Coating equipment for optical fiber cable processing

A technology for cladding equipment and optical fiber cables, which is applied in the field of cladding equipment, can solve the problems of slow work progress, lack of prompt function, and inability to know the use of raw materials, etc., and achieve the effect of improving the efficiency of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

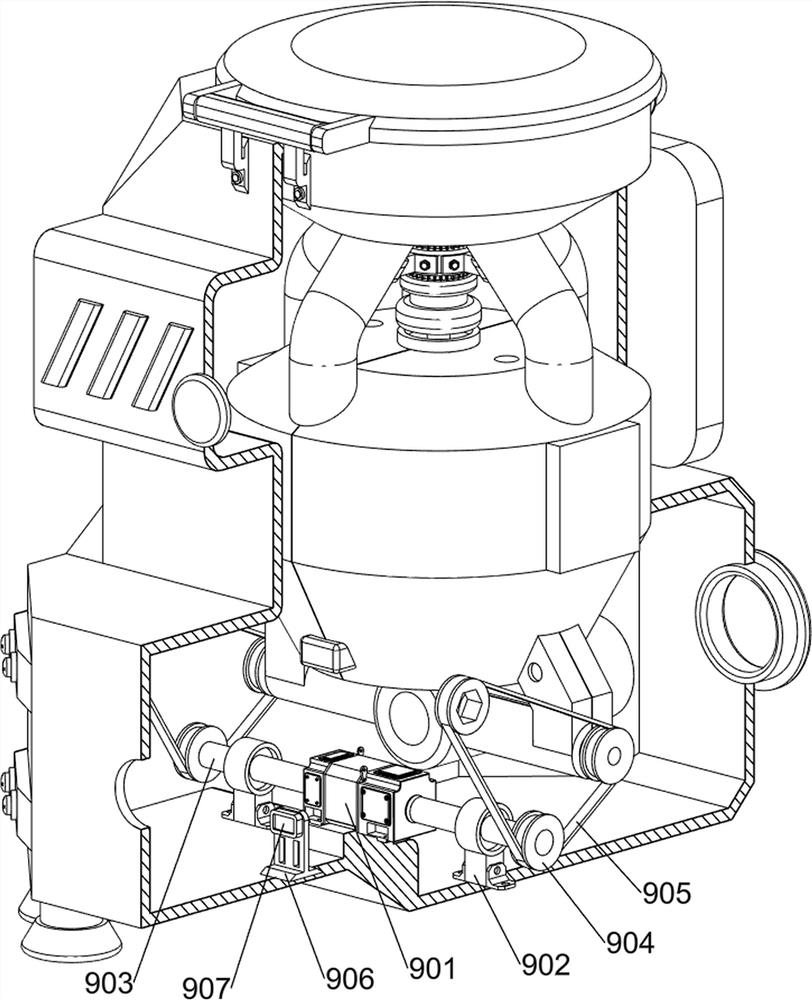

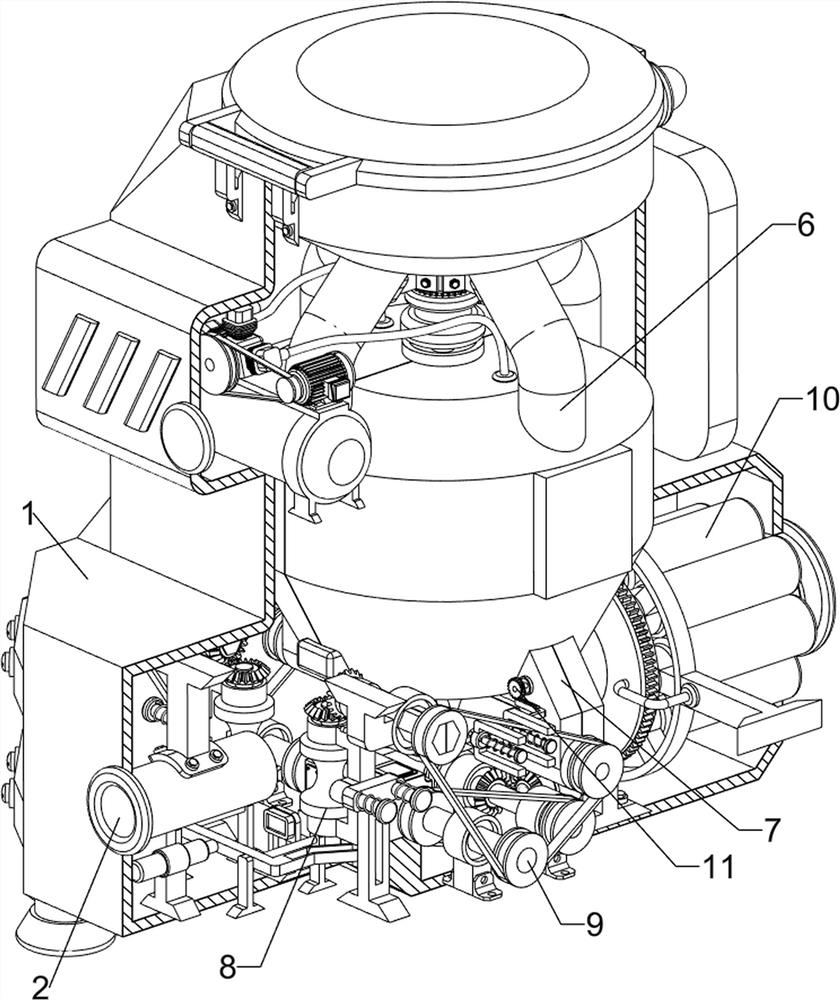

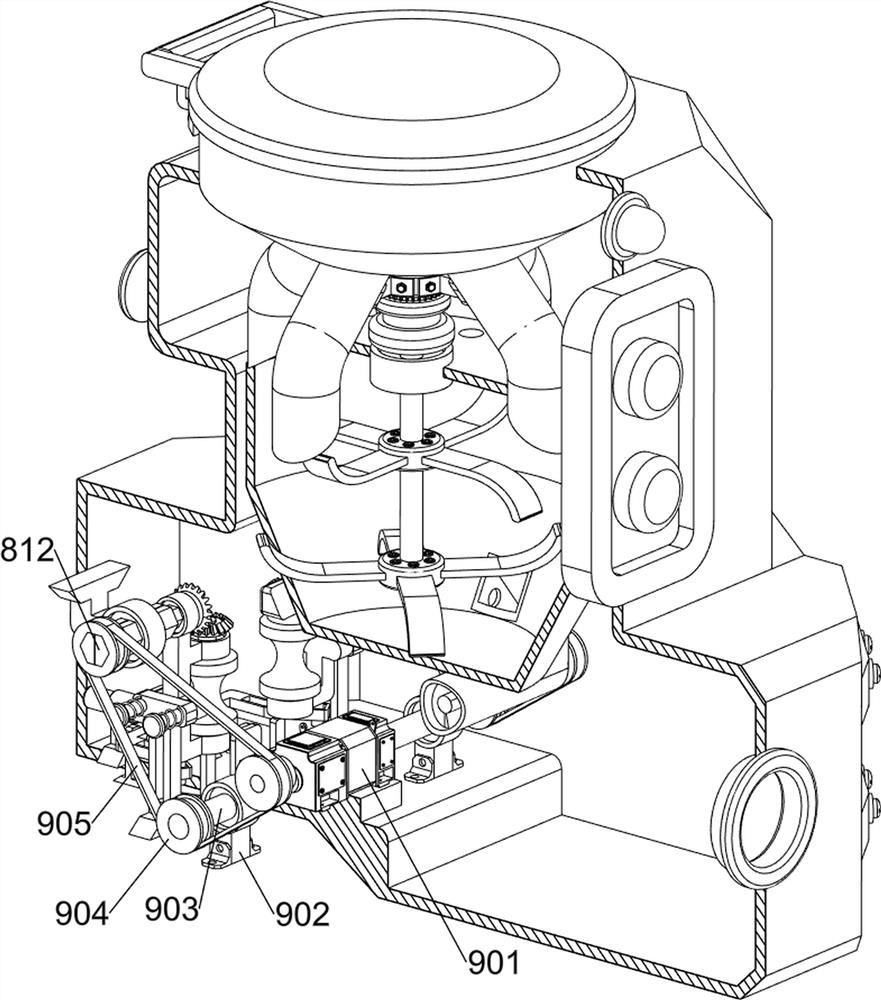

[0039] A kind of cladding equipment for optical fiber and cable processing, such as Figure 1-Figure 13 As shown, it includes a support shell 1, a feed port 2, a stirring blade 4, a discharge cylinder 5, a stirring assembly 6, an extruding assembly 7, a feeding assembly 8 and a driving assembly 9. Material port 2, a stirring assembly 6 is installed on the inner upper side of the supporting shell 1, and the stirring blade 4 is symmetrically connected up and down on the inner side of the stirring assembly 6, and an extruding assembly 7 is connected in the middle of the inner lower side of the supporting shell 1, and an outlet assembly 7 is installed on the extruding assembly 7. The feeding cylinder 5 is provided with a feeding assembly 8 on the lower left side inside the supporting shell 1 , and a driving assembly 9 is connected between the feeding assembly 8 and the extruding assembly 7 .

[0040] The stirring assembly 6 includes a cover plate 601, a feeding frame 602, a stirri...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 14-Figure 19 As shown, a sizing assembly 10 is also included, and the sizing assembly 10 includes a second transmission wheel 1001, a second transmission belt 1002, a fifth support block 1003, a third rotating shaft 1004, a second bevel gear 1005, a sixth support block 1006, The first gear 1007, the second support frame 1008, the fixed plate 1009, the ring rack 1010, the second gear 1011 and the shaping roller 1012, the fifth support block 1003 is fixed symmetrically front and back in the middle of the lower side of the support shell 1, and the fifth support A third rotating shaft 1004 is rotatably arranged between the inner side of the upper part of the block 1003, and the front and rear sides of the third rotating shaft 1004 are connected with a second transmission wheel 1001, and the inner side of the second rotating shaft 903 is also connected with a second transmission wheel 1001. A second transmission belt 1002 is wound b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com