Novel FLVV valve, combination valve and CFLVV valve

A combined valve, a new type of technology, applied in the fields of FLVV valve, combined valve and CFLVV valve, can solve the problems of fuel escape, single spool slowness, dynamic leakage, etc., and achieve the effects of reducing fuel dynamic leakage, low transformation cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

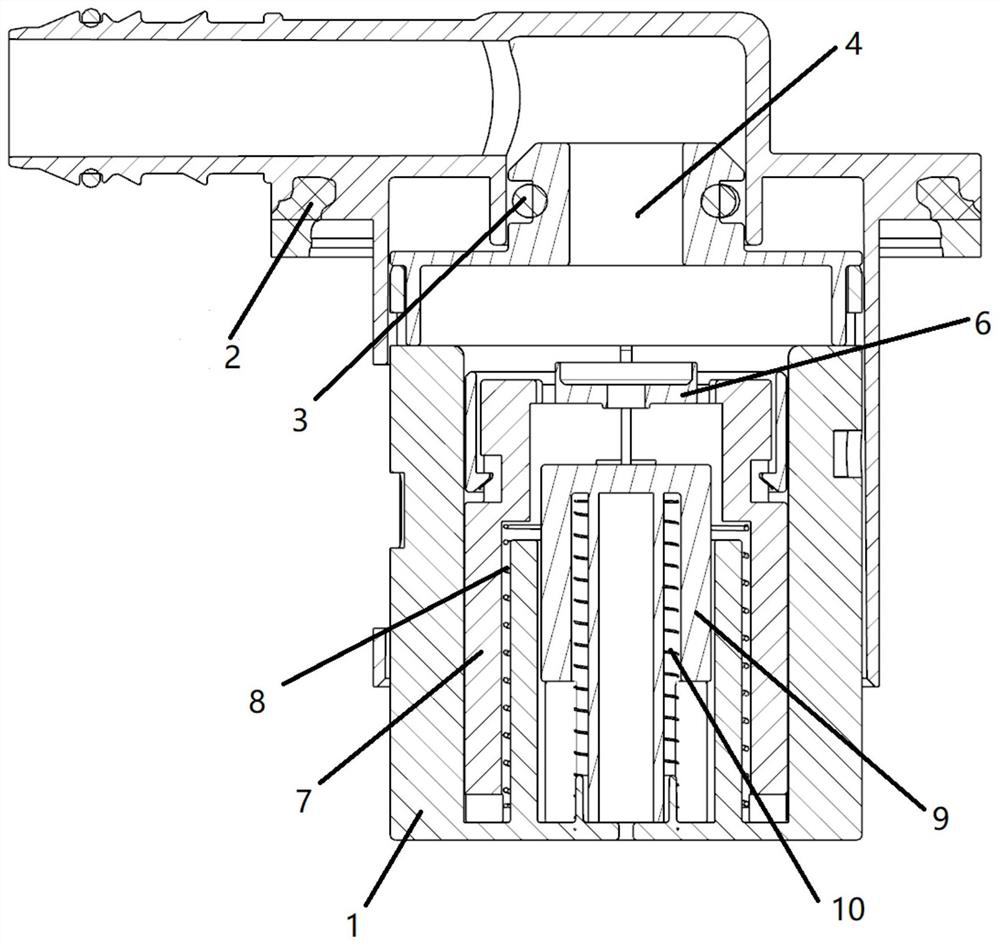

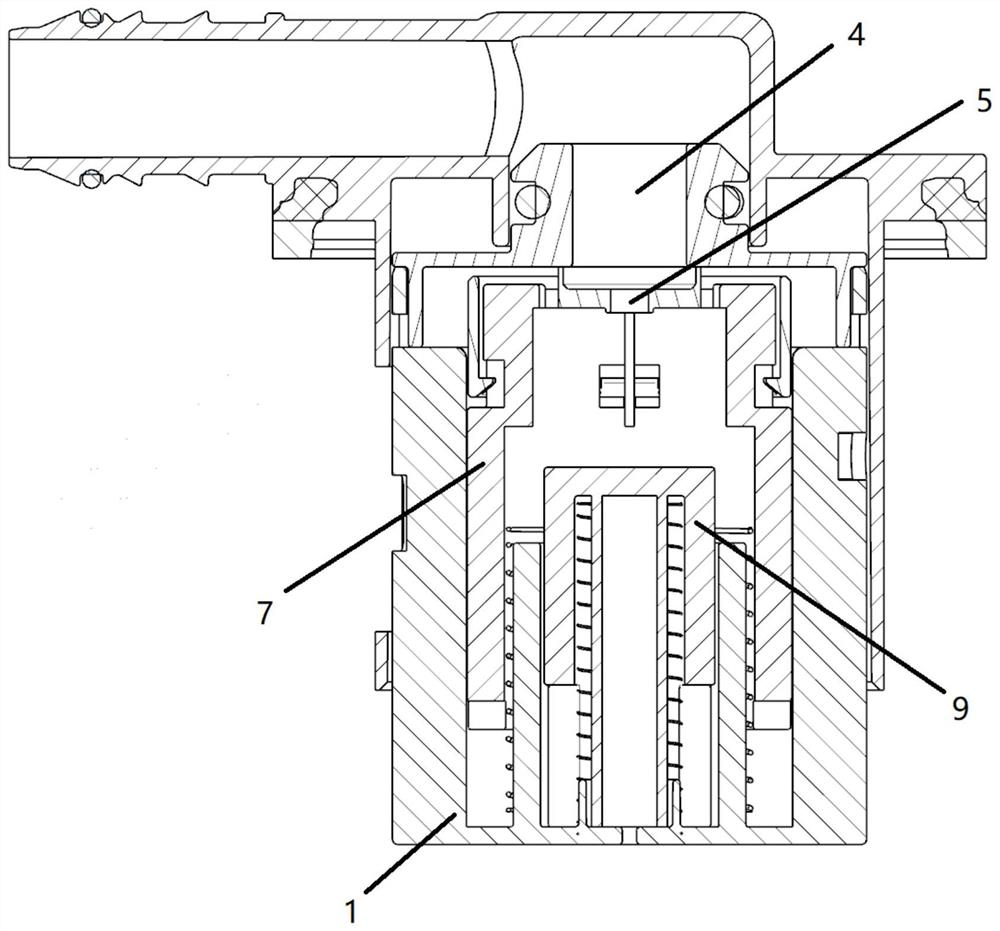

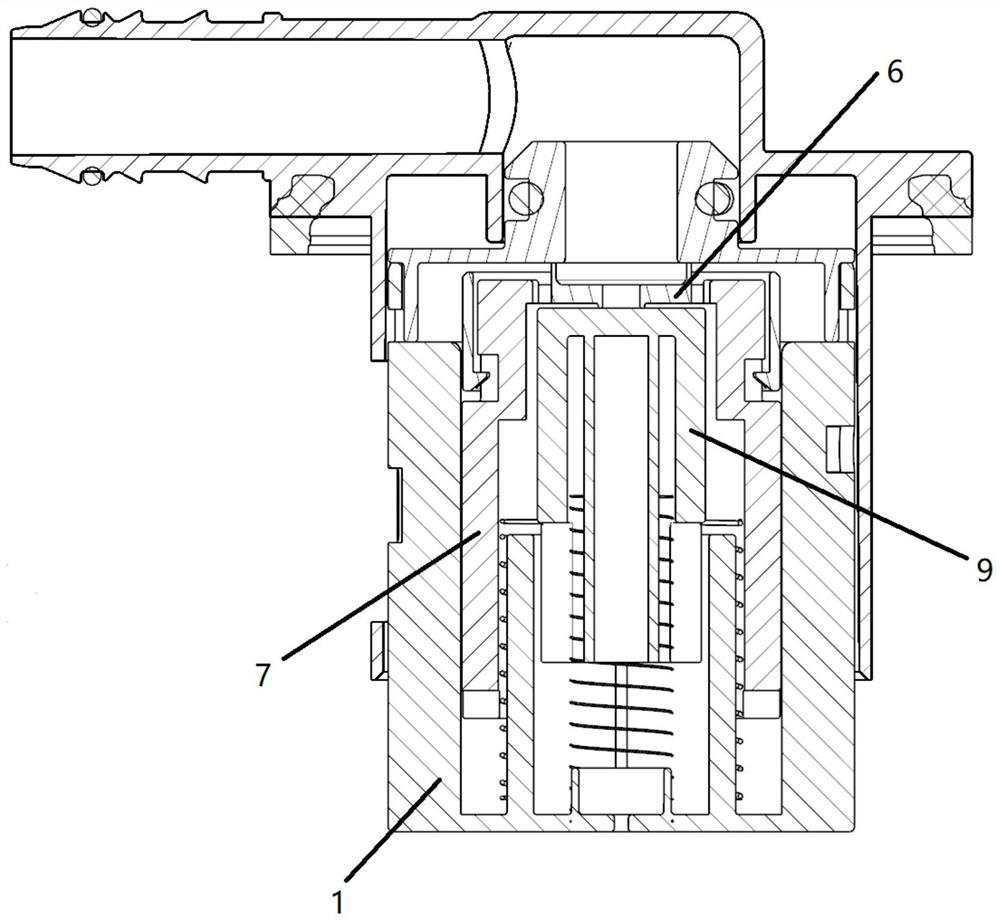

[0036] like figure 1 , figure 2 and image 3 The shown embodiment of a novel FLVV valve of the present invention includes a valve base 1 and a flange 2, and the valve base 1 is fixedly connected to the fuel tank through the flange 2, and the valve base 2 is fixedly connected to the fuel tank. An "O" seal ring 3 is also provided between the seat 1 and the flange 2, and the valve base 1 is provided with a large valve core assembly and a small valve core assembly, and the small valve core assembly is set Inside the large valve core assembly, the upper end of the valve base 1 is provided with a large vent hole 4 and a small vent hole 5 corresponding to the large valve core assembly and the small valve core assembly, and a sealing assembly 6 is provided Make a seal. The flange 2 is welded on the fuel tank for easy assembly and disassembly; the large valve core assembly includes a large float 7 and a large spring 8 used to balance the gravity of the large float 7, and the large ...

Embodiment 2

[0039] This embodiment is mainly a combined valve capable of simultaneously realizing the functions of a refueling limit valve and a reversing valve. It is applied and installed in a fuel tank, and the fluid in the fuel tank is oil and air in the fuel tank.

[0040] see Figure 4 , Figure 5 , Figure 7 and Figure 8 , The combined valve of this embodiment includes a valve base 1, a spool portion, and a pressure maintaining portion.

[0041] The valve base 1 is provided with a valve core accommodating chamber 14, and the valve base 1 is provided with a first inflow channel and a second inflow channel communicating with the valve core accommodating cavity 14 and the external space of the valve base 1, and the second The inlet of the inflow channel is higher than the inlet of the first inflow channel. The first inflow channel is mainly used for the inflow of oil and gas, and the second inflow channel is mainly used for the inflow of gas.

[0042]The upper end of the valve b...

Embodiment 3

[0068] see Figure 9 to Figure 11 In this embodiment, on the basis of the second embodiment above, several preferred implementation modes of the sealing assembly 6 are further described:

[0069] In this embodiment, the sealing assembly 6 can be specifically divided into two types of arrangement. The first is to be arranged on the top surface of the inner cavity of the spool accommodating cavity 14, and the second is to be slidably connected to the spool accommodating cavity 14. Inside.

[0070] First, the first case is explained, as follows:

[0071]The seal assembly 6 can specifically be a plurality of seals 601 respectively sleeved at the large vent hole 4 and the small vent hole 5, and each seal 601 has a seal ring extending into the spool accommodating cavity 14, and the seal rings can communicate with each other respectively. The spool accommodating cavity 14 is located in the large air hole 4 or the small air hole 5 . At this time, the large float 7 can be lifted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com