A Robust Scheduling Method Based on Process Time Difference Relaxation

A scheduling method and process technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as damage to corporate reputation, loss of potential customer groups, and increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

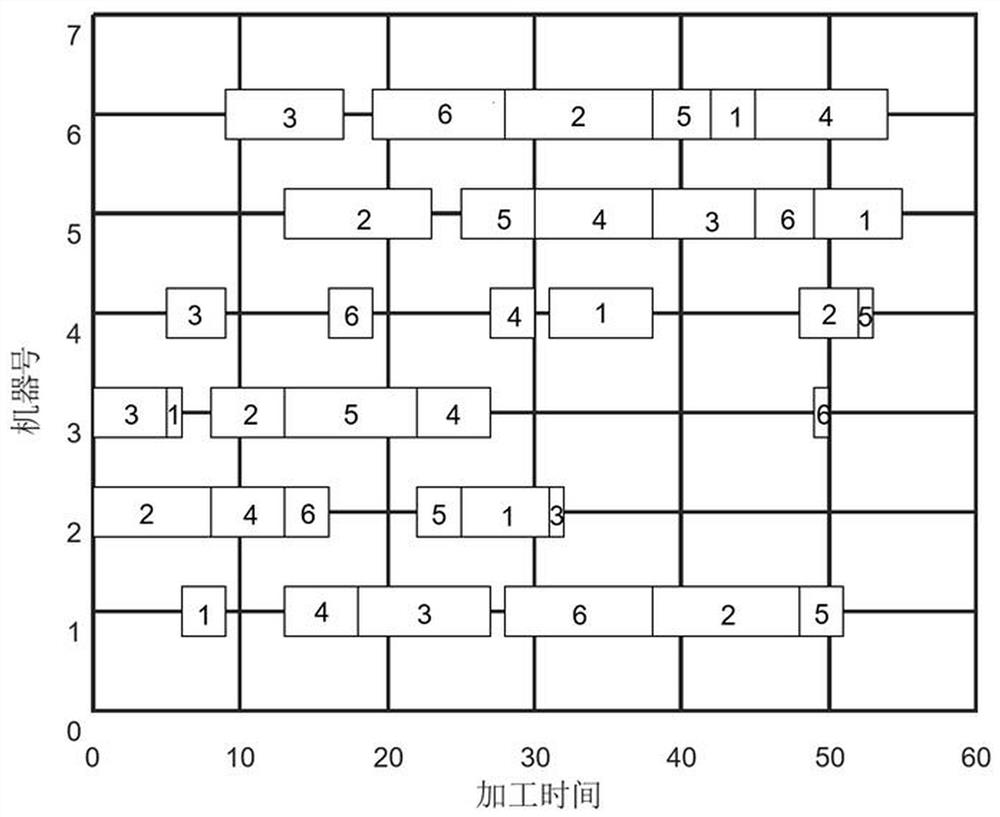

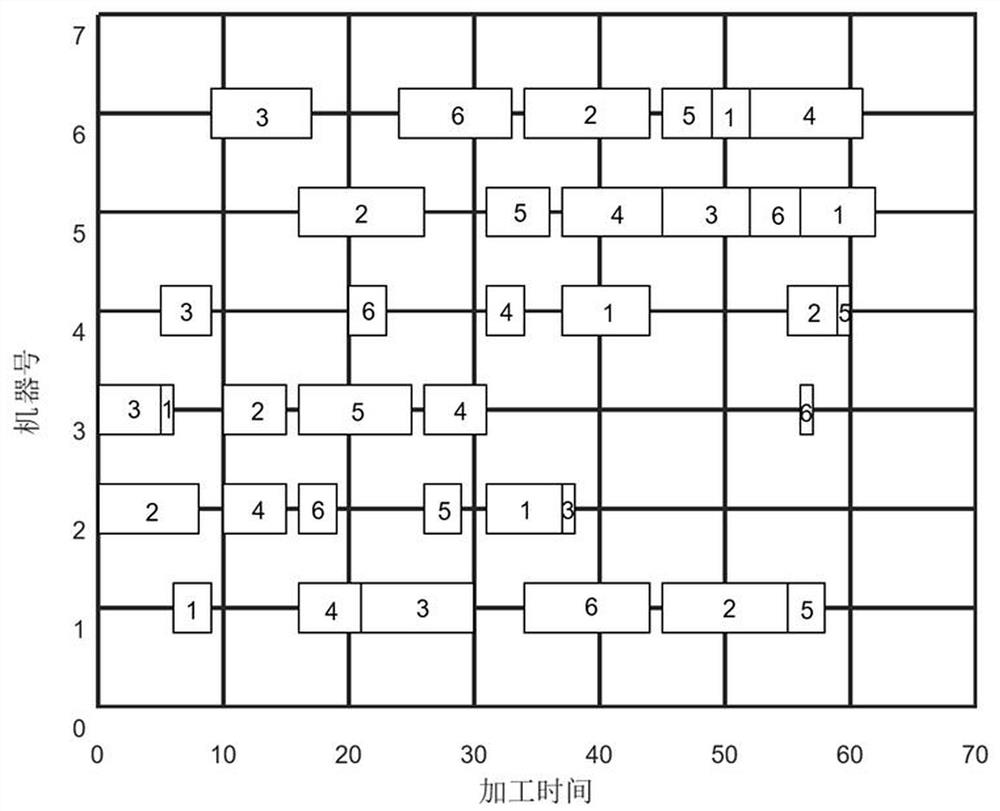

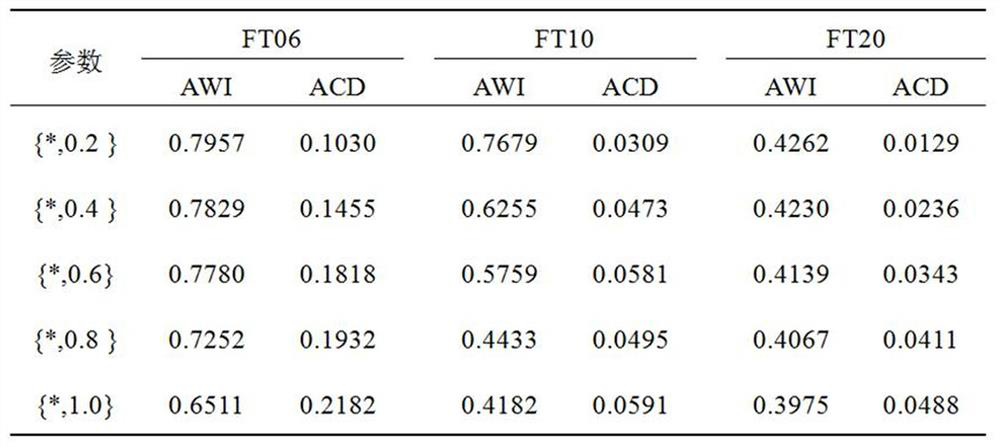

[0062] As a basic embodiment of the present invention, the present invention includes a robust scheduling method based on process time difference relaxation, including the following steps:

[0063] a. Determine the priority of the process jet lag relaxation in the initial scheduling plan.

[0064] Traversing all the processes in the initial scheduling scheme, assigning multiple random initial delay values to the process, calculating the robust objective function value of each process under multiple initial delay values, that is, the delay accumulation degree, and then calculating the robust objective function value The mean value of , according to the order of the mean value from large to small, gives the priority order of process jet lag relaxation.

[0065] b. Identification of the slack position of the time difference in the process.

[0066] According to the priority order of process time difference relaxation generated in step a, select the process with the highest pri...

Embodiment 2

[0072] As the best implementation mode of the present invention, the present invention includes a robust scheduling method based on process time difference relaxation. This method is based on job shop scheduling. The specific description of the job shop scheduling problem is: there are m machines in the shop, and the processing methods of each machine are different. There are n different workpieces to be processed, and each workpiece has m processes. The process sequence and processing time of the workpieces are given in advance, and each workpiece must be processed on the machine in the specified order according to the process route. Due to random disturbances in the job shop, machine resources are unavailable for certain periods of time. The task of scheduling is to arrange the processing sequence of all workpieces on each machine so that the constraints are met and the goal is optimized. In addition, the following constraints must be met:

[0073] (1) Each workpiece must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com