Automobile trunk cover automatic soft edge structure

A trunk lid, fully automatic technology, applied in the direction of vehicle parts, transportation and packaging, can solve the problems of uneven folding, low efficiency, no way to achieve edge wrapping, etc., to achieve neat folding, simple structure, and improved packaging. The effect of edge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

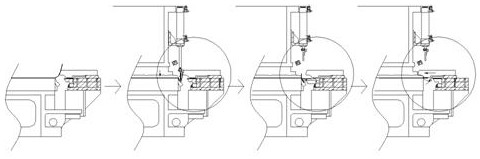

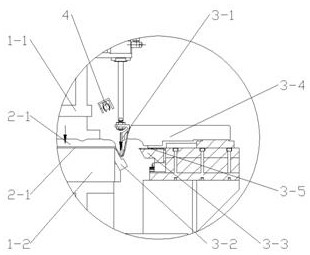

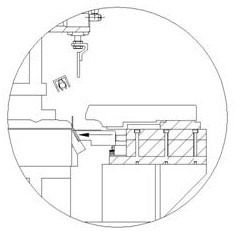

[0021] Such as Figure 1-4 As shown, a fully automatic soft hemming structure for the trunk lid of an automobile, which is installed on the composite hemming tooling of the trunk lid, and the composite hemming tooling of the trunk lid includes an upper mold 1-1, a lower mold 1 -2; the trunk cover of the car includes a substrate 2-1 and a blanket 2-2; the substrate 2-1 is mounted on the lower surface of the upper mold 1-1, and the blanket 2-2 is covered on the lower mold 1-2 On the surface, glue is coated on the back of the surface blanket 2-2, the substrate 2-1 goes down with the upper mold 1-1, the upper mold 1-1 and the lower mold 1-2 are molded together, and the substrate 2-1 is pressed against the surface blanket 2-2; the edge of the base plate 2-1 protrudes out of the upper mold 1-1 and is flush with the edge of the lower mold 1-2, and the edge of the surface blanket 2-2 extends out of the base plate 2-1; the Soft edging structure 3 includes blanket pre-bending top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com