A corrugated plate h steel group welding machine

A technology for assembling welding machines and corrugated plates, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to guarantee efficiency, affecting the subsequent process of corrugated plate forming, and high labor intensity of welding technicians. The effect of reducing the labor intensity of personnel, simple structure and reducing operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

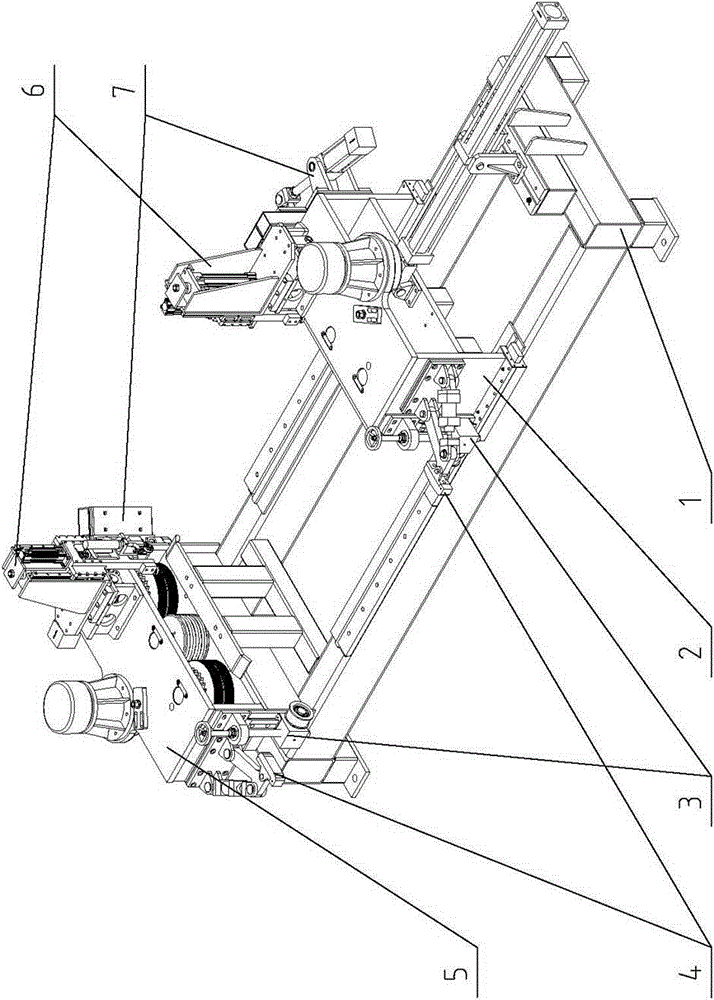

[0024] Please refer to the instruction manual figure 1 Attached Image 6 As shown, the present invention is a corrugated plate H steel group welding machine, which is assembled by the main frame 1, the movable mechanism 2, the conductive mechanism 3, the lifting mechanism 4, the fixed mechanism 5, the welding mechanism 6 and the swing mechanism 7. to make.

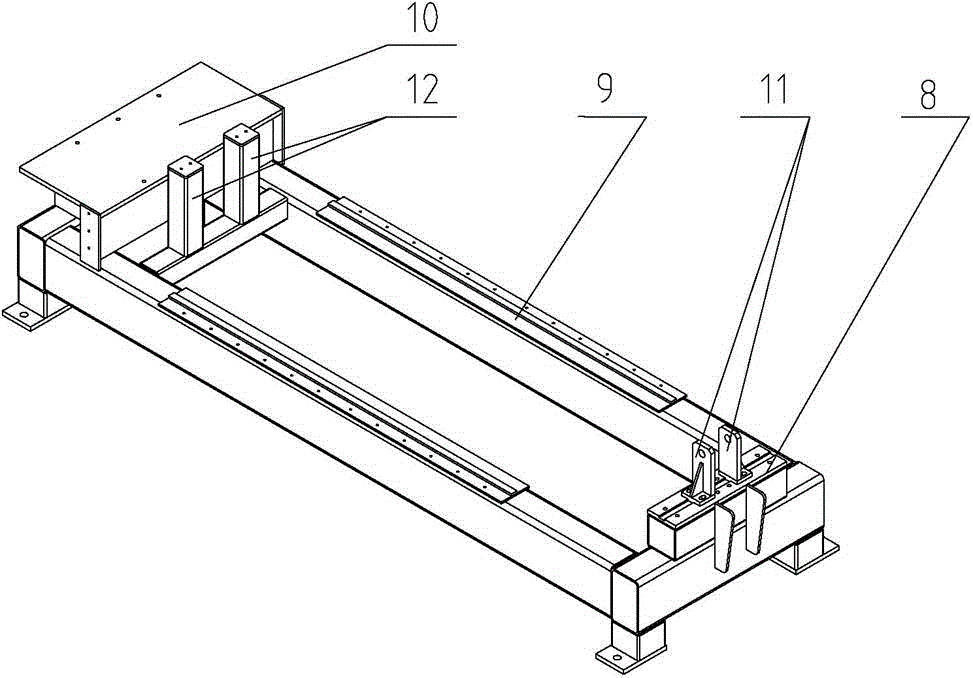

[0025] Wherein, one end of the main frame 1 is provided with a sliding seat 8, the other end is provided with a connecting seat 10, and a guide rail 9 is arranged in the middle; the sliding seat 8 is connected with a cylinder seat 11. The main frame 1 and the movable mechanism 2 are also provided with two equal-height uprights 12, and the four uprights 12 have the same height.

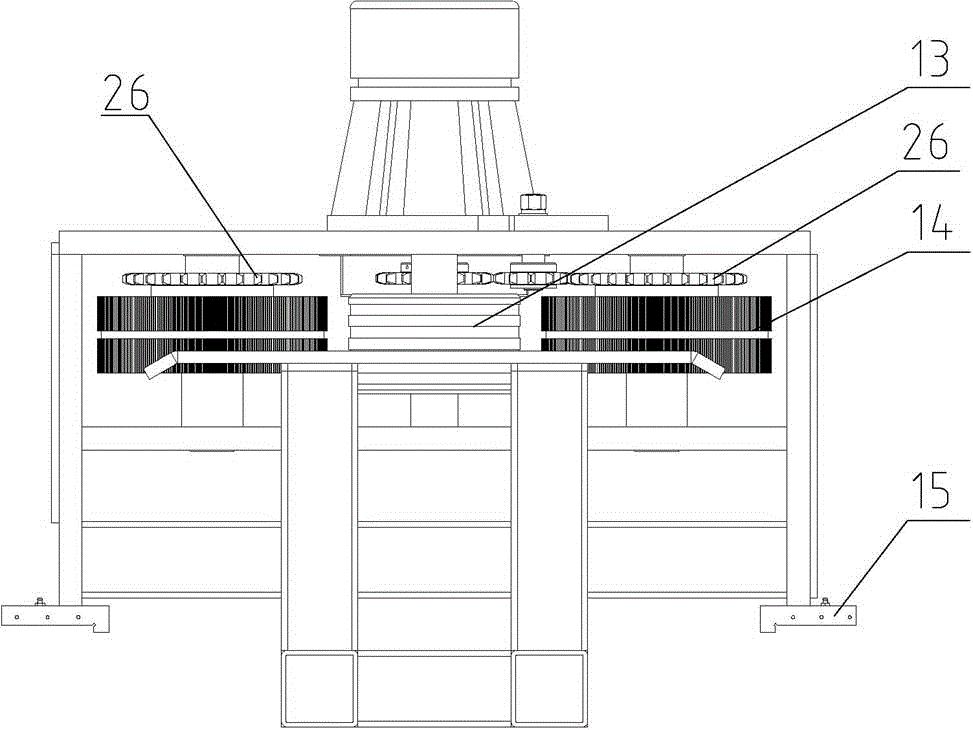

[0026] The movable mechanism 2 is arranged on the guide rail 9. The movable mechanism 2 is provided with two gear discs 14 and a magnetic roller 13; each of the gear discs 14 is provided with a sprocket 26, which are connected by a chain (not shown), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com