Polishing equipment with cleaning function

A function and equipment technology, applied in the field of polishing equipment with cleaning function, can solve the problems of low automation, low work efficiency, and high labor intensity, and achieve the effects of high automation, improved work efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

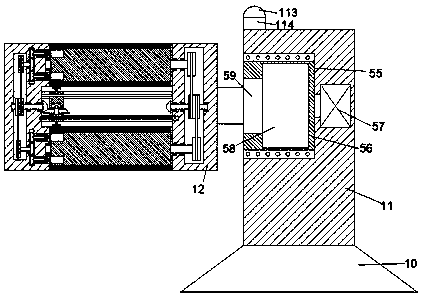

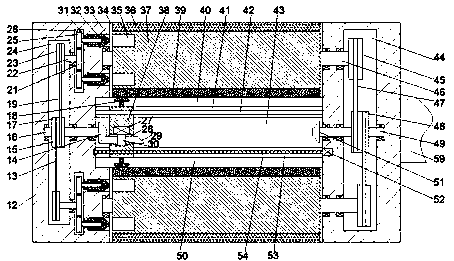

[0019] Such as Figure 1-2 As shown, a polishing device with a cleaning function of the present invention includes a base 10, a support column 11 fixedly arranged above the base 10, and a rotary sleeve 12 arranged on the left end surface of the support column 11. The sleeve 12 is provided with a first rotary cavity 34 which is symmetrical up and down and the port is facing outwards. A rotary plate 37 is rotatably provided in the first rotary cavity 34 through the first rotary shaft 46. The outer end surface of the rotary plate 37 is fixed with a Polishing strip 36, the inner end surface of the rotating plate 37 is fixed with cleaning cotton 39, the left end surface of the rotating plate 37 is symmetrically provided with a locking hole 35 with the port facing left, and the left inner wall of the first rotating cavity 34 A first sliding groove 33 opposite to the locking hole 35 is provided symmetrically in the middle and up and down, and a locking block 32 is slidably installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com