Zipper type connecting mechanism of prefabricated column and mounting method of zipper type connecting mechanism

A technology of connecting mechanism and prefabricated column, applied in the field of machinery, can solve the problem of difficult installation, and achieve the effect of compact structure, high stability, convenient and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

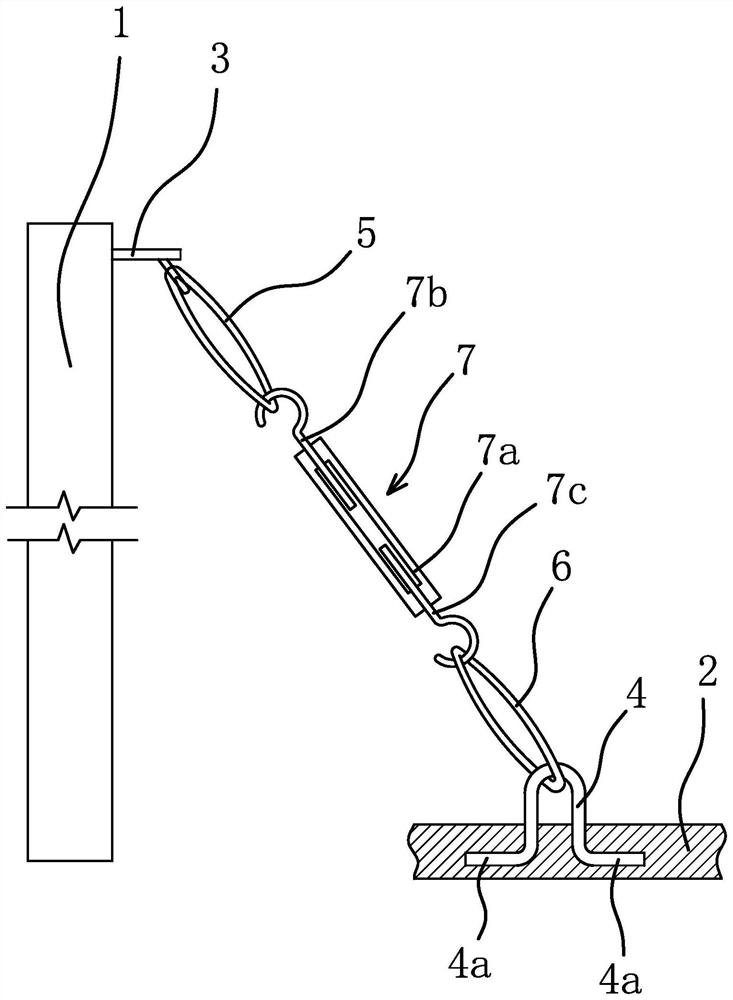

[0033] Such as figure 1 As shown, the prefabricated column 1 is connected to the floor 2, and the zipper connection mechanism of the prefabricated column is located between the prefabricated column 1 and the floor 2. This mechanism includes embedded parts 1, 2, collar 5, sleeve Ring 2 6 and tightening member 7, the above-mentioned embedded part 1 3 is fixedly connected to the side of the precast column 1, the above-mentioned embedded part 2 is fixedly connected to the floor 2 on the side of the precast column 1, the above-mentioned collar 1 5 and the sleeve The inner ends of the ring two 6 are respectively connected to the two ends of the tightening part 7, the above-mentioned collar one 5 is connected with the embedded part one 3, and the above-mentioned collar two 6 is connected with the embedded part two.

[0034] The second embedded part includes a U-shaped body 4, the U-shaped port of the body 4 has a connecting edge 4a protruding to its side, the connecting edge 4a is em...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap