On-load voltage and capacitance regulation transformer

A technology for transformers and transformer shells, applied in transformers, variable transformers, variable inductors, etc., can solve the problems of transformer oil insulation performance degradation, pollution of arc-extinguishing medium transformer oil, and endangering the service life of transformers, etc., to achieve extinction Reliable arc performance, prolonging the life of the switch, and eliminating the effect of residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

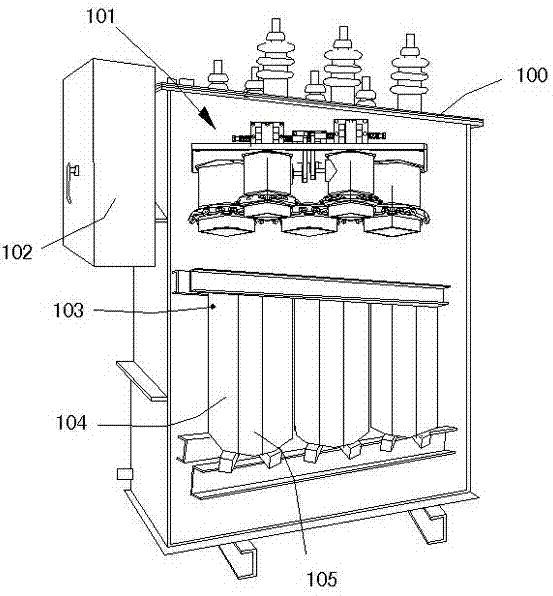

[0021] See figure 1 . The automatic controller 102 is installed on the upper left outer wall of the transformer housing 100, and the tap changer 101, the high voltage winding 103, the low voltage winding 104 and the winding core 105 are arranged in the inner cavity of the transformer housing 100 and immersed in transformer oil.

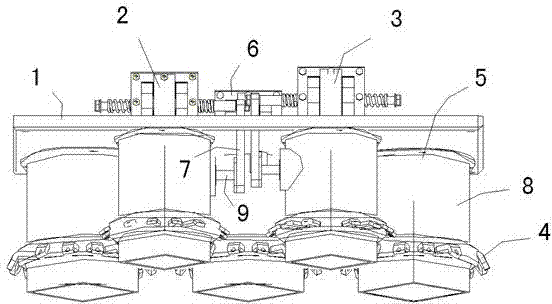

[0022] See figure 2 . The mounting plate 1 is horizontally fixedly arranged on the upper part of the inner cavity of the transformer, and its top surface is used to fix the operating components, namely: the volume adjustment operating mechanism 6, the first voltage adjusting operating mechanism 2, and the second voltage adjusting operating mechanism 3. The structure of the mechanism is exactly the same, with a set of independent bistable permanent magnet components and their toggle levers 7 respectively. The coil in the bistable permanent magnet assembly is connected to the output terminal of the automatic controller on the transformer. The upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com