Full-tube pulse demagnetization device and method

A demagnetization and pulse technology, applied in the direction of magnetic objects, circuits, electrical components, etc., can solve problems such as unsatisfactory effect, difficulty in reaching the standard of DC residual magnetism, and affecting oil well construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

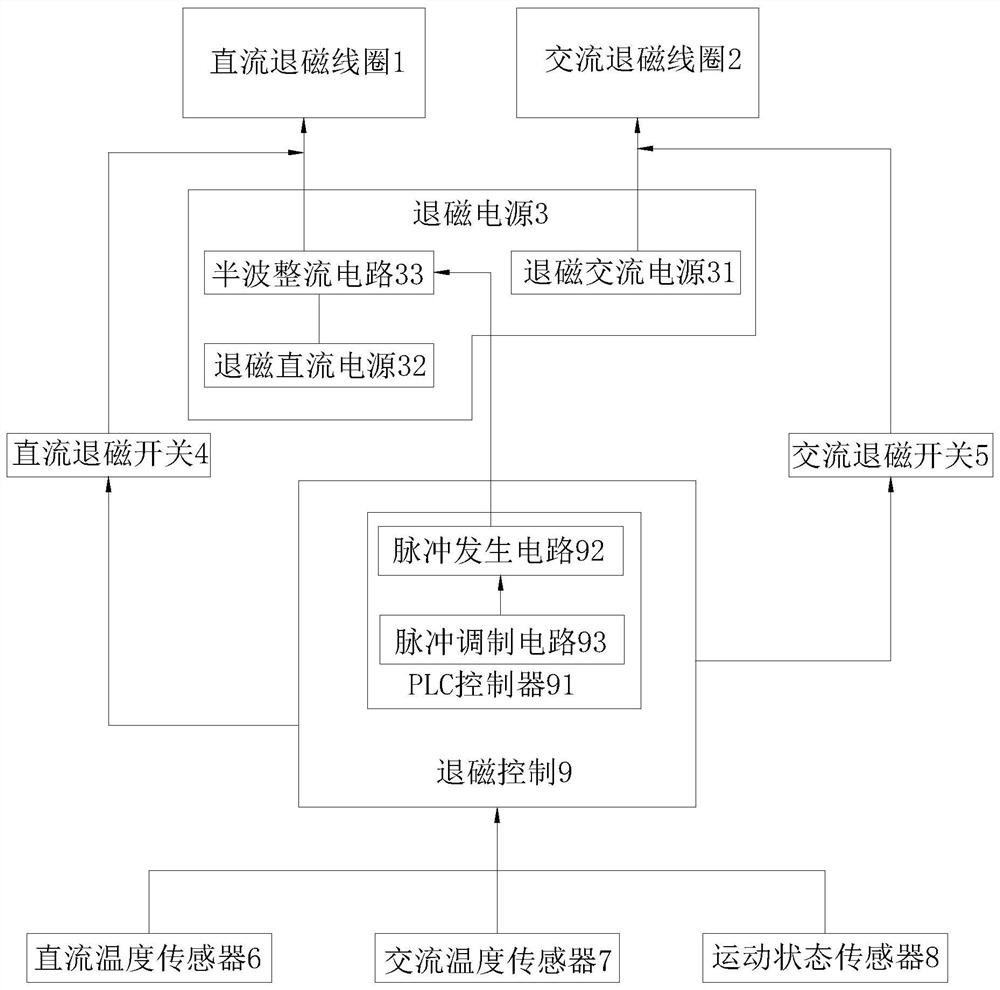

[0053] This embodiment is similar to Embodiment 1, the difference is that the DC demagnetization coil 1 and the AC demagnetization coil 2 of this embodiment are respectively provided with a DC temperature sensor 6 and an AC temperature sensor 7, and the DC temperature sensor 6 and the AC temperature sensor 7 are both It is connected to the PLC controller 91; a motion state sensor 8 is arranged at the transport roller table, and the motion state sensor 8 is connected to the PLC controller 91. The motion state sensor 8 can be any sensor capable of detecting the motion state of the conveying roller table, such as an encoder, a photoelectric sensor, a speed sensor arranged on the roller table, and the like.

[0054] The PLC controller 91 receives the DC demagnetization coil temperature signal and the AC demagnetization coil temperature signal, and disconnects the corresponding demagnetization coil when the DC demagnetization coil temperature or the AC demagnetization coil temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com