A high-speed tube-loading mechanism for a single-channel tube-feeding filling machine

A filling machine, single-channel technology, applied in packaging and other directions, can solve the problems of complex equipment structure, low work efficiency, large footprint, etc., and achieve the effect of accurate pendulum movement curve, high work efficiency, and convenient installation and maintenance.

Active Publication Date: 2022-05-31

NANTONG UNIVERSAL MACHINERY

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing upper pipe mechanism usually adopts the pipe feeding mode on both sides, which has poor precision and is prone to failure, and can only turn over one pipe at the same time. The work efficiency is low, and the equipment structure is complicated, the floor space is large, and the maintenance is difficult.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The technical scheme of the present invention is further described below in conjunction with the accompanying drawings. Examples of such embodiments are shown in the accompanying drawings,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

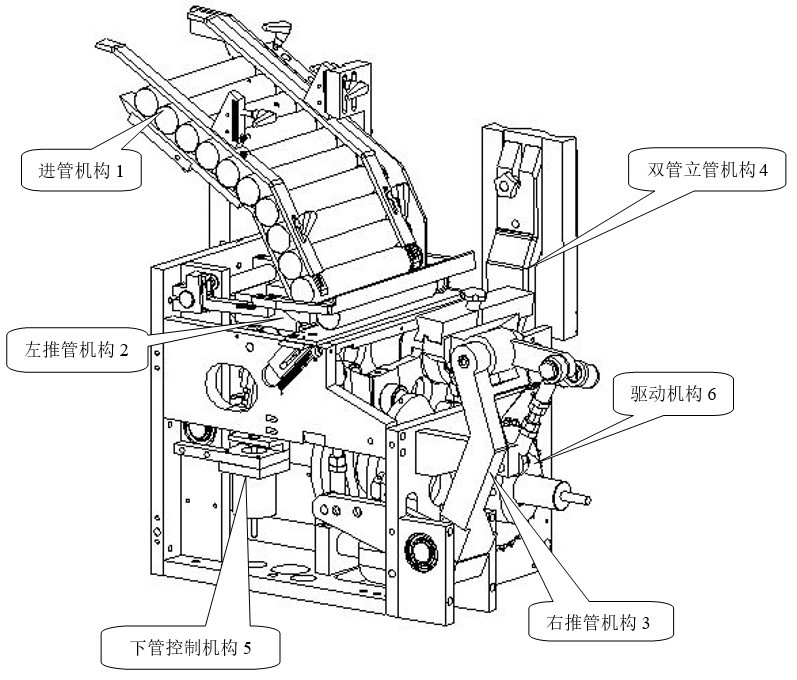

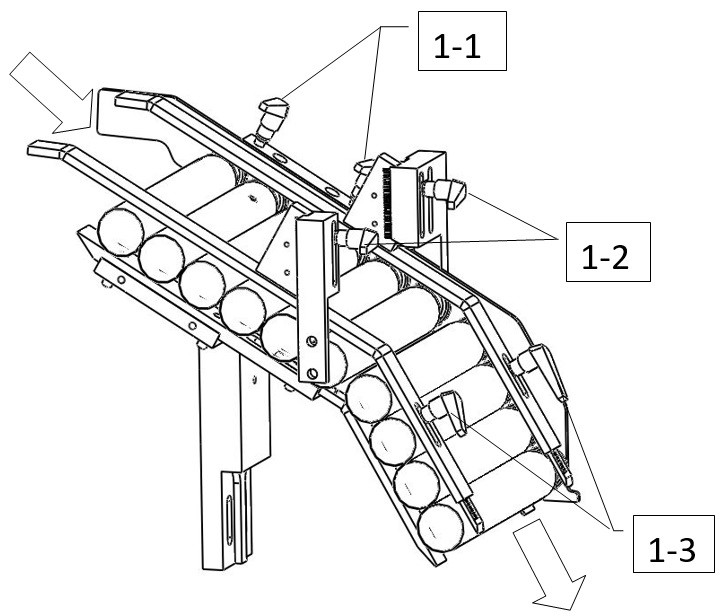

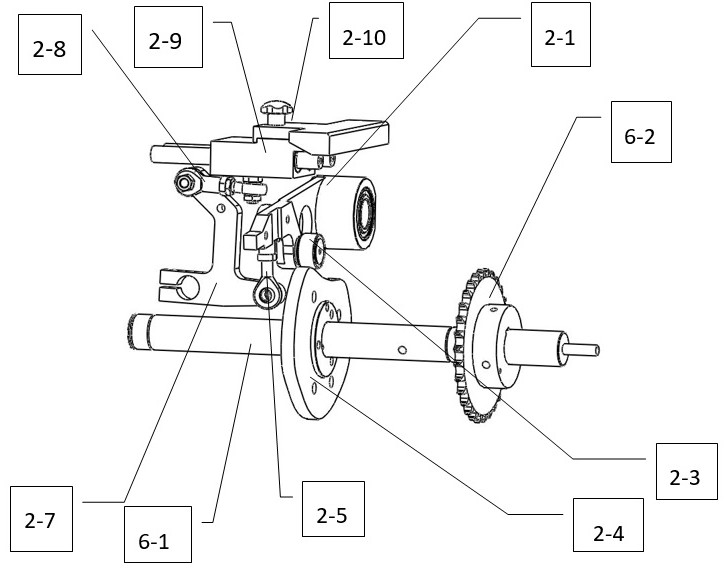

The present invention proposes a high-speed upper pipe mechanism for a filling machine with single-channel pipe feeding. , Drive mechanism; wherein the tube feeding mechanism is installed on the top of the frame, the left push tube mechanism is installed on the left side of the frame and below the tube feeding mechanism, the right pushing tube mechanism is installed on the right side of the frame, and the double tube vertical The tube mechanism is installed on the upper rear side of the right push tube mechanism, the lower tube control mechanism is installed on the left side inside the frame, and the driving mechanism is installed on the right side inside the frame. The invention adopts special conjugated cam design, high precision, accurate movement curve of the swing rod, reliable realization of the design trajectory, precise movement of the mechanism, no gap, no empty position, fast movement speed and high stability, and the movement of the three sets of swing rods adopts Coaxial design, compact structure, easy installation and maintenance; single-channel inlet pipe, double pipes are turned upside down at the same time, high work efficiency.

Description

A high-speed tube loading mechanism of a filling machine with a single channel feeding tube technical field What the present invention relates to is a kind of high-speed pipe-up mechanism of a filling machine of a single-channel feeding pipe, belonging to the technical field of filling equipment. area. Background technique [0002] The upper tube mechanism is used for the hose feeding device of the filling and sealing machine, which is the most important component of the filling and sealing machine. now Some upper pipe mechanisms usually use the two-side pipe feeding mode, which has poor accuracy and is prone to failure, and can only turn over one pipe at the same time. The efficiency is low, the equipment structure is complex, the floor space is large, and the maintenance is difficult. SUMMARY OF THE INVENTION The object of the present invention is to solve the above-mentioned problem that existing pipe filling machine upper tube mechanism exists, propose a kind of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B43/42B65B43/48B65B43/46

CPCB65B43/42B65B43/48B65B43/46

Inventor 常菲周建鹏张磊郁燕辉杨江涛李建彬

Owner NANTONG UNIVERSAL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com