Firmly buckled cable hanging bracket

A cable hanger, a solid technology, applied in the direction of cable installation, cable installation, electrical components, etc. in the tunnel, can solve the problem of the cable suspension device not being fastened tightly, so as to improve the aesthetics, easy to use, and avoid being stuck in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

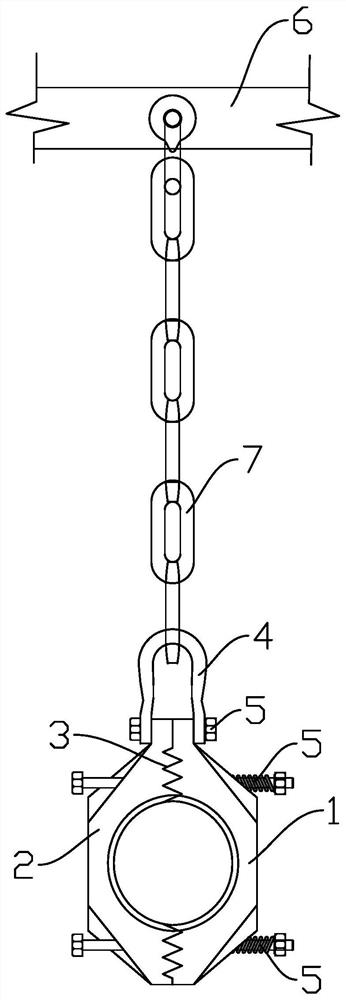

[0052] like Figure 1-2 As shown, the present invention provides a cable hanger with firm fastening. The cable hanger includes a fixed angle steel 6, a suspension device 7 and a clamp, wherein the suspension device 7 is a chain structure, and the clamp includes a connecting hardware 4 and a first claw. 1 and the second claw 2, wherein the first claw 1 is set opposite to the second claw 2, one end of the coupling hardware 4 is connected to the suspension device 7, and the other end is connected to the first claw 1 through a shaft connection or a bolt 5 connection. It is fixedly connected with the upper end of the second claw 2, and at this moment, the first claw 1 and the second claw 2 can rotate relative to each other and there is no gap between the two.

[0053] It should be noted that, as shown in the figure, the opposite parts of the first claw 1 and the second claw 2 are recessed and the joints of the two are connected by a toothed connection surface 3, so when fixing the ...

Embodiment 2

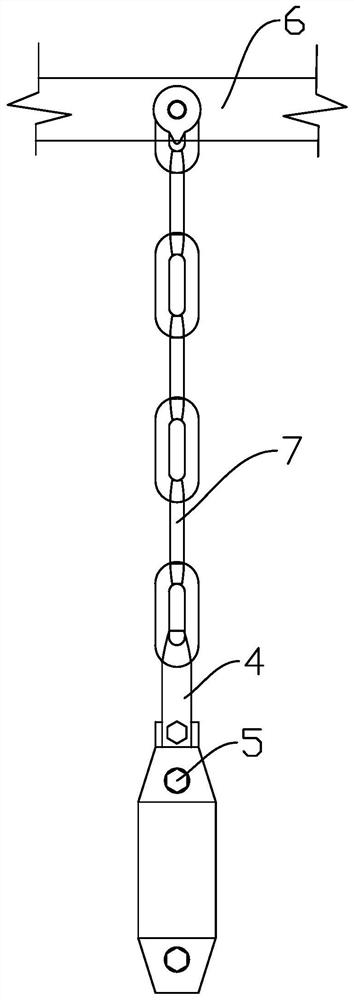

[0057] The difference between this embodiment 2 and embodiment 1 is: as Figure 3-Figure 5 As shown, the present invention provides a cable hanger with strong fastening. The clamp part of the cable hanger is quite different from the embodiment, and its overall structure is shown in the figure.

[0058] Specifically, the clamp includes a first jaw 1 and a second jaw 2, wherein the first jaw 1 includes a first connecting piece 11 and a second connecting piece 12, and the second jaw 2 includes a third connecting piece 21 and a second connecting piece 21. Four connectors 22, such as Figure 4 As shown, the first connecting piece 11 and the third connecting piece 21 are both fixedly connected with the coupling hardware 4, the second connecting piece 12 is rotationally connected with the lower end of the first connecting piece 11, the fourth connecting piece 22 is connected with the third connecting piece 21 The lower end of the rotary connection. When fixing the cables, the secon...

Embodiment 3

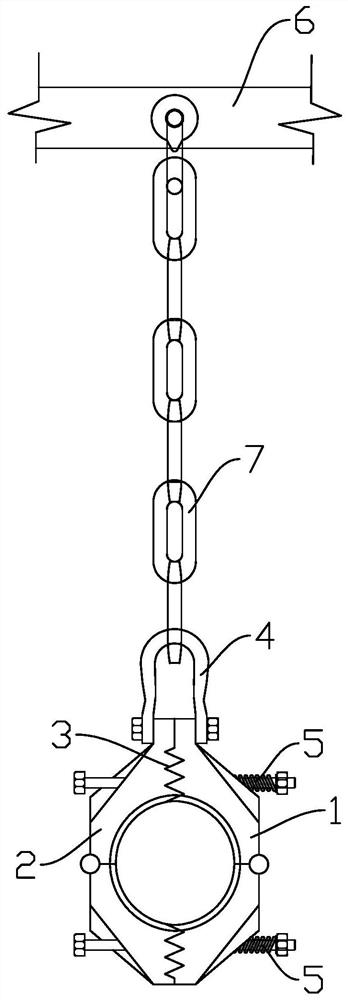

[0062] The difference between this embodiment 3 and embodiment 1 is: as Figure 6-8 As shown, the present invention provides a cable hanger with firm fastening. Compared with Embodiment 1, the cable hanger changes the fixing method of the clamp. 8 Fasten on the fixture from bottom to top by means of sleeve.

[0063] Under the action of the fixing assembly 8, the lower ends of the first claw 1 and the second claw 2 can be firmly fixed together, or the penetrating space formed by the first claw 1 and the second claw 2 can be fixed in the fixing assembly 8 The closure is achieved with the help of the , which helps to secure the cable.

[0064] Specifically, the fixing assembly 8 is a U-shaped structure with an open upper end, and its two ends extend upwards and are slightly offset toward the direction of the clamp to form buckles 81, and the distance between the two buckles 81 is smaller than the maximum width of the clamp. The maximum width of the fixed assembly 8 is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com