Interlayer alignment visual monitoring method

A technology with the same position in the middle layer, applied in the direction of electrical components, electrical components, etc., can solve problems such as short-circuit scrapping, cumulative deviation exceeding the standard, and unstable punching accuracy of the substrate, so as to save costs and avoid waste of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

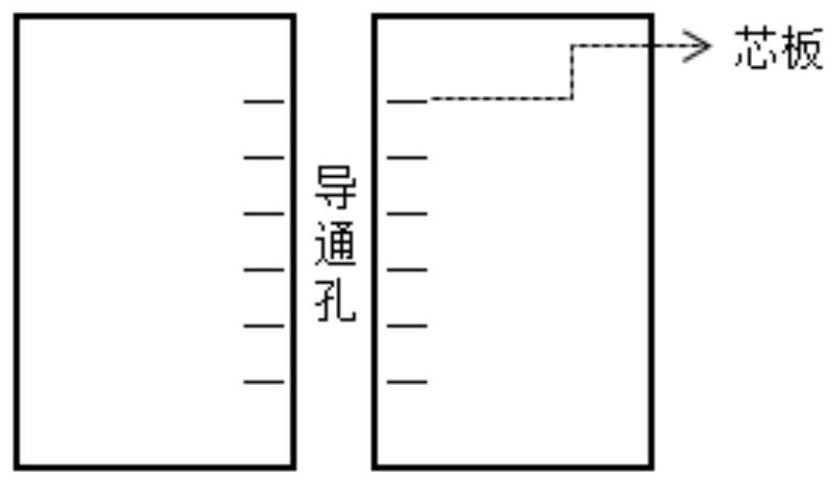

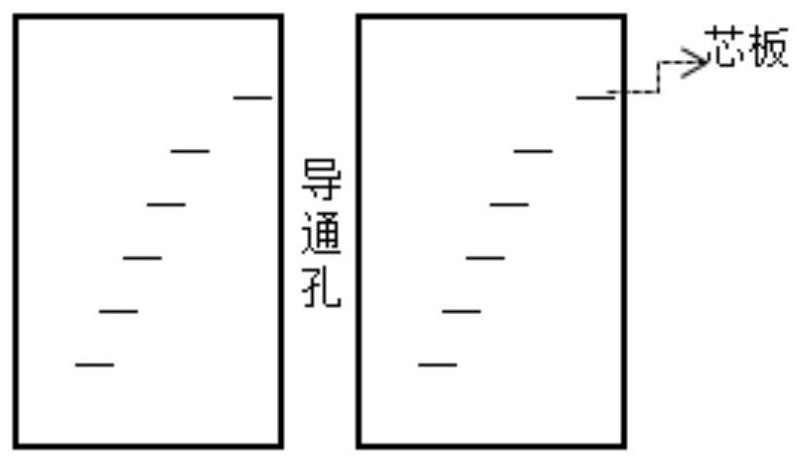

[0032] A 22-layer board contains 10 core boards. Each core board is double-sided. The first core board is numbered 2 / 3, the second core board is numbered 3 / 4, and so on. Such as Figure 9 As shown, a concentric circle is respectively set at the same position A and B on the four corners of each core board, wherein the diameter of each layer of concentric circles at position A increases with the order of the core board in equal increments, and the diameter of each layer of concentric circles at position B diameter by Figure 7 Way cross settings:

[0033] The diameter of the concentric circles of the first core plate is the smallest, which is a;

[0034] The core board in the middle layer is set as the second largest concentric circle b (the number of core boards is an even number, and there are 2 in the middle layer, take the one with the larger code);

[0035] The last layer of core board is set as the third largest concentric circle c;

[0036] The first core board betwee...

Embodiment 2

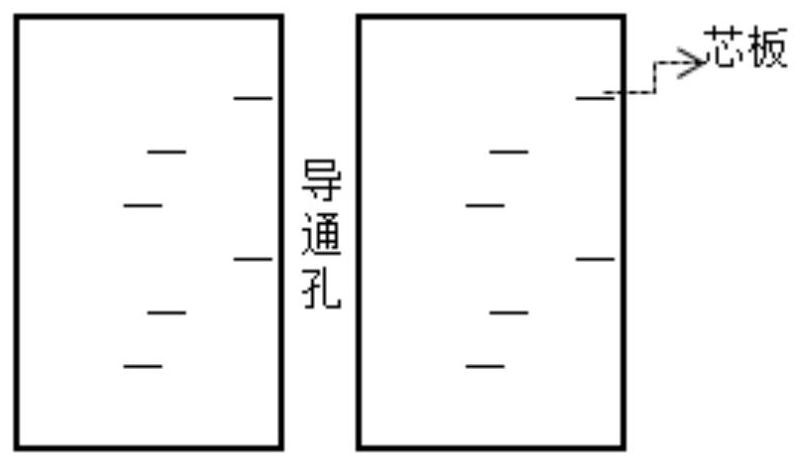

[0045] A 20-layer board, which contains 9 core boards, each core board is double-sided, the first core board is numbered 2 / 3, the second core board is numbered 3 / 4, and so on. Such as Figure 9 As shown, a concentric circle is respectively set at the same position A and B on the four corners of each core board, wherein the diameter of each layer of concentric circles at position A increases with the order of the core board in equal increments, and the diameter of each layer of concentric circles at position B diameter by Figure 8 Way cross settings:

[0046] The diameter of the concentric circles of the first core plate is the smallest, which is a;

[0047] The core board in the middle layer is set as the second largest concentric circle b (the number of core boards is an even number, and there are 2 in the middle layer, take the one with the larger code); the last layer of core board is set as the third largest concentric circle c;

[0048] The first core board between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com