A test device for compression test of thermoplastic composite sheet after impact

A composite material sheet and test device technology, which is applied in the direction of using a single impact force to test the material strength, using a stable tension/pressure test to test the material strength, measuring devices, etc. , the effect of reducing the impact and reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

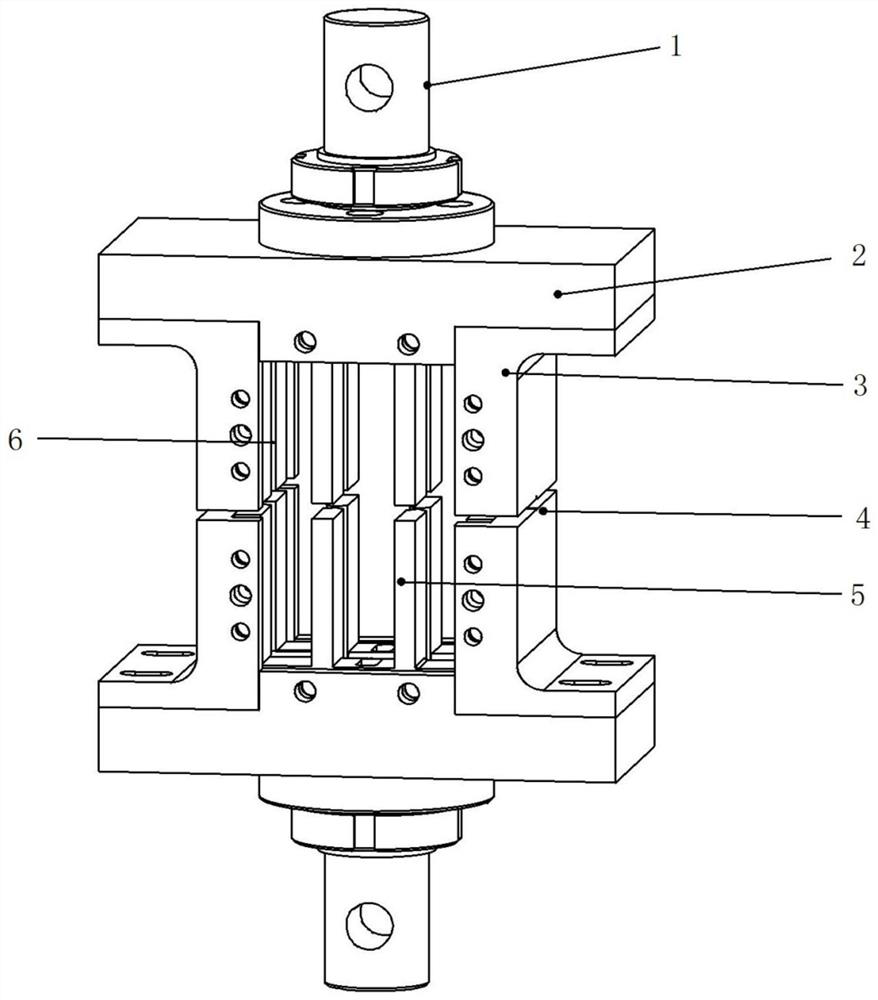

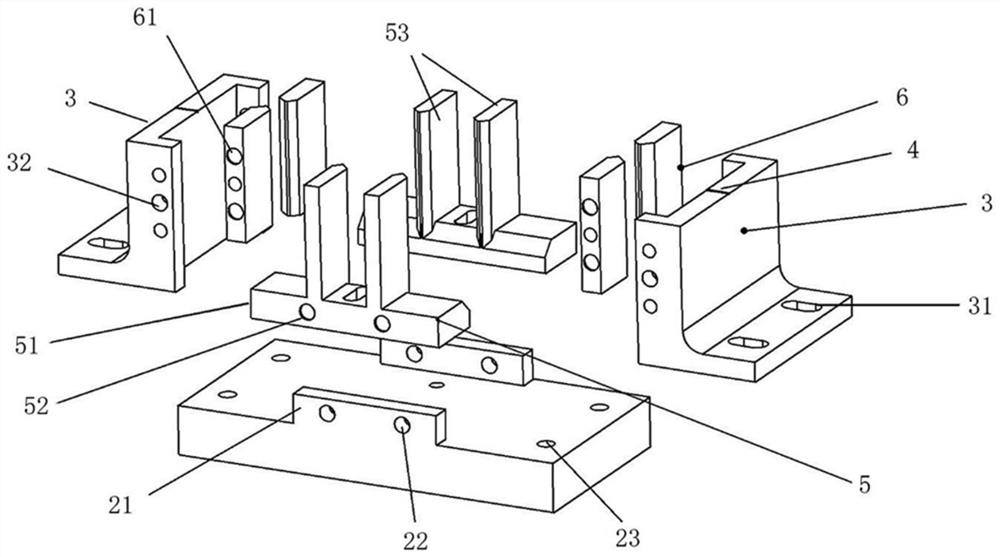

[0031] The invention relates to a test device for compression test of thermoplastic composite sheet after impact. The device is mainly composed of upper and lower parts which are separated and identical. The two parts are arranged symmetrically up and down during actual work. Each part includes a coupling piece 1 , a base 2 and a baffle part, and the baffle part includes a side base 3 , an inner side baffle 6 and an anti-buckling plate 5 . The couplings 1 of the upper and lower two identical parts are connected with the universal testing machine in the form of a top coupling and a bottom coupling during actual operation.

[0032] This embodiment is described with the upper portion. Such as figure 1 As shown, the connecting piece 1 is arranged on the top of the base 2, and is connected with the base 2 through threads, and is used for connecting the universal testing machine. Two anti-buckling plates 5 are connected to the bottom of the base 2 and are respectively arranged at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com