Kerf cover plate with locking function

A cover and slit technology, which is applied in the direction of metal sawing equipment, sawing machine accessories, metal processing equipment, etc., can solve the problems of the work surface of the slit cover and the inconvenient disassembly of the slit cover, and achieve the elimination of The effect of conflicting effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

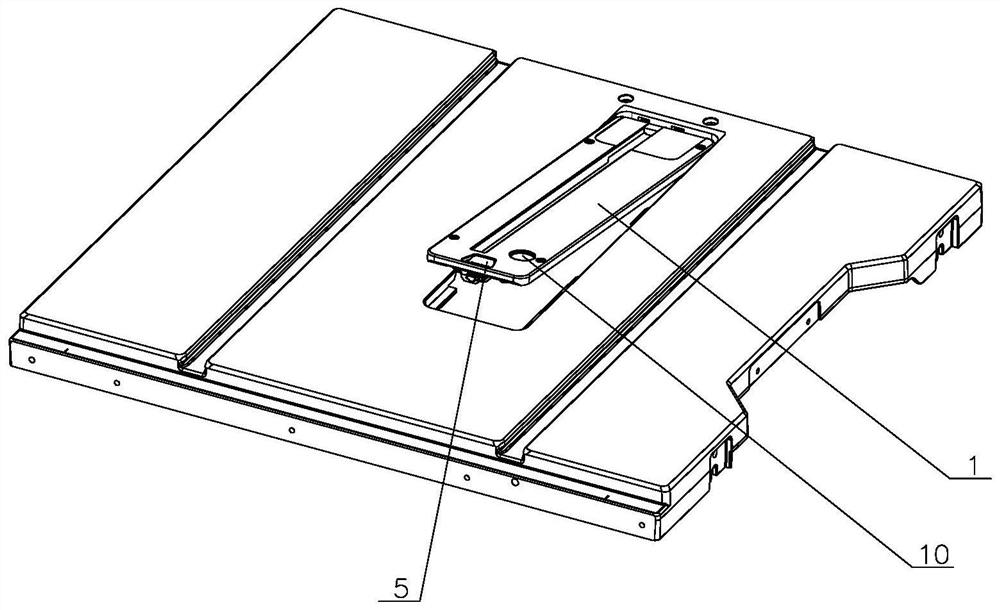

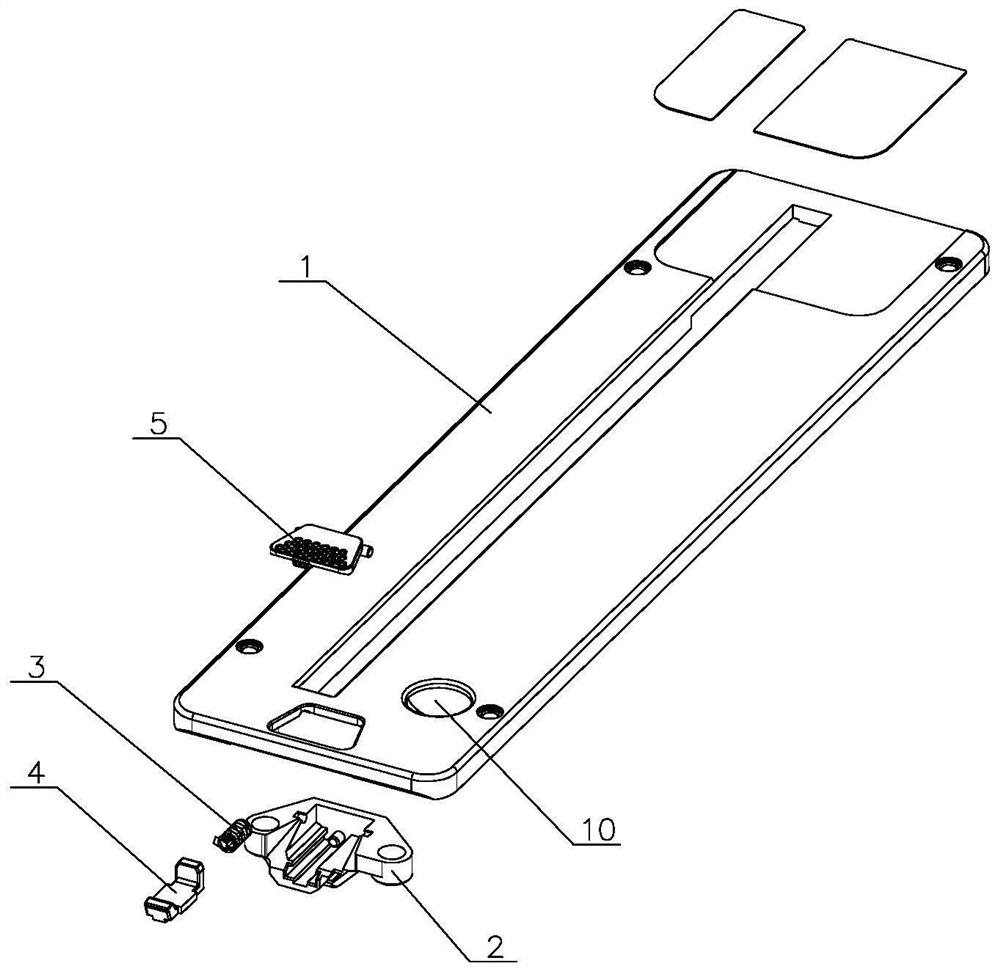

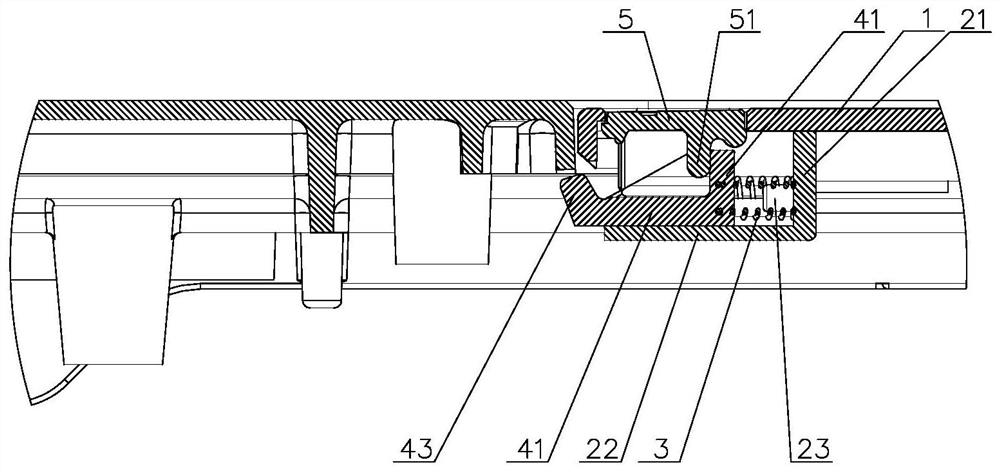

[0022] Such as figure 1 , 2 , 3, 4, and 5, a kerf cover with a locking function is applied to the worktable of a table saw, and the worktable corresponds to the kerf and the area around the kerf is a rectangular hollow area. The slit cover is installed inside, and the cover main body 1 of the slit cover is a rectangular plate. The end of the cover main body 1 near the edge of the worktable has two relatively protruding engaging parts. At the same time, the above-mentioned hollow area The corresponding end of 1 has two concave slots, and the end of the main body of the cover plate is matched with the unevenness of the work surface to form a snap-fit positioning, and the other end of the main body 1 of the cover plate is equipped with a locking mechanism.

[0023] The locking mechanism is mainly composed of a mounting seat 2, an elastic expansion member 3, a locking member 4, and an operating member 5; specifically, the mounting seat 2 is L-shaped and fixed under the cover ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com