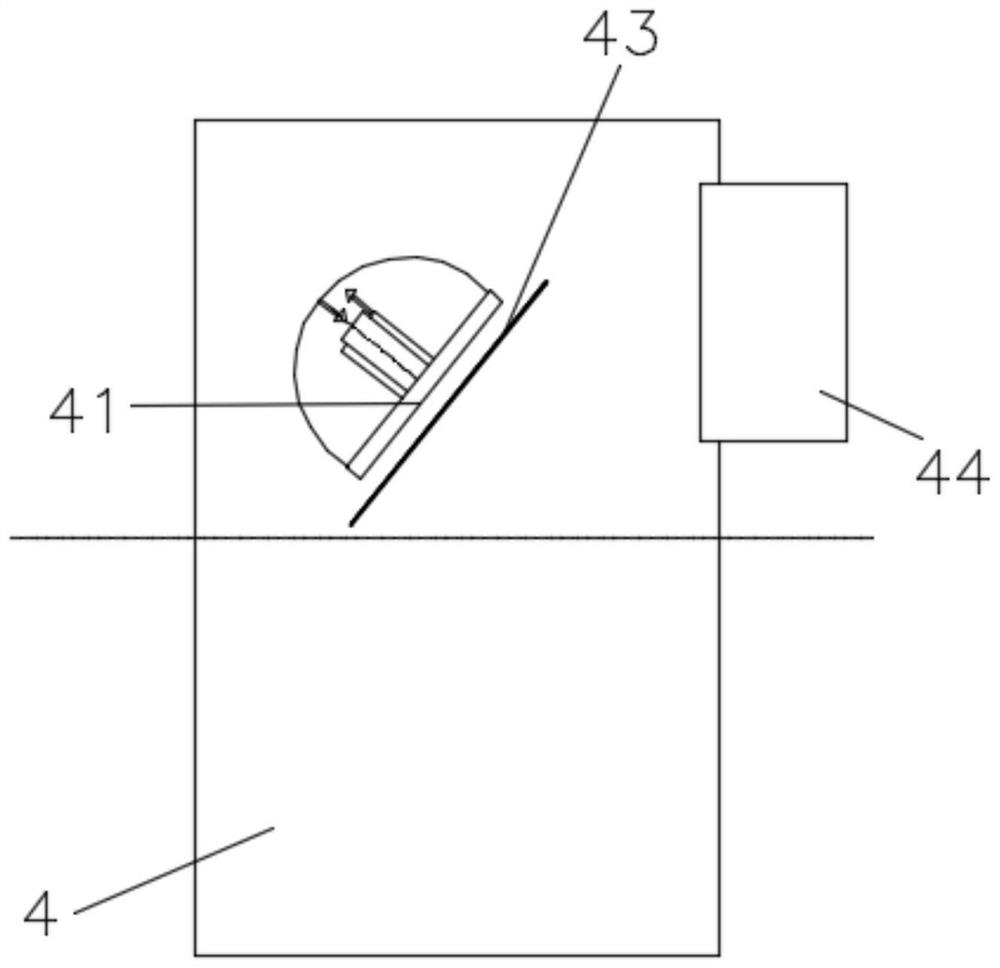

[0039] like figure 1 , figure 2 and image 3 As shown, the ion beam coating equipment of this embodiment includes a loading and unloading chamber 1, a transfer chamber 2 for transferring substrates, at least one coating chamber 3 for substrate coating and a cleaning chamber 4; loading and unloading chambers The chamber 1, the coating chamber 3 and the cleaning chamber 4 are respectively connected to the transfer chamber 2; an isolation valve 5 is provided between the loading and unloading chamber 1 and the transfer chamber 2; between the transfer chamber 2 and the coating chamber 3 An isolation valve 5 is provided; an isolation valve 5 is provided between the transfer chamber 2 and the cleaning chamber 4 ; a transfer mechanism 21 for transferring substrates is provided in the transfer chamber 2 .

[0040] In the present invention, a loading and unloading chamber 1 is provided for storing different types of substrates, and a variety of different types of substrates can be pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com