Crankshaft bending torsion combined load test device

A composite load and test device technology, applied in the direction of measuring device, testing material strength by applying stable bending force, testing material strength by applying stable torsion force, etc., to achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

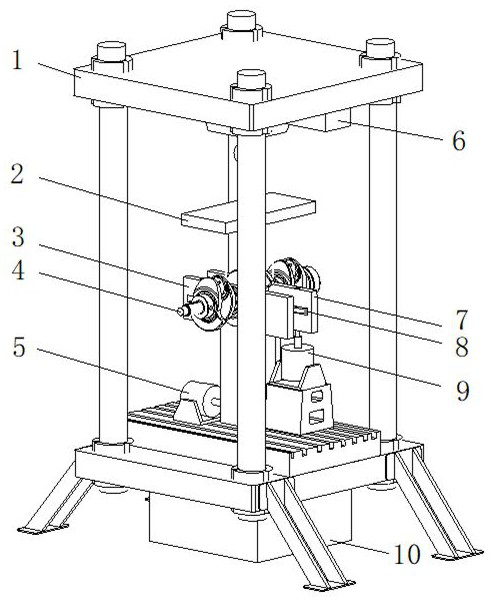

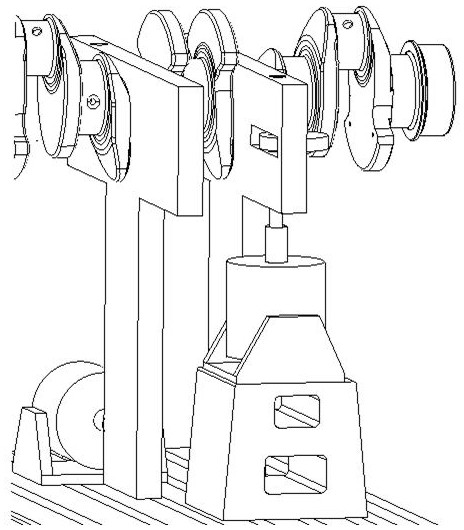

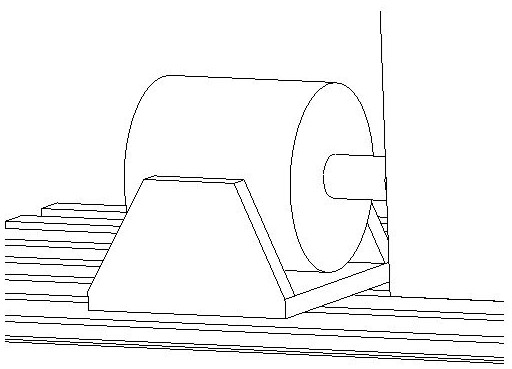

[0015] Such as figure 1 As shown, the test bench in the present invention includes a bench 1, a hanger 2, a torsion fixture 3, an exciter 5, a slide rail 6, a bending fixture 7, an eccentric wheel 8, a motor 9, an electric control cabinet 10 (including a power amplifier , function generator, dynamic strain gauge); the stand 1 is four-column-shaped, with two upper and lower platforms, the slide rail 6 for horizontal sliding is arranged on the lower surface of the upper platform, the electric control cabinet 10 is located under the lower platform, and the vibration exciter 5. The motor 9 is located above the lower platform; the slider on the slide rail 6 is connected to the hanger 2, and the hanger 2 is used to hang the torsion fixture 3 and the bending fixture 7, and the torsion fixture 3 and the bending fixture 7 are used to fix the crankshaft sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com