Insert injection molding robot

A technology of insert injection molding and robotics, applied in the field of robotics, can solve the problem that the side of the ball cannot be completely wrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

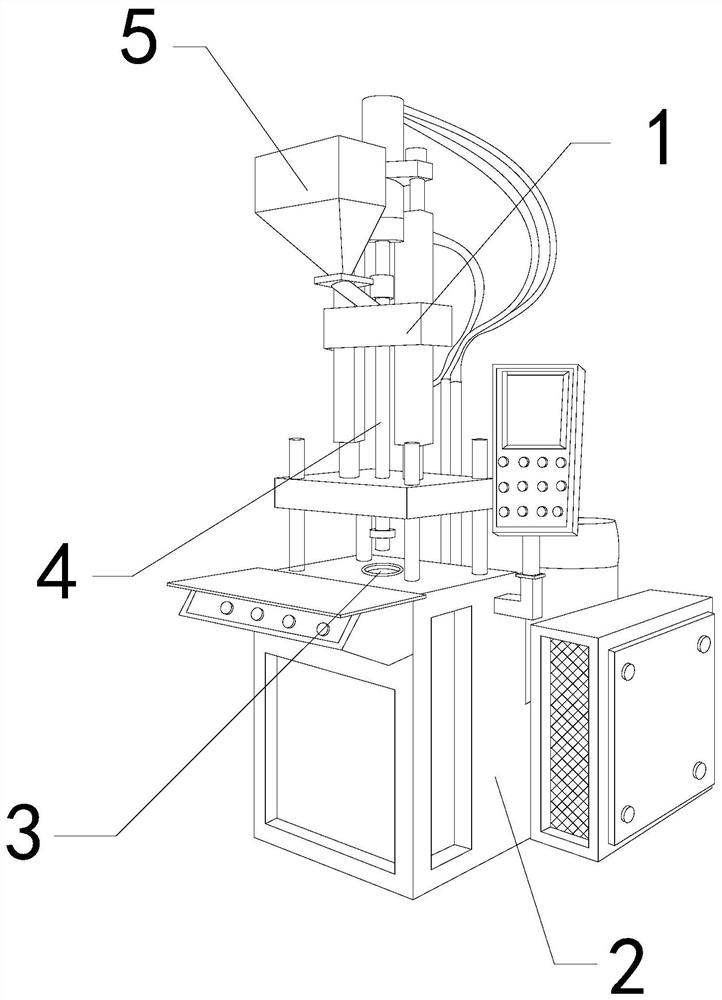

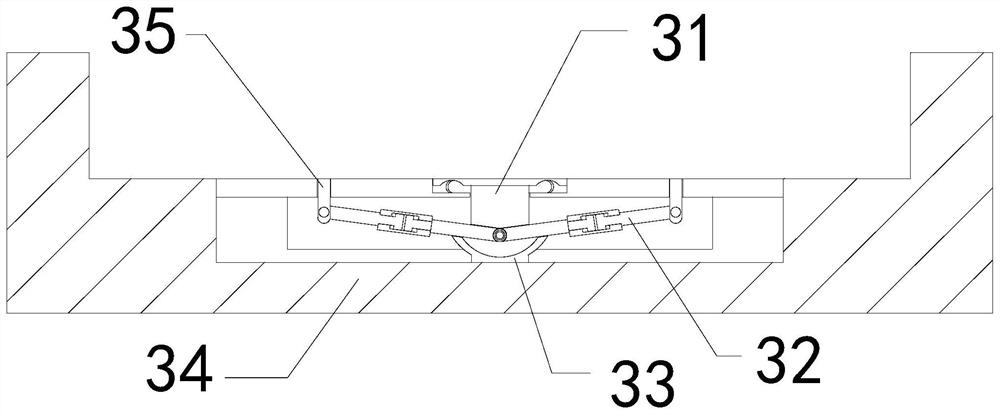

[0027] The invention provides an insert injection molding robot, the structure of which includes a support frame 1, a base 2, a mold groove 3, an injection pipe 4, and a heating bucket 5. The support frame 1 is embedded and connected to the upper end of the base 2, and the injection pipe 4 is welded with the support frame 1, the heating bucket 5 is connected with the injection pipe 4, the mold groove 3 and the base 2 are an integrated structure; the mold groove 3 includes a force-bearing block 31, a linkage frame 32, a fixing seat 33. Frame body 34, blocking mechanism 35, the force-bearing block 31 and the middle part of the frame body 34 are in clearance fit, one end of the linkage frame 32 is connected to the blocking mechanism 35, and the other end of the linkage frame 32 is connected to the frame body 34 The inner wall is hingedly connected, the fixed seat 33 and the frame body 34 are an integrated structure, and th...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

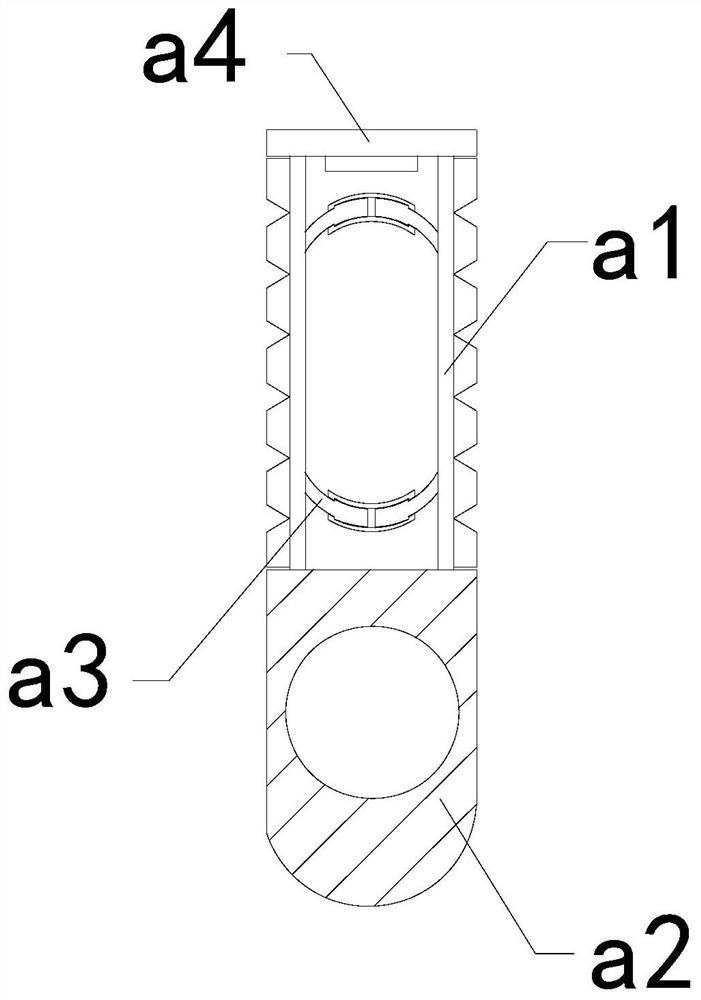

[0035] Wherein, the upper connection plate a4 includes a sliding plate c1, a guide frame c2, and a pull-back bar c3, the slide plate c1 is movably engaged with the guide frame c2, and the pull-back bar c3 is installed between the two slide plates c1 There are two sliding plates c1, which are evenly distributed symmetrically on the pedestal c2, and the sliding plate c1 can slide to both sides through the thrust generated by the plastic material on the sliding plate c1.

[0036]Wherein, the sliding plate c1 includes a contact plate c11, an upper extension plate c12, a base plate c13, and a connecting frame c14, the contact plate c11 is embedded and connected with the upper end of the upper extension plate c12, and the upper extension plate c12 is connected with the base plate c13 is movable and engaged, and the connecting frame c14 is installed between the base plate c13 and the upper extension plate c12, and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com