hood latch

A technology of engine hood and latch device, which is applied in building locks, vehicle locks, locks, etc. It can solve the problems of easy warping and deformation of the bottom plate, difficulty in preventing the warping and deformation of the bottom plate, and poor closing of the engine hood, etc., to achieve The effect of high dispersion succession effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

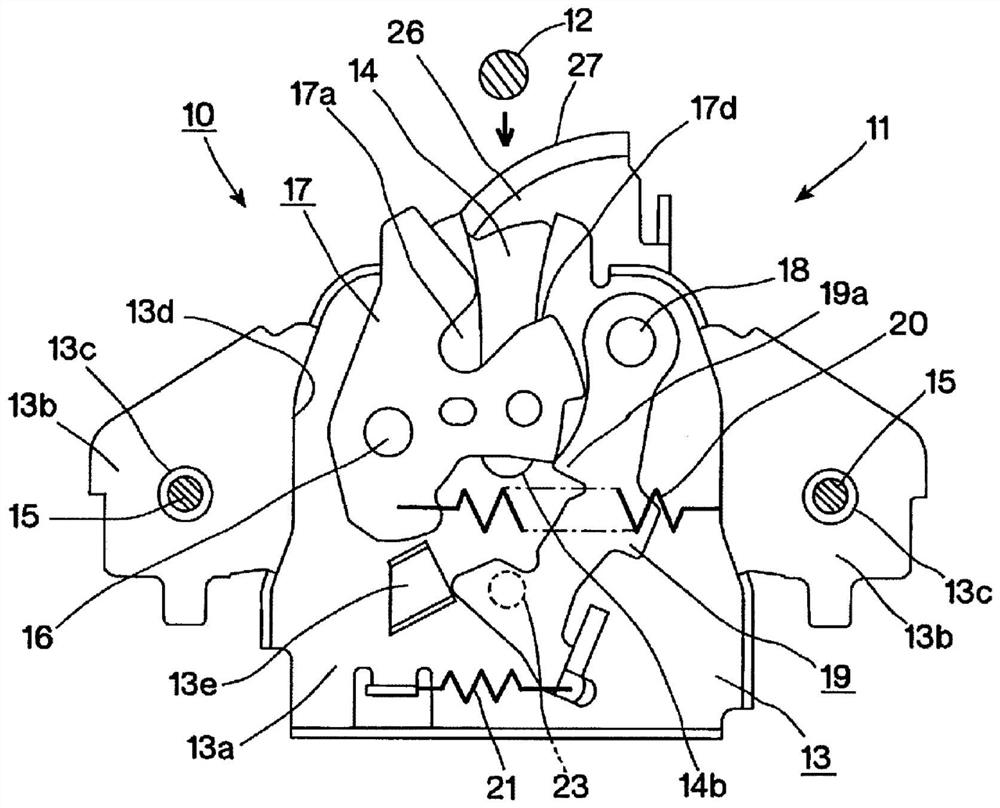

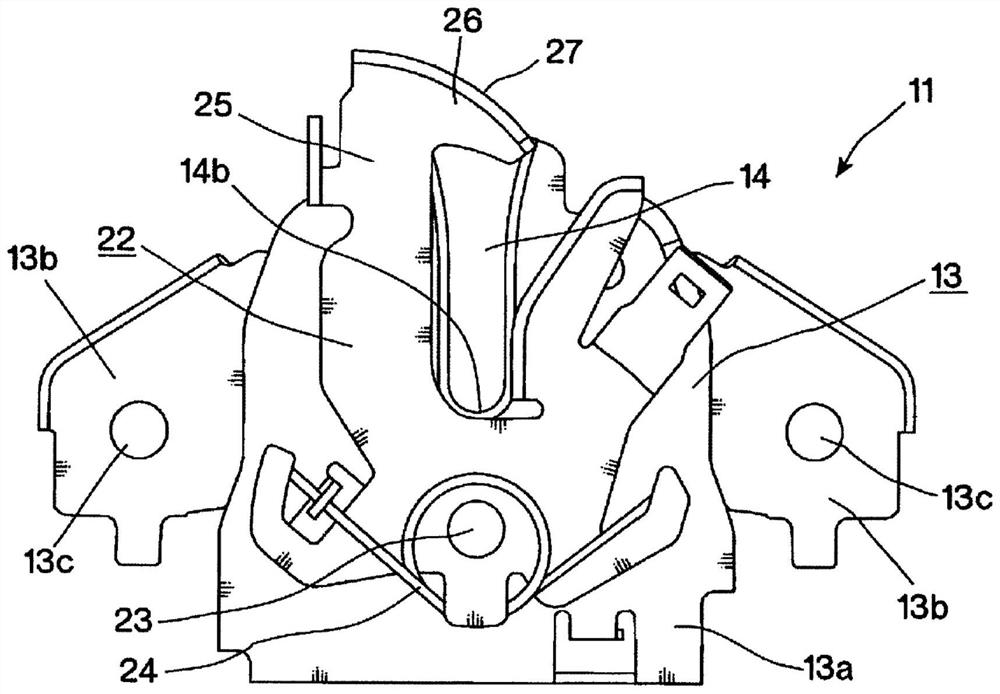

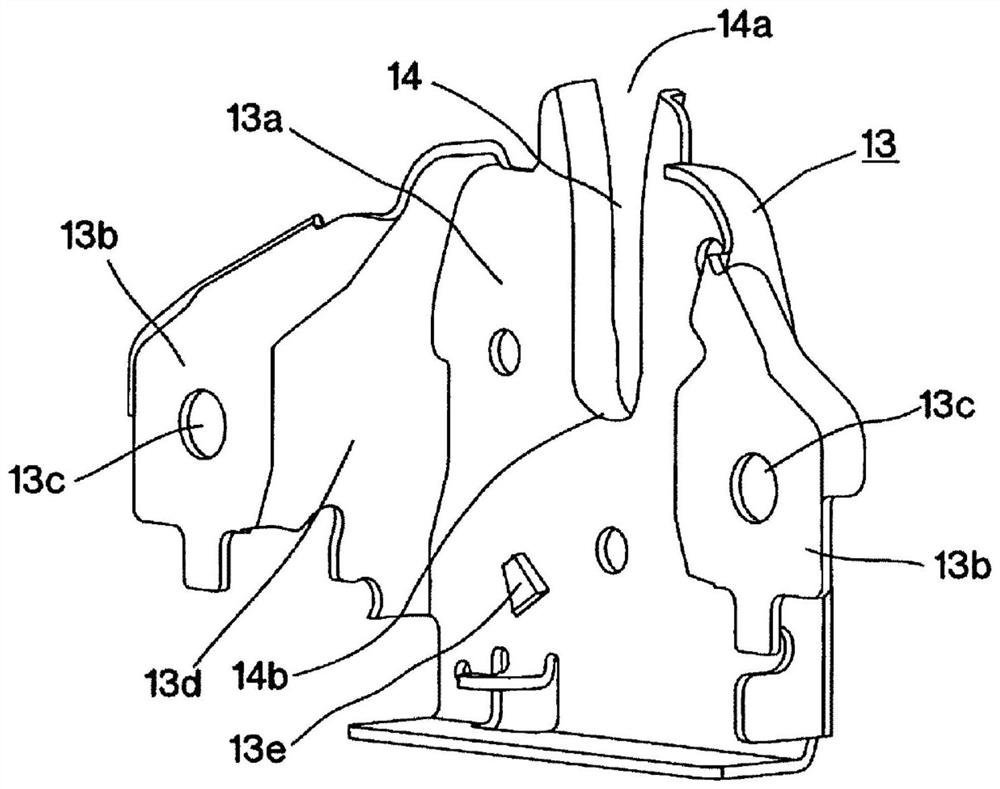

[0035] One embodiment of the present invention will be described based on the drawings. figure 1 The front of the hood latch device 10 for an engine hood of this invention is shown. In most vehicles, the engine room is disposed on the front side of the vehicle, and an end (base end) of a typical hood (not shown) covering the engine room is equiaxially fixed to the vehicle body by a hinge. The hood latch device 10 includes a latch unit 11 fixed to the front end of the vehicle body, and a striker 12 fixed to the front end (rotational end) of the hood.

[0036] The latch unit 11 includes a metal bottom plate 13 . Bottom plate 13 is stamping molding product, as Figure 1 ~ Figure 3 As shown, a central plate 13a and left and right fixing plates 13b are provided. A striker entry passage 14 is formed in the upper center of the center plate 13a. The striker entry passage 14 is in the shape of a longitudinal U, with an opening 14a at the top and a bottom wall 14b at the bottom. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com