A Method for Improving the Coating Quality of Linear Magnetron Sputtering Target Gun on Concave Cylindrical Substrate

A magnetron sputtering and substrate technology, applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc. Reduce and other problems, achieve the effects of reducing adverse effects, improving film quality, and improving reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

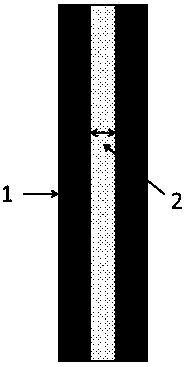

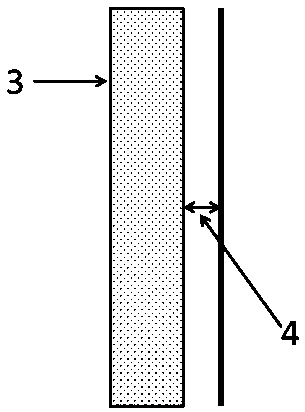

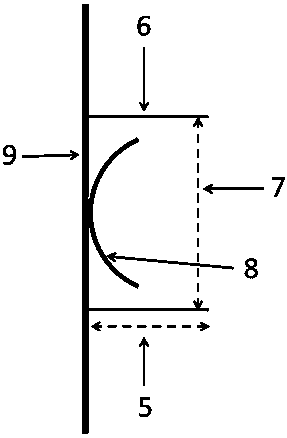

[0022] The equipment for process improvement has the following characteristics: the target gun is a linear magnetron sputtering target gun, and the size of the sputtering surface of the target gun is 38mm×508mm. In view of the special shape of the target gun and the large incident angle of the sputtered particles on the substrate due to its special shape, the combination of the mask plate and the partition plate is used to limit the incident angle of the sputtered particles on the substrate. Improve film quality.

[0023] When preparing a cylindrical concave mirror, the plated sample is cylindrical D263 glass with a diameter of 170 mm, an arc angle of 60°, an axial length of 210 mm, and a thickness of 0.27 mm. The sample busbar is placed along the horizontal direction, and the central busbar is parallel to the sample holder on the target surface and located in the center of the sample holder. Two partitions parallel to the horizontal direction and perpendicular to the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com