Intelligent modern logistics sorting machine

A modern logistics and sorting machine technology, applied in the field of intelligent modern logistics, can solve the problem that logistics boxes are not easy to pick up and sort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

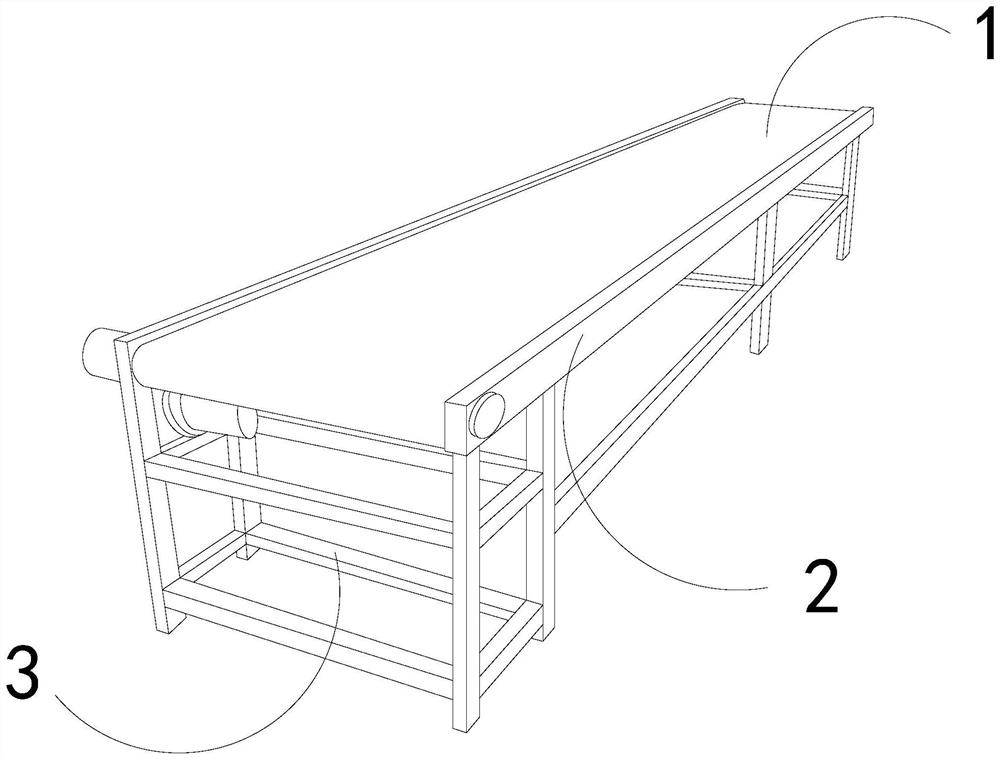

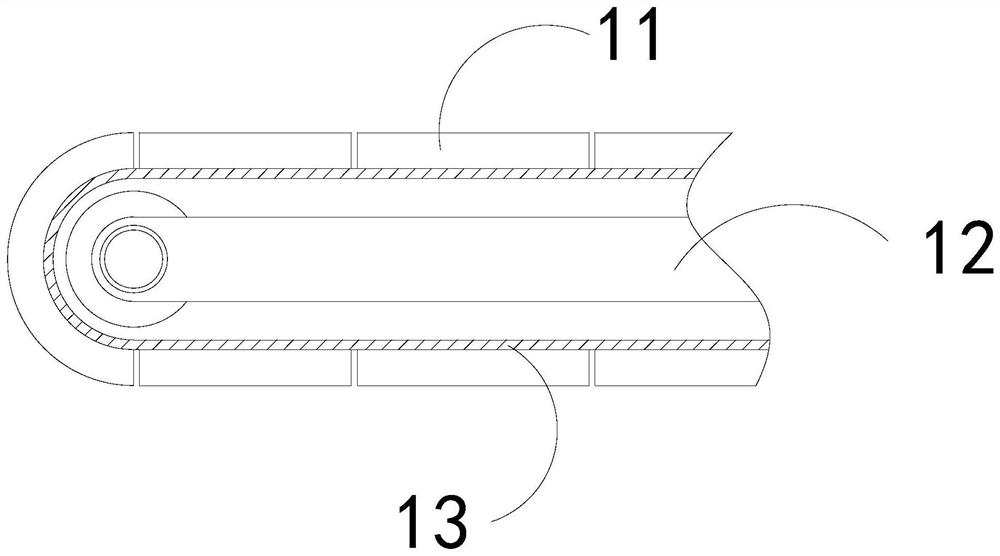

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides an intelligent modern logistics sorting machine, the structure of which includes a conveyor belt 1, a frame 2, and a base 3, the frame 2 and the base 3 are welded, and the conveyor belt 1 and the frame 2 are movably engaged; the conveyor belt 1 includes 11. The power frame 12 and the linkage belt 13, the said 11 is embedded and fixed on the outer surface of the linkage belt 13, and the said linkage belt 13 is engaged with the power frame 12 movably.

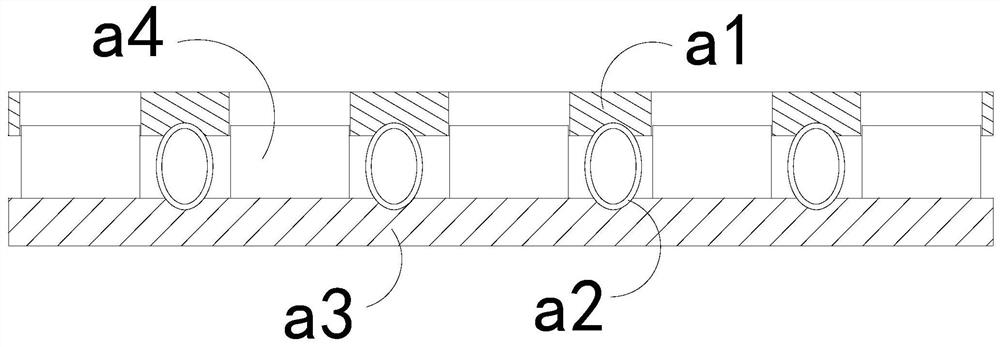

[0028] Wherein, the said 11 includes a contraction plate a1, an elastic ring a2, a bottom plate a3, and an upward stretching plate a4, the shrinking plate a1 is movably engaged with the bottom plate a3 through the elastic ring a2, and the bottom of the upward stretching plate a4 is connected to the bottom of the bottom plate a3. The upper surface is embedded and connected, and the upper stretching plate a4 is in clearance fit with the ...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the air outlet b2 includes an outer frame b21, a middle solid rod b22, an elastic bar b23, and a force-bearing block b24. The middle solid bar b22 and the outer frame b21 are an integrated structure, and the elastic bar b23 is installed The internal position of the rod b22, the force-bearing block b24 is movably engaged with the middle solid rod b22, the force-bearing block b24 has an isosceles trapezoidal structure, and the force-bearing block b24 can be pushed upward by the airflow to the upper end outlet of the outer frame b21. clogged.

[0036] Wherein, the force-bearing block b24 includes a blocking piece c1, an outer connecting plate c2, a movable plate c3, and an engaging ring c4. It is an integrated structure, the connecting ring c4 is installed between the two movable plates c3, there are six blocking pieces c1, and three are evenly distributed symmetrically on the left and right sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com