A bearing gland device

A bearing gland and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as failure of pressing the inclined gland, production interruption, impact on subsequent stations, etc., to prevent gland failure, use Simple, highly adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

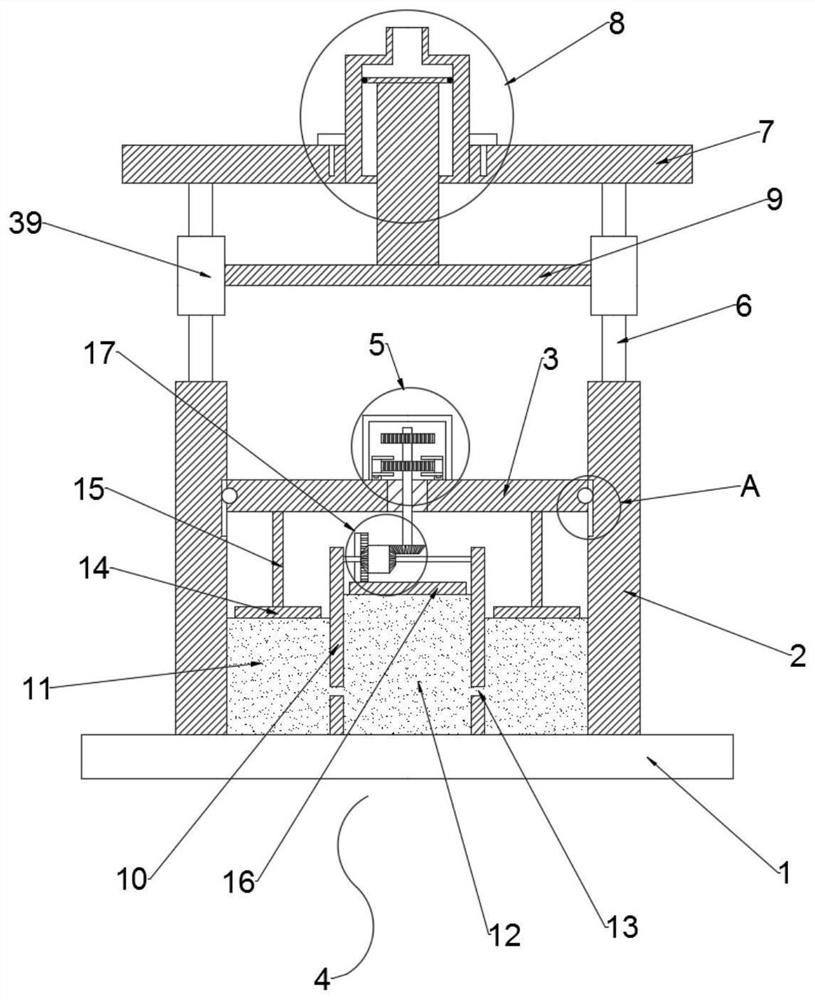

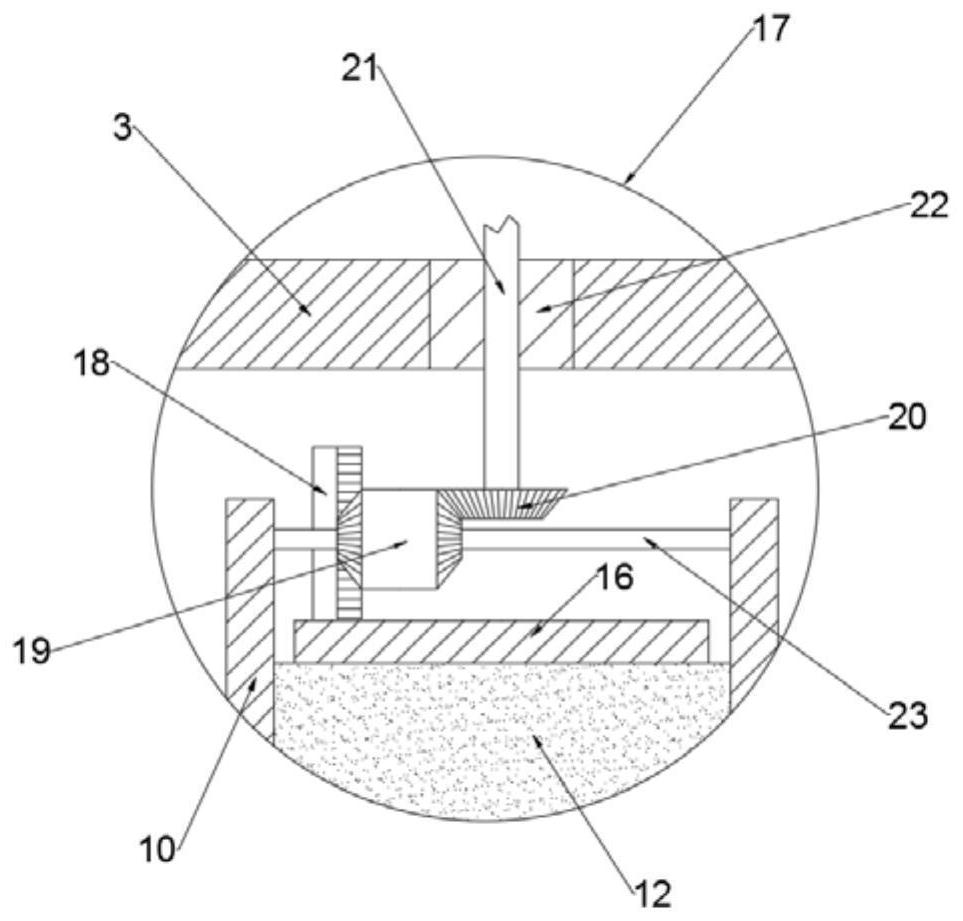

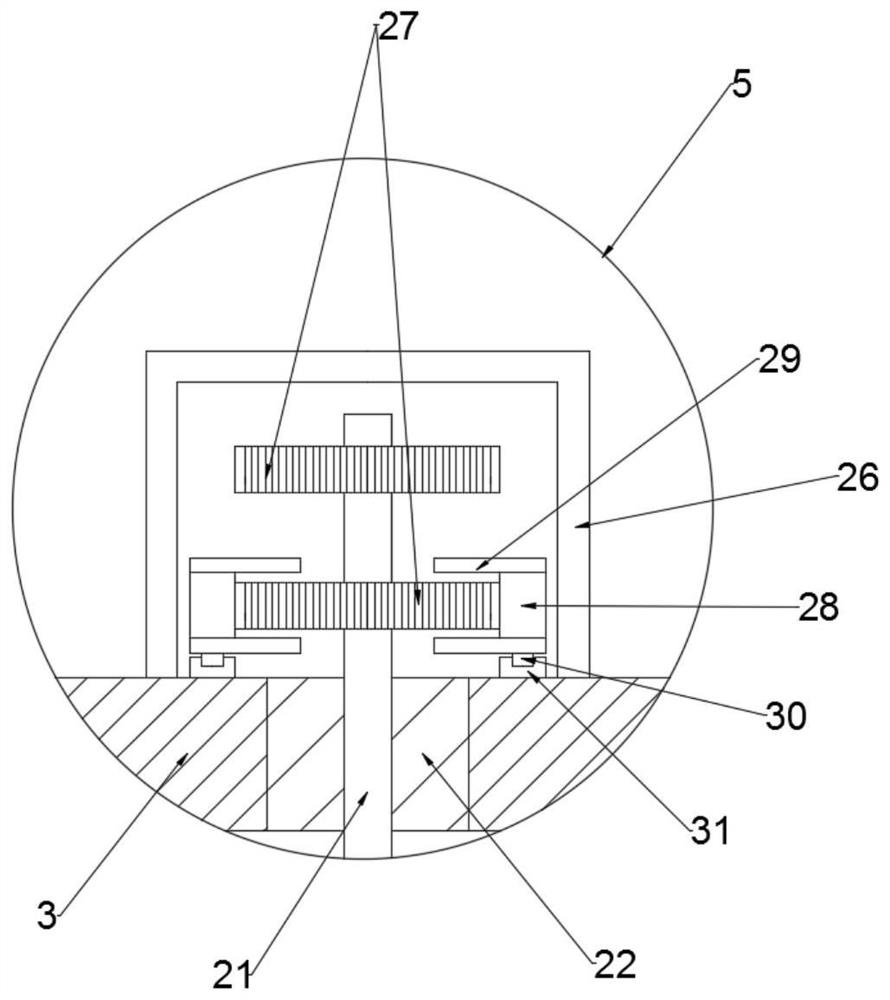

[0031] Embodiment: the present invention provides technical scheme, as figure 1, a bearing gland equipment, comprising a support plate 1, the upper end of the support plate 1 is provided with an outer cylinder 2, the outer cylinder 2 is a cylinder structure with an upper end open, used to support the device, the outer cylinder 2 is provided with a lower plate 3, The lower plate 3 is a circular plate-shaped structure for placing the bearing to be capped. The lower end of the lower plate 3 is provided with a movable mechanism 4, and the upper end of the lower plate 3 is provided with a center clamping mechanism 5. When the bearing to be capped is placed On the lower plate 3, its own weight will make it move down, and the vertical linear motion will be converted into rotational motion by the adaptive mechanism 4, and the rotational motion will be converted into horizontal linear motion by the central clamping mechanism 5, so as to clamp Hold the inner ring of the bearing, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com