Resin hardening agent of coating film, ink coating film composition and ink coating film manufacturing method

A resin hardening and manufacturing method technology, which is applied in the field of resin hardener and ink coating film manufacturing, can solve the problems of reduced production capacity, increased process cost, and increased process complexity of fingerprint identification devices, so as to improve production capacity and reduce the process. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

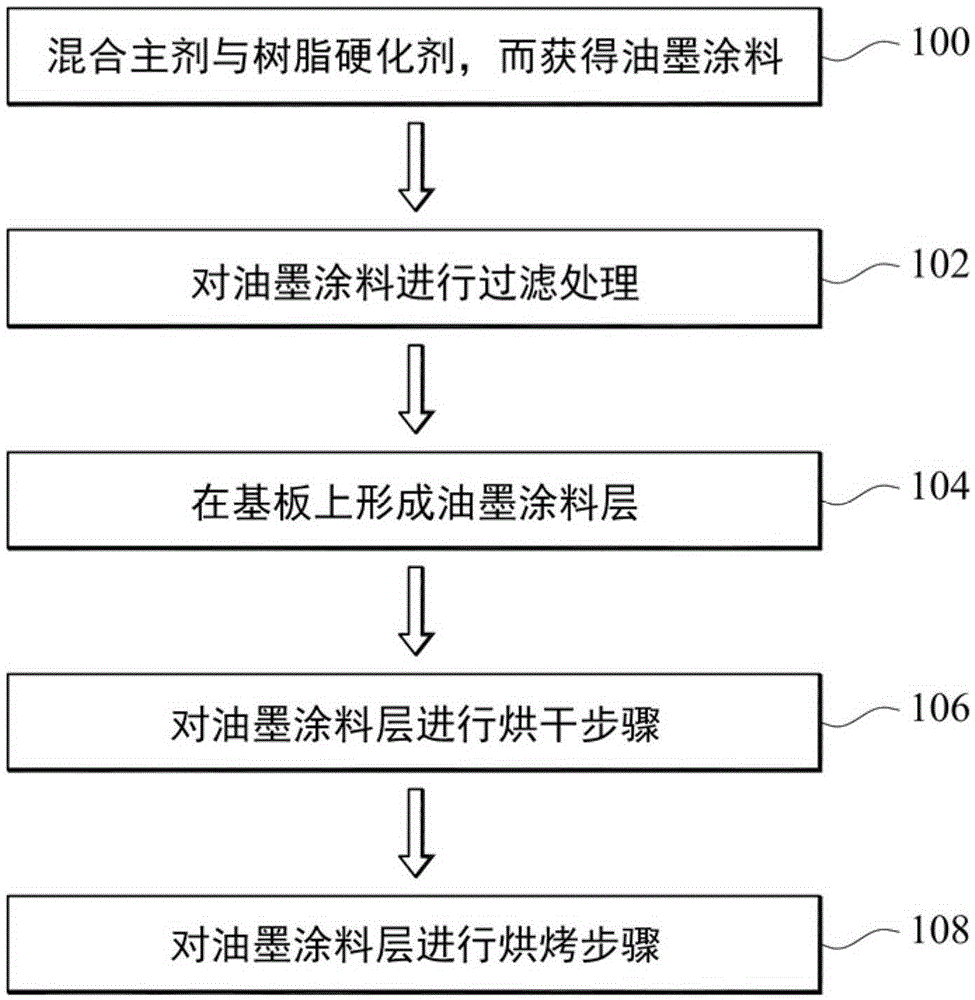

Image

Examples

Embodiment Construction

[0042] In one embodiment of the present invention, the resin hardener of the coating film is suitable for the production of the ink coating film of the fingerprint reader. In some examples, the resin hardener of the coating film includes silicone resin, silicone coupling agent resin and organic solvent. For example, based on the total weight percentage of the resin hardener being 100wt%, the content of the silicone resin is 0.1wt% to 99.8wt%, the content of the silicone coupling agent resin is 0.1wt% to 99.8wt%, and the content of the organic solvent The content is 0.1wt% to 99.8wt%.

[0043] The silicone resin can be, for example, silicone modified resin or silicone oil. Silicone resin is a polymer between organic and inorganic. In some instances, silicone resins have the formula [-R 2 SiO-] n , wherein R is an alkane, acrylic, epoxy or aromatic group. The material of silicone resin is composed of inorganic silicon-oxygen bond skeleton (...-Si-O-Si-O-Si-O-...) and branch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com