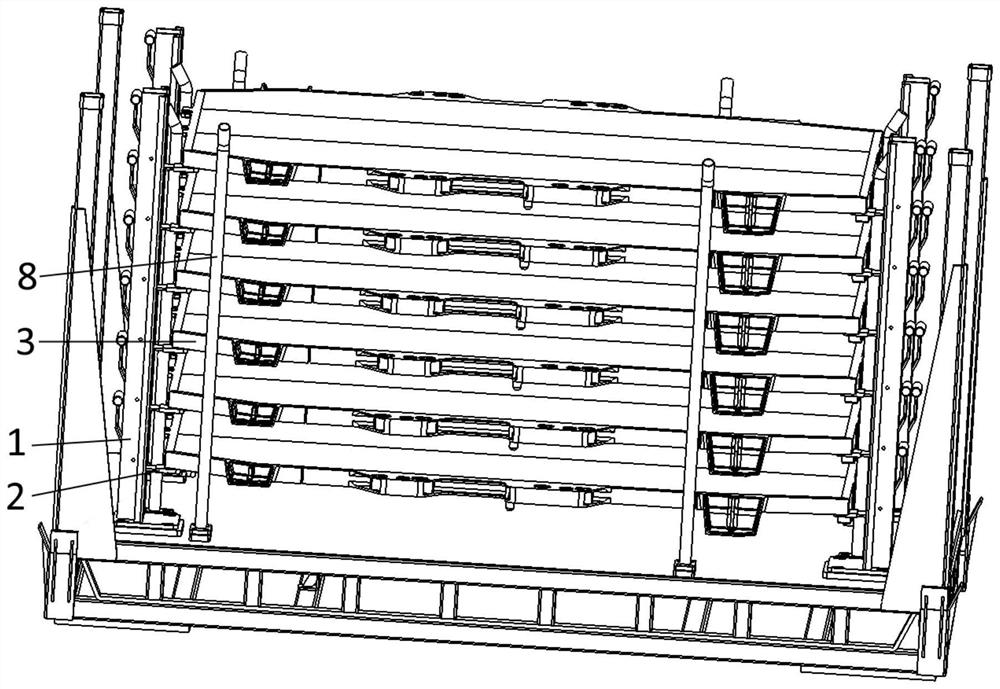

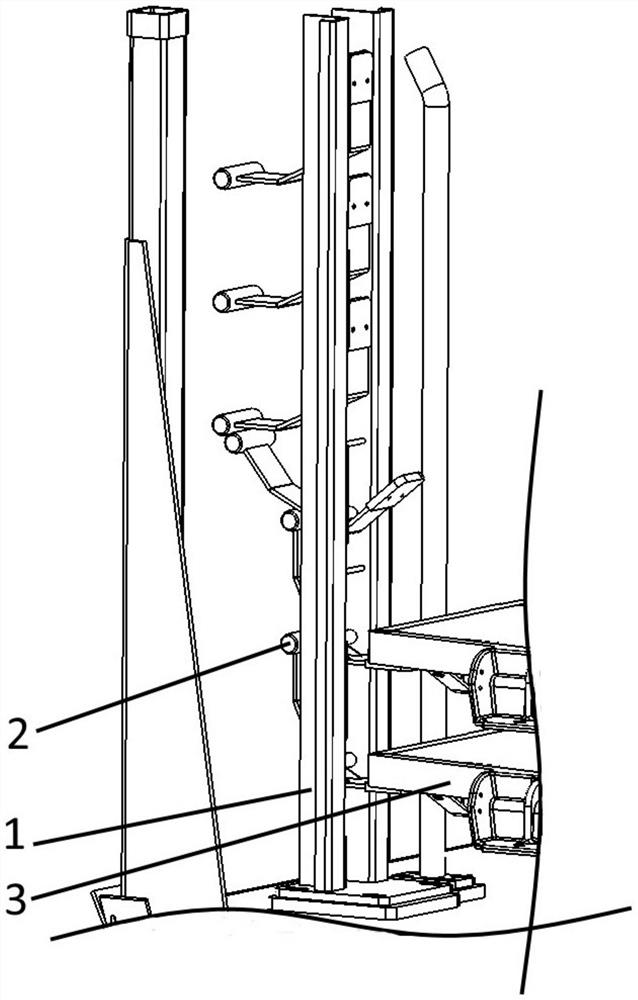

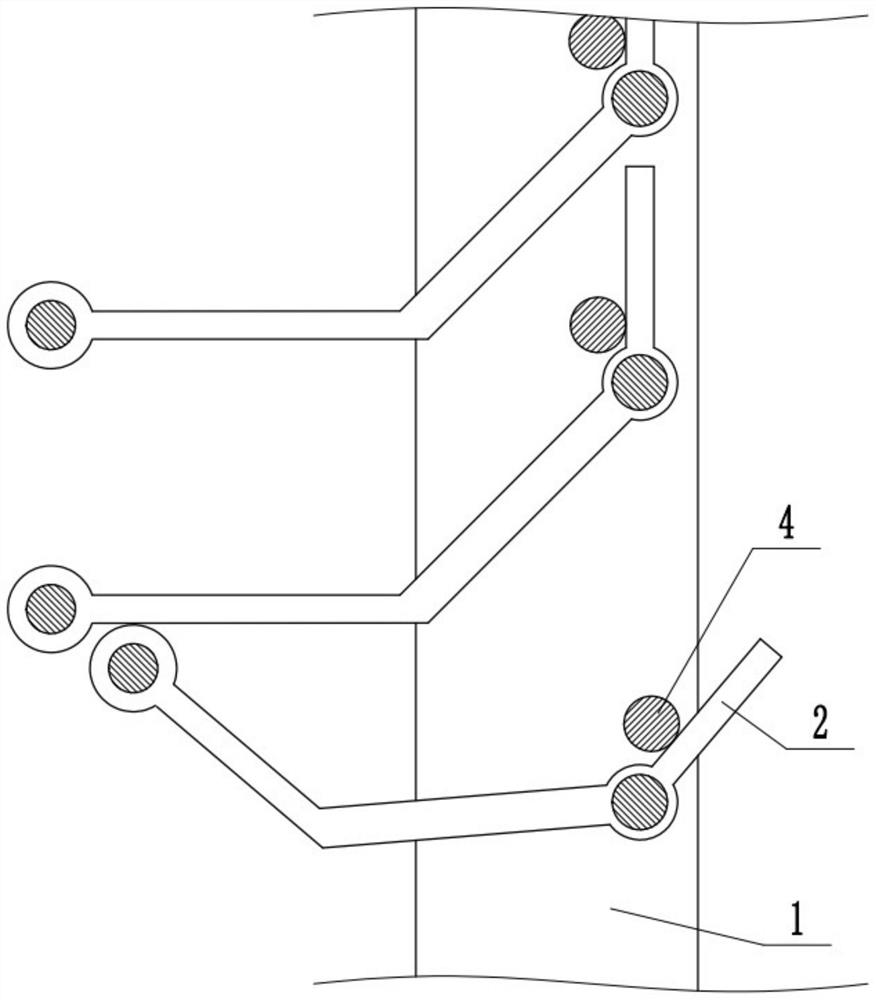

Material rack facilitating material storing and taking and material storing and taking method

A material and material rack technology, applied in the field of storage equipment, can solve the problems of increasing the difficulty of material access, wasting storage space, and delaying assembly time, so as to reduce the number of adjustments of manipulators, reduce power sources and transmission components, and reduce assembly time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0037] When the applicant debugged the automatic material rack, he found that the partitions between the existing material racks limited the upper space of the materials. To realize the access of materials, the staff or manipulators had to be inserted between the partitions, which increased the access of materials Difficulty, always pay attention to the distance between the material and the partition when accessing, which greatly delays the interval between material access and use. When using a manipulator to access materials, electrical engineers need to be bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com