A wood floor residual wax wiping machine

A floor and deceleration motor technology, which is applied in the direction of cleaning floors, carpets, cleaning machines, etc., can solve the problems of low work efficiency and manpower consumption, and achieve the effects of improving work efficiency, simple operation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

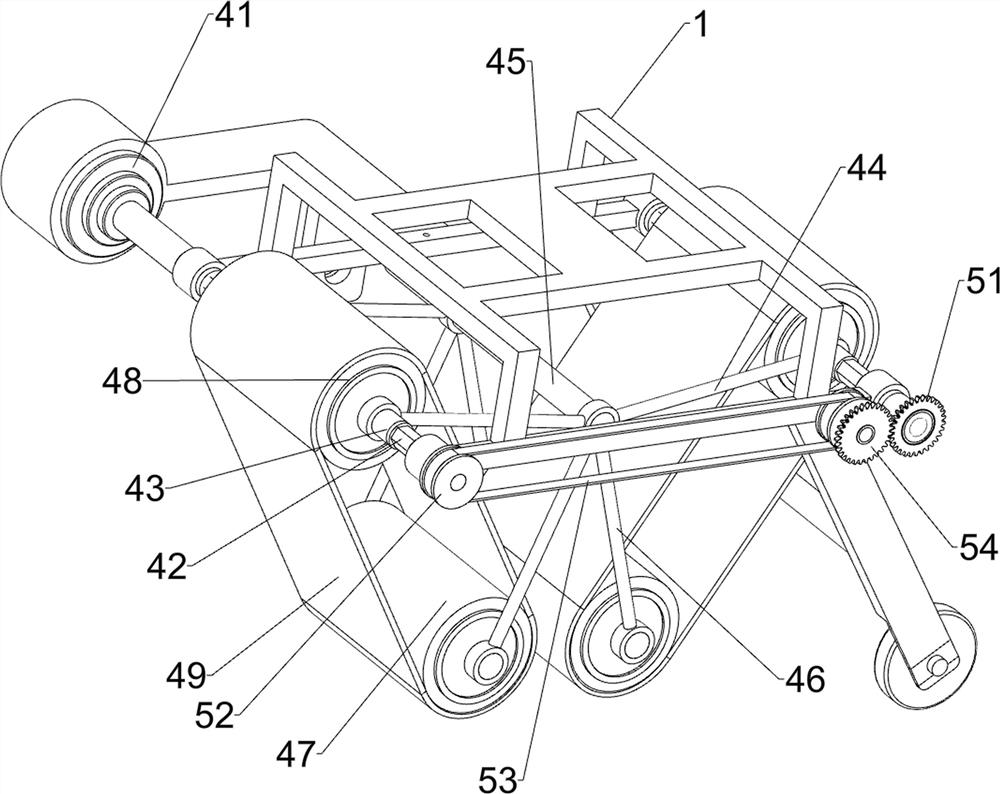

[0027] A wooden floor residual wax erasing machine, such as Figure 1-2 As shown, it includes a bracket 1, a handle frame 2 and a walking wheel 3, the top of the bracket 1 is connected with a handle frame 2, the front and rear sides of the right side of the bottom of the bracket 1 are rotatably connected with a walking wheel 3, and a wax wiping component 4 is also included. And the transmission mechanism 5, the wax wiping assembly 4 is provided on the support 1, and the transmission mechanism 5 is provided on the wax wiping assembly 4.

[0028] The wax wiping assembly 4 includes a geared motor 41, a rhombic shaft 42, an inner rhombic sleeve 43, a first connecting rod 44, a cross bar 45, a second connecting rod 46, a lower cylinder 47, an upper cylinder 48 and a wax wiping cotton belt 49, A deceleration motor 41 is installed on the left side of the rear side of the support 1, and the left and right sides of the support 1 are rotationally connected with a rhombus shaft 42, the l...

Embodiment 2

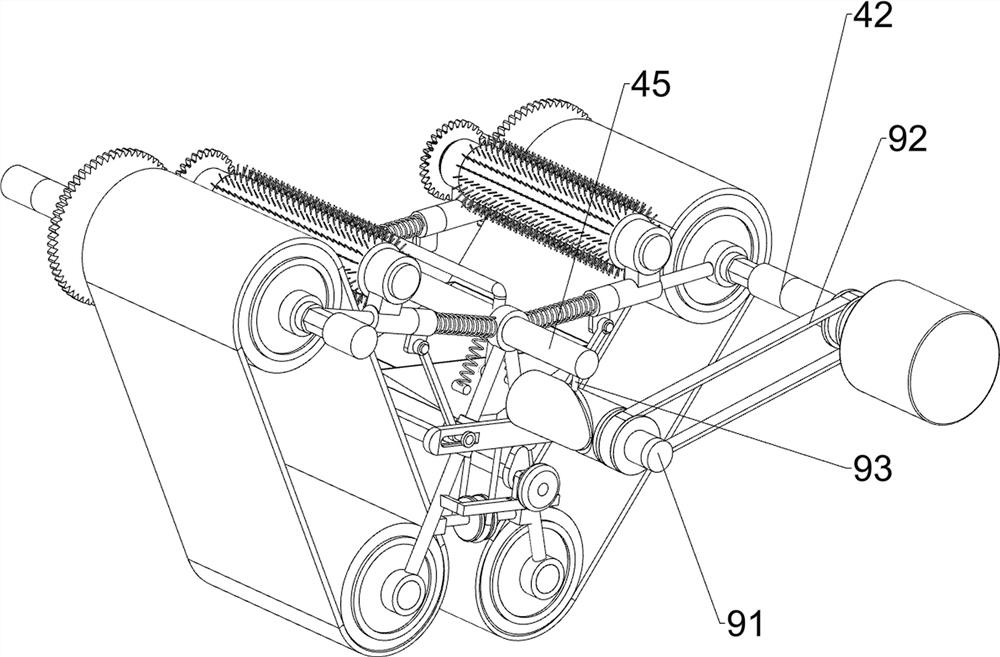

[0032] On the basis of Example 1, such as image 3 As shown, it also includes a cotton tape cleaning mechanism 6, and the cotton tape cleaning mechanism 6 includes an upper sliding sleeve 61, a lower sliding sleeve 62, a first return spring 63, a roller brush 64, a large gear 65, a pinion 66, a connecting shaft 67, The lifting groove plate 68 and the connecting rod 69, the upper sliding sleeve 61 is slidably connected on the first connecting rod 44, and the lower sliding sleeve 62 is slidably connected on the second connecting rod 46, between the upper sliding sleeve 61 and the first connecting rod 44 A first return spring 63 is connected, and a roller brush 64 is rotatably connected between the two upper sliding sleeves 61 on the same side. The roller brush 64 will be in contact with the wax wiping cotton belt 49, and the front sides of the inner diamond-shaped sleeves 43 on both sides are connected There is a large gear 65, and the front sides of the roller brushes 64 on bot...

Embodiment 3

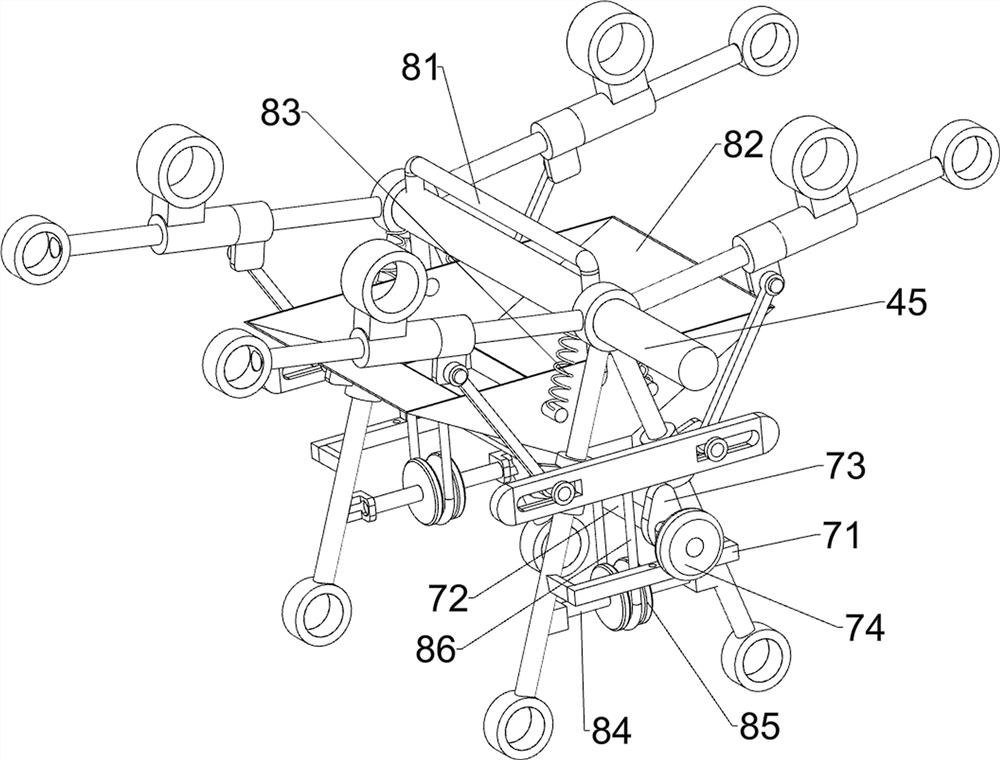

[0037] On the basis of Example 2, such as Figure 4 As shown, it also includes a collection assembly 8. The collection assembly 8 includes an n-type guide rod 81, a collection bucket 82, a second return spring 83, a rotating shaft 84, a fixed pulley 85 and a stay wire 86, and the cross bar 45 is slidably connected with n Type guide rod 81, the bottom of n-type guide rod 81 is connected with collection bucket 82, is connected with second return spring 83 between collection bucket 82 and cross bar 45, between two second connecting rods 46 on the front side and the rear side A rotating shaft 84 is connected between the two second connecting rods 46, a fixed pulley 85 is connected to the rotating shaft 84, and a backguy 86 is connected to the front and rear sides of the bottom of the collecting bucket 82, and the backguy 86 bypasses the fixed pulley 85 and connects with the lifting groove plate 68. .

[0038] Lifting groove plate 68 pulls collection bucket 82 to move downwards by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com