Glass lining equipment firing frame

A glass-lined and equipment technology, applied in the field of glass-lined equipment firing frames, can solve problems such as adhesion, glass-lined difficult to remove directly, enamel fixed on, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

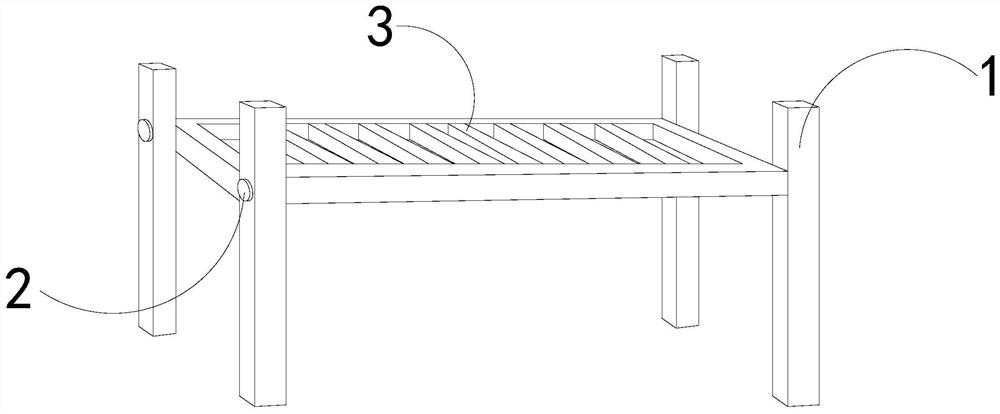

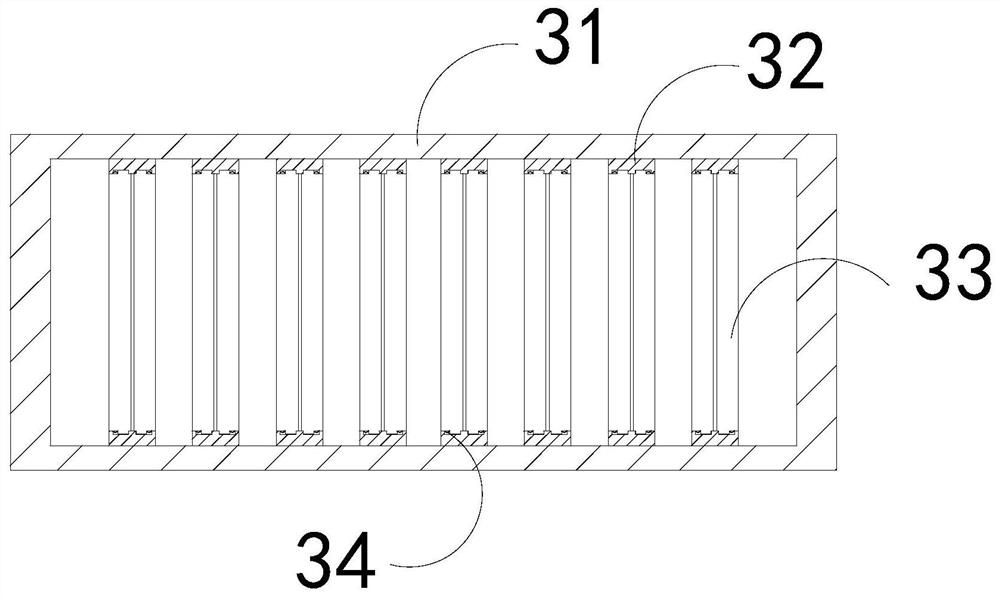

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides a firing frame for glass-lined equipment, the structure of which includes a support frame 1, fixing nails 2, and a bearing plate 3. The fixing nails 2 are embedded and connected to the support frame 1, and the bearing plate 3 and the support frame 1 are Integrated structure; the bearing plate 3 includes an outer frame 31, a guide block 32, a receiving plate 33, and a reset piece 34, the guide block 32 and the outer frame 31 are an integrated structure, and the receiving plate 33 and the guide block 32 are movable The reset piece 34 is installed between the receiving plate 33 and the guide block 32 .

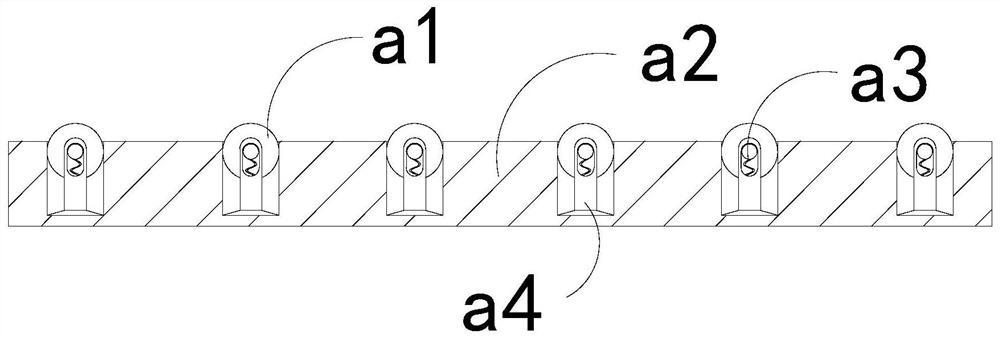

[0028] Wherein, the receiving plate 33 includes a shrinking roller a1, a plate body a2, an elastic strip a3, and a connecting rod a4, the shrinking roller a1 is movably engaged with the connecting rod a4, and the elastic strip a3 is installed on the shrinking roller a1 and the connecti...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the board surface b2 includes a blocking roller b21, an external connecting plate b22, and a guide cavity b23, the blocking roller b21 is movably engaged with the external connecting plate b22, the guiding cavity b23 and the external connecting plate b22 are an integrated structure, and the guiding cavity b23 is integrated with the external connecting plate b22. The cavity b23 has a transparent structure inside and outside, and enamel debris can be introduced into the cavity through the guiding cavity b23.

[0036] Wherein, the blocking roller b21 includes an outer plate c1, an elastic ring c2, a middle solid plate c3, and a middle connecting piece c4. The position of the outer surface of the middle solid plate c3, the middle joint c4 is fixed between the two outer plates c1, the two outer plates c1 are evenly distributed symmetrically outside the middle solid plate c3 , the outer panel c1 can be shrun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com