Shirt collar manufacturing process with soluble lining

A production process and collar technology, applied in the field of clothing, can solve the problems of lack of anti-bacteria and anti-mildew functions, discomfort of the human body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

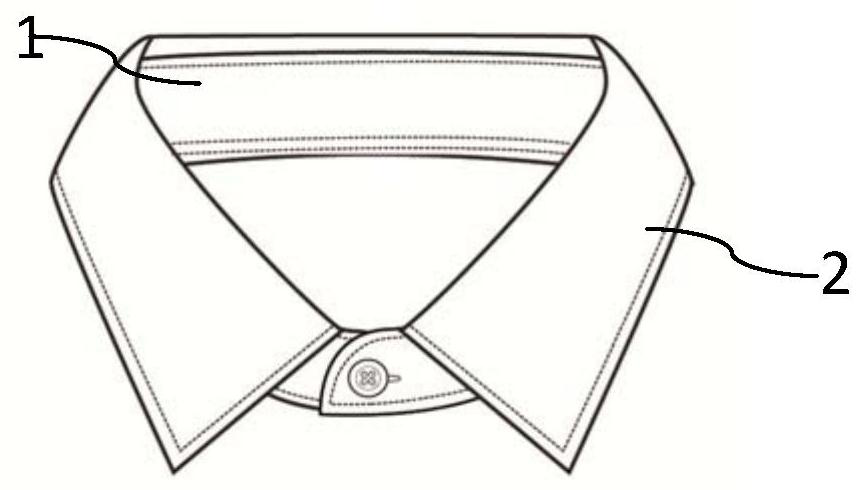

[0023] combined with Figure 1 to Figure 4 A manufacturing process of a shirt collar with a soluble lining is illustrated in the present invention.

[0024] A kind of shirt collar manufacturing process that adds dissolvable liner, comprises material, upper collar liner 23 and lower collar liner 13, described upper collar liner 23 and / or lower collar liner 13 have anti-mildew and antibacterial layer, described lower collar liner 13 is water-soluble resin lining; Described technique comprises the following steps:

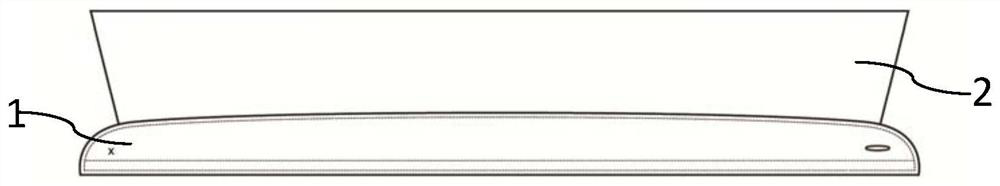

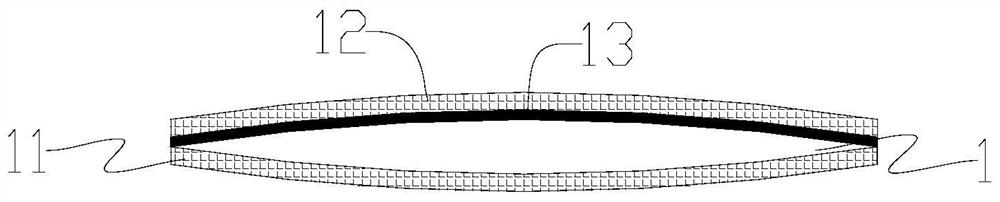

[0025] Cutting, cutting the fabric to form the upper collar surface 21, the upper collar bottom 22, the lower collar surface 11 and the lower collar bottom 12;

[0026] Trimming, trimming the edges of the upper collar bottom 22, the upper collar bottom 22, the lower collar surface 11 and the lower collar bottom 12;

[0027] Sticking the lining, sticking and pressing the upper collar lining 23 on the upper collar bottom 22, and sticking and pressing the lower collar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com