A mechanical polishing device for faucet production

A mechanical polishing and faucet technology, which is applied in the direction of grinding/polishing equipment, machine tools for surface polishing, and parts of grinding machine tools, etc., can solve problems such as grinding, and achieve the effect of reducing manpower and polishing comprehensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

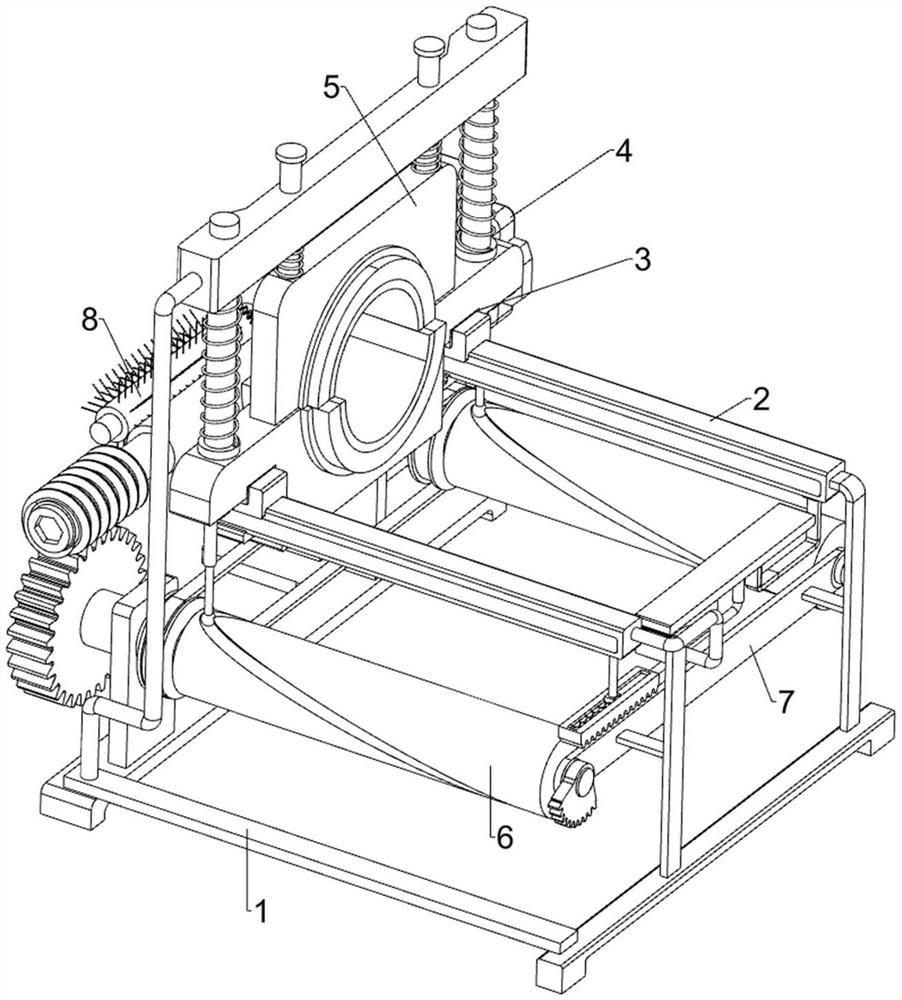

[0028] A mechanical polishing device for faucet production, such as Figure 1-4 As shown, it includes a bracket 1, a moving component 2, a placing component 3 and a polishing component 4. The upper side of the bracket 1 is provided with a moving component 2, the moving component 2 is provided with a placing component 3, and the left side of the bracket 1 is provided with a polishing component. 4.

[0029] When the faucet needs to be polished, the faucet is placed on the placing component 3, and then the polishing component 4 is started, and the polishing component 4 will polish the faucet, and at the same time, the moving component 2 can be controlled to move, thereby driving the faucet to move. Control the rotation of the faucet, and then polish the faucet in multiple directions. When the polishing of the faucet is completed, close the polishing component 4, then stop controlling the moving component 2, and then take out the polished faucet from the placement component 3.

...

Embodiment 2

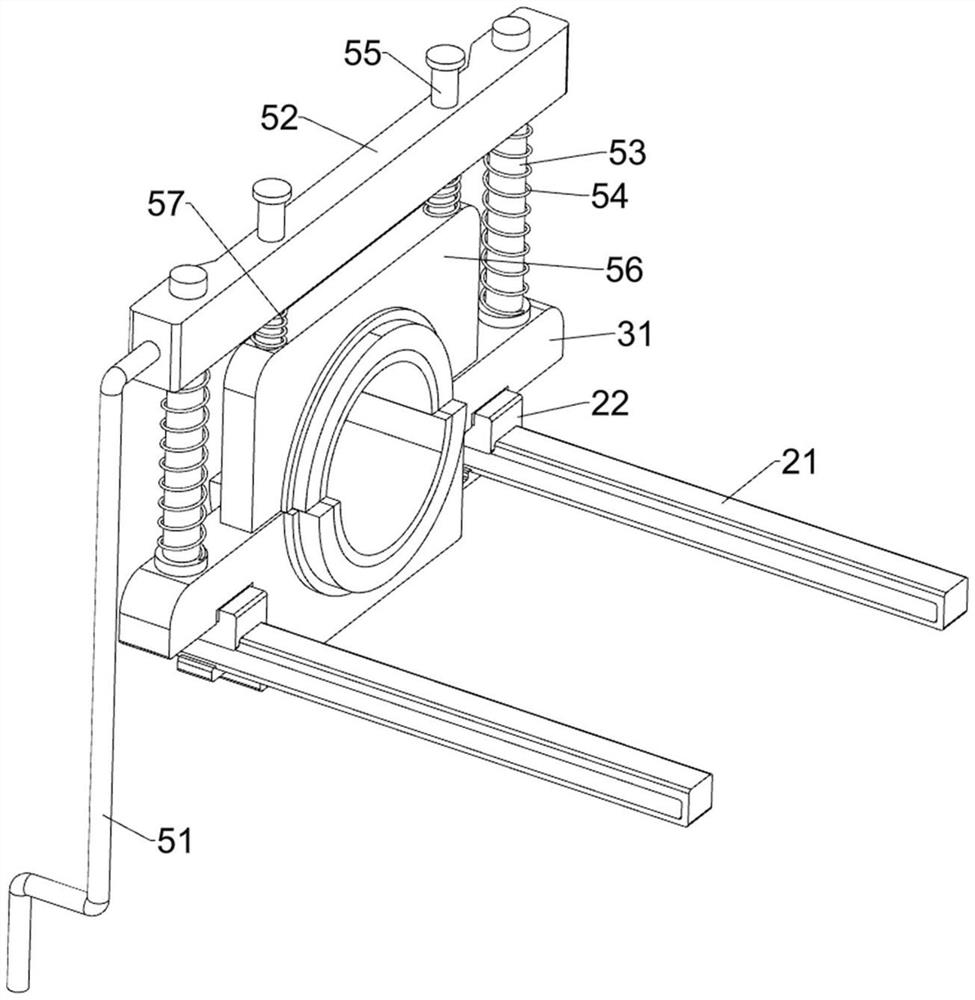

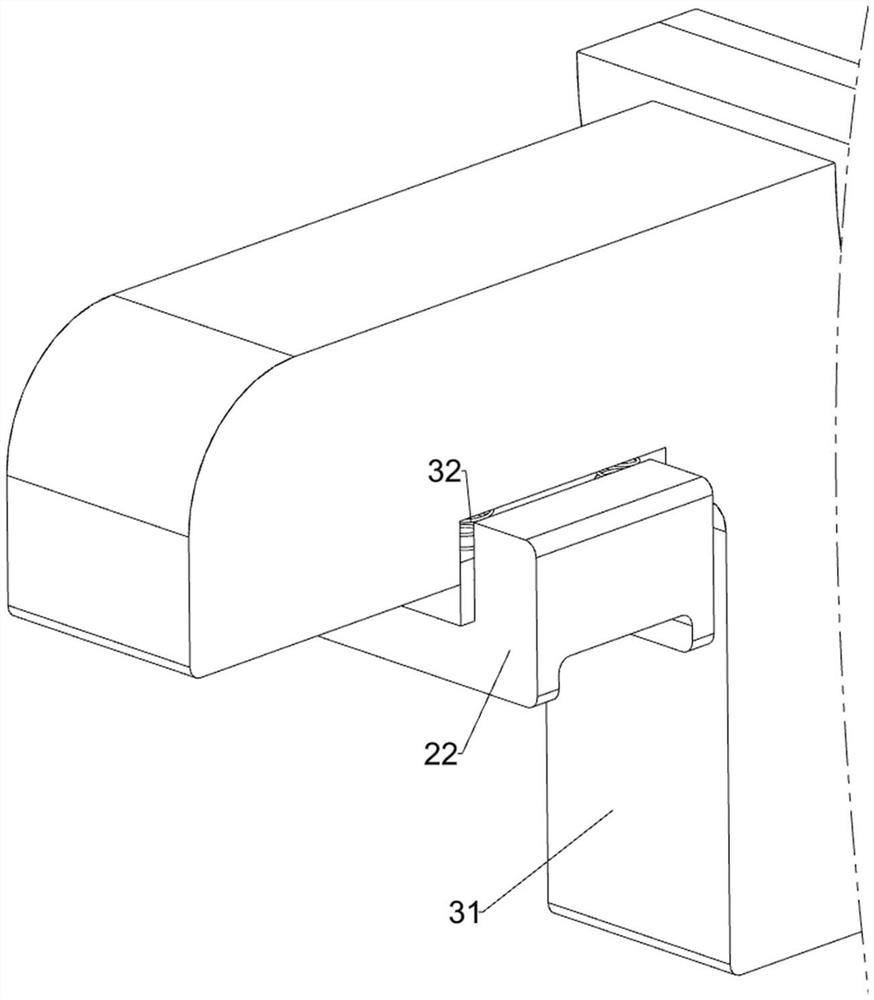

[0037] On the basis of Example 1, such as figure 2 , Figure 5 , Figure 6 and Figure 7As shown, a fixed assembly 5 is also included, and the fixed assembly 5 includes a pole 51, a mounting plate 52, a first guide rod 53, a second spring 54, a second guide rod 55, a second concave plate 56 and a third spring 57, the left front side of the bracket 1 is slidably connected with a strut 51, the rear end of the strut 51 is welded with a mounting plate 52, the front and rear sides of the mounting plate 52 are slidingly provided with a first guide rod 53, the first guide The rod 53 is connected with the first concave plate 31, the second spring 54 is connected between the first guide rod 53 and the mounting plate 52, the front and rear sides of the mounting plate 52 are all slidingly connected with the second guide rod 55, the second A second concave plate 56 is connected between the lower sides of the guide rods 55, the second concave plate 56 cooperates with the first concave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com