Spring with limiting structure and using method thereof

A technology of limiting structure and positioning sleeve, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of inability to adjust the spring force, reduce the flexibility of equipment use, and reduce the diversity of spring use, so as to ensure stability performance, improve the actual use effect, and the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

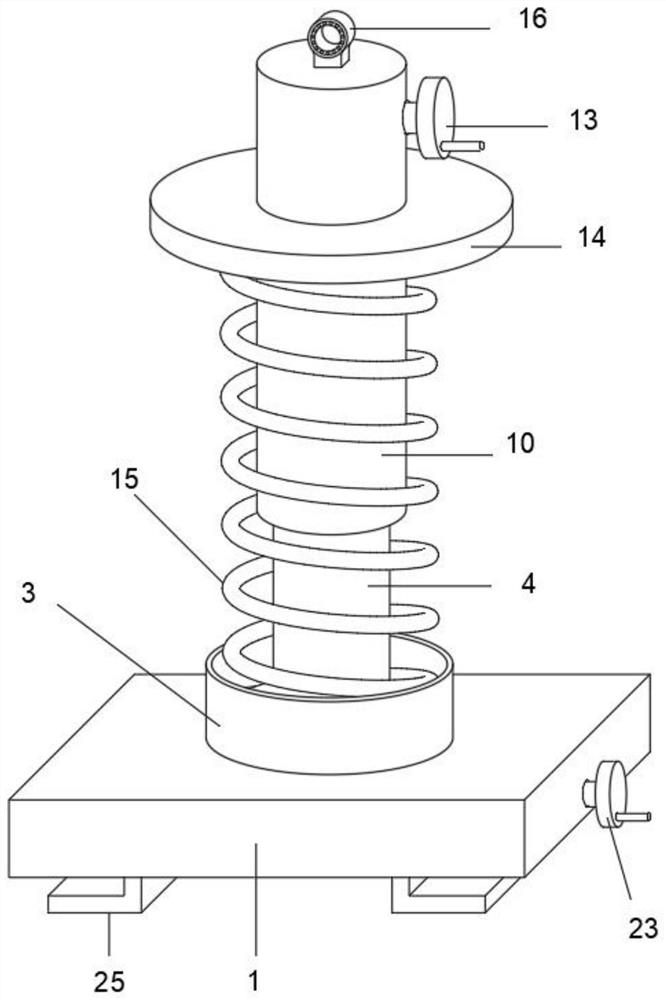

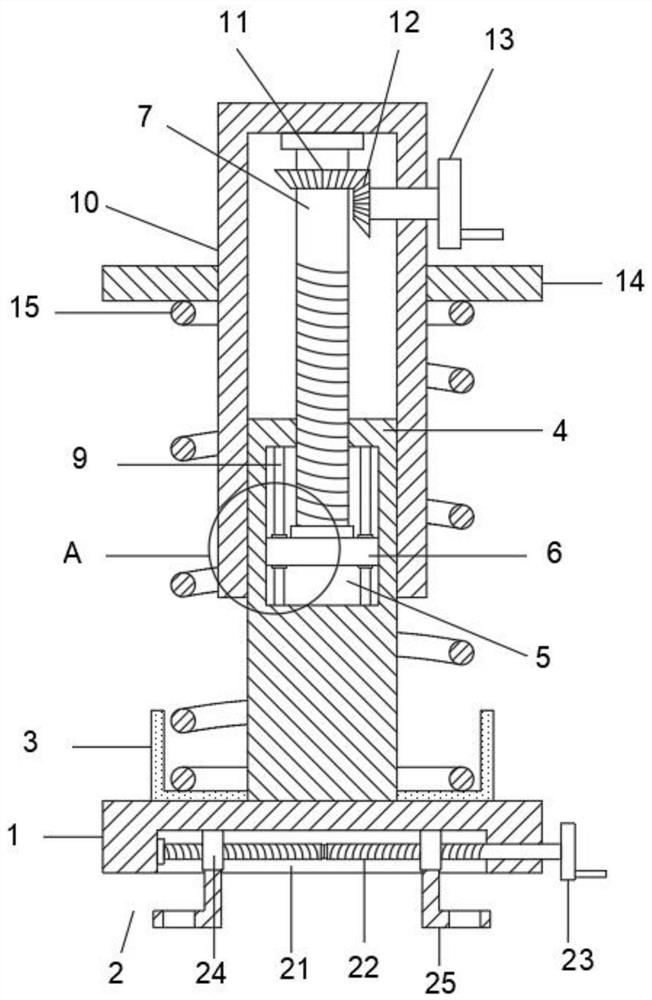

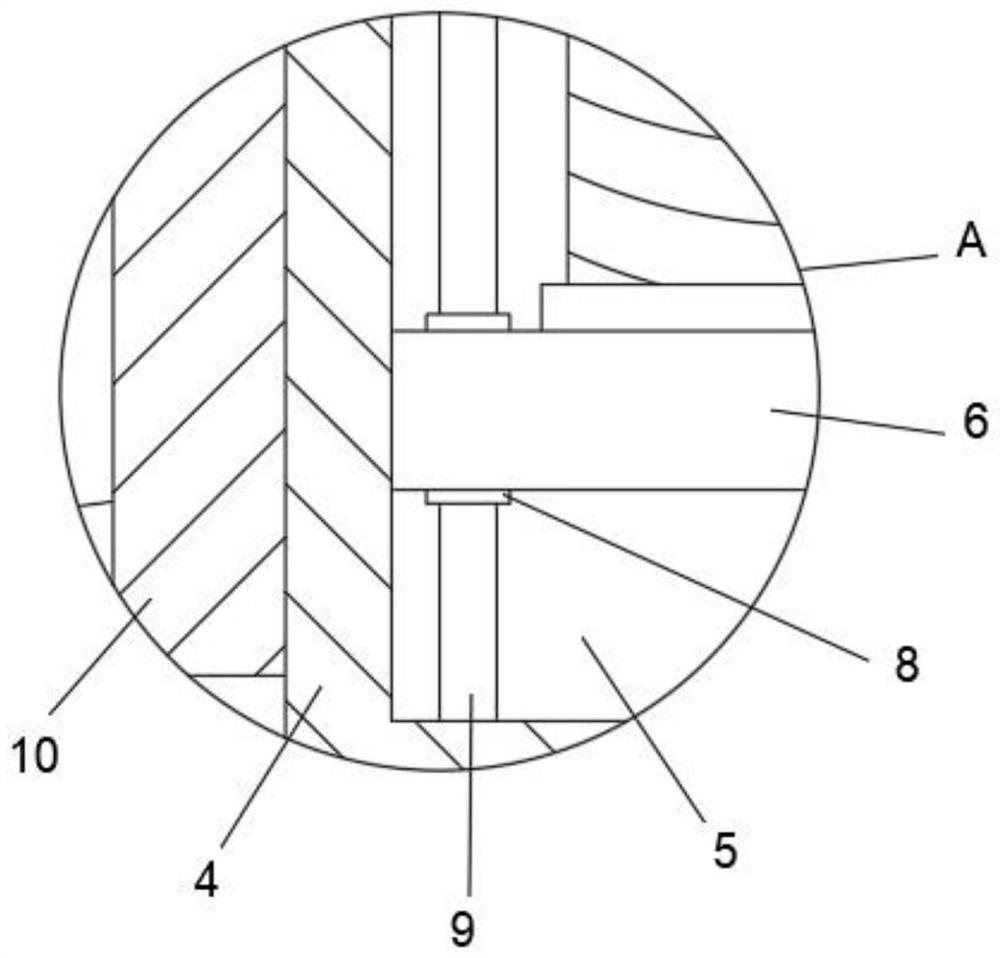

[0024] A spring with a position-limiting structure, including a base plate 1, an adjustment assembly 2, a positioning sleeve 3, a support rod 4, an adjustment screw 7, a main pipe 10 and a second hand wheel 13, the bottom of the base plate 1 is provided with an adjustment assembly 2, and the base plate 1 The top is fixedly connected with a positioning sleeve 3, and the position of the spring 15 is conveniently fixed to prevent the spring 15 from shifting. 4 There is an installation groove 5 inside, the inside of the installation groove 5 is slidingly connected with a slide plate 6, and the center of the top of the slide plate 6 is rotatably connected with an adjustment screw 7. The top of the top is rotationally connected, and the top threaded connection of the adjustment screw rod 7 and the pole 4 is convenient for moving up and down the position of the main pipe 10.

[0025] Wherein, the adjustment assembly 2 includes a chute 21, a two-way screw rod 22, a first hand wheel 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com