Automatic spin lock device

A lock device and automatic technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increased waiting time and unsatisfactory, and achieve the effect of fast action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

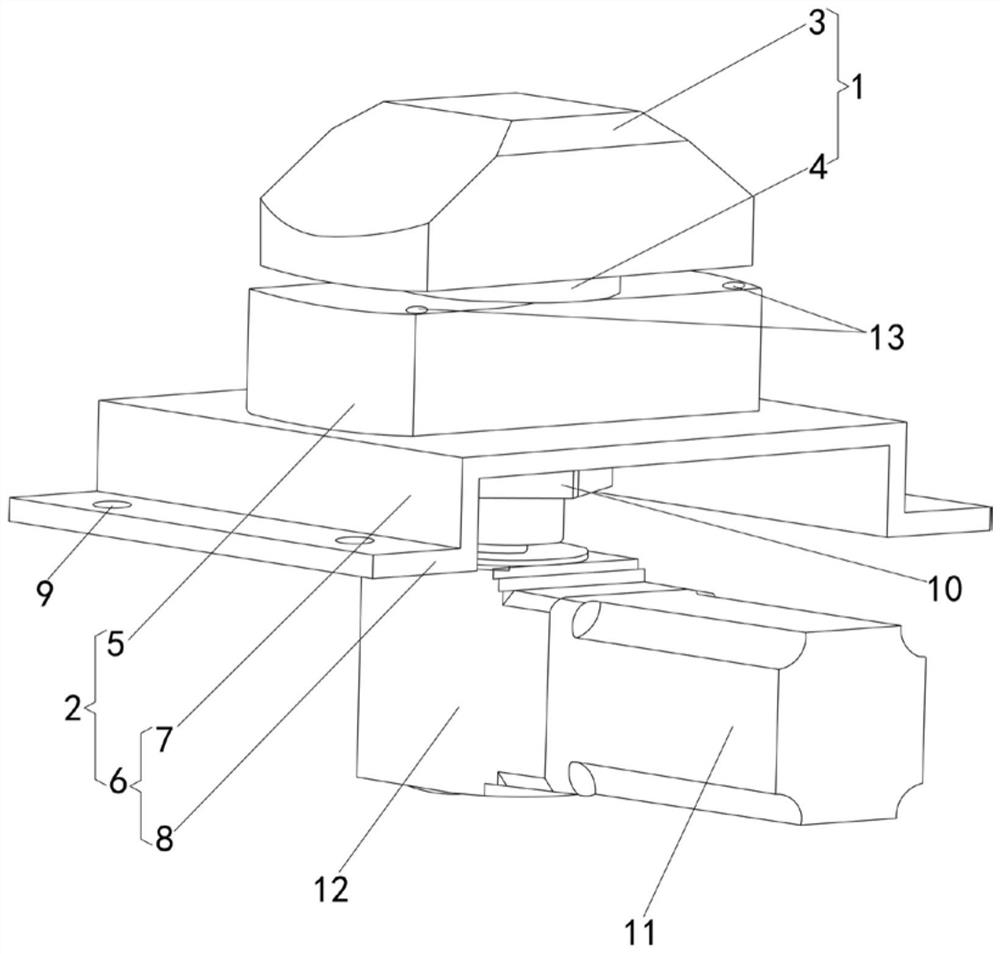

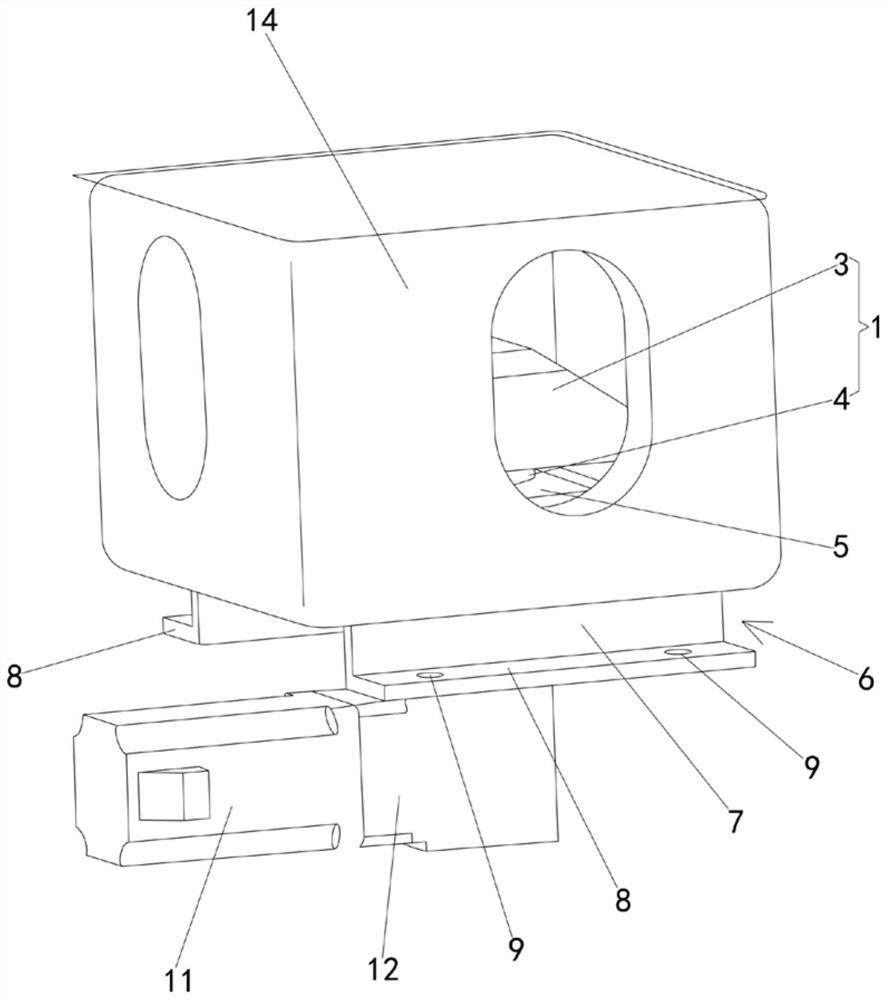

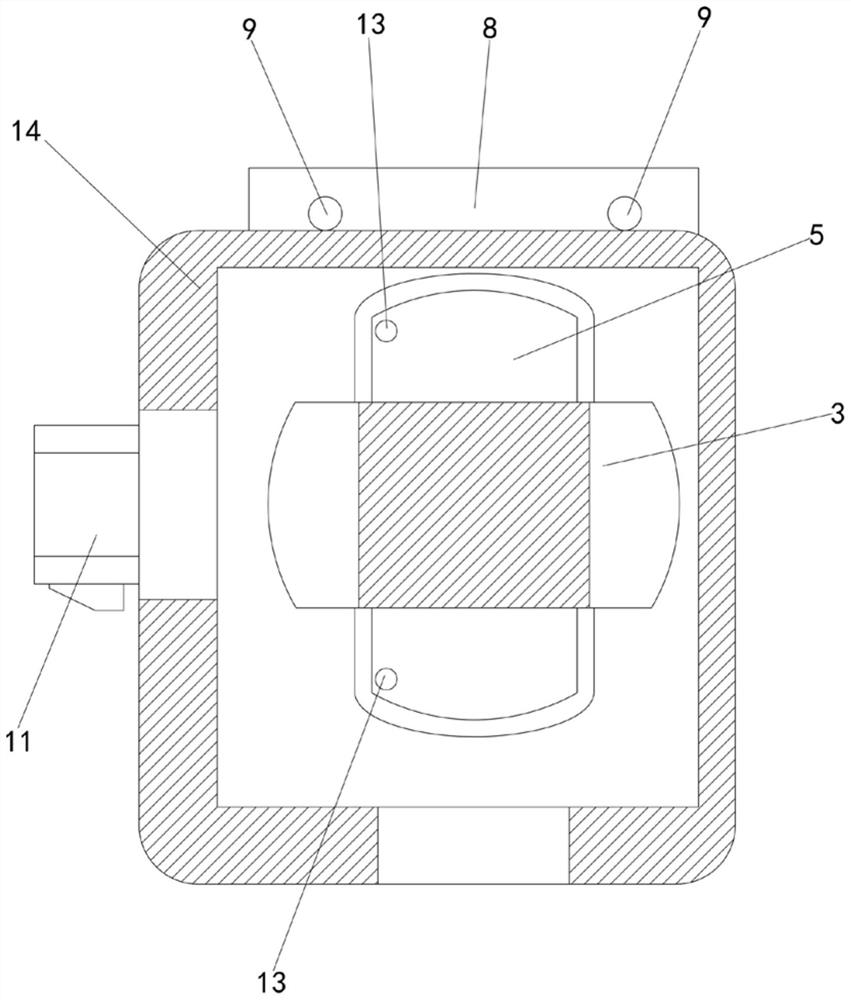

[0020] Such as figure 1 As shown, the automatic twist lock device of the present invention includes a lock head 1 and a lock body 2, the lock head 1 is connected with the lock body 2 through a threaded connection structure, and one end of the lock head 1 passes through the lock body 2 and is connected with the power mechanism. The size is such that it can extend into the inner cavity of the corner fitting, and can be clamped and fixed in the inner cavity of the corner fitting after being driven by the power mechanism to rotate at a predetermined angle.

[0021] The specific structure is: the lock head 1 includes a lock head head 3 at the upper end and a rod body 4 at the lower end of the lock head head 3. The cross-sectional size of the rod body 4 is smaller than the cross-sectional size of the lock head head 3. The lock of this embodiment The head head 3 is approximately cuboid, and its cross-sectional length is less than the lower opening length of the corner fitting but gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com