Multi-stress-based rail transit electronic control device service life evaluation method and device

An electronic control device and life evaluation technology, applied in electrical digital data processing, instruments, geometric CAD, etc., can solve the problems of low evaluation accuracy, complex implementation process, low efficiency, etc., to improve evaluation accuracy, reduce test costs, Guaranteed effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

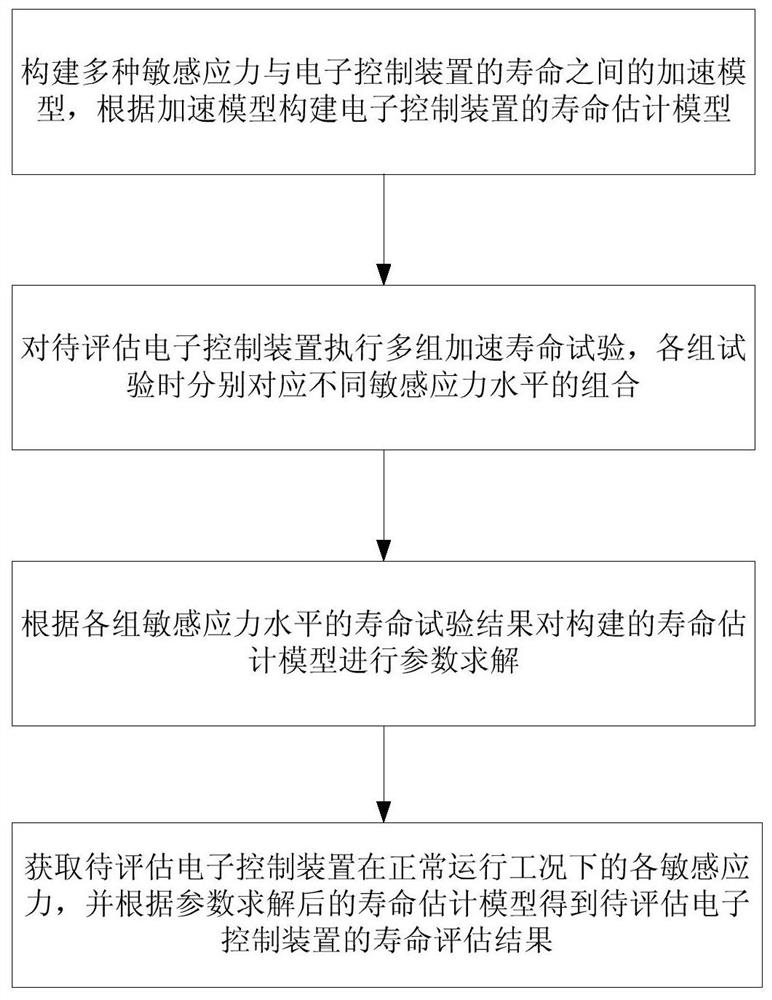

[0049] Such as figure 1 As shown, the steps of the multi-stress-based rail transit electronic control device life assessment method in this embodiment include:

[0050] S1. Acceleration model construction: construct an acceleration model between various sensitive stresses that comprehensively affect the life and the life of the electronic control device, and construct a life estimation model of the electronic control device according to the acceleration model;

[0051] S2. Accelerated life test: Perform multiple sets of accelerated life tests for the electronic control device to be evaluated, each set corresponds to a combination of different sensitive stress levels, and obtain multiple sets of life test results corresponding to different sensitive stress levels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com